Cyclone duster

A technology of cyclone dust collector and cyclone, which is applied in the direction of swirl devices and devices whose axial direction of swirl can be reversed, etc., which can solve the problems of increasing the motor load of the suction generator, damaging the suction generator, and long flow path , to achieve the effect of reducing load, reducing pressure loss and reducing contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

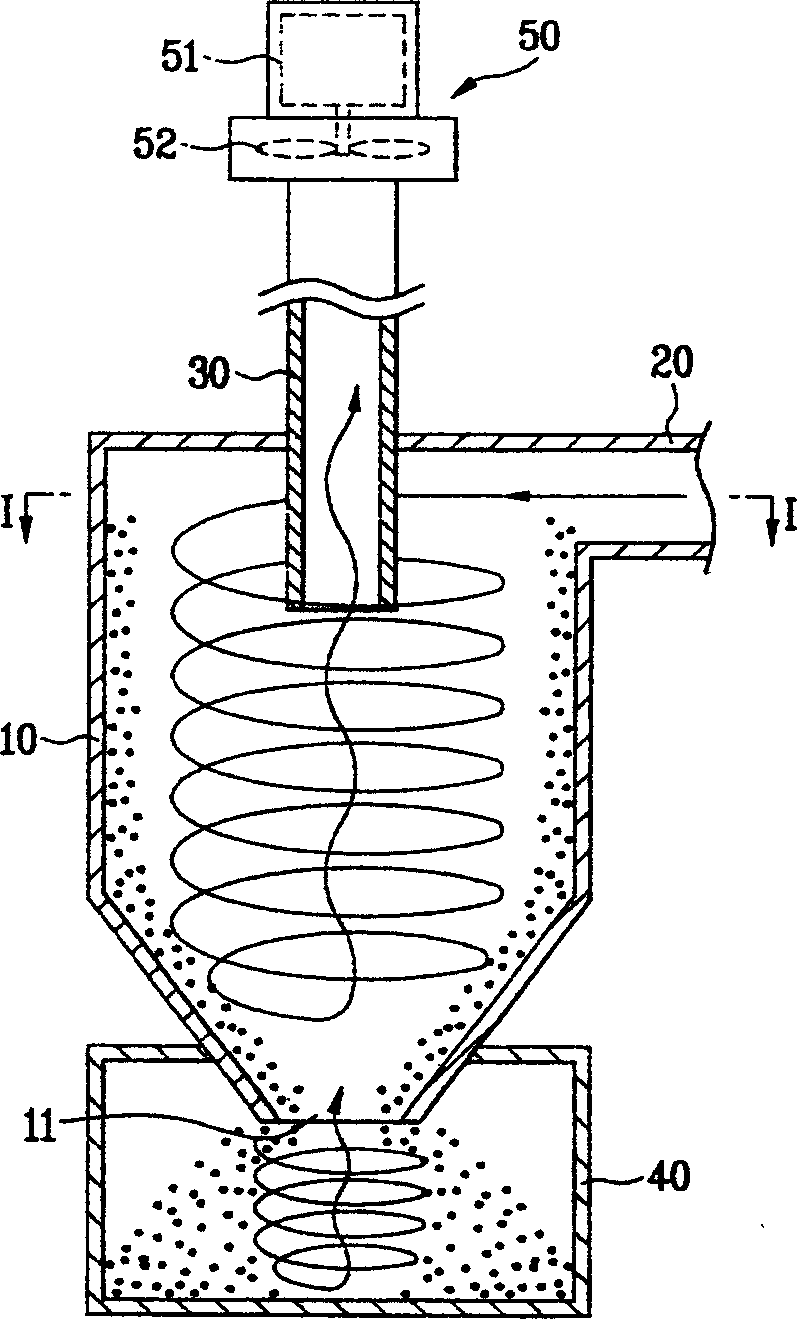

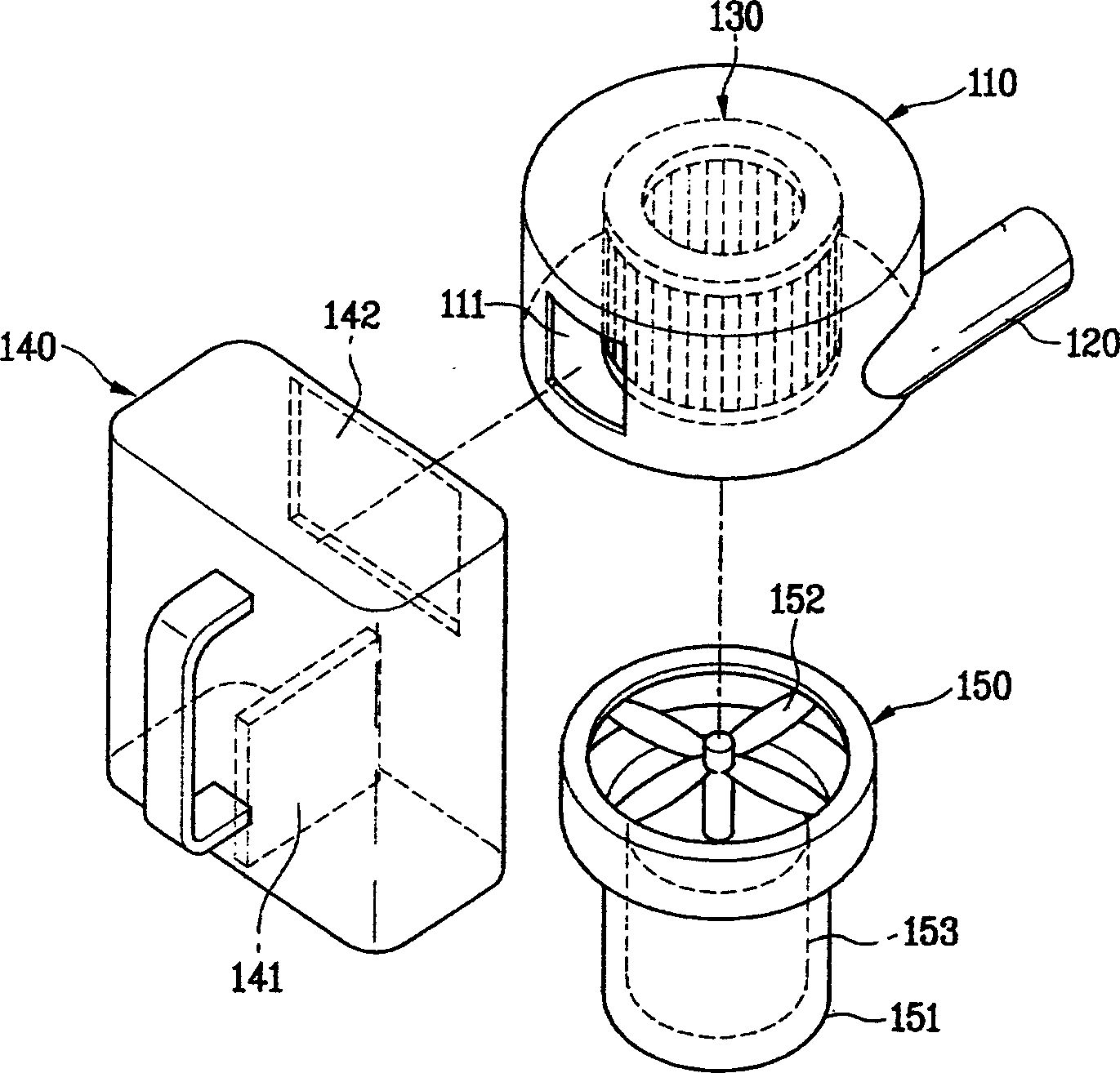

[0033] The cyclone dust collector of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments:

[0034] Such as image 3 , 4 , 5, the cyclone dust collector designed by the present invention includes a cyclone body 110, a dirt