ETS-10 titanium silicalite molecular sieve modification method

A titanium-silicon molecular sieve and modification technology, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of low product crystallinity, low Al content, and many factors that limit the amount of Al introduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

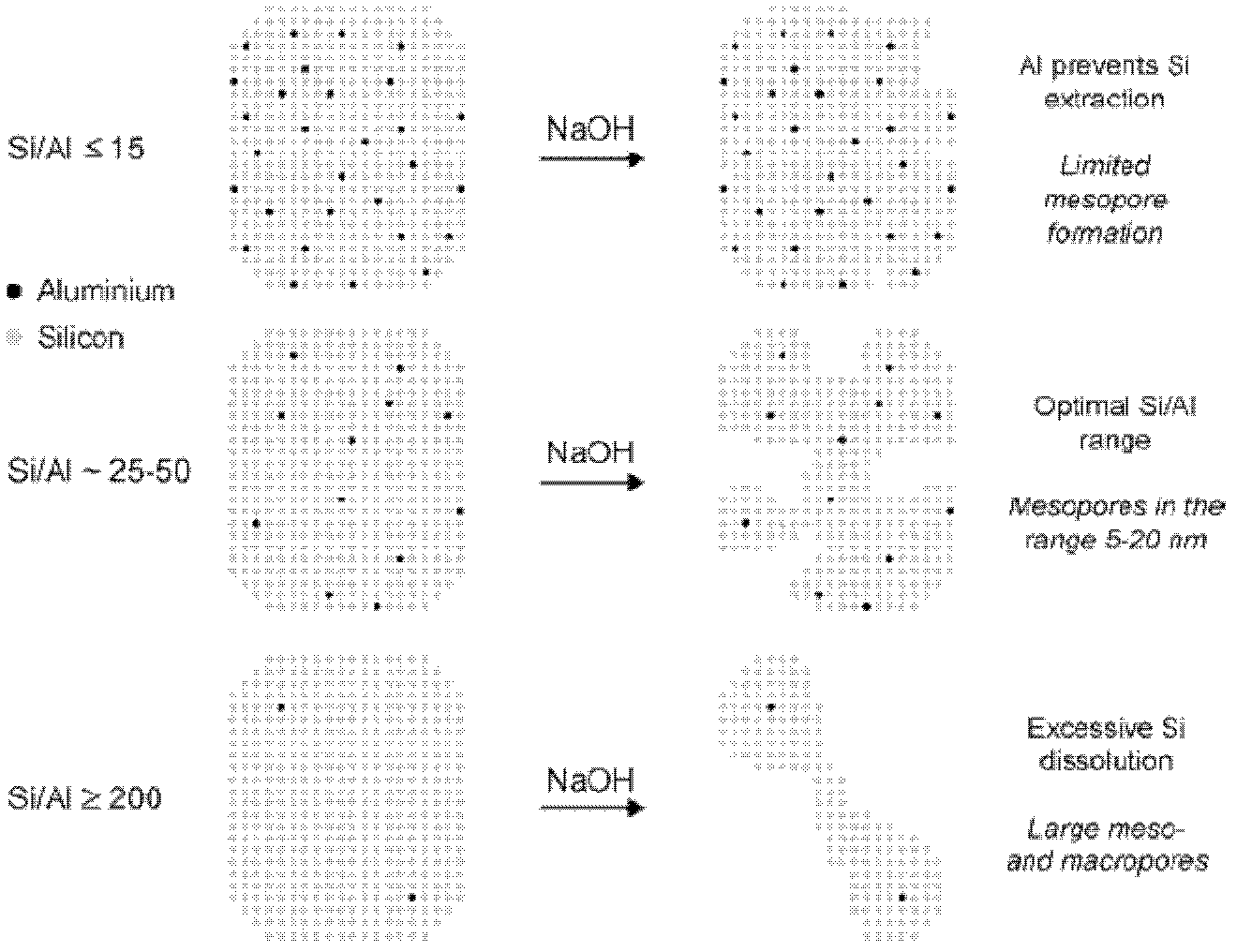

Method used

Image

Examples

Embodiment 1

[0053] Get two parts of 20.00g of the original powder of ETS-10 titanium silicon molecular sieve, add 200.00g deionized water respectively, under the condition of stirring, then add 1.67g NaOH particles respectively (at this time the alkali concentration is about 0.2mol / L), get two mixed slurries;

[0054] After the two mixed slurries were stirred evenly, they were respectively placed in a water bath at 90°C, and the stirring was continued for 1h and 2h respectively;

