Preparation method of high-temperature-resistant ferric oxide yellow pigment

A technology of iron oxide yellow and high temperature resistance, applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve the problems of reducing the dispersibility of iron oxide yellow and affecting performance, and achieve excellent dispersibility, high resistance Discoloration, good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

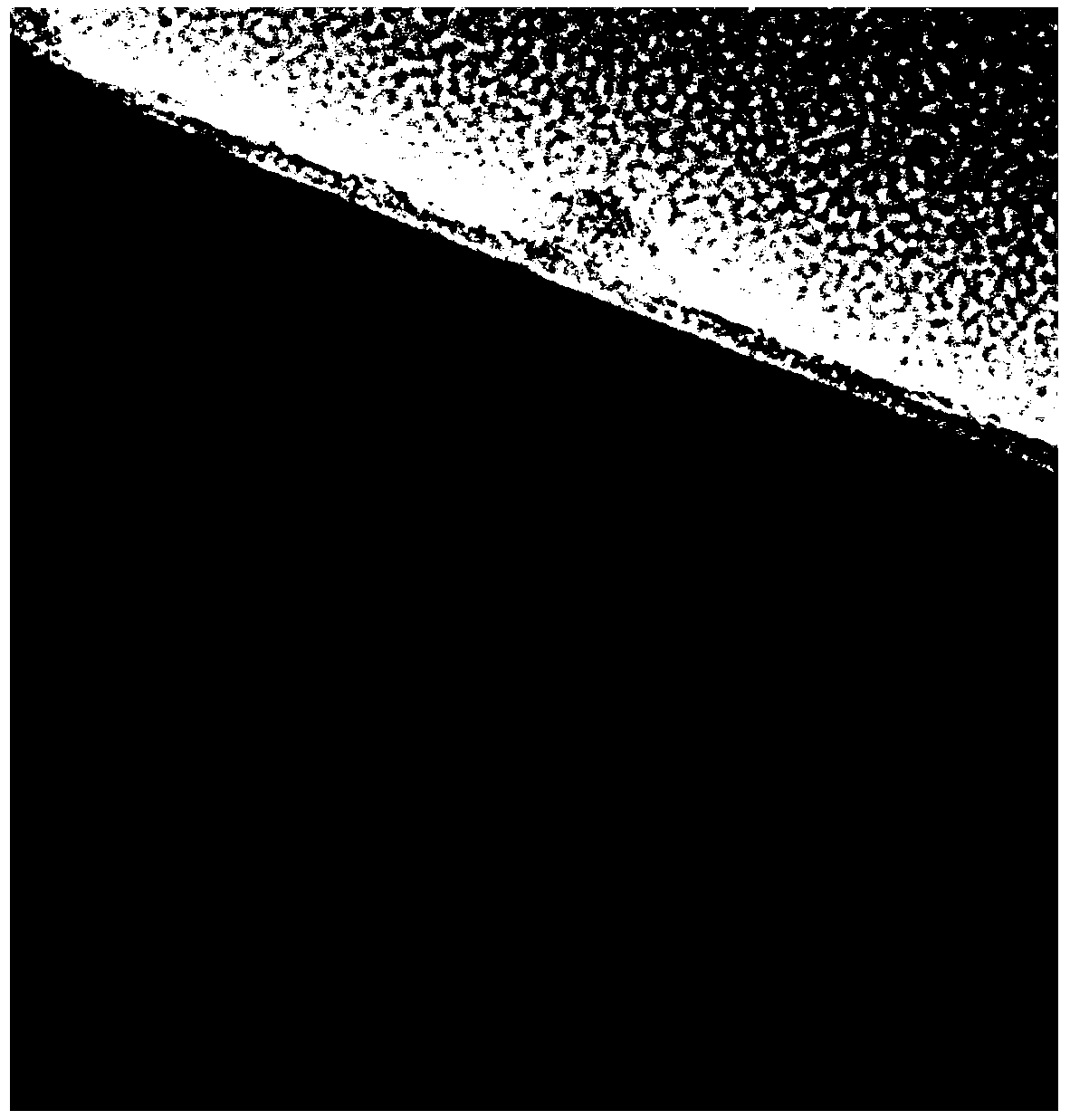

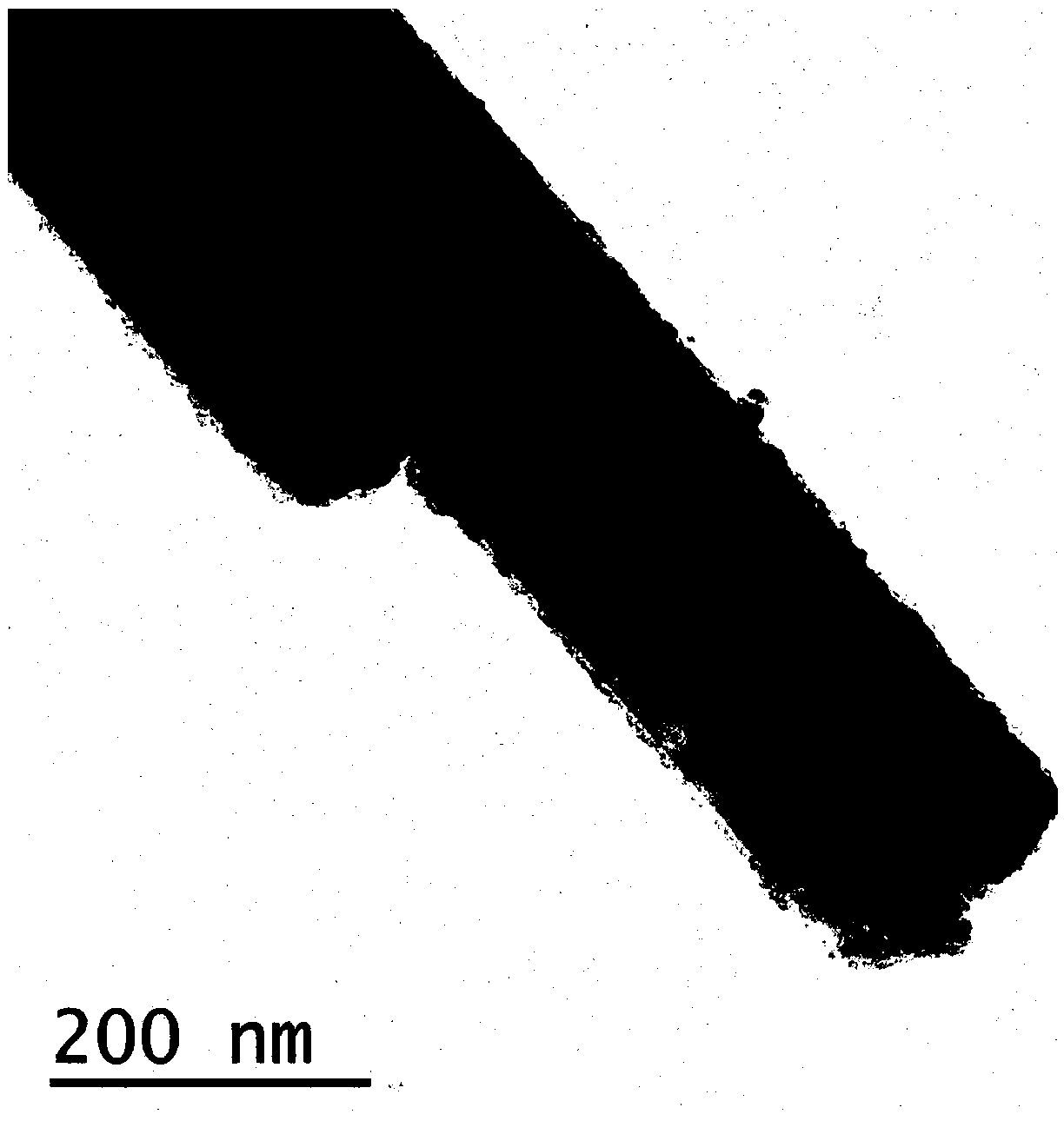

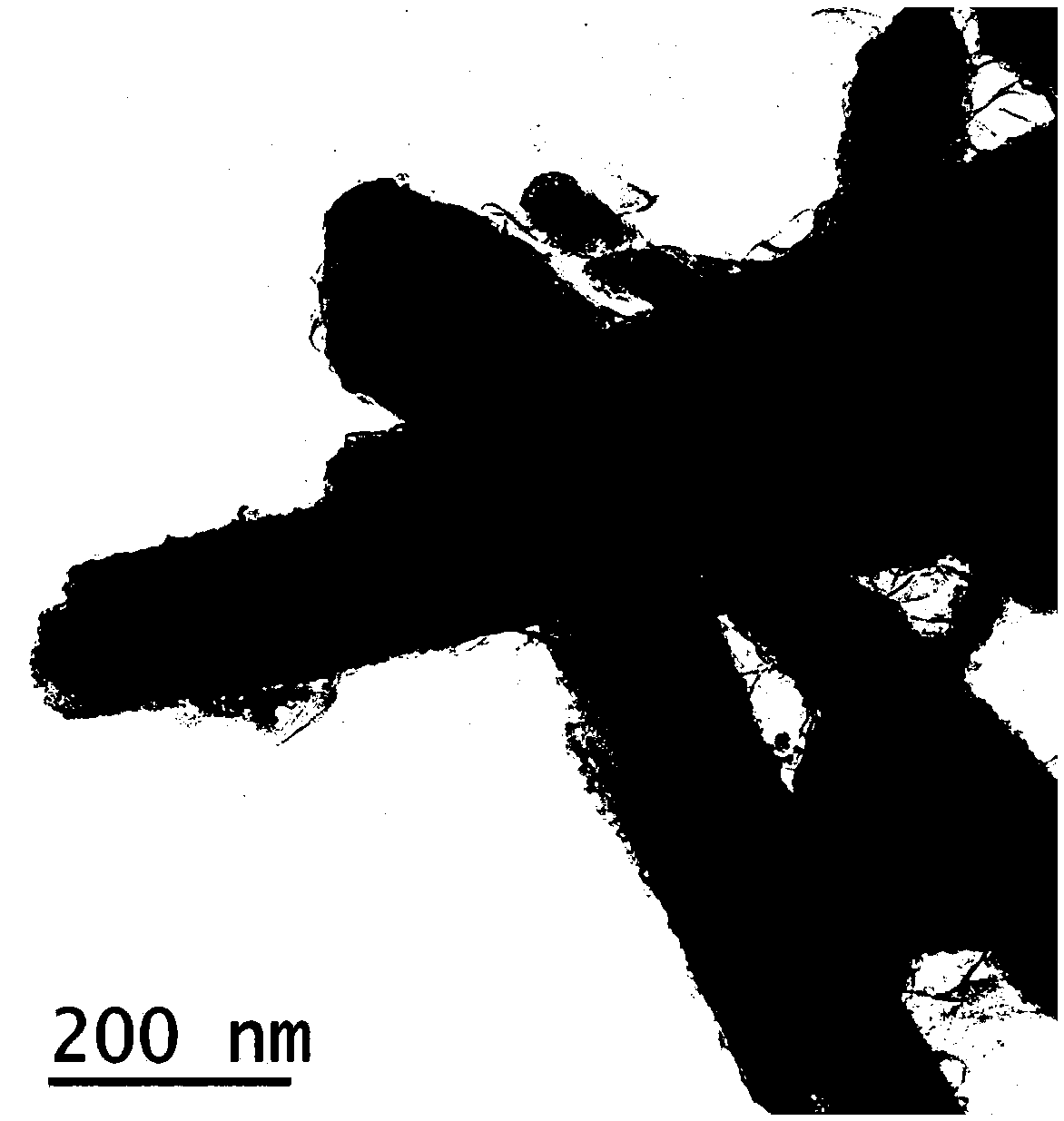

Image

Examples

Embodiment 1

[0037] Use deionized water to prepare 1000g of the primary product of iron oxide yellow into a slurry containing a concentration of 260g / L of the primary product of iron oxide yellow, add 0.03L of an aqueous sodium silicate solution with a mass concentration of sodium silicate of 100g / L, and then pass the slurry into the sand Sand grinding in the mill, and the sand-milled slurry is filtered through a sieve to remove coarse particles to obtain a water suspension of the primary product of iron oxide yellow.

