Method for improving activity of distillate oil hydrogenation catalyst

A hydrogenation catalyst and a catalyst technology, which are applied in the field of regeneration and activation, can solve the problems that the regenerated catalyst does not have physical properties and acid sites, and the reaction activity does not achieve satisfactory results, and achieves good industrial application prospects, improved activity, The effect of pore size distribution concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

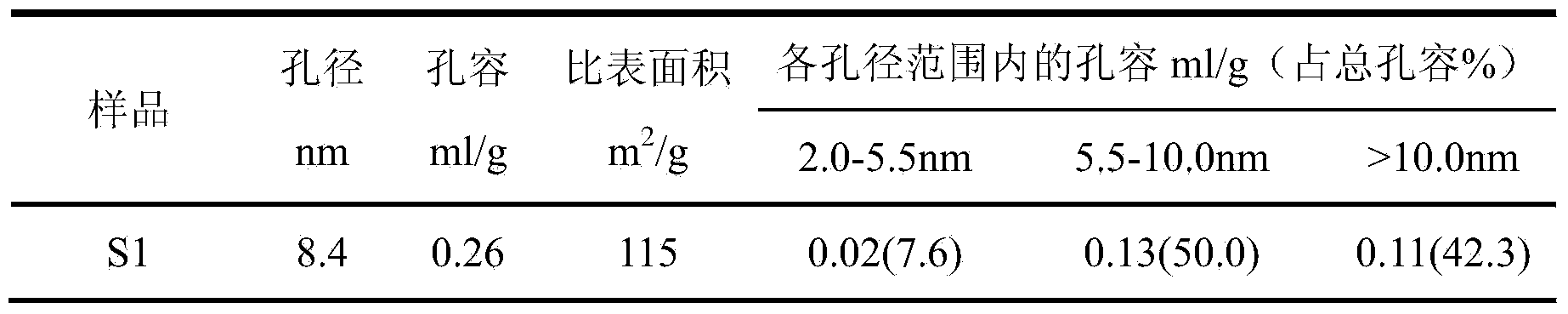

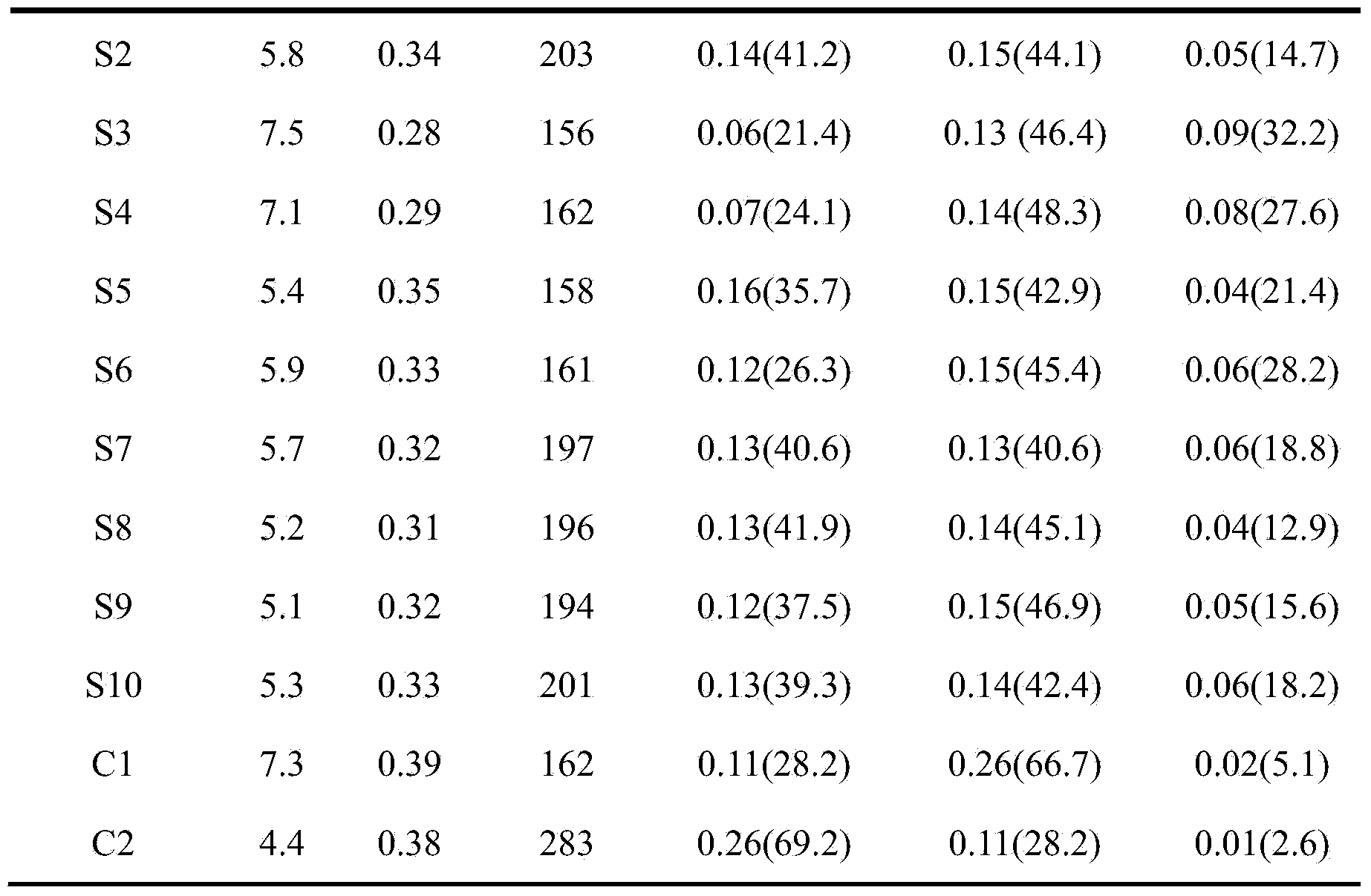

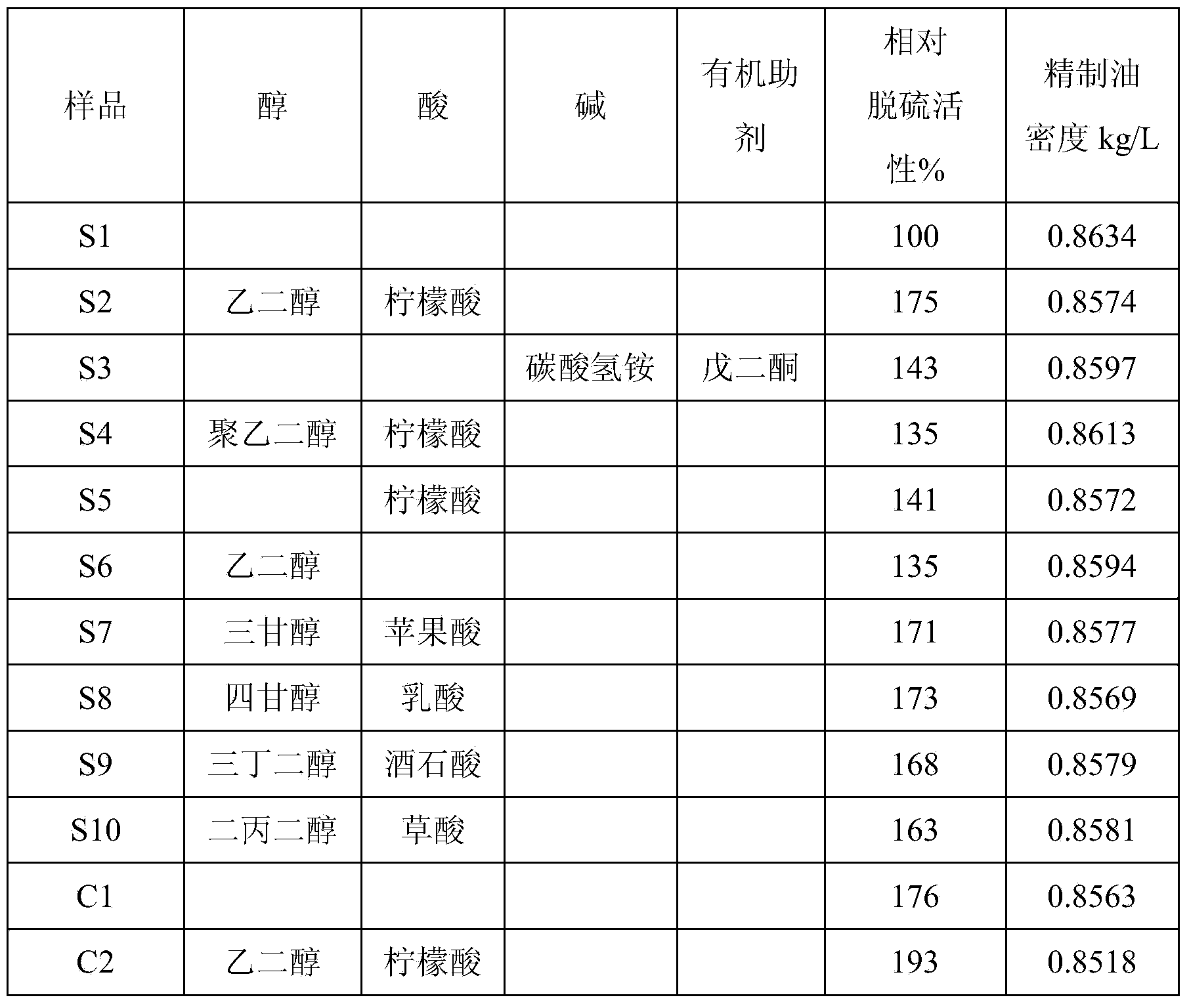

Embodiment 1

[0027] 1000ml of diesel hydrotreating catalyst with 5.0% carbon deposition was taken during the catalyst replacement process of a certain diesel hydrotreating unit. Under an oxygen atmosphere, the temperature was raised to 450° C. at a rate of 2° C. / min and kept for 4 hours for charcoal