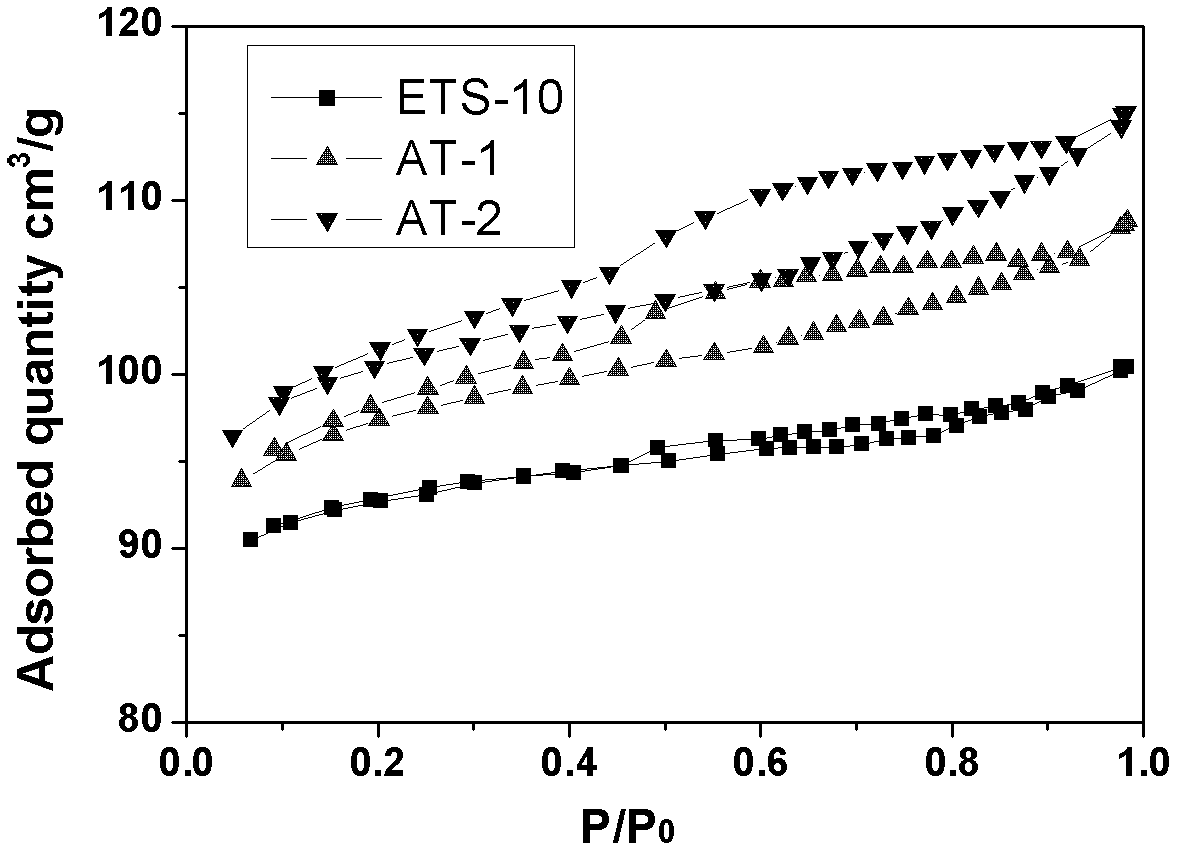

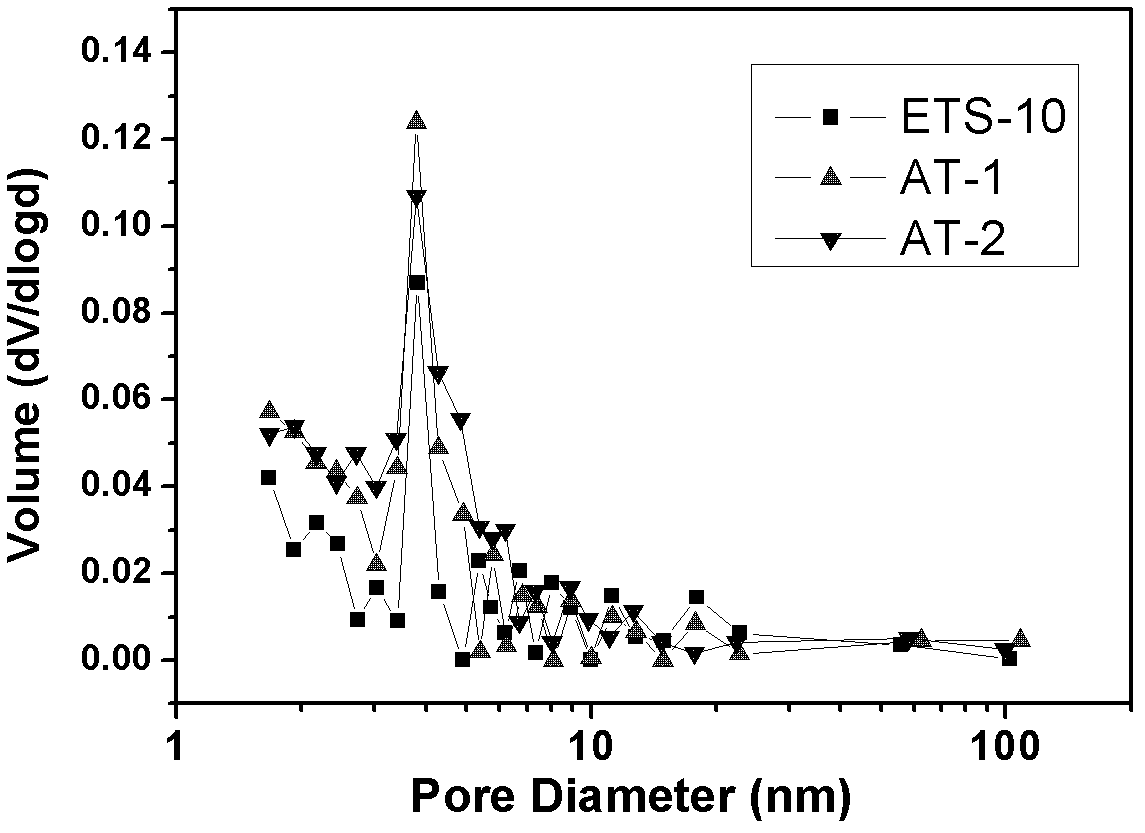

[0055] Filter the obtained two slurries, wash the solid product repeatedly until the pH of the washing liquid is less than 9, and then place the solid product at 120°C for 12 hours to obtain the ETS-10 titanium silicon molecular sieve modified by alkali treatment. They are marked as AT-1 and AT-2 respectively, and their pore structure data are shown in Table 2, and their nitrogen adsorption-desorption isotherms and pore distribution curves are shown in Table 2, respectively. Figure 2a with Figure 2b shown. ...

Embodiment 2

[0059] Take two parts of 20.00g of ETS-10 titanium silicon molecular sieve raw powder, add 200.00g of deionized water respectively, and add 4.17g of NaOH particles respectively under the condition of stirring (at this time, the alkali concentration is about 0.5mol / L);

[0060] After the two mixed slurries were stirred evenly, they were respectively placed in a water bath at 90°C, and the stirring was continued for 1h and 2h respectively;

[0061] Filter the obtained two slurries, wash the solid product repeatedly until the pH of the washing liquid is less than 9, and then place the solid product at 120°C for 12 hours to obtain the ETS-10 titanium silicon molecular sieve modified by alkali treatment. They