A preparation method of copper foil and a modification additive for the production of the copper foil

An additive, copper foil technology, applied in electrolytic components, electrolytic process, electroforming and other directions, can solve the problem of organic impurities cannot be removed, achieve convenient and fast installation and replacement, improve purity, and achieve the effect of flattening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The concrete preparation process of modified additive is as follows:

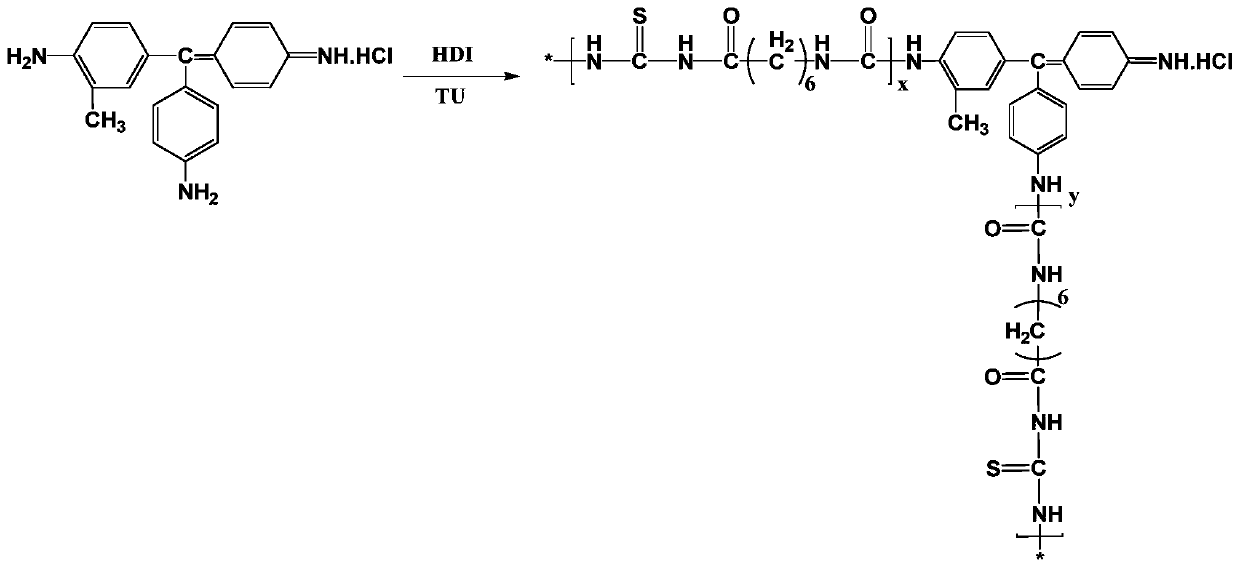

[0054] Step 1: Add 1kg of fuchsin into 5.5L ethanol solution, stir to dissolve, heat up to 70°C and reflux, add 0.65kg of thiourea to it, stir to dissolve, then add 1.13kg of 1,6-diisocyanate to the reaction vessel Acyl hexane, constant temperature reaction 2h, then filter and wash to obtain mercapto fuchsin (BF-SH);

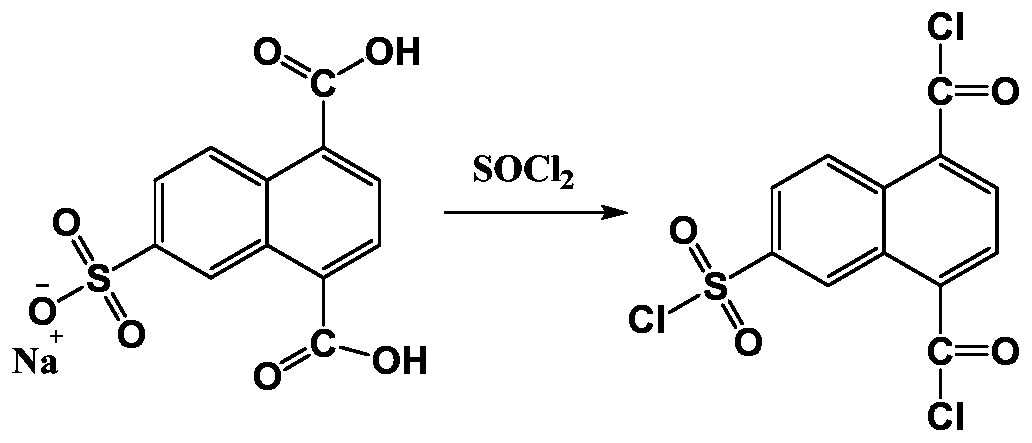

[0055] Step 2: Add 1kg of 5,8-dicarboxynaphthalene-2-sulfonate sodium and 8L of water into the reaction vessel, raise the temperature to 80°C, add 1.34kg of thionyl chloride to it, react at constant temperature for 5 hours, and then proceed at 90°C Evaporated and crystallized to obtain 5,8-diacylchloronaphthalene-2-sulfonyl chloride;

