Preparation method of hierarchical pore ZSM-5/ZSM-11 eutectic zeolite molecular sieve

A technology of ZSM-11 and eutectic zeolite is applied in the directions of molecular sieve catalyst, crystalline aluminosilicate zeolite, borocarbonane silicone crystalline aluminosilicate zeolite, etc., to achieve the effects of simple process, low cost, and easy operation and realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

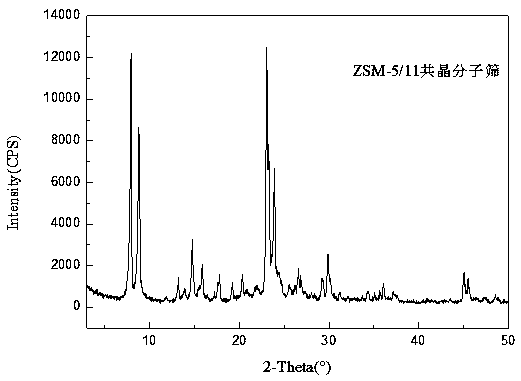

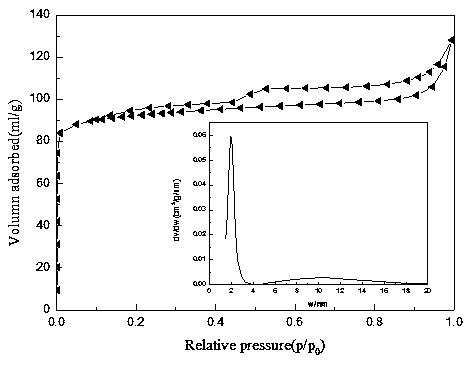

[0025] Silica sol (SiO 2 weight percentage content 40%) as silicon source, aluminum source then selects sodium metaaluminate, template agent adopts tetrabutyl ammonium hydroxide, according to 150SiO 2 :1Al 2 o 3 :6 template agent: 12M 2 O (M=K or Na, K / Na=0.5): 2300 molar ratio of deionized water was weighed. After mixing well, crystallize at 160°C for 48 hours, wash and dry, treat with 0.2mol / L NaOH solution at 65°C for 30min, filter, wash and dry, continue to use 1mol / L NH 3 NO 3 The solution was treated at 65° C. for 6 hours, and finally put into a muffle furnace and calcined at 500° C. for 5 hours to obtain a hierarchically porous ZSM-5 / ZSM-11 eutectic zeolite molecular sieve. Obtained XRD pattern, N 2 The adsorption isotherm diagram is shown in figure 1 , figure 2 . It can be seen from the XRD pattern that there are strong diffraction peaks at 2θ=7.90°, 8.82°, 23.04°, 23.88°, and 45.82° respectively, which are the characteristic diffractions of multi-level hole ...

Embodiment 2

[0027] Tetraethyl orthosilicate is selected as the silicon source, aluminum chloride is selected as the aluminum source, and tetrabutylammonium bromide is used as the template agent, according to 120SiO 2 :1Al 2 o 3 :7 template agent: 16M 2 O (M=K or Na, K / Na=0.7): 2700 Deionized water molar ratio weighing. After mixing well, crystallize at 180°C for 24 hours, wash and dry, treat with 0.25mol / l NaOH solution at 70°C for 45min, filter, wash and dry, continue to use 1mol / l NH 3 NO 3 The solution was treated at 65° C. for 6 hours, and finally put into a muffle furnace and calcined at 550° C. for 5 hours to obtain a hierarchically porous ZSM-5 / ZSM-11 eutectic zeolite molecular sieve. Its XRD pattern, N 2 The adsorption isotherm is similar to figure 1 , figure 2 .

Embodiment 3

[0029] Silica sol (SiO 2 weight percentage content 40%) as silicon source, aluminum source then selects aluminum sulfate, template agent adopts tetrapropyl ammonium hydroxide, according to 180SiO 2 :1Al 2 o 3 :8 template agent: 18M 2 O (M=K or Na, K / Na=1.2): 3000 deionized water molar ratio weighing. After mixing well, crystallize at 160°C for 96 hours, wash and dry, treat with 0.3mol / l NaOH solution at 75°C for 45min, filter, wash and dry, continue to use 1mol / l NH 3 NO 3 The solution was treated at 65° C. for 6 hours, and finally put into a muffle furnace and calcined at 580° C. for 4 hours to obtain a hierarchically porous ZSM-5 / ZSM-11 eutectic zeolite molecular sieve. Its XRD pattern, N 2 The adsorption isotherm is similar to figure 1 , figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com