Low oil absorption ferric oxide yellow pigment

A technology of iron oxide yellow and oil absorption, applied in the field of pigments, to achieve the effect of extensive equipment and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

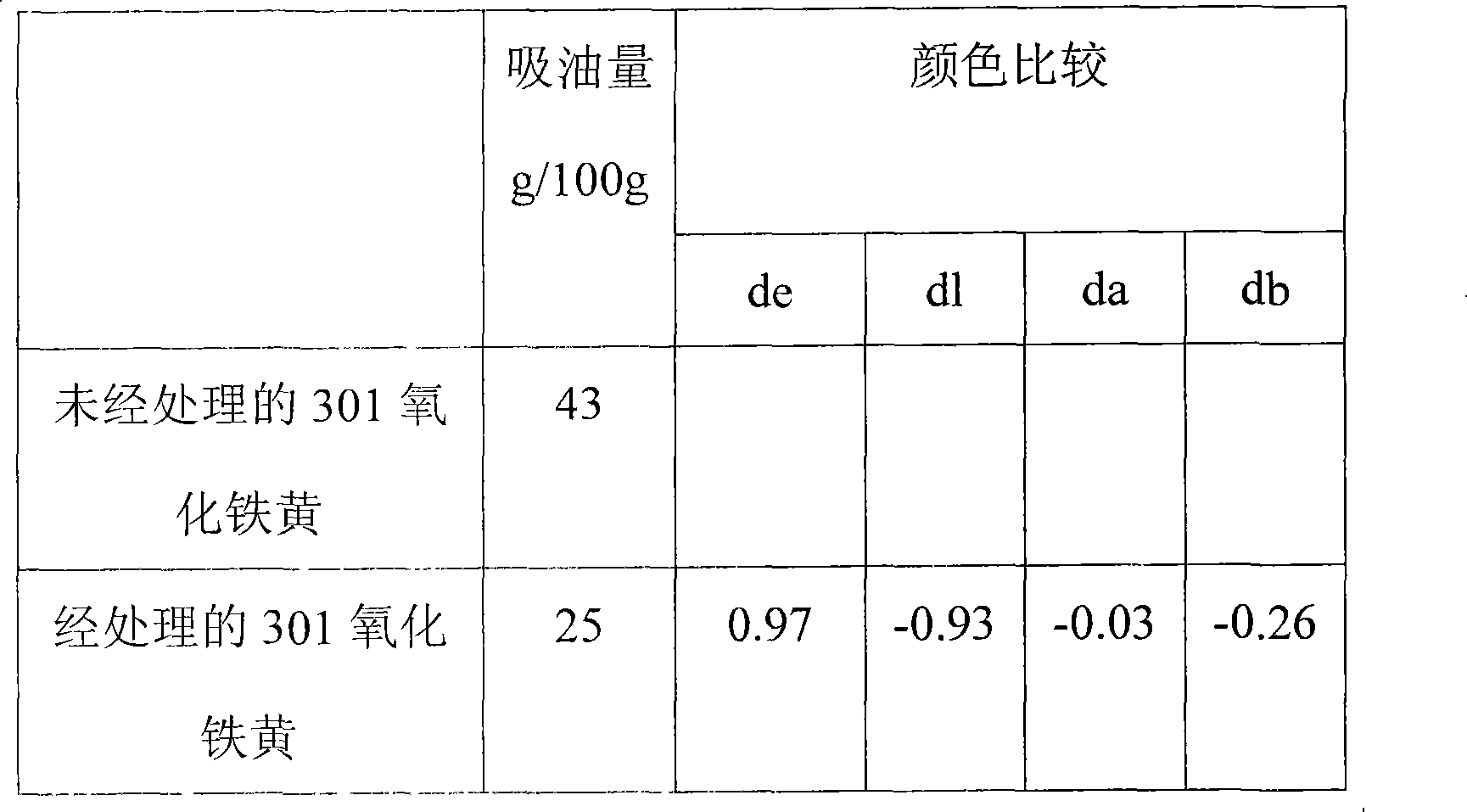

[0014] Commercially available common iron oxide yellow (trade name 301) is 250 kg, which is fed between two pairs of counter-rotating rollers by the feeding device, and the pressure of 500 MPa is applied by the hydraulic device, and the passing material is circulated 30 times by the device for compaction treatment Finally, crush it with an impact mill, and the obtained product is the same as the iron oxide yellow that has not been compacted. The test results are as follows:

[0015]

