Device used for rapid preparation of hydrogen oxygen mixed gas

A technology of mixed gas and hydrogen-oxygen, applied in electrodes, cells, electrolysis process, etc., can solve the problem that the amount of water electrolyzed is not enough, and achieve the effect of increasing the amount of gas produced by electrolysis, preventing the corrosion of electrolyte, and improving the efficiency of electrolysis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

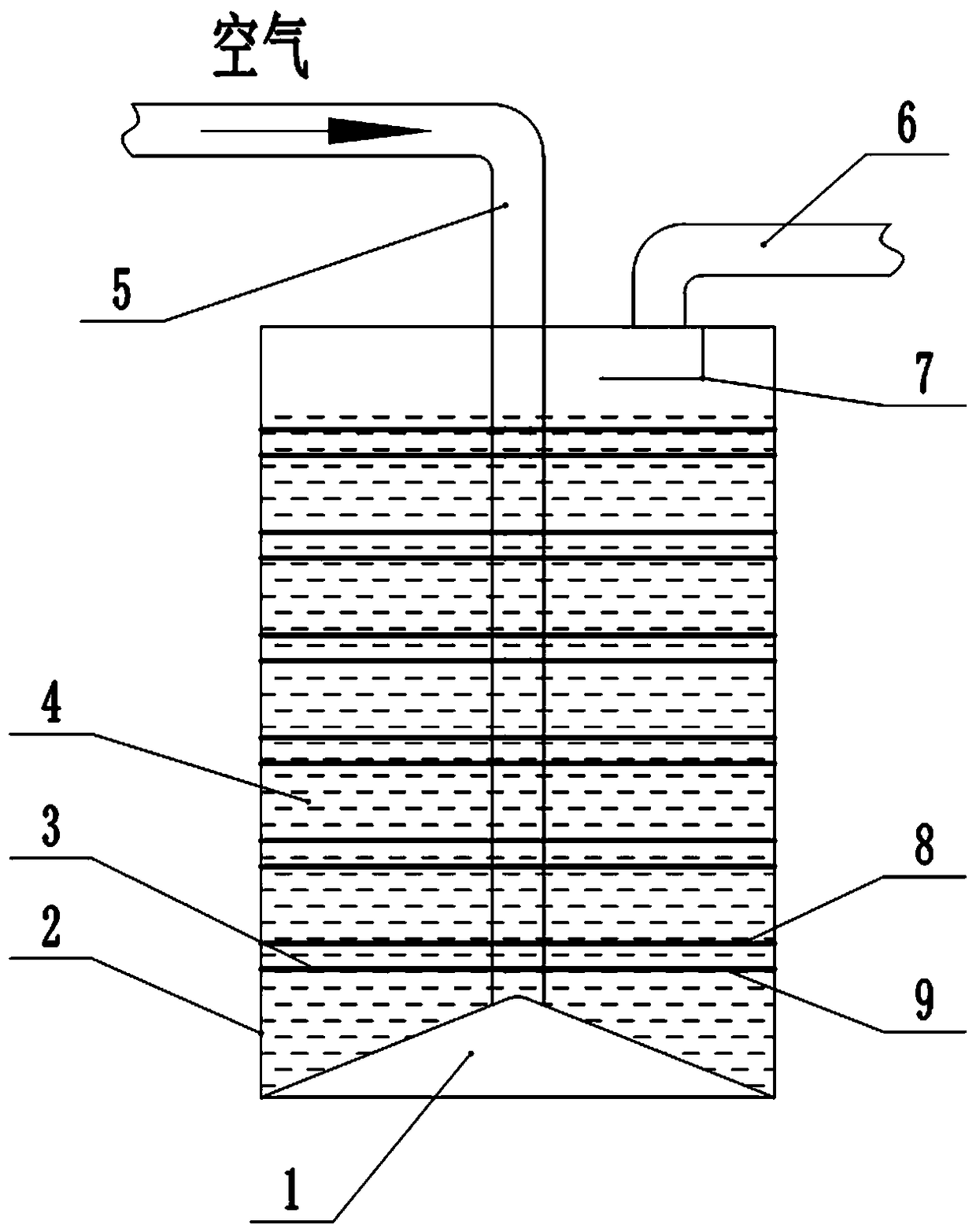

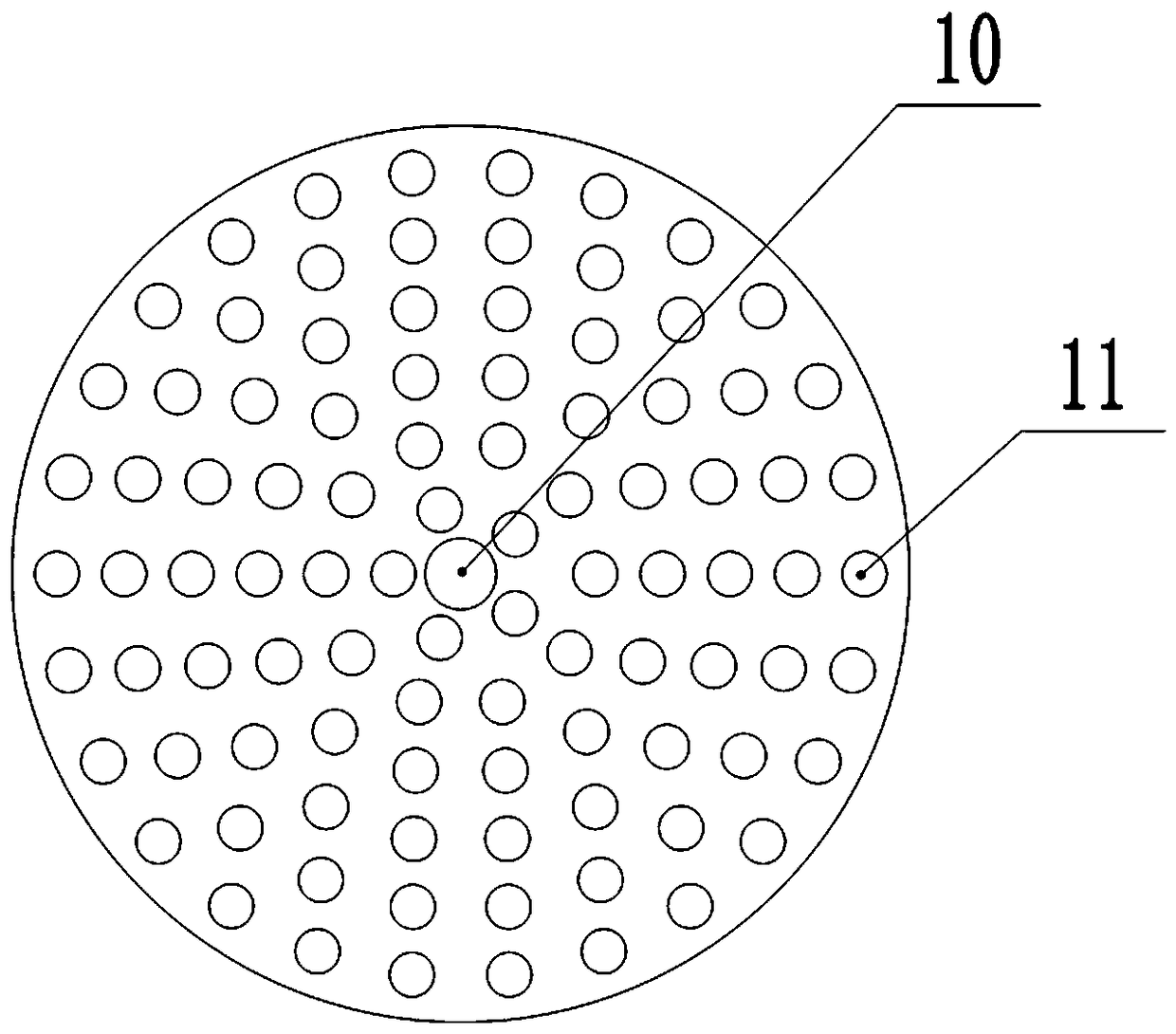

[0041] See Figure 1 to 3 As shown, a device for quickly preparing a mixture of hydrogen and oxygen includes a foamer 1, an electrolytic cell 2, an electrode group 3, an air inlet pipe 5, and an air outlet pipe 6. The top of the electrolytic cell 2 is provided with an air outlet pipe 6, and the bottom The foamer 1 and the electrode assembly 4 are installed in sequence from bottom to top. The top of the foamer 1 is connected to the air inlet pipe 5, and compressed air is introduced into the air inlet pipe 5. The compressed air itself has a certain pressure, which makes The compressed air flows faster. When the compressed air enters the foamer 1, a large number of bubbles are generated by the foamer 1, which continuously moves upward from the bottom of the electrolytic cell 2, and impacts the hydrogen and oxygen generated on the electrode assembly 3, making Hydrogen and oxygen quickly leave the electrode group 3 and move upward; and the electrode group 3 includes A electrode 8 and...

