Method for treating asphalt gas efficiently and harmlessly

A technology for harmless treatment of asphalt fume, applied in chemical instruments and methods, separation methods, and separation of dispersed particles, etc., can solve the problems of excessive discharge of pollutants, waste of raw materials, large fuel consumption, etc., and achieve the reduction of emission concentration , low operating cost, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

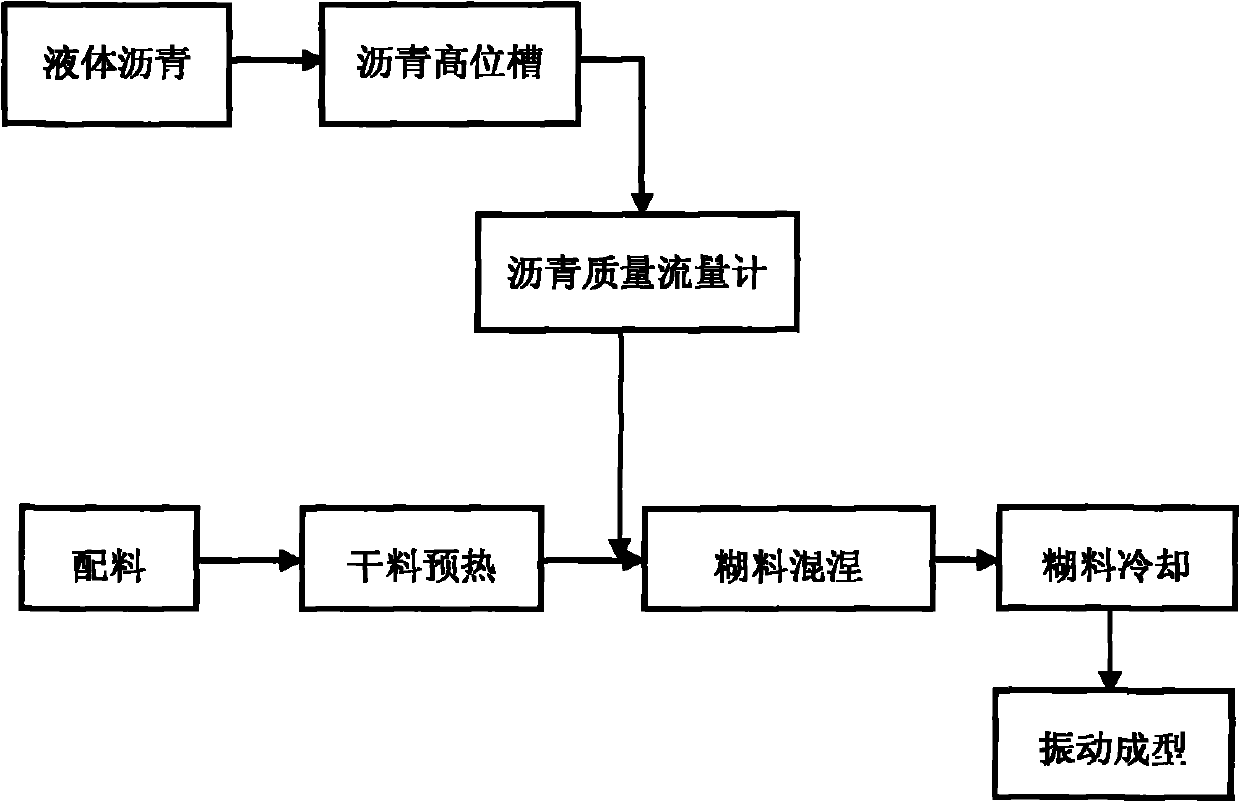

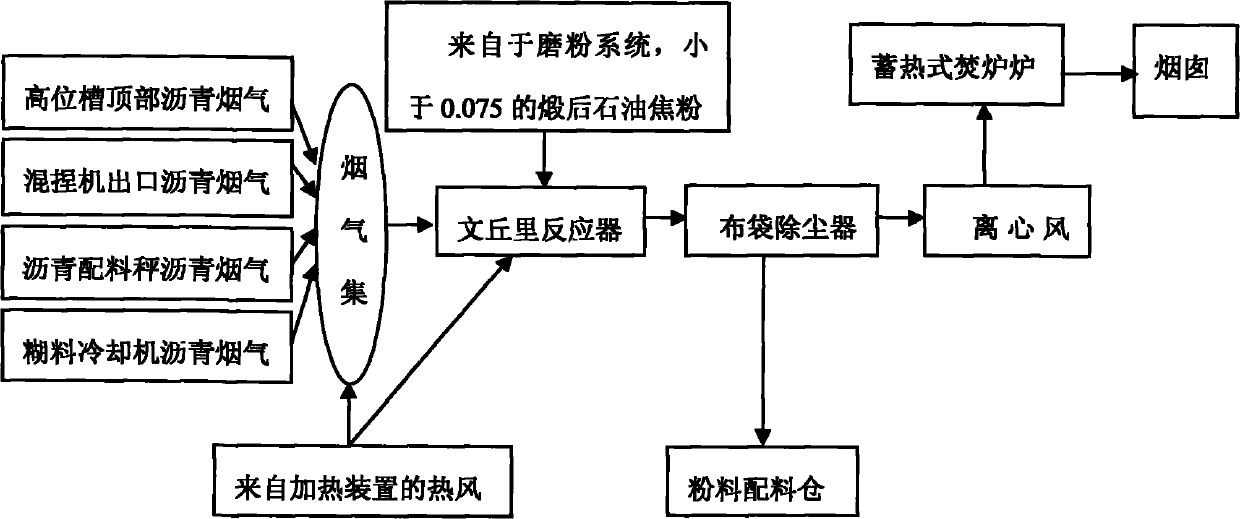

[0018] First collect asphalt flue gas produced by asphalt head tank and asphalt mass flow meter, kneading, paste cooling, and vibration molding, and the flue gas induced draft fan will introduce the asphalt flue gas into the Venturi reactor, and mix it with the calcined petroleum coke powder in the Venturi reactor. In the reactor for reaction adsorption, the flue gas enters the bag filter to collect and reuse the dust and tar, and after removing the tar and dust-containing water vapor in the asphalt flue gas, it is incinerated in a regenerative incinerator, and the incineration temperature is > 800°C, incinerate for 1-2 seconds, decompose polycyclic aromatic hydrocarbons such as benzopyrene, benzanthracene, and carbazole in the flue gas after incineration, and effectively remove harmful substances such as benzopyrene. The content of harmful substances is less than 5mg / m 3, , far below the national secondary emission standards. During the treatment process, the low-temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com