Burning treatment process of waste gas and waste liquid containing chlorosilane in polysilicon production

A treatment process and polysilicon technology, applied in combustion methods, combustion types, incinerators, etc., can solve the problems of a large amount of waste water, inability to remove chloride ions, and high operating costs, and achieve the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

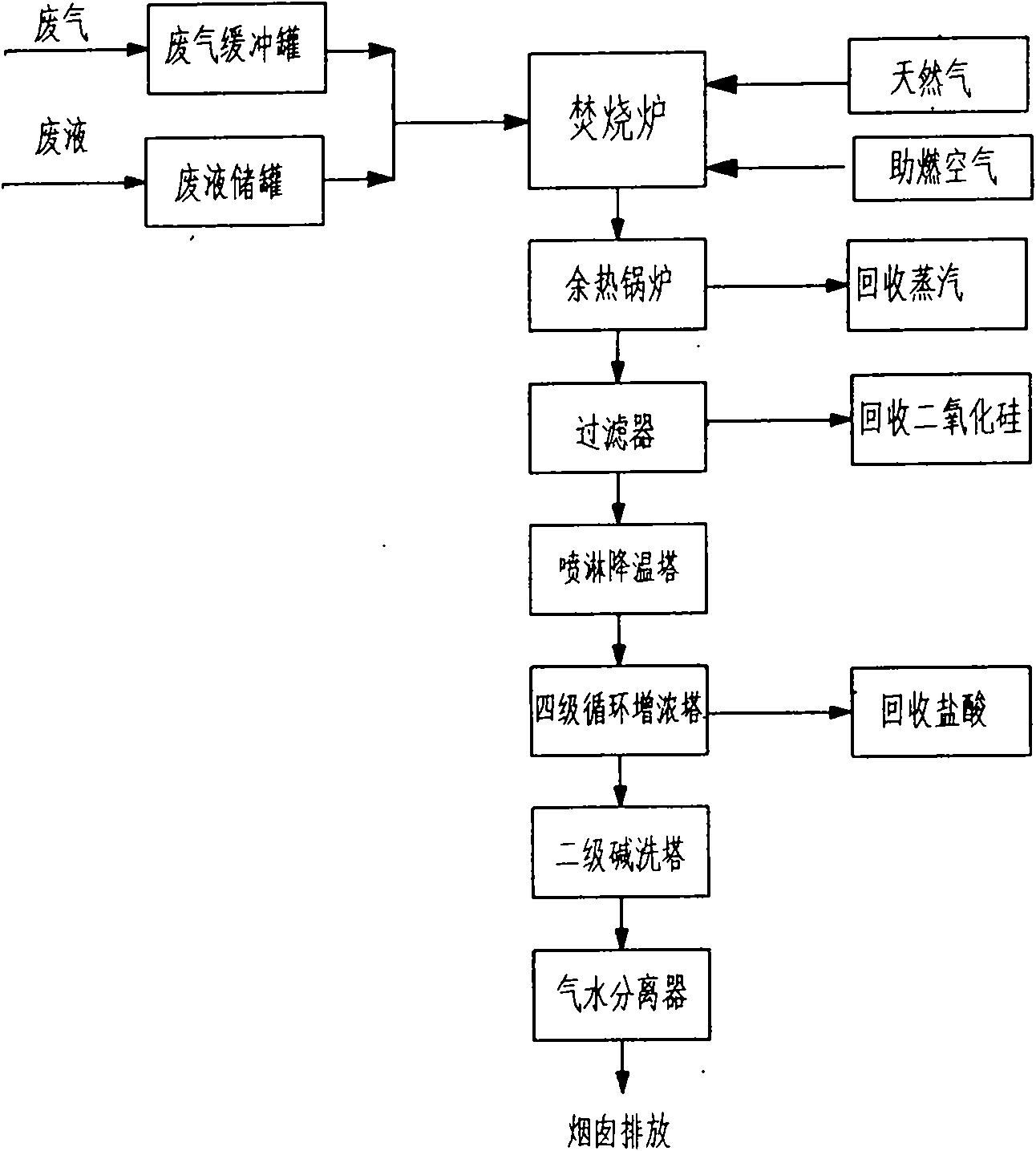

[0014] The waste gas containing chlorosilane in production first enters the waste gas buffer tank, and then enters the combustion furnace through the pressure regulating valve for combustion treatment; the waste liquid containing chlorosilane in production first enters the waste liquid temporary storage tank, using natural gas as fuel and combustion air respectively Provide oxygen-enrichment. At a high temperature of 950°C, the combustion-supporting air provides excess oxygen to fully hydrolyze chlorine-containing silanes during the combustion process, and then recover steam in the waste heat boiler; recover silicon dioxide SiO2 in the filter; in the fourth cycle Hydrochloric acid HCl and a small amount of Cl2 are recovered in the enrichment tower; the rest is discharged after passing through the secondary alkali washing tower and the gas-water separator.

[0015] The combustion treatment process of waste gas and waste liquid containing chlorosilane in the production of polysil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com