A kind of preparation method of hierarchical porous zsm-5/zsm-11 eutectic zeolite molecular sieve

A technology of ZSM-11 and ZSM-5, which is applied in the field of catalyst preparation, achieves the effects of simple process, easy operation and realization, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

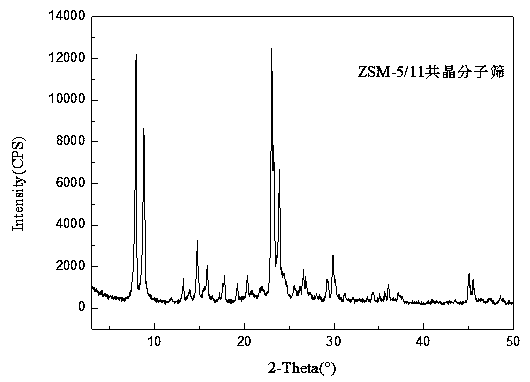

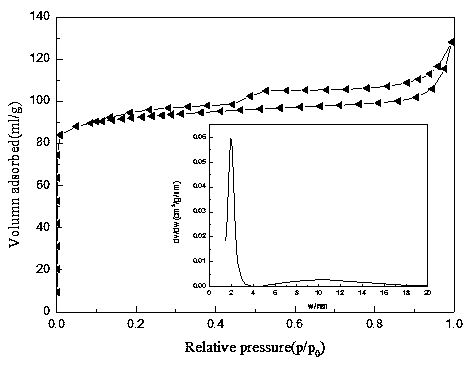

[0025] Silica sol (SiO 2 weight percentage content 40%) as silicon source, aluminum source then selects sodium metaaluminate, template agent adopts tetrabutyl ammonium hydroxide, according to 150SiO 2 :1Al 2 o 3 :6 template agent: 12M 2 O (M=K or Na, K / Na=0.5): 2300 molar ratio of deionized water was weighed. After mixing well, crystallize at 160°C for 48 hours, wash and dry, treat with 0.2mol / L NaOH solution at 65°C for 30min, filter, wash and dry, continue to use 1mol / L NH 4 NO 3 The solution was treated at 65° C. for 6 hours, and finally put into a muffle furnace and calcined at 500° C. for 5 hours to obtain a hierarchically porous ZSM-5 / ZSM-11 eutectic zeolite molecular sieve. Obtained XRD pattern, N 2 The adsorption isotherm diagram is shown in figure 1 , figure 2 . It can be seen from the XRD pattern that there are strong diffraction peaks at 2θ=7.90°, 8.82°, 23.04°, 23.88°, and 45.82° respectively, which are the characteristic diffractions of multi-level hole ...

Embodiment 2

[0027] Tetraethyl orthosilicate is selected as the silicon source, aluminum chloride is selected as the aluminum source, and tetrabutylammonium bromide is used as the template agent, according to 120SiO 2 :1Al 2 o 3 :7 template agent: 16M 2 O (M=K or Na, K / Na=0.7): 2700 Deionized water molar ratio weighing. After mixing well, crystallize at 180°C for 24 hours, wash and dry, treat with 0.25mol / l NaOH solution at 70°C for 45min, filter, wash and dry, continue to use 1mol / l NH 4 NO 3 The solution was treated at 65° C. for 6 hours, and finally put into a muffle furnace and calcined at 550° C. for 5 hours to obtain a hierarchically porous ZSM-5 / ZSM-11 eutectic zeolite molecular sieve. Its XRD pattern, N 2 The adsorption isotherm is similar to figure 1 , figure 2 .

Embodiment 3

[0029] Silica sol (SiO 2 weight percentage content 40%) as silicon source, aluminum source then selects aluminum sulfate, template agent adopts tetrapropyl ammonium hydroxide, according to 180SiO 2 :1Al 2 o 3 :8 template agent: 18M 2 O (M=K or Na, K / Na=1.2): 3000 deionized water molar ratio weighing. After mixing well, crystallize at 160°C for 96 hours, wash and dry, treat with 0.3mol / l NaOH solution at 75°C for 45min, filter, wash and dry, continue to use 1mol / l NH 4 NO 3 The solution was treated at 65° C. for 6 hours, and finally put into a muffle furnace and calcined at 580° C. for 4 hours to obtain a hierarchically porous ZSM-5 / ZSM-11 eutectic zeolite molecular sieve. Its XRD pattern, N 2 The adsorption isotherm is similar to figure 1 , figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com