Surface heat treatment modification method of fluorescent powder and COB light source made of fluorescent powder

A technology of surface heat treatment and modification method, which is applied in the field of LED inorganic luminescent materials, can solve the problems of increasing the production of luminescent materials and environmental protection costs, affecting the optical properties of luminescent materials, and environmentally harmful substances, so as to expand the scope of use, low cost, The effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Example 1 (Ca 0.08 Sr 0.90 )(Al 0.5 Si 0.5 ) 2 N 3 : Eu 0.02

[0061] The raw material that synthesis embodiment 1 material adopts is Sr 3 N 2 , Ca 3 N 2 , Si 3 N 4 , AlN, Eu 2 o 3 . Weigh 100 g of the raw materials shown below and mix them.

[0062]

[0063]

[0064] After weighing the above raw materials, put the powder in a mortar and mix evenly in a glove box (oxygen content<1ppm, water content<1ppm).

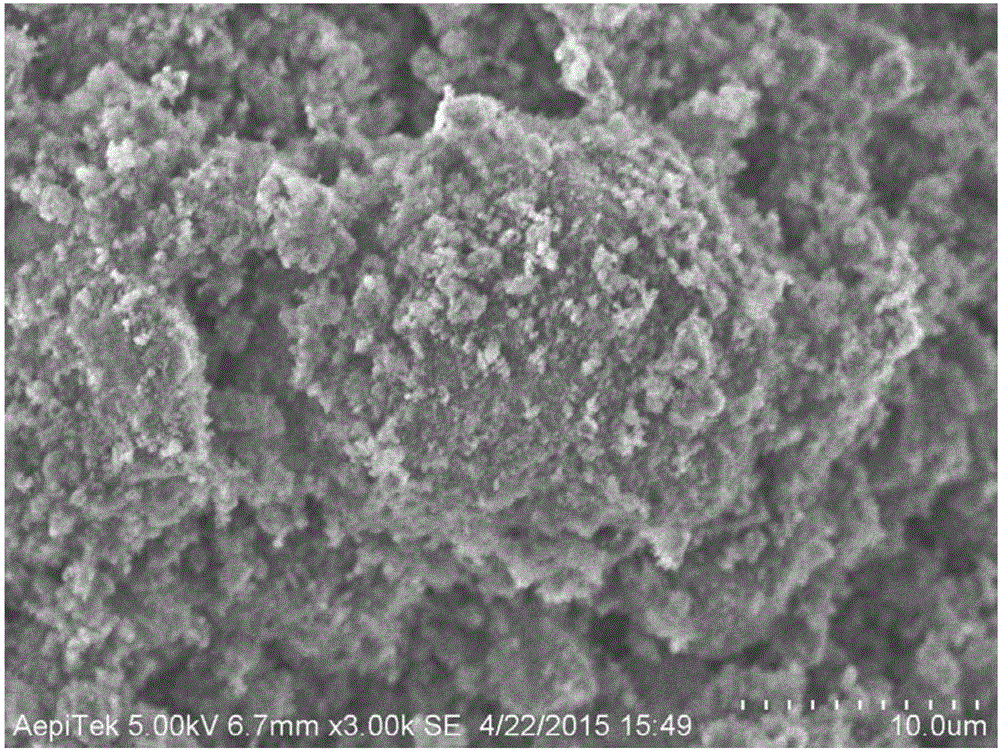

[0065] The mortar is onyx or alumina ceramic. Put the mixed powder into the crucible, compact it lightly, then take it out from the glove box and place it in a high-temperature graphite furnace. The material of the crucible is molybdenum or boron nitride. After the graphite furnace is evacuated and filled with nitrogen, it starts to heat up. The temperature rise rate is 10°C / min, and the nitrogen pressure is 0.8MPa. Heat up to 1800°C and keep warm for 6 hours. After the keep warm, turn off the power and cool down with the furnace. The burnt ...

Embodiment 2

[0068] Example 2 (Ca 0.08 Sr 0.90 )(Al 0.5 Si 0.5 ) 2 N 3 : Eu 0.02

[0069] The raw material that synthetic embodiment 2 material adopts is Sr 3 N 2 , Ca 3 N 2 , Si 3 N 4 , AlN, Eu 2 o 3 , Weigh 100 g of the raw materials shown below and mix them.

[0070]

[0071] After weighing the above raw materials, put the powder in a mortar and mix evenly in a glove box (oxygen content<1ppm, water content<1ppm).

[0072] Consistent with the method of preparing the finished product in Example 1, only the heat treatment surface treatment is not carried out after the finished product is produced.

