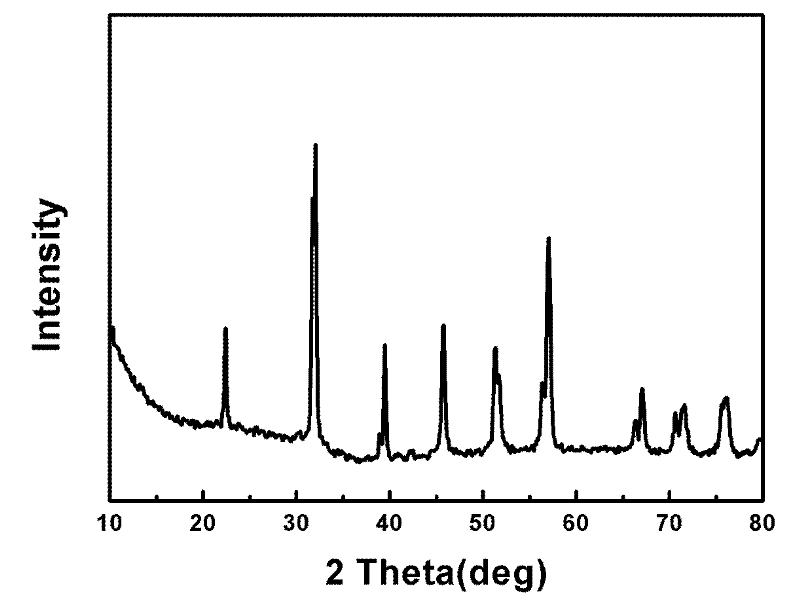

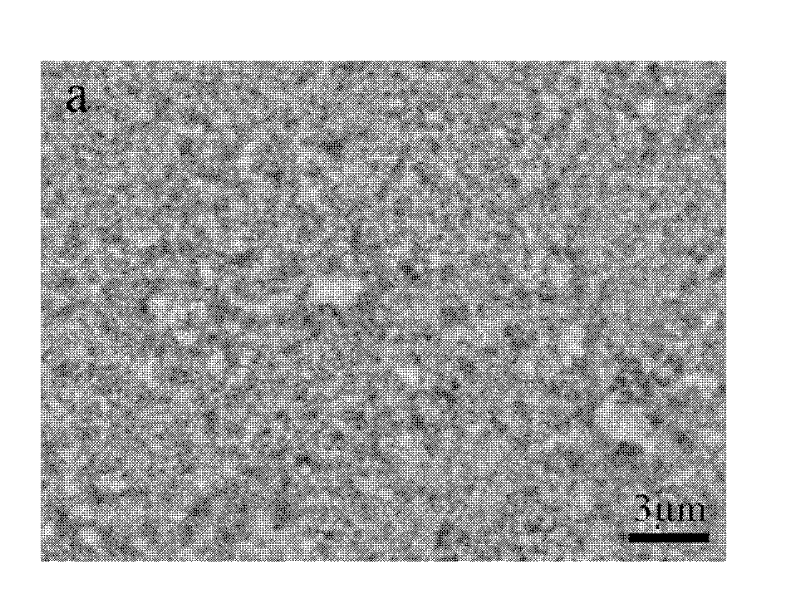

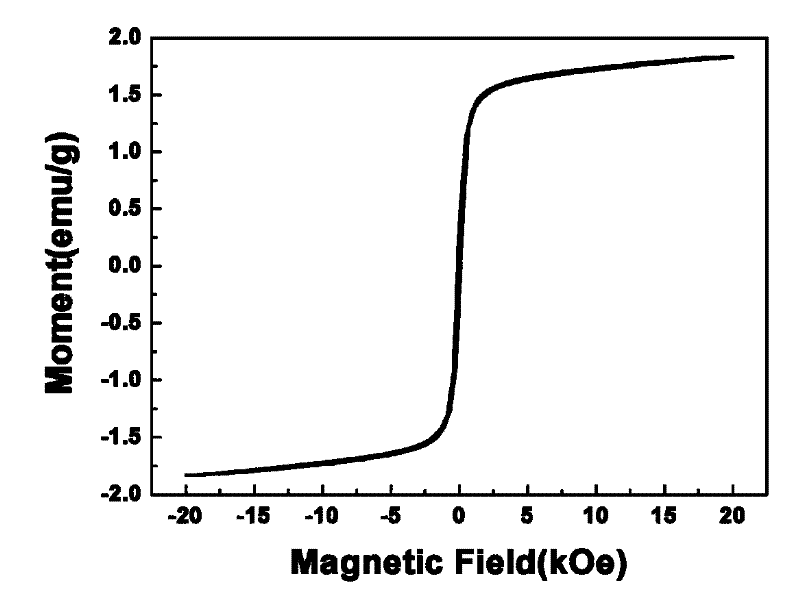

Method for preparing multiferroic single-phase bismuth ferric ceramic

A bismuth ferrite and multiferroic technology, applied in the field of material science, can solve the problems of large spiral period length, etc., and achieve the effects of saving electric energy, good insulation performance, and simple equipment and preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Weigh BiCl with a molar ratio of 1.1:1 3 (20.8g) and FeCl 3 ·6H 2 O (16.2g), heated and stirred at 80°C, fully dissolved in 200ml of ethylene glycol, the sol concentration was about 0.3mol / L, forming a reddish-brown uniform sol.

[0027] 2. Place the sol obtained in step 1 in an oven and dry it at 120° C. to form a light yellow xerogel.

[0028] 3. Put the xerogel obtained in step 2 into a mortar for grinding, pass it through a 200-mesh sieve to obtain a loose xerogel powder, and transfer it to an alumina crucible.

[0029] 4. Put this alumina crucible into the furnace for the first pre-firing. After rising from room temperature to 400 °C at a heating rate of 3 °C / min, cool down to room temperature with the furnace without heat preservation.

[0030] 5. Repeat step 4 for the second pre-calcination to obtain reddish-brown precursor powder.

[0031] 6. Grind the precursor powder obtained in step 5 again, granulate with deionized water, and press into a mold to for...

Embodiment 2

[0034] 1. Weigh Bi(NO 3 ) 3 ·5H 2 O(40.50g) and Fe(NO 3 ) 3 9H 2 O (33.67g), heated and stirred at 80°C, fully dissolved in 200ml of ethylene glycol, the sol concentration is about 0.4mol / L, forming a reddish-brown uniform sol.

