Biomass granular fuel produced by utilizing tobacco waste materials and preparation method thereof

A biomass pellet and waste technology, applied in the field of biomass pellet fuel and its preparation, can solve environmental problems, troubled tobacco leaf waste disposal, cost and other issues, and achieve the effects of convenient transportation and storage, adjustable shape, and long burning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

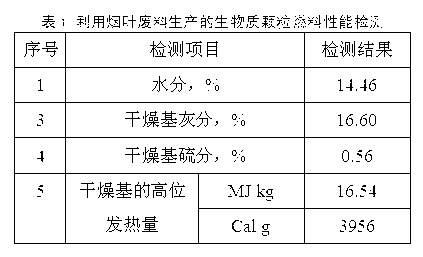

Image

Examples

Embodiment 1

[0032] A kind of biomass particle fuel that utilizes tobacco leaf waste production, the raw material of described biomass particle fuel comprises tobacco leaf waste material and water, and the weight and number ratio of described tobacco leaf waste material and water is:

[0033] Tobacco waste 100

[0034] Water 3~12.0

[0035] The particle size of the tobacco leaf waste described in this embodiment is 1-55mm.

[0036] The preparation method of the biomass pellet fuel produced by utilizing tobacco leaf waste is as follows:

[0037] (1) Crushing raw materials: pulverizing the waste tobacco leaves with a pulverizer to obtain pulverized tobacco leaf waste with a particle size of 20 mm or less;

[0038] (2) Mixing of raw materials: adding the appropriate amount of water to the crushed tobacco leaf waste with a particle size below 20 mm, and stirring evenly in a mixer to obtain a mixture;

[0039] (3) Fermentation of raw materials: the mixture is placed in the coalification area...

Embodiment 2

[0048] The present embodiment is a preferred scheme based on embodiment 1, the quality of the raw material used is the same as that of embodiment 1, and the weight and number ratio of the raw material that described biomass particle fuel comprises is:

[0049] Tobacco waste 100

[0050] Potassium permanganate 6.0

[0051] The unit of weight used in this embodiment is kilogram, and may also be ton.

[0052] The preparation method of the biomass pellet fuel produced by utilizing tobacco leaf waste is as follows:

[0053] (1) Crushing raw materials: pulverizing the waste tobacco leaves with a pulverizer to obtain pulverized tobacco leaf waste with a particle size of 20 mm or less;

[0054] (2) Mixing of raw materials: adding an appropriate amount of water to the crushed tobacco leaf waste with a particle size below 20mm;

[0055] (3) Fermentation of raw materials: the mixture is placed in the coalification area for fermentation, and the stacking fermentation method is adopted....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com