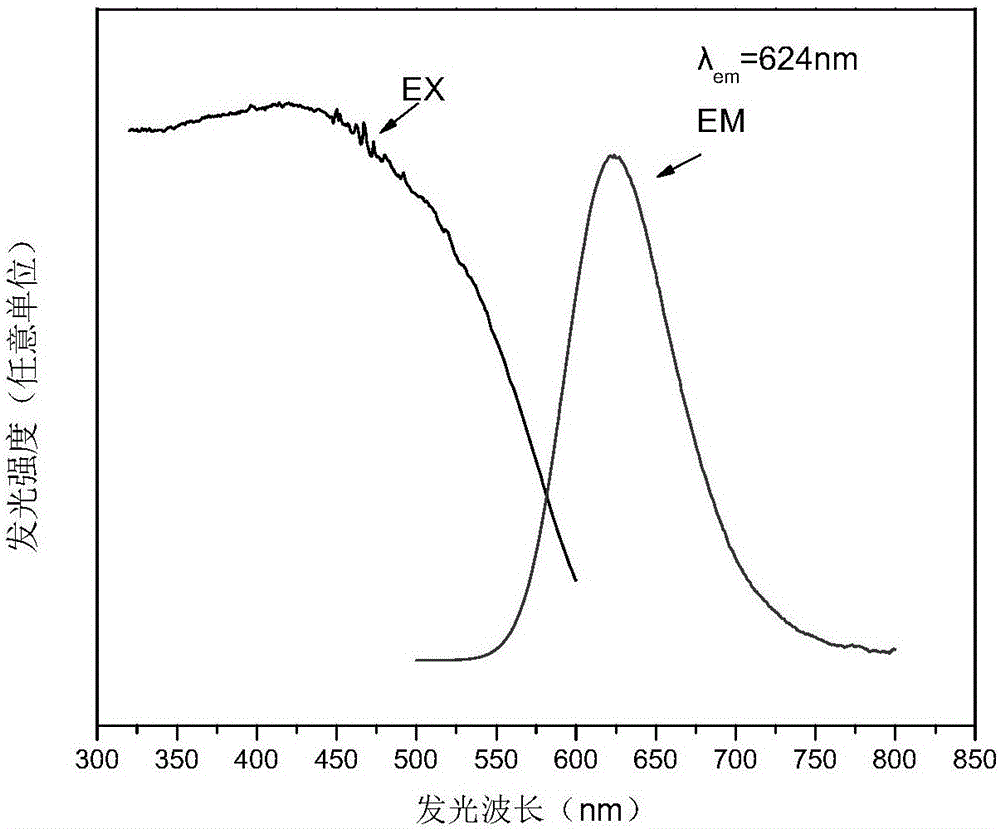

[0073] Figure 5 Be the emission spectrum of embodiment 2. Like Example 1, the excitation spectrum (EX) of Example 2 is relatively broad, indicating that the luminescent material can be excited by blue light and ultraviolet light. The emission spectrum (EM) is a broad spectrum, covering the range of 550-800nm, the half-maximum width (FWHM) is about 75nm, and the emission pe...

Embodiment 3

[0075] Example 3 (Ca 0.51 Sr 0.48 )(Al 0.5 Si 0.5 ) 2 (N 0.8 C 0.2 ) 3 : Eu 0.01

[0076] The raw material that synthetic embodiment 3 materials adopt is Sr 3 N 2 , Ca 3 N 2 , Si 3 N 4 , AlN, EuN, weigh 100g of the raw materials shown below and mix them. And using 1.0wt% porous ammonium fluoride (NH 4 F) as a flux.

[0077]

[0078] After weighing the above raw materials, put the powder in a mortar and mix evenly in a glove box (oxygen content<1ppm, water content<1ppm).

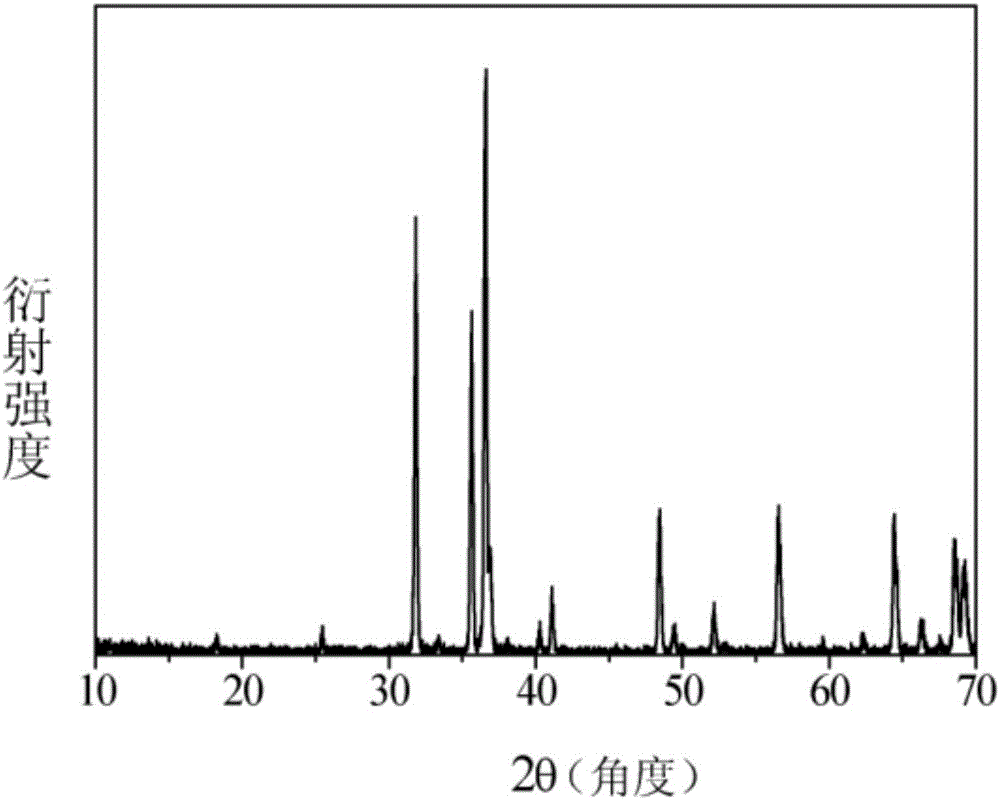

[0079] The mortar is onyx or alumina ceramic. Put the mixed powder into the crucible, compact it lightly, then take it out from the glove box and place it in a high-temperature graphite furnace. The material of the crucible is molybdenum or boron nitride. After the graphite furnace is evacuated and filled with nitrogen, it starts to heat up at a rate of 10°C / min, and the pressure of nitrogen is 1 atmosphere. Heat up to 1750°C and keep warm for 6 hours. After the keep warm, turn off the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com