separator 110, a dust collector 140, and is directly connected to the cyclone body 110 and directly connected to the dirt separator 130 The suction generator 150 above constitutes.

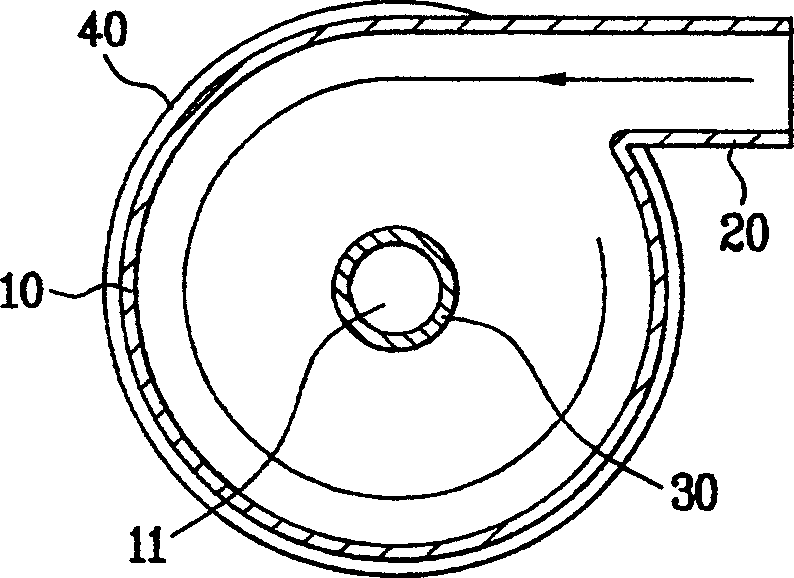

[0035] The cyclone body 110 constituting the cyclone dust collector adopts a cylindrical structure with a width (diameter) equal to or greater than the height, and is connected with a suction pipe 120 for sucking in outside air, and is also provided with a sewage hole 111 for discharging dirt.

[0036] The suction pipe 120 is connected to the cyclone body 110 in the tangential direction of the outer surface of the cyclone body 110, and the suction pipe 120 and the sewage hole 111 are arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com