Modification method for rice husk based capacitance carbon material

A technology of capacitive carbon and rice husk, which is applied in chemical instruments and methods, hybrid capacitor electrodes, carbon compounds, etc., can solve the problems of limiting the application of rice husk-based capacitive carbon materials, and achieves the advantages of being conducive to industrialization, popularization and application, simple preparation process, The effect of good specific capacitance and power characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Rice husk is cleaned, dried and ground;

[0027] (2) carbonizing the rice husk in the above step (1) at 500° C. for 1 h under the protection of nitrogen to obtain a carbonized product;

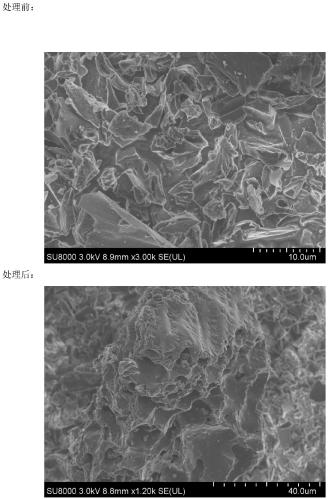

[0028] (3) Mix the carbonized product obtained in the above step (2) with 2% sodium hydroxide solution at a mass volume ratio of 1:3, control the temperature at 100°C, heat for 2h, filter, wash to pH 7, and dry to obtain template carbon,

[0029] (4) Mix the template carbon obtained in the above step (3) with 1mol L-1 strong alkali sodium hydroxide in a mass ratio of 1:3, control the reaction temperature to 750°C, the heating rate to 10°C / min, and the reaction time to 1h. get activated product;

[0030] (5) Soak the activated product obtained in the above step (4) with hot water at 90° C. for 2 hours, filter, wash until neutral, and dry to obtain rice husk-based capacitor carbon;

[0031] (6) the rice husk-based capacitor carbon obtained in the above step (5) is pulverized to 8-1...

Embodiment 2

[0034] (1) Rice husk is cleaned, dried and ground;

[0035] (2) carbonizing the rice husk in the above step (1) at 500° C. for 1 h under the protection of nitrogen to obtain a carbonized product;

[0036] (3) Mix the carbonized product obtained in the above step (2) with 2% sodium hydroxide solution at a mass volume ratio of 1:3, control the temperature at 100°C, heat for 2h, filter, wash to pH 7, and dry to obtain template carbon,

[0037] (4) Mix the template carbon obtained in the above step (3) with 1mol L-1 strong alkali sodium hydroxide in a mass ratio of 1:3, control the reaction temperature to 750°C, the heating rate to 10°C / min, and the reaction time to 1h. get activated product;

[0038] (5) Soak the activated product obtained in the above step (4) with hot water at 90° C. for 2 hours, filter, wash until neutral, and dry to obtain rice husk-based capacitor carbon;

[0039] (6) the rice husk-based capacitor carbon obtained in the above step (5) is pulverized to 8-1...

Embodiment 3

[0042] (1) Rice husk is cleaned, dried and ground;

[0043] (2) carbonizing the rice husk in the above step (1) at 500° C. for 1 h under the protection of nitrogen to obtain a carbonized product;

[0044] (3) Mix the carbonized product obtained in the above step (2) with 2% sodium hydroxide solution at a mass volume ratio of 1:3, control the temperature at 100°C, heat for 2h, filter, wash to pH 7, and dry to obtain template carbon,

[0045](4) Mix the template carbon obtained in the above step (3) with 1mol L-1 strong alkali sodium hydroxide in a mass ratio of 1:3, control the reaction temperature to 750°C, the heating rate to 10°C / min, and the reaction time to 1h. get the activated product;

[0046] (5) Soak the activated product obtained in the above step (4) with hot water at 90° C. for 2 hours, filter, wash until neutral, and dry to obtain rice husk-based capacitor carbon;

[0047] (6) the rice husk-based capacitor carbon obtained in the above step (5) is pulverized to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com