are respectively marked as AT-3 and AT-4, and their pore structure data are shown in Table 3, and their nitrogen adsorption-desorption isotherms and pore distribution curves are shown in Table 3, respectively. Figure 3a with Figure 3b shown.

[0062] table 3

[0063] ...

Embodiment 3

[0065] Get five parts of 20.00g of the original powder of ETS-10 titanium silicon molecular sieve, add 200.00g of deionized water respectively, under the condition of stirring, then add 1.67g, 3.33g, 5.00g, 6.67g, 8.33g of NaOH particles (this Alkali concentration corresponds to 0.2mol / L, 0.4mol / L, 0.6mol / L, 0.8mol / L, 1.0mol / L respectively);

[0066] After stirring the five mixed slurries evenly, place them in a water bath at 90°C and continue stirring for 1 hour respectively;

[0067] Filter the obtained five slurries, wash the solid product repeatedly until the pH of the washing liquid is less than 9, and then place the solid product at 120°C for 12 hours to obtain the ETS-10 titanium-silicon molecular sieve modified by alkali treatment. They are respectively marked as AT-5, AT-6, AT-7, AT-8, and AT-9, and their pore structure data are shown in Table 4, and their nitrogen adsorption-desorption isotherms and pore distribution curves are shown in Table 4, respectively. Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com