Centrifugal vacuum cleaner

A vacuum cleaner, centrifugal technology, applied in the direction of the suction filter, etc., can solve the problems of increasing noise, damaging the motor, damaging the suction generator, etc., to achieve the effect of reducing noise, preventing damage, and preventing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

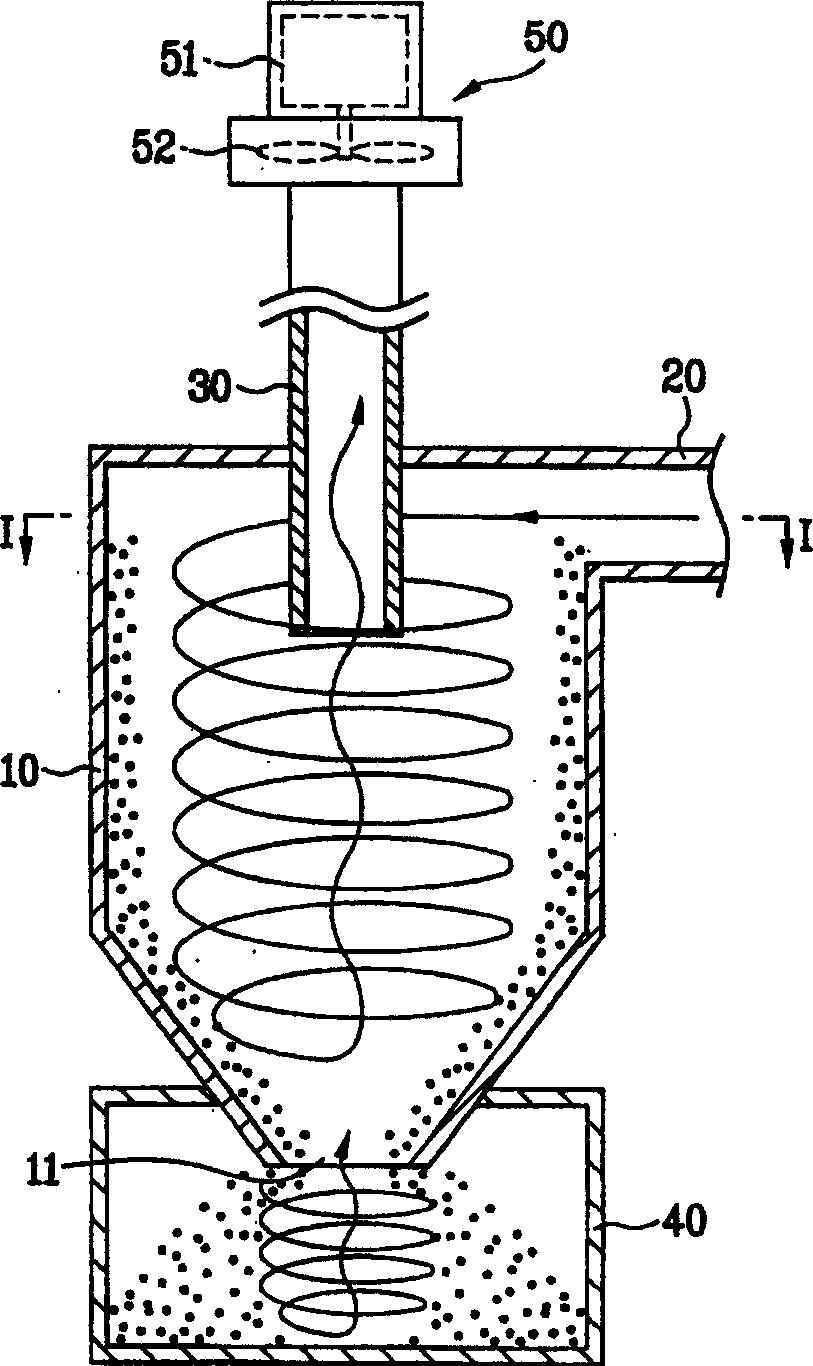

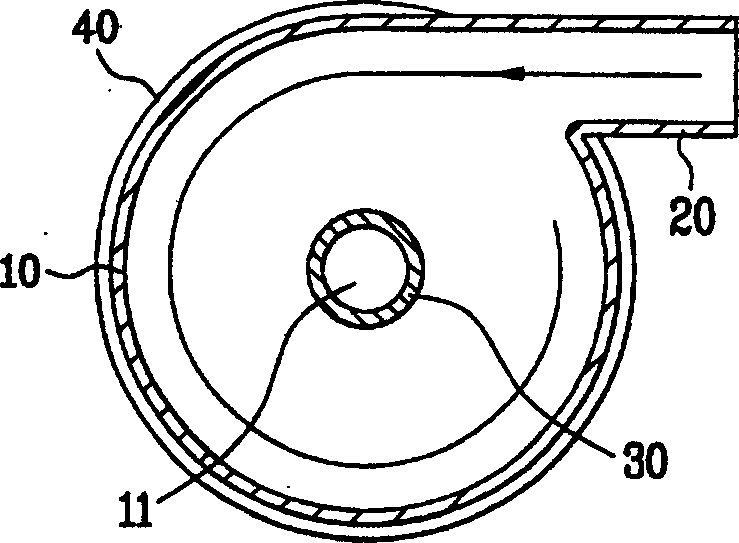

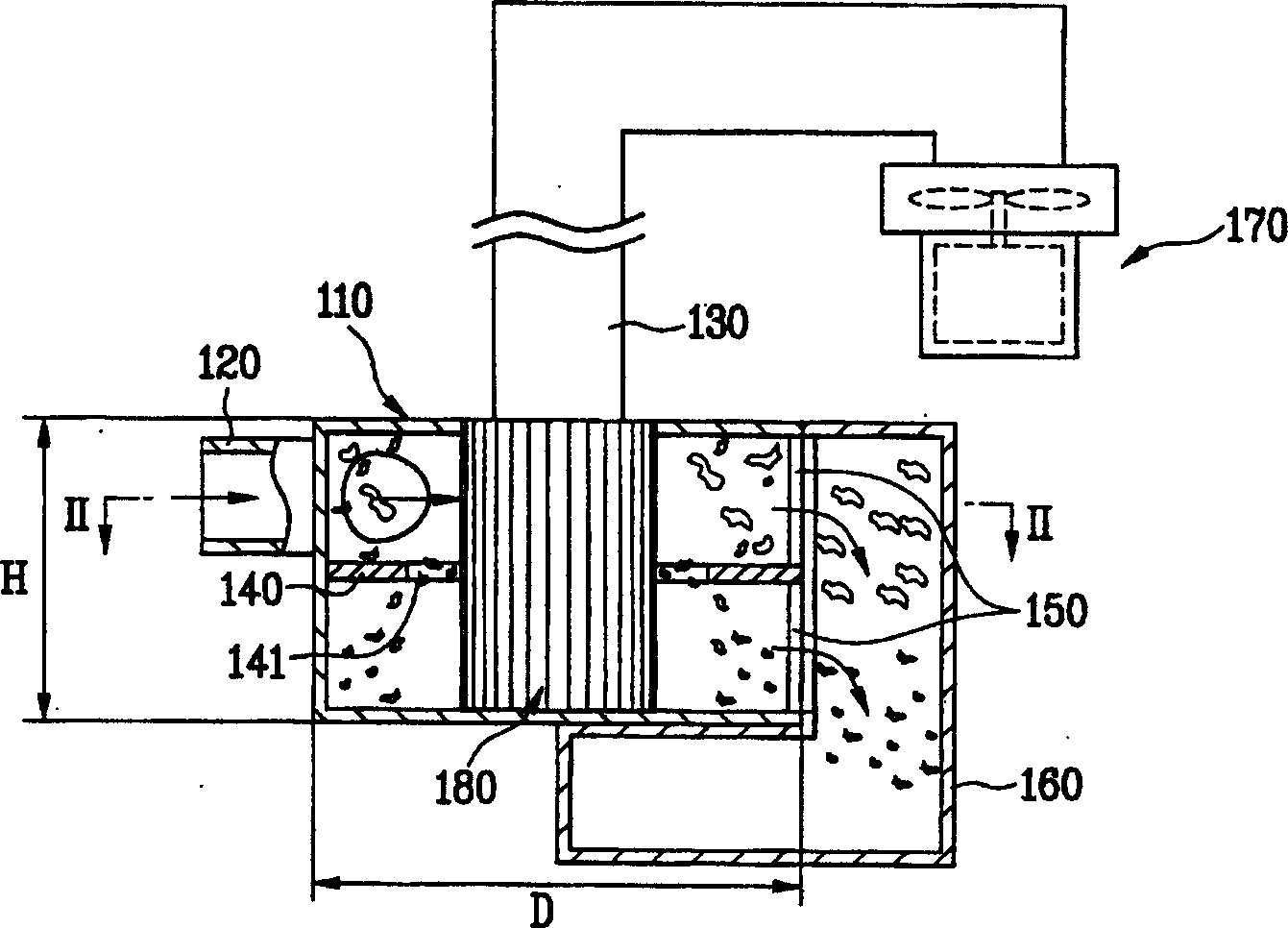

[0026] The centrifugal vacuum cleaner of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments:

[0027] like Figure 3 to Figure 5 As shown, the centrifugal vacuum cleaner designed by the present invention includes a body 110 , a suction pipe 120 , an exhaust pipe 130 , a partition 140 , a sewage hole 150 and a dust collection cylinder 160 . The overall shape of the body 110 is cylindrical, and its height H is smaller than or equal to the diameter D. However, not limited thereto, the height H of the fuselage 110 may be greater than the diameter D of the fuselage 110 .

[0028] The suction pipe 120 runs through the outer end of the fuselage 110 and is connected with the fuselage. More specifically, the suction duct 120 is connected to the periphery of the fuselage 110 in a tangential direction.

[0029] The function of the exhaust pipe 130 is to discharge the outside air flowing into the inside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com