[0035] 2. Place the sol obtained in step 1 in an oven and dry it at 80° C. to form a light yellow xerogel.

[0036] 3. Put the xerogel obtained in step 2 into a mortar for grinding to obtain a loose xerogel powder, and transfer it to an alumina crucible.

[0037] 4. Put this alumina crucible into the furnace for the first pre-firing. After rising from room temperature to 400 °C at a heating rate of 5 °C / min, it is cooled to room temperature with the furnace without heat preservation.

[0038] 5. Repeat step 4 for the second pre-calcination to obtain reddish-brown precursor powder.

[0039]6. Grind the precursor powder obtained in step 5 again, granulate with deionized water, and press into a mold to form a tablet. The forming pressure is 2 MP...

Embodiment 3

[0042] 1. Weigh Bi(NO 3 ) 3 ·5H 2 O(53.35g) and Fe(NO 3 ) 3 9H 2 O (33.67g), heated and stirred at 80°C, fully dissolved in 200ml of ethylene glycol, the sol concentration is about 0.4mol / L, forming a reddish-brown uniform sol.

[0043] 2. Place the sol obtained in step 1 in an oven and dry it at 100° C. to form a light yellow xerogel.

[0044] 3. Put the xerogel obtained in step 2 into a mortar for grinding, pass it through a 200-mesh sieve to obtain a loose xerogel powder, and transfer it to an alumina crucible.

[0045] 4. Put this alumina crucible into the furnace for the first pre-firing. After rising from room temperature to 400 °C at a rate of 1 °C / min, cool down to room temperature with the furnace without heat preservation.

[0046] 5. Repeat step 4 for the second pre-calcination to obtain reddish-brown precursor powder.

[0047] 6. Grind the precursor powder obtained in step 5 again, granulate with deionized water, and press into a mold to form a tablet. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com