Carbonization apparatus for producing activated carbon

A carbonization device, activated carbon technology, applied in carbon compounds, coke ovens with mechanical devices, inorganic chemistry, etc., can solve the problem of not much heat recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

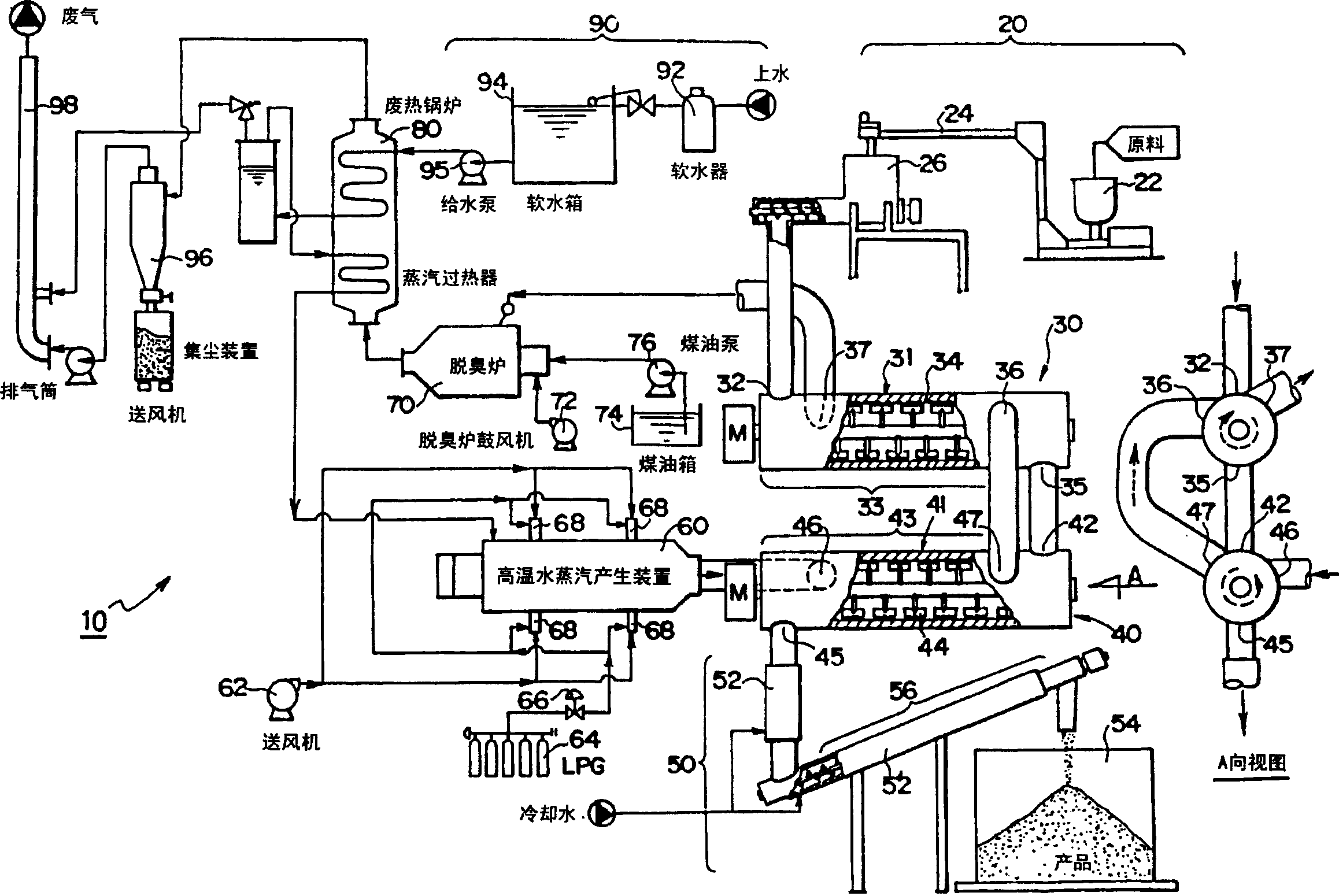

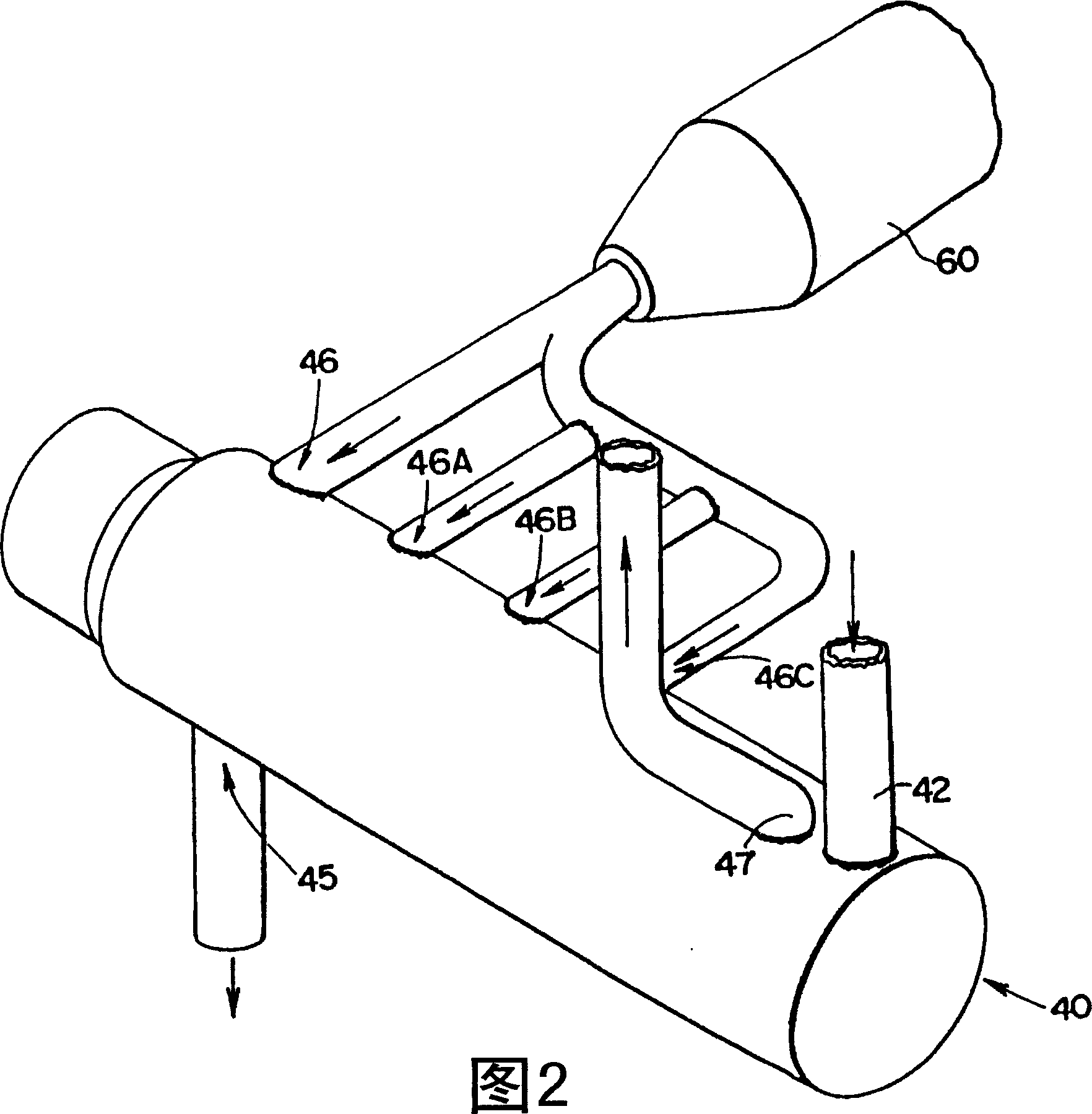

[0077] figure 1 It is the whole structure diagram of the carbonization apparatus for activated carbon manufacture of this invention. As shown in the figure, in the carbonization device 10 for activated carbon production, there is provided: a processing object supply mechanism 20, which stores organic processing objects such as garbage, wood, meat and bone meal, rags, plastics, etc. The object is supplied into the drying furnace 30; the drying furnace 30 introduces the water vapor discharged from the carbonization furnace 40 to dry the object to be processed, and discharges the processed object and the used water vapor; the carbonization furnace 40 is supplied by The object to be processed dried by the drying furnace 30 is introduced into superheated steam from the high-temperature steam generating device 60 to carbonize the object to be processed, and the carbonized activated carbon and the used water vapor are discharged; The carbonized activated carbon is cooled and stored....

Embodiment 2

[0094] In the above-mentioned examples, the activated carbon was used for carbonization treatment such as drying, carbonization, and activation of organic objects to be treated using two types of reaction furnaces: the drying furnace 30 (first reaction furnace) and the carbonization furnace 40 (second reaction furnace). The carbonization apparatus for production has been described, but the present invention is not limited to the example of carbonization treatment using two types of reaction furnaces.

[0095] For example, depending on the type of object to be treated and the amount of treatment, if high-temperature superheated steam is generated by using superheated steam that has been heat-recovered from the high-temperature exhaust gas discharged from the deodorization furnace 70, and the high-temperature superheated steam The object of the present invention can also be achieved by introducing into a dry carbonization furnace (first reaction furnace) to dry and carbonize the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com