Sludge burning treatment method and system

A sludge incineration and treatment method technology, applied in the direction of combustion method, oxidation treatment sludge, incinerator, etc., can solve the problems of huge investment in treatment equipment, large sludge output, high operating costs, etc., and achieve combustion stability Good, reduced NOx and CO formation, rapid combustion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

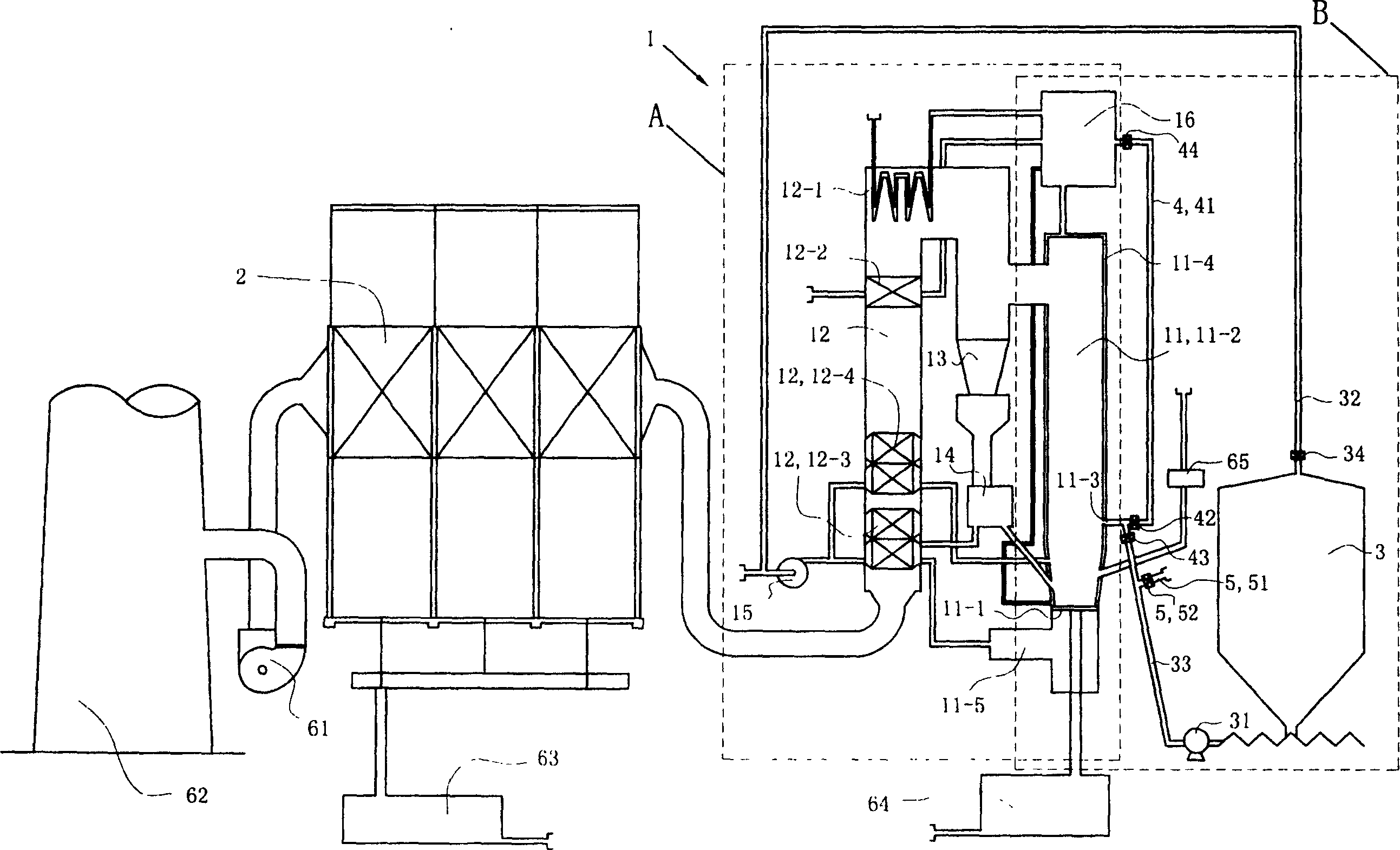

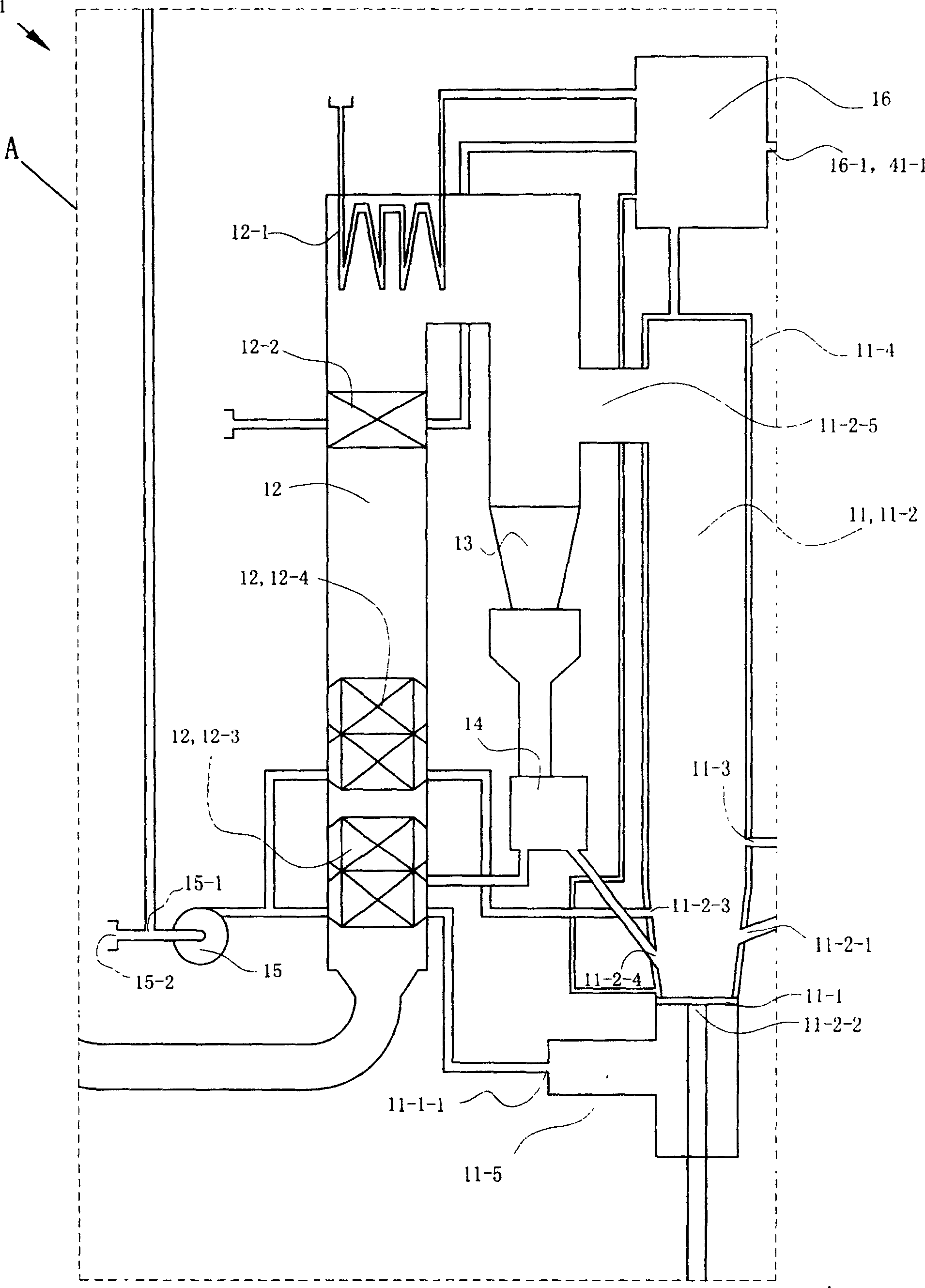

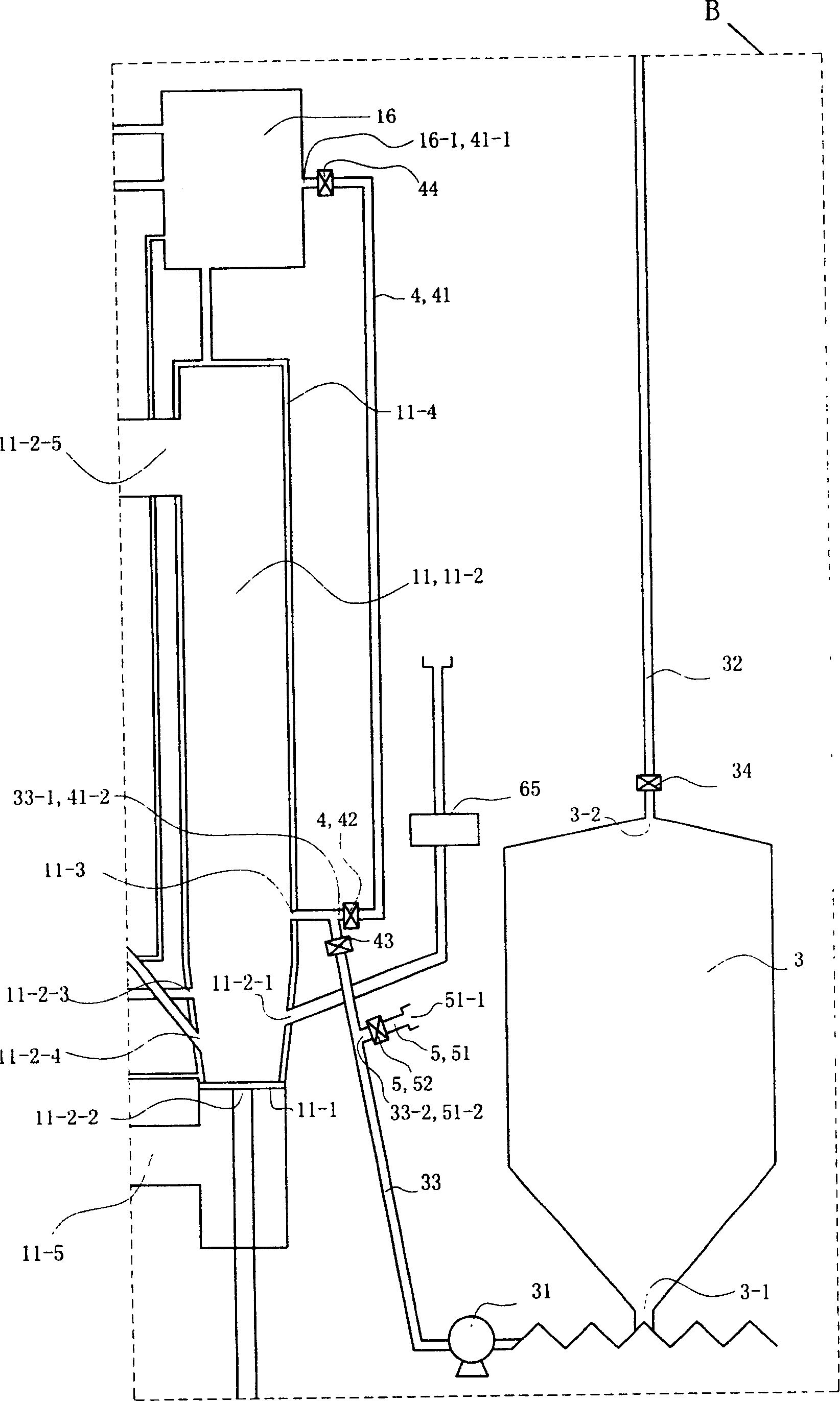

[0028] (Example 1, sludge incineration treatment system)

[0029] See Figure 1 to Figure 3 , the sludge incineration treatment system in this embodiment has a circulating fluidized bed boiler 1, a dust collector (the dust collector 2 is an electrostatic precipitator, and its model is FAA3×35M-44-55A2, purchased from Shanghai Metallurgical Mining Machinery Factory ) 2 and sludge storage room 3; circulating fluidized bed boiler 1 includes boiler main body 11, tail shaft flue 12, separator (the separator is a cyclone separator) 13, feeder 14, primary fan 15 and steam Package 16; the primary air blower 15 is provided with a first air inlet 15-1 for inputting the polluted gas produced in the storage process of the dewatered sludge and a second air inlet 15-2 for inputting air, and the tail shaft flue 12 is provided with The superheater 12-1, the economizer 12-2, the second air preheater 12-4 and the first air preheater 12-3 are arranged in sequence from top to bottom; the boiler ...

Embodiment 2

[0034] (Embodiment 2, sludge incineration treatment method)

[0035] See Figure 1 to Figure 3 , The sludge incineration treatment system used in this example is the sludge incineration treatment system in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com