burning. The treated sample was named S1, the carbon content of the catalyst was 0.09%, the mass fraction of NiO was 4.0%, MoO 3 The mass fraction is 21.2%.

[0028] S1 is activated with citric acid and ethylene glycol. The specific method is to take a mixed solution of citric acid and ethylene glycol and carry out equal-volume vacuum impregnation of S1, wherein the molar ratio of citric acid, ethylene glycol and the active metal molybdenum in the catalyst is 0.3:0.2:1. After impregnation, the samples were placed in a high-temperature hydrothermal treatment device for hydrothermal treatment for 6 hours, and the temperature was controlled at 130 °C. After hydrothermal treatment, it was dried ...

Embodiment 2

[0030] S1 is activated with malic acid and triethylene glycol. The specific method is to take a mixed solution of malic acid and triethylene glycol to impregnate S1 with equal volume of vacuum, wherein the molar ratio of malic acid, triethylene glycol to the active metal molybdenum in the catalyst is It is 0.3:0.2:1. After impregnation, the samples were placed in a high-temperature hydrothermal treatment device for hydrothermal treatment for 8 hours, and the temperature was controlled at 150 °C. After hydrothermal treatment, it was dried at 120° C. for 4 hours to obtain catalyst S7. S1 is also activated by lactic acid and tetraethylene glycol, tartaric acid and tributylene glycol, oxalic acid and dipropylene glycol in the same treatment method to obtain examples S8, S9, and S10.

Embodiment 3

[0032] According to the method described in the patent CN03148494.8, distillate oil hydrotreating catalyst C1 was prepared. Wherein NiO content is 4.8%, MoO 3 The content is 21%, P 2 o 5 The content is 4.5%. Catalyst C2 was obtained by treating C1 with citric acid and ethylene glycol according to the method described in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com