[0038]Add the aqueous suspension of the primary product of iron oxide yellow into the coating tank while stirring and raising the temperature to 75°C, and keep this temperature until the coating of aluminum hydroxide is completed. Start to pack dense silicon dioxide, add dropwise sodium silicate aqueous solution with a concentration of 50g / L at a concentration of 2.0% relative to the initial iron oxide yellow product, and simultaneously add 1mol / L hydrochloric acid in parall...

Embodiment 2

[0043] Use deionized water to prepare 1000g of the primary iron oxide yellow product into a slurry containing a concentration of 70g / L of the primary iron oxide yellow product, add 0.4L of sodium silicate aqueous solution with a mass concentration of sodium hexametaphosphate of 35g / L, and then pass the slurry into the sand Sand grinding in the mill, and the sand-milled slurry is filtered through a sieve to remove coarse particles to obtain a water suspension of the primary product of iron oxide yellow.

[0044] Add the aqueous suspension of the primary product of iron oxide yellow into the coating tank while stirring and raising the temperature to 50°C, and keep this temperature until the coating of aluminum hydroxide is completed. Start to pack dense silicon dioxide, dropwise add 1.5% sodium silicate aqueous solution with a sodium silicate concentration of 150g / L relative to the initial iron oxide yellow product, and simultaneously add 4mol / L hydrochloric acid to maintain pH =...

Embodiment 3

[0049] Use distilled water to prepare 1000g of iron oxide yellow primary product into a slurry containing 200g / L of iron oxide yellow primary product, add 0.05L of sodium hexametaphosphate aqueous solution with a mass concentration of sodium hexametaphosphate of 70g / L, and then pass the slurry into the sand Sand grinding in the mill, and the sand-milled slurry is filtered through a sieve to remove coarse particles to obtain a water suspension of the primary product of iron oxide yellow.

[0050] Add the aqueous suspension of the primary product of iron oxide yellow into the coating tank while stirring and raising the temperature to 40°C. Start to pack dense silicon dioxide, add dropwise an aqueous solution of sodium silicate with a concentration of 100g / L relative to the amount of 1.0% added to the primary product of iron oxide yellow, and add the aqueous solution of sodium silicate continuously and at a constant speed for 3 hours. After the addition, stir and mature for 20 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com