Textile waste collection device of chemical fiber cloth

A textile waste and collection device technology, applied to chemical instruments and methods, cleaning methods using tools, cleaning methods using liquids, etc., can solve the problem of inability to collect large-scale waste, poor waste collection effect, and unreasonable settings and other issues, to achieve the effect of improving the use value, easy to take, and reasonable setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

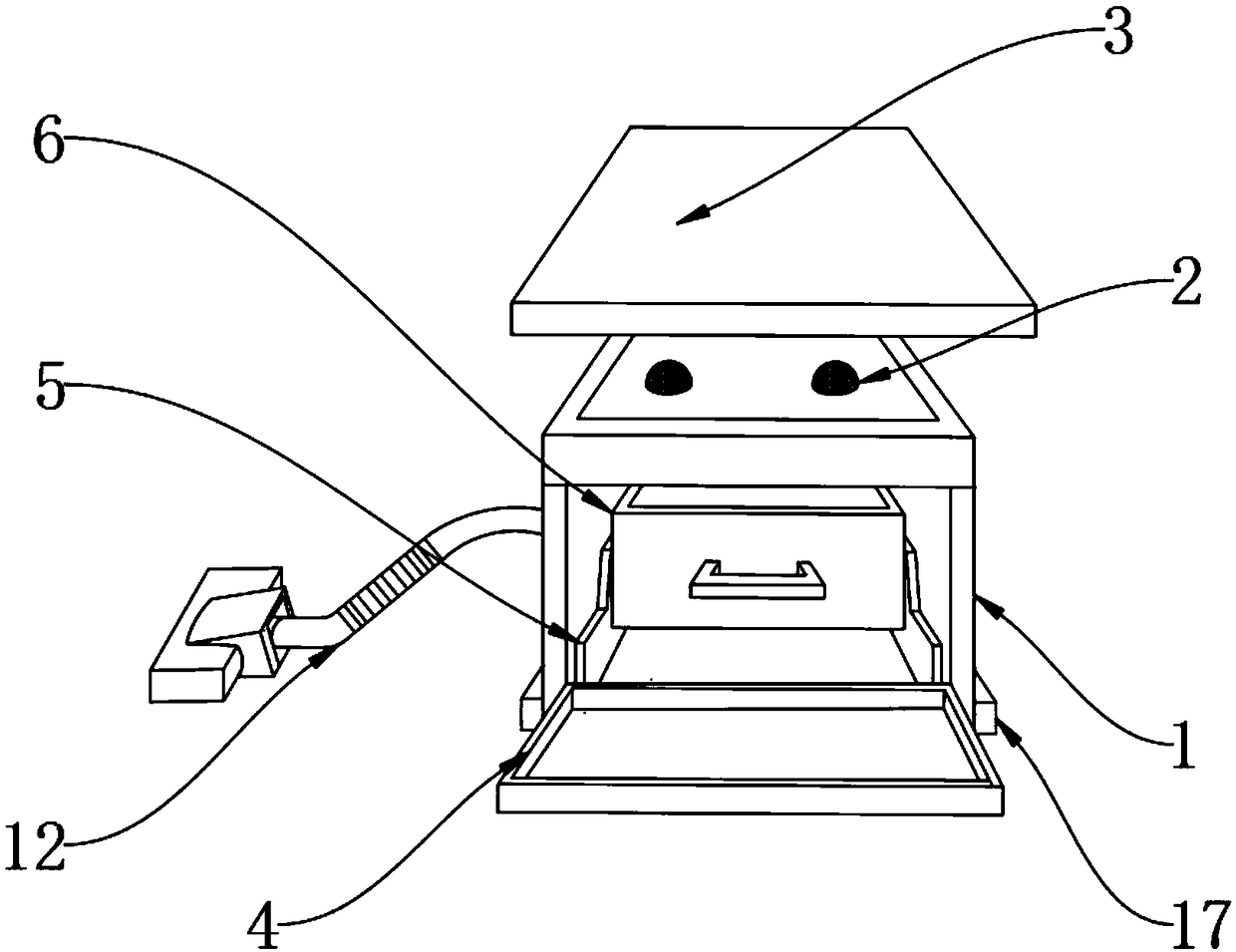