Embodiment 2

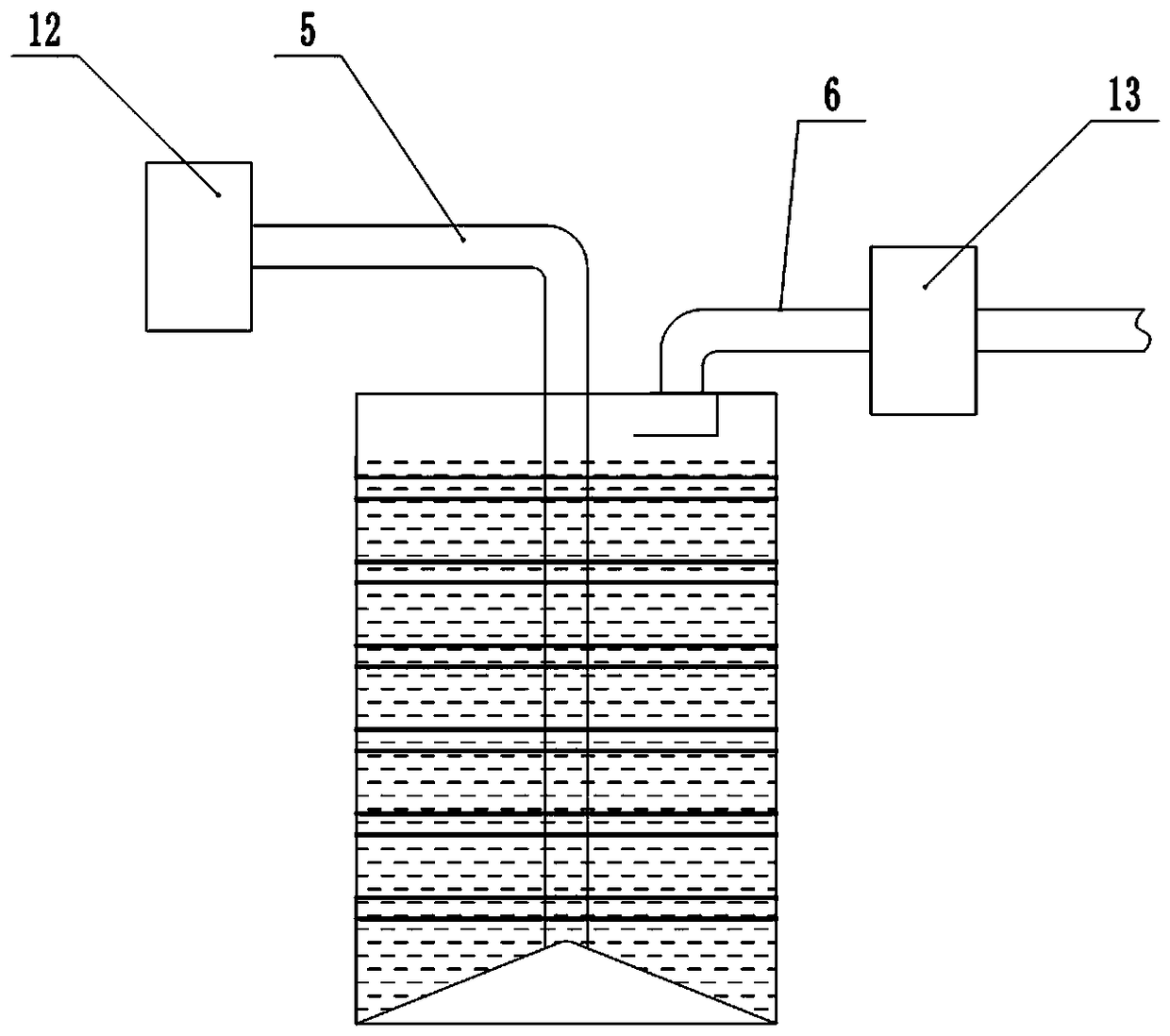

[0050] See Figure 2 to 5 As shown, a device for rapidly preparing a mixture of hydrogen and oxygen includes a foamer 1, an electrolytic cell 2, an electrode group 3, an air inlet pipe 5 and an air outlet pipe 6. The top of the electrolytic tank 2 is provided with an air outlet pipe 6 and the bottom The foamer 1 and the electrode assembly 4 are installed in sequence from bottom to top. The top of the foamer 1 is connected to an air inlet pipe 5, and air is blown into the air inlet pipe 5 through a fan 12, which effectively improves the air flow Speed, when compressed air enters the foamer 1, a large number of bubbles are generated by the foamer 1, and they move upward from the bottom of the electrolytic cell 2, impacting the hydrogen and oxygen generated on the electrode group 3, making the hydrogen and oxygen fast Separate from the electrode group 3 and move upward; and the electrode group 3 includes the A electrode 8 and the B electrode 9. Both the A electrode 8 and the B ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com