Method for preparing transparent iron oxide pigment with microemulsion method

A technology of transparent iron oxide and transparent iron oxide yellow, which is applied in the fields of iron oxide, chemical instruments and methods, iron oxide/iron hydroxide, etc., can solve problems such as precedents and literature reports that have not yet been found, and achieve significant technological advancement , Based on science, highly operable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

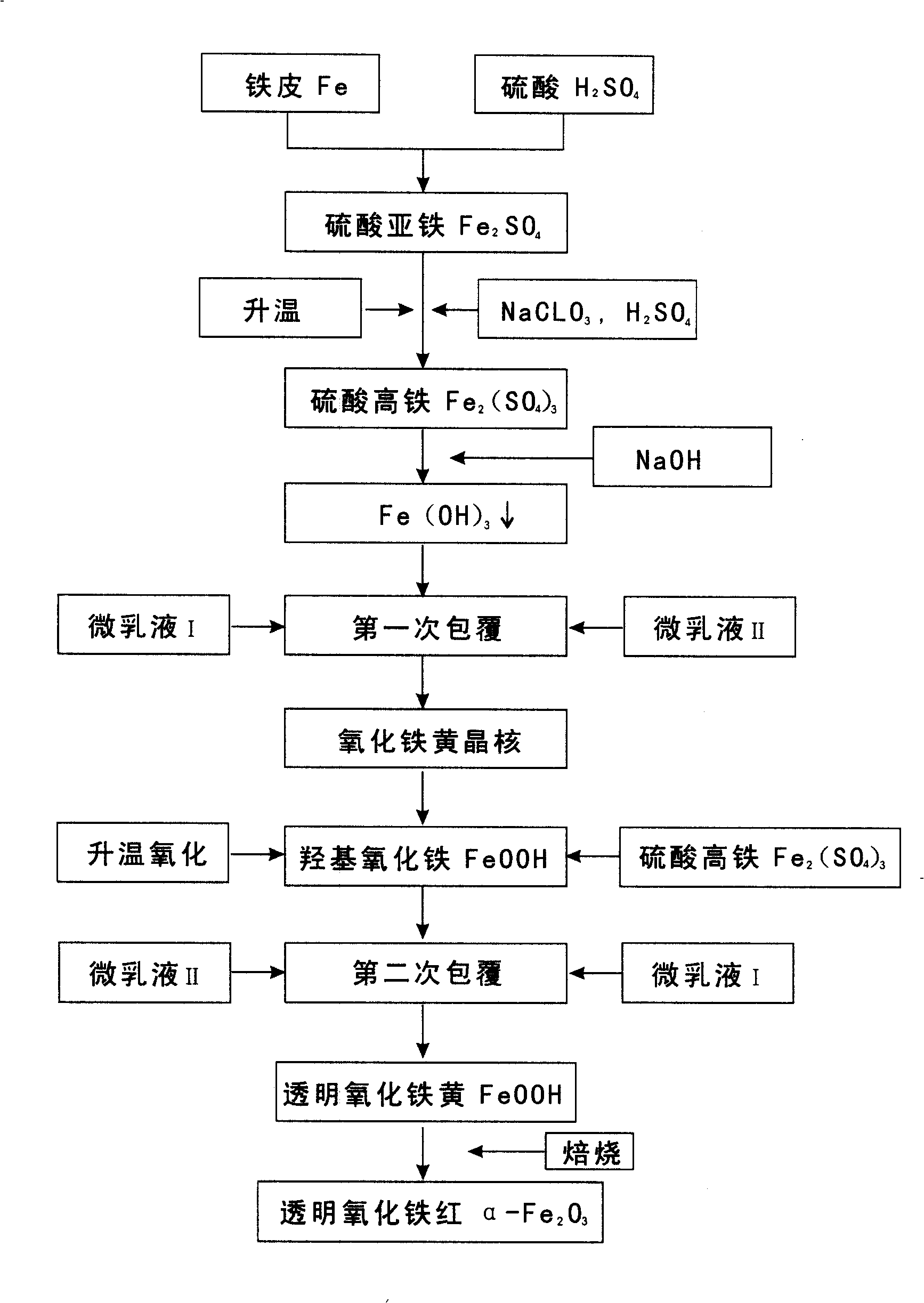

[0042] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

[0043] In the accompanying drawings, the key technology involved in the method for producing transparent iron oxide pigments using the microemulsion method of the present invention is to prepare ferrous sulfate solution, ferric sulfate solution, and ferric hydroxide crystals on the basis of preparing the microemulsion dispersant Subsequent particle refinement treatment of nuclear and iron oxide yellow wet slurry, the process flow is as follows:

[0044] 1. Prepare ferrous sulfate with sulfuric acid and iron sheets as raw materials, and the reaction is as follows:

[0045] Fe+H 2 SO 4 →FeSO 4 +H 2 ↑

[0046] The reaction is carried out in an acid-resistant open reaction tank made of ceramic tiles, the reaction temperature is 40-60 DEG C, and the sulfuric acid concentration is 10-20% (wt).

[0047] 2. Add concentrated sulfuric acid and sodiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com