Alkali treatment modification method of alumina carrier as well as preparation method and application of silver catalyst supported by alumina carrier

An alumina carrier and silver catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, catalyst carriers, etc., can solve the problem of high equipment requirements, little improvement in selectivity, The production cost is high, and the preparation method has the advantages of simple steps, good selectivity, and easy to obtain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Example 1 Preparation of α-Al 2 O 3 The carrier is used as a comparative example for Examples 2 to 7; Examples 2 to 7 are respectively under different reaction conditions to the α-Al prepared in Example 1. 2 O 3 The carrier is treated with alkali to obtain modified α-Al 2 O 3 Carrier; Example 8 adopts the α-Al prepared in Example 1 2 O 3 The carrier was used to prepare a silver catalyst, which was used as a comparative example for Examples 9 to 14; Examples 9 to 14 respectively adopted the modified α-Al prepared in Examples 2 to 7. 2 O 3 Support for the preparation of silver catalysts. Determination of catalyst performance

[0063] The various silver catalysts involved in the present invention are tested for their initial activity and selectivity with a laboratory microreactor (hereinafter referred to as "microreactor") evaluation device. The reactor used in the micro-reaction evaluation device is a stainless steel tube with an inner diameter of 4 mm, and the r...

Embodiment

[0072] Example 1: Preparation of α-Al 2 O 3 carrier

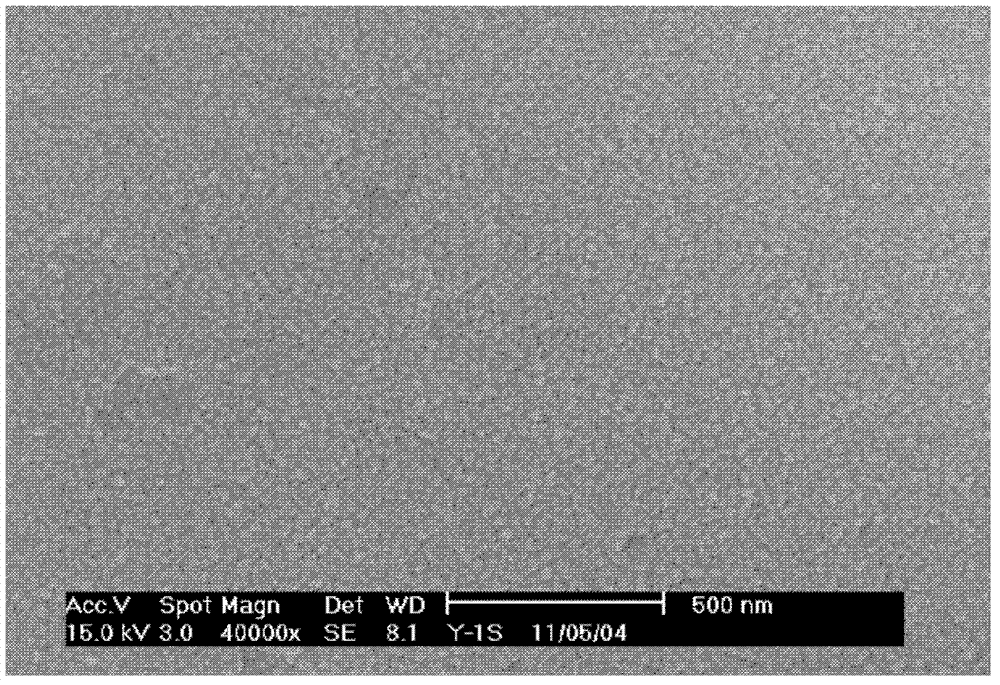

[0073] 200-500 mesh trihydrate α-Al 2 O 3 403g, 200~400 mesh fake monohydrate Al 2 O 3 81g, NH 4 F3g and BaSO 4 0.5g was put into a mixer and mixed, then transferred to a kneader, added with 90ml of dilute nitric acid (nitric acid: water = 1:3, weight ratio), and kneaded into an extrudable paste. It is extruded into a five-hole column with an outer diameter of 8.0 mm, a length of 6.0 mm and an inner diameter of 1.0 mm, and is dried at 80-120 ° C for 10 hours to reduce the free water content to less than 10 wt%, and the molded α-alumina carrier is prepared. blank. Then the green body was put into an electric furnace, raised from room temperature to 1400°C for 30 hours, and kept at a constant temperature for 2 hours. 2 O 3 The carrier is named Z-1, and its crushing strength and water absorption rate are measured, the results are shown in Table 1, and the scanning electron microscope photo of the carrier is shown in ...

Embodiment 2

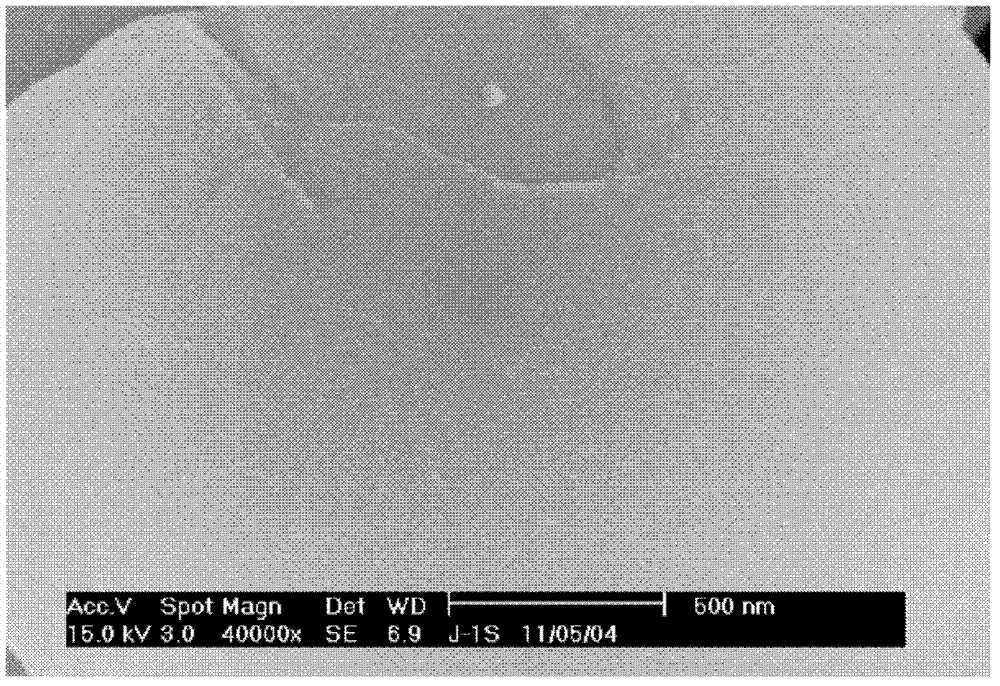

[0074] Example 2: Preparation of modified α-Al 2 O 3 carrier

[0075] Prepare 20g 0.2mol / l Ba(OH) according to the solid-liquid mass ratio of 1:1 2 solution, and Ba(OH) 2 The temperature of the solution was kept constant to 20°C, and 20g of Z-1 carrier was weighed and put into Ba(OH) 2 After stirring for 0.2 h, the carrier was taken out and washed with deionized water until the pH value of the filtrate was about 7. Then put the carrier into an oven to dry at 100°C for 10 hours, and name the obtained modified α-alumina carrier as Z-2, and measure its crushing strength and water absorption. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com