Low-VOC high-corrosion-resistance environment-friendly epoxy coating material and preparation method thereof

An epoxy coating, corrosion-resistant technology, applied in the direction of epoxy resin coating, anti-corrosion coating, coating, etc., can solve problems such as less research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

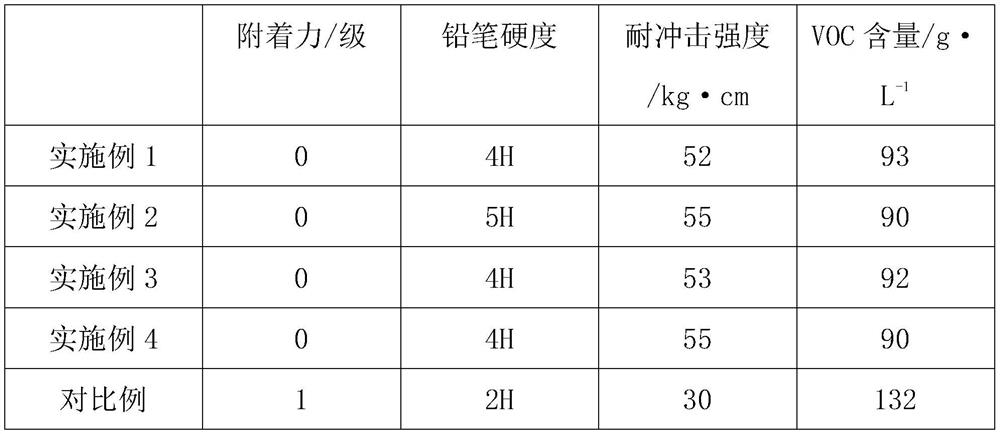

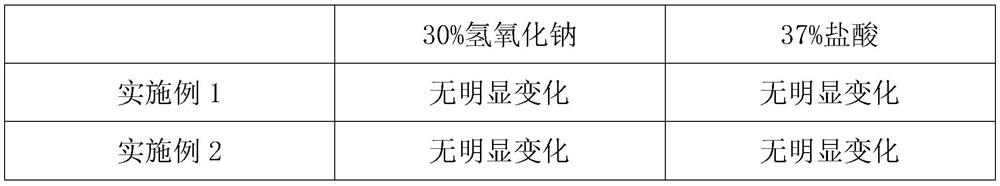

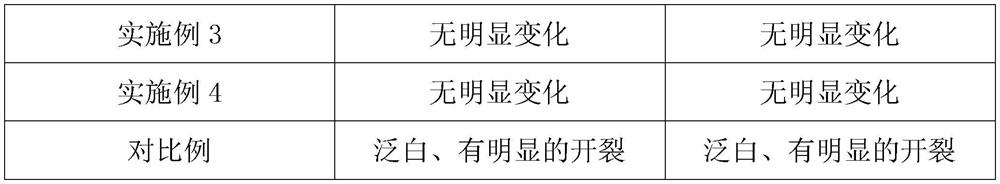

Examples

Embodiment 1

[0028] (1) Prepare the methanol solution of zinc nitrate hexahydrate with a concentration of 0.12mol / L and the methanol solution of 2-methylimidazole with a concentration of 0.45mol / L respectively, mix the methanol solution of zinc nitrate hexahydrate with 2-methylimidazole The methanol solution was mixed with a volume ratio of 1:1, stirred at room temperature and 1000 rpm for 20 hours, then centrifuged, the obtained precipitate was washed with methanol, and finally dried to obtain ZIF-8 particles;

[0029] (2) Disperse 0.15gg ZIF-8 particles in 50ml of absolute ethanol, add 0.1g of cetyltrimethylammonium bromide, stir and disperse, then add dropwise ammonia water with a concentration of 25wt% to adjust the pH of the solution to 11 , slowly add 0.15ml of tetrabutyl titanate dropwise and vigorously stir for 24h, then centrifuge, the obtained precipitate is washed with ethanol and deionized water in turn, and then dried to obtain a TiO2 / ZIF-8 composite material;

[0030](3) In p...

Embodiment 2

[0033] (1) Prepare the methanol solution of zinc nitrate hexahydrate with a concentration of 0.14mol / L and the methanol solution of 2-methylimidazole with a concentration of 0.55mol / L respectively, mix the methanol solution of zinc nitrate hexahydrate with 2-methylimidazole The methanol solution was mixed with a volume ratio of 1:1, stirred at room temperature and 2000 rpm for 25 hours, then centrifuged, the obtained precipitate was washed with methanol, and finally dried to obtain ZIF-8 particles;

[0034] (2) Disperse 0.17g of ZIF-8 particles in 50ml of absolute ethanol, add 0.3g of hexadecyltrimethylammonium bromide, stir and disperse, then add dropwise the concentration of 25wt% ammonia to adjust the pH of the solution to 11 , slowly add 0.15ml of tetrabutyl titanate dropwise and vigorously stir for 24h, then centrifuge, the obtained precipitate is washed with ethanol and deionized water in turn, and then dried to obtain a TiO2 / ZIF-8 composite material;

[0035] (3) In par...

Embodiment 3

[0038] (1) Prepare the methanol solution of zinc nitrate hexahydrate with a concentration of 0.13mol / L and the methanol solution of 2-methylimidazole with a concentration of 0.55mol / L respectively, mix the methanol solution of zinc nitrate hexahydrate with 2-methylimidazole The methanol solution was mixed with a volume ratio of 1:1, stirred at room temperature and 1500 rpm for 20 hours, then centrifuged, the obtained precipitate was washed with methanol, and finally dried to obtain ZIF-8 particles;

[0039] (2) Disperse 0.16g of ZIF-8 particles in 50ml of absolute ethanol, add 0.2g of hexadecyltrimethylammonium bromide, stir and disperse, then add dropwise the concentration of 25wt% ammonia to adjust the pH of the solution to 11 , slowly add 0.15ml of tetrabutyl titanate dropwise and vigorously stir for 24h, then centrifuge, the obtained precipitate is washed with ethanol and deionized water in turn, and then dried to obtain a TiO2 / ZIF-8 composite material;

[0040] (3) In par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com