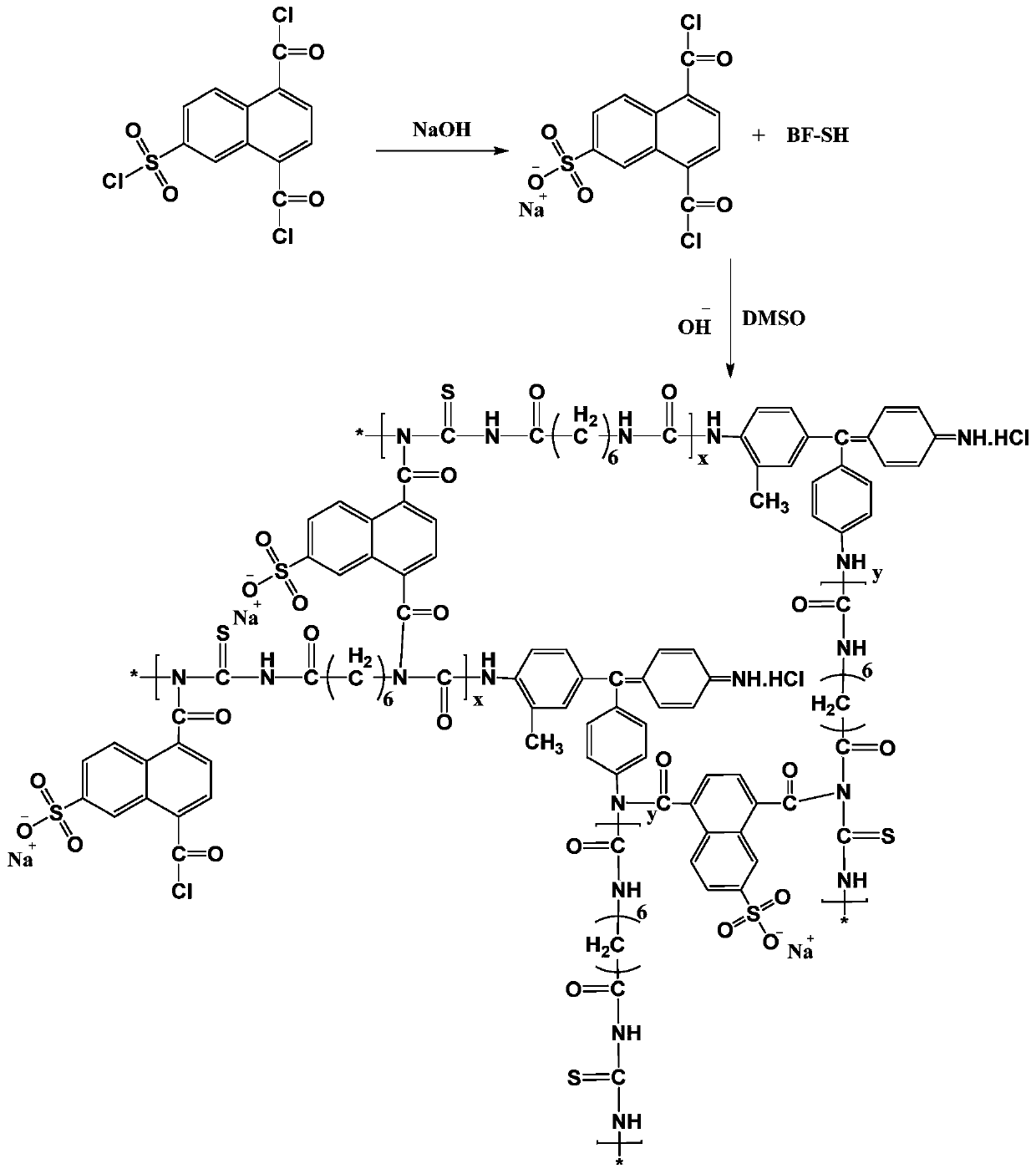

[0056] Step 3: Add 1kg of the mercapto fuchsin prepared in Step 1 into the reaction vessel, and at the same time add 7L of dimethyl sulfoxide to it. After mixing evenly, add 0.077kg of sodium hydroxide into the reaction vessel, and then raise the temper...

Embodiment 2

[0058] The concrete preparation process of modified additive is as follows:

[0059] Step 1: Add 1kg of fuchsin into 5.5L ethanol solution, stir to dissolve, heat up to 70°C and reflux, add 0.68kg of thiourea to it, stir to dissolve, then add 1.15kg of 1,6-diisocyanate to the reaction vessel Acyl hexane, react at constant temperature for 2 hours, then filter and wash to obtain thiolated fuchsin (BF-SH); add 5.5L of ethanol to each kilogram of fuchsin, add 0.65-0.68kg of thiourea, and add 1,6-diisocyanate Acyl hexane 1.13-1.15kg;

[0060] Step 2: Add 1kg of 5,8-dicarboxynaphthalene-2-sulfonate sodium and 8L of water into the reaction vessel, raise the temperature to 80°C and add 1.35kg of thionyl chloride to it, react at constant temperature for 5 hours, and then proceed at 90°C Evaporated and crystallized to obtain 5,8-diacylchloronaphthalene-2-sulfonyl chloride;

[0061]Step 3: Add 1kg of the mercapto fuchsin prepared in Step 1 into the reaction vessel, and at the same time...

Embodiment 3

[0063] A preparation method of copper foil, the specific preparation process is as follows:

[0064] Step 1: Clean the broken copper pieces and add them to the dissolving tank. At the same time, add deionized water to the dissolving tank, then add concentrated sulfuric acid, and blow air into the dissolving tank, and heat to slowly oxidize the copper in the dissolving tank into Copper oxide, the generated copper oxide reacts with sulfuric acid to form a copper sulfate aqueous solution, real-time detection of the concentration of copper ions in the dissolution tank, and the concentration of copper ions is controlled to 120-150g / L;

[0065] In the second step, the copper sulfate aqueous solution prepared in the dissolution tank is added to the storage tank, and multi-stage adsorption filtration is carried out through a multi-layer plate filter, and the organic impurities are removed through the filtration and adsorption components in the multi-layer plate filter. The multi-stage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com