Intelligent sorting system for inner rings of knuckle bearings

A technology for spherical plain bearings and inner rings, which is applied in the field of intelligent sorting system for the inner rings of spherical plain bearings, can solve the problems of low precision and low efficiency, and achieve the effects of improving production efficiency, improving cleaning efficiency, and compact equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

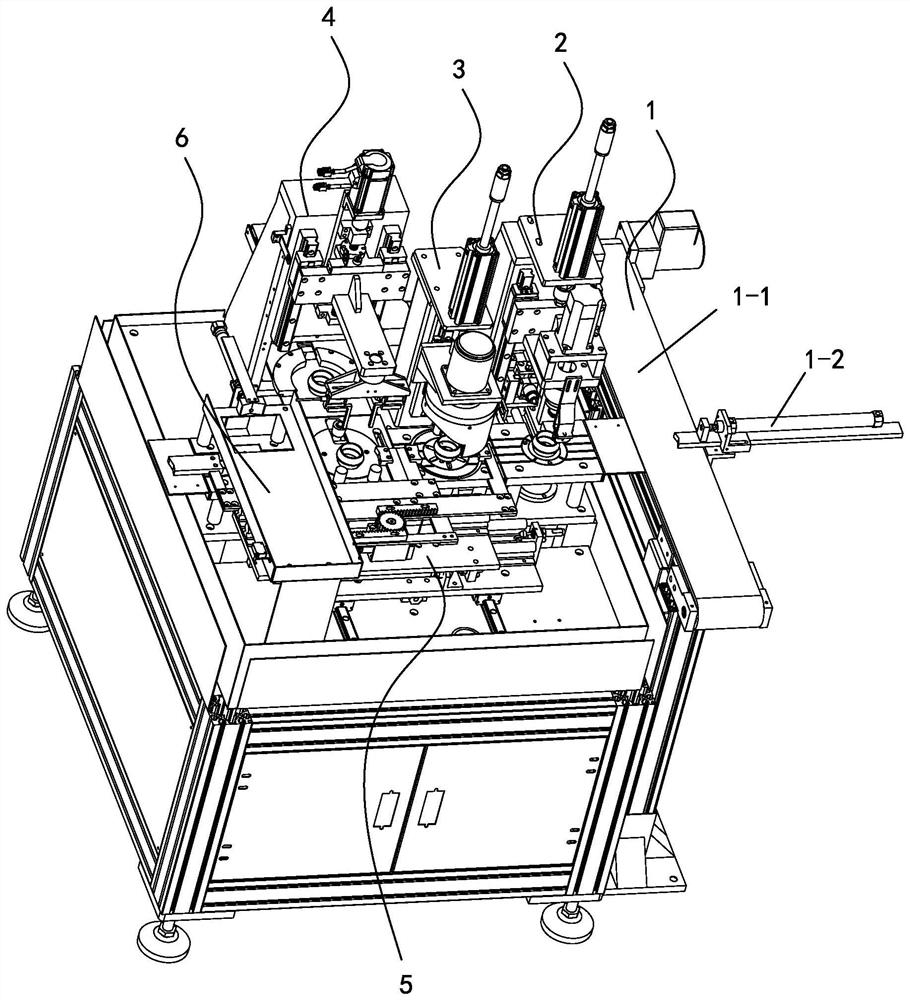

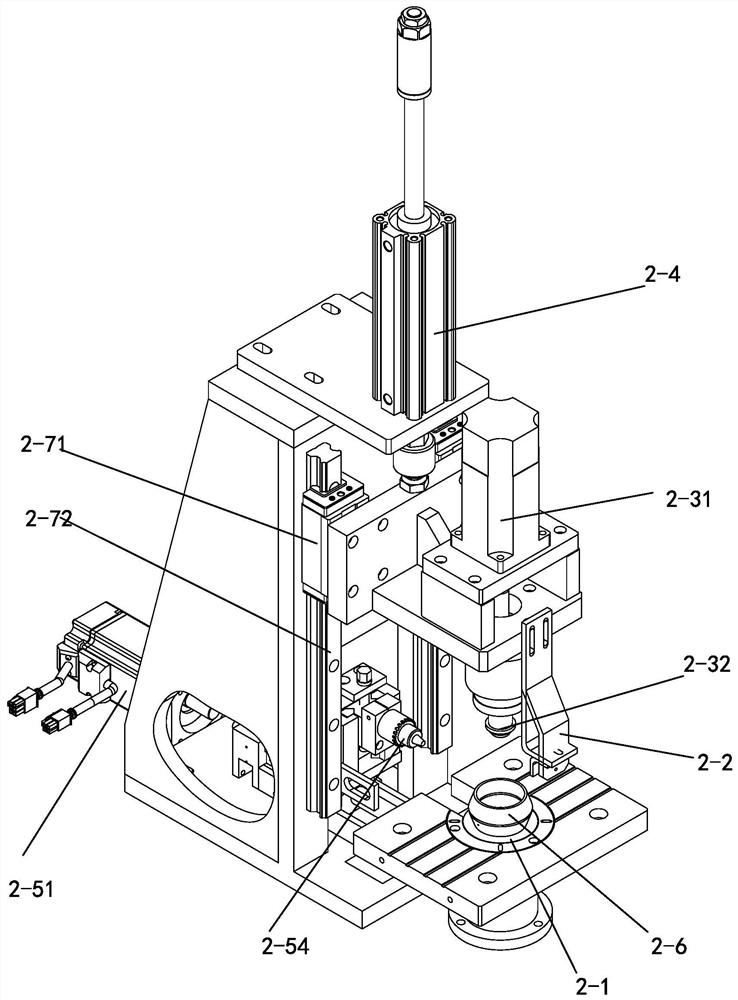

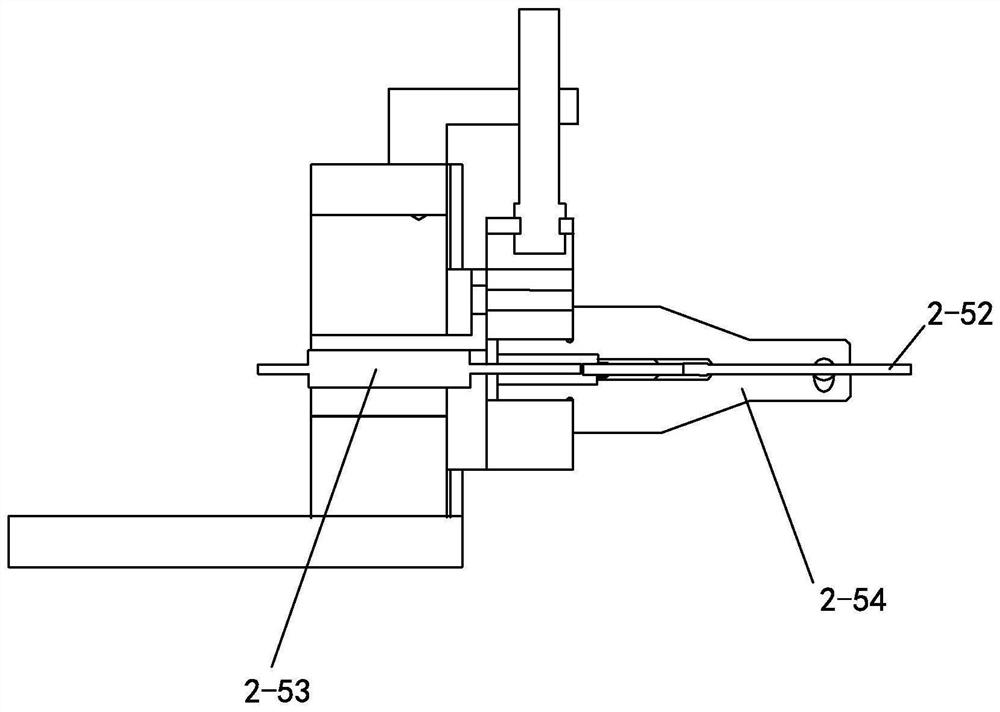

[0041] Examples, see figure 1As shown, an intelligent sorting system for the inner ring of the joint bearing of the present invention includes a material pushing mechanism 1, an oil hole deburring station 2, a cleaning and drying station 3, an inner diameter detection station 4, a manipulator 5 and a sorting station 6. The pushing mechanism 1 pushes the inner ring of the joint bearing to be processed to the oil hole deburring station 2 for oil hole deburring, and then is pinched by the manipulator 5 to the cleaning and drying station 3 for cleaning and drying, and then through The manipulator 5 is pinched to the inner diameter detection station 4 for inner diameter detection, and finally sent to the sorting station 6 by the manipulator 5 for sorting. The structure and working principle of each station will be described in detail below.

[0042] The push mechanism 1 includes a conveyor belt 1-1 and a first push rod 1-2. After the parts enter the conveyor belt 1-1, they are tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com