Embodiment 2

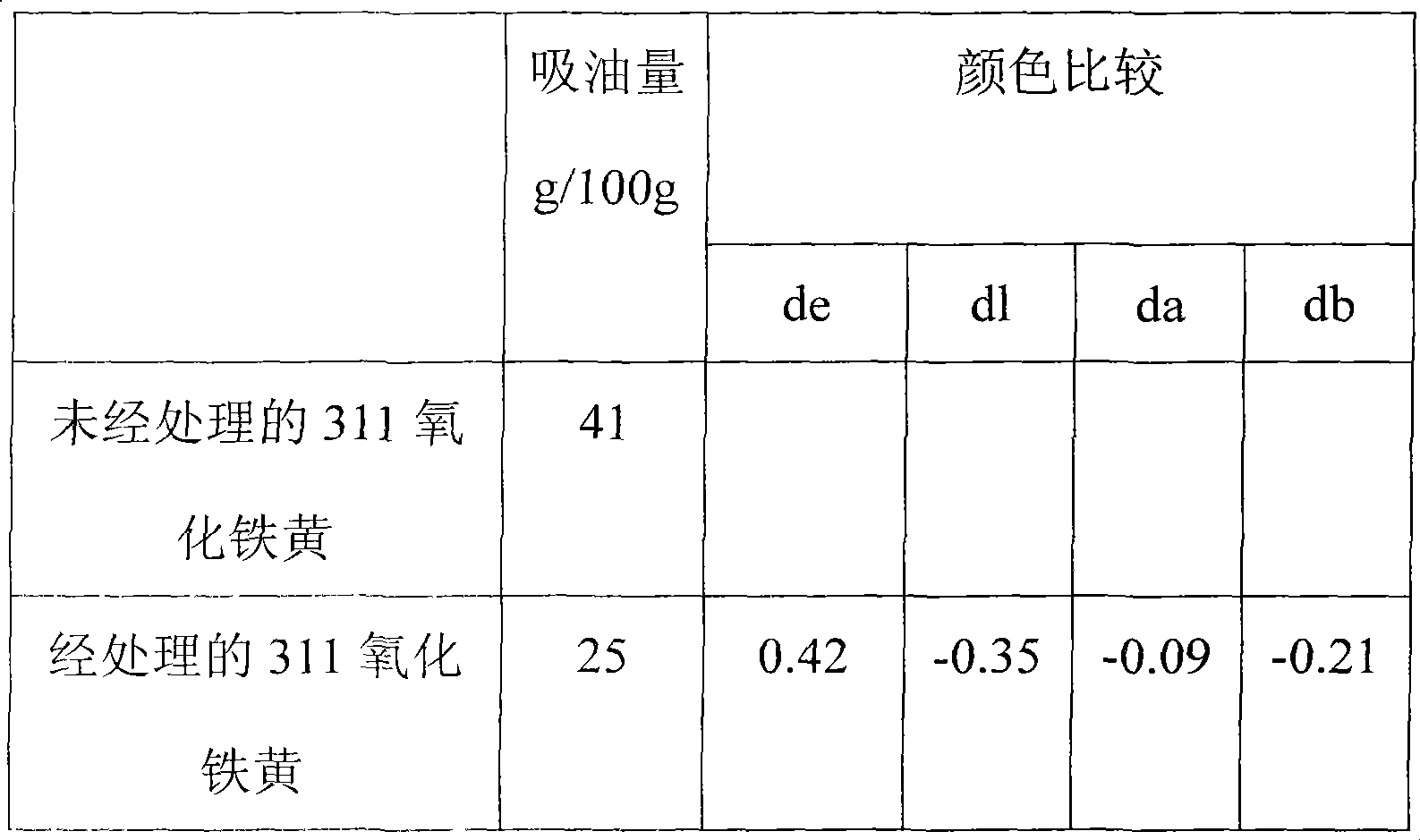

[0017] 260 kilograms of commercially available common iron oxide yellow (trade name 311) are fed into the roller compactor by a feeding device, and after compaction treatment of 60 minutes of rolling under a pressure of 1000 MPa, pulverize with an impact mill, and the product obtained is the same as that without The comparison of iron oxide yellow for compaction treatment is as follows:

[0018]

[0019] The results of the above comparison show that the oil absorption of the iron oxide yellow pigment after the compaction treatment is between 20-29g / 100g, while the oil absorption of the iron oxide yellow pigment without the compaction treatment is significantly increased.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com