Low-viscosity iron oxide yellow

A technology of iron oxide yellow and low viscosity, which is applied in the direction of iron oxide, iron oxide/iron hydroxide, etc., can solve the problems of insufficient effect, reducing the aspect ratio of iron oxide yellow particles, destroying the shape of iron oxide yellow pigment particles, etc. Achieve the effects of reducing viscosity, increasing added value, and increasing economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

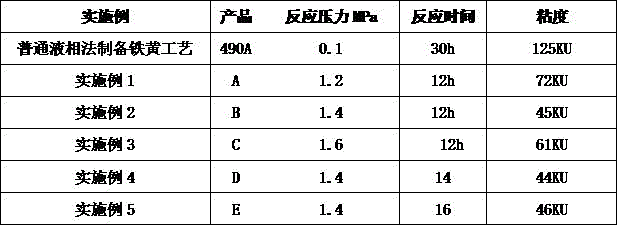

Embodiment 1

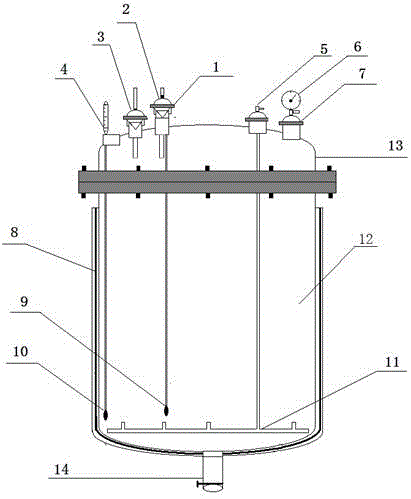

[0032] 1. Seed crystal preparation: Add 8 L of ferrous sulfate solution with a concentration of 1.5 mol / L into a 30 L stainless steel reaction tank, then add 2.5 L of 10 mol / L sodium hydroxide solution, and control the reaction temperature at 30 °C. The total reaction time is controlled to be 15 hours. Air is fed to the bottom of the reaction solution in the first 5-7 hours, and the air volume is controlled at 230L / h. Air is fed to the bottom of the reaction solution in the next 7-10 hours, and the air volume is controlled at 460L / h.

[0033] 2. High-pressure reaction: Put 10L of the prepared seed crystal into the high-pressure reactor, and heat the reactor at the same time. The temperature is controlled at 70°C. At this time, the pressure in the reactor is 1 atmosphere. When the temperature reaches 70°C, add For a sodium hydroxide solution with a concentration of 10mol / L, the amount of liquid caustic soda added is based on the pH value, and when the pH reaches 4.0, stop adding...

Embodiment 2

[0036] 1. Seed crystal preparation: Add 8 L of ferrous sulfate solution with a concentration of 1.5 mol / L into a 30 L stainless steel reaction tank, then add 2.5 L of 10 mol / L sodium hydroxide solution, and control the reaction temperature at 30 °C. The total reaction time is controlled to be 15 hours. Air is fed to the bottom of the reaction solution in the first 5-7 hours, and the air volume is controlled at 230L / h. Air is fed to the bottom of the reaction solution in the next 7-10 hours, and the air volume is controlled at 460L / h.

[0037] 2. High-pressure reaction: Put 10L of the prepared seed crystal into the high-pressure reactor, and heat the reactor at the same time. The temperature is controlled at 70°C. At this time, the pressure in the reactor is 1 atmosphere. When the temperature reaches 70°C, add For a sodium hydroxide solution with a concentration of 10mol / L, the amount of liquid caustic soda added is based on the pH value, and when the pH reaches 4.0, stop adding...

Embodiment 3

[0040] 1. Seed crystal preparation: Add 8 L of ferrous sulfate solution with a concentration of 1.5 mol / L into a 30 L stainless steel reaction tank, then add 2.5 L of 10 mol / L sodium hydroxide solution, and control the reaction temperature at 30 °C. The total reaction time is controlled to be 15 hours. Air is fed to the bottom of the reaction solution in the first 5-7 hours, and the air volume is controlled at 230L / h. Air is fed to the bottom of the reaction solution in the next 7-10 hours, and the air volume is controlled at 460L / h.

[0041] 2. High-pressure reaction: Put 10L of the prepared seed crystal into the high-pressure reactor, and heat the reactor at the same time. The temperature is controlled at 70°C. At this time, the pressure in the reactor is 1 atmosphere. When the temperature reaches 70°C, add For a sodium hydroxide solution with a concentration of 10mol / L, the amount of liquid caustic soda added is based on the pH value, and when the pH reaches 4.0, stop adding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com