Preparation method of banana nanofiber

A nanofiber, banana technology, applied in the field of fiber processing, can solve the problems of affecting fiber purity, poor quality of banana fiber, short nanofiber length, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

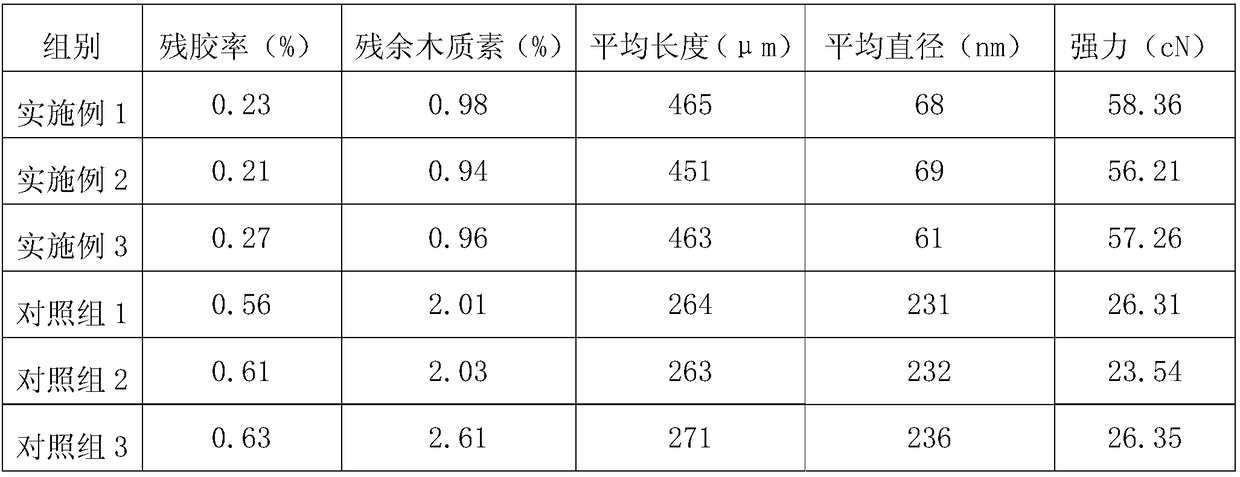

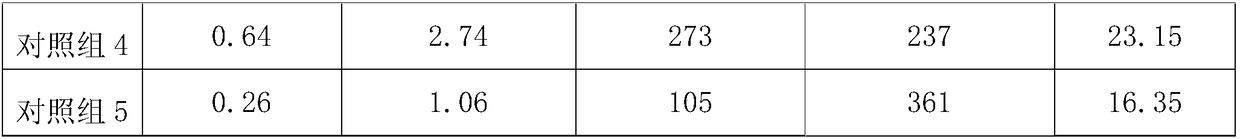

Embodiment 1

[0031] The present embodiment provides a kind of banana nanofiber preparation method, and this method comprises the steps:

[0032] (1) Raw material pretreatment: take the banana peel, leaves or stems and cut them into sections, and then tear the pieces into flakes with a thickness of 0.5 mm, press, scrape, and dry to obtain hemp;

[0033] (2) Degumming treatment: the hemp in step (1) is sequentially subjected to expansion treatment, oxidation treatment, acid treatment, biological enzyme treatment, enzyme inactivation treatment, dehydration, oil supply, and drying to obtain crude fiber;

[0034]The processing method of the puffing treatment is: mix the hemp with the sodium hydroxide solution whose mass concentration is 2g / L and mix according to the solid-to-liquid mass ratio of 1:17, then rapidly heat to 95°C, and boil at constant temperature for 20min, Drain the sodium hydroxide solution, remove the hemp, put it in hot water with a pressure of 7MPa and a temperature of 90°C a...

Embodiment 2

[0052] The present embodiment provides a kind of banana nanofiber preparation method, and this method comprises the steps:

[0053] (1) Raw material pretreatment: take banana skin, leaves or stems and cut them into sections, and then tear the pieces into flakes with a thickness of 2mm, press, scrape, and dry to obtain hemp;

[0054] (2) Degumming treatment: the hemp in step (1) is sequentially subjected to expansion treatment, oxidation treatment, acid treatment, biological enzyme treatment, enzyme inactivation treatment, dehydration, oil supply, and drying to obtain crude fiber;

[0055] The processing method of the puffing treatment is: mix the hemp with the sodium hydroxide solution whose mass concentration is 4g / L and mix according to the solid-to-liquid mass ratio of 1:22, then rapidly heat to 100°C, and boil at constant temperature for 30min, Drain the sodium hydroxide solution, remove the hemp, put it in hot water with a pressure of 8MPa and a temperature of 95°C and ke...

Embodiment 3

[0072] The present embodiment provides a kind of banana nanofiber preparation method, and this method comprises the steps:

[0073] (1) Raw material pretreatment: take the banana peel, leaves or stems and cut them into sections, and then tear the pieces into flakes with a thickness of 1mm, press, scrape, and dry to obtain hemp;

[0074] (2) Degumming treatment: the hemp in step (1) is sequentially subjected to expansion treatment, oxidation treatment, acid treatment, biological enzyme treatment, enzyme inactivation treatment, dehydration, oil supply, and drying to obtain crude fiber;

[0075] The processing method of the puffing treatment is as follows: mixing hemp with a sodium hydroxide solution with a mass concentration of 3g / L according to a solid-to-liquid mass ratio of 1:20, then rapidly heating to 98°C, and boiling at a constant temperature for 25 minutes, Drain the sodium hydroxide solution, remove the hemp, put it in hot water with a pressure of 7.5MPa and a temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com