One-step method for flame soaking heat treatment modification of silicon electrode

A technology of heat treatment modification and silicon electrode, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems such as difficult to achieve the modification effect, and achieve the effect of simple electrode modification method, high charge and discharge efficiency, and excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

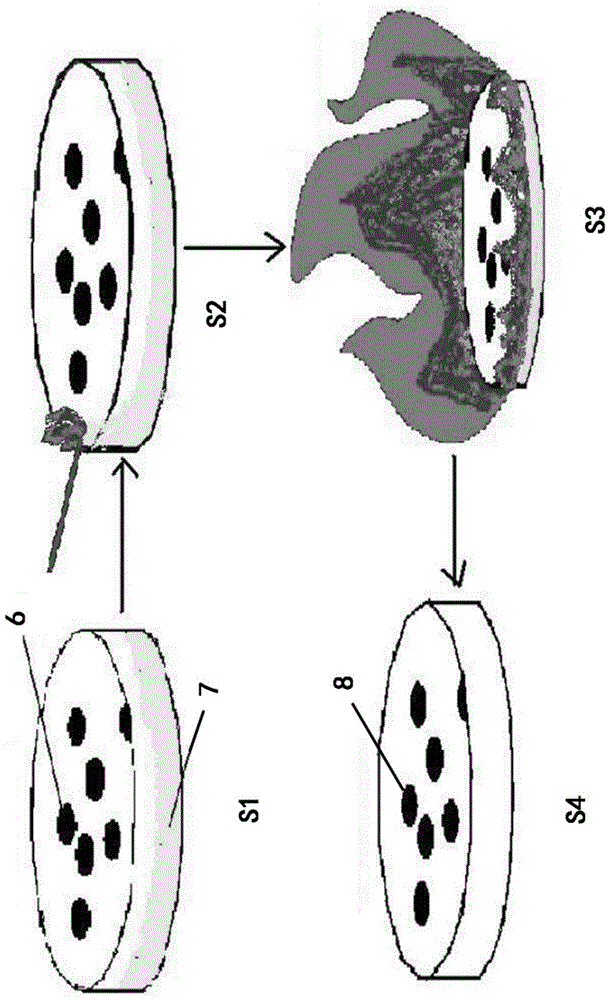

Method used

Image

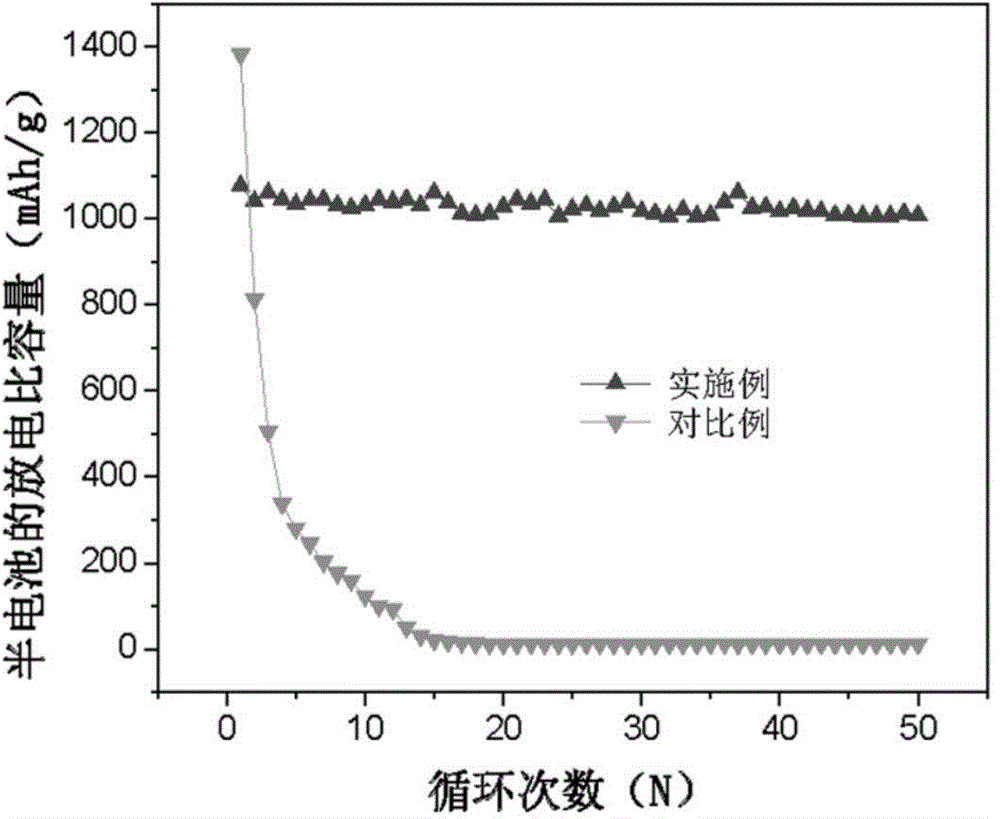

Examples

Embodiment 1

[0044] Example 1: After immersing the silicon electrode in absolute ethanol as a solvent, ignite the solvent for heat treatment to modify

[0045] In this embodiment, high-purity crystalline silicon (Wt%=99.9%) with a diameter of 100nm, conductive agent (carbon black: acetylene black w / w=1:1) and polyacrylonitrile (PAN) were selected as materials for preparing electrodes.

[0046] Follow the steps below to prepare high-purity crystalline silicon electrodes:

[0047] (a) Dissolve 50 mg of PAN powder in 5000 μL of DMF solution and stir well to obtain a PAN matrix solution

[0048] (b) Weigh 400 mg of high-purity crystalline silicon and 50 mg of conductive agent, add them into the solution of (a) in batches, stir vigorously, and mix thoroughly to obtain a silicon electrode slurry.

[0049] (c) The silicon electrode slurry obtained in step (b) is directly coated on the copper foil with a coating machine (the coating thickness is 100 μm).

[0050] (d) Place the copper foil flat i...

Embodiment 2

[0054] Example 2: After immersing the silicon electrode with thiophene as a solvent, ignite the solvent for heat treatment to modify

[0055] In this embodiment, high-purity crystalline silicon (Wt%=99.9%) with a diameter of 100 nm, conductive agent (carbon black: acetylene black w / w=1:1) and phenolic resin are selected as materials for preparing electrodes.

[0056] Follow the steps below to prepare high-purity crystalline silicon electrodes:

[0057] (a) Dissolve 50 mg of phenolic resin in 5000 μL of DMF solution and stir well to obtain a phenolic resin matrix solution

[0058] (b) Weigh 400 mg of high-purity crystalline silicon and 50 mg of conductive agent, add them into the solution of (a) in batches, stir vigorously, and mix thoroughly to obtain a silicon electrode slurry.

[0059] (c) The silicon electrode slurry obtained in step (b) is directly coated on the copper foil with a coating machine (the coating thickness is 100 μm).

[0060] (d) Place the copper foil flat ...

Embodiment 3

[0064] Example 3: After immersing the silicon electrode in ethyl acetate as a solvent, ignite the solvent for heat treatment to modify

[0065] In this embodiment, high-purity crystalline silicon (Wt%=99.9%) with a diameter of 100 nm, conductive agent (carbon black: acetylene black w / w=1:1) and polystyrene are selected as materials for preparing electrodes.

[0066] Follow the steps below to prepare high-purity crystalline silicon electrodes:

[0067] (a) Dissolve 50 mg of polystyrene in 5000 μL of DMAc solution and stir well to obtain a polystyrene matrix solution

[0068] (b) Weigh 400 mg of high-purity crystalline silicon and 50 mg of conductive agent, add them into the solution of (a) in batches, stir vigorously, and mix thoroughly to obtain a silicon electrode slurry.

[0069] (c) The silicon electrode slurry obtained in step (b) is directly coated on the copper foil with a coating machine (the coating thickness is 100 μm).

[0070] (d) Place the copper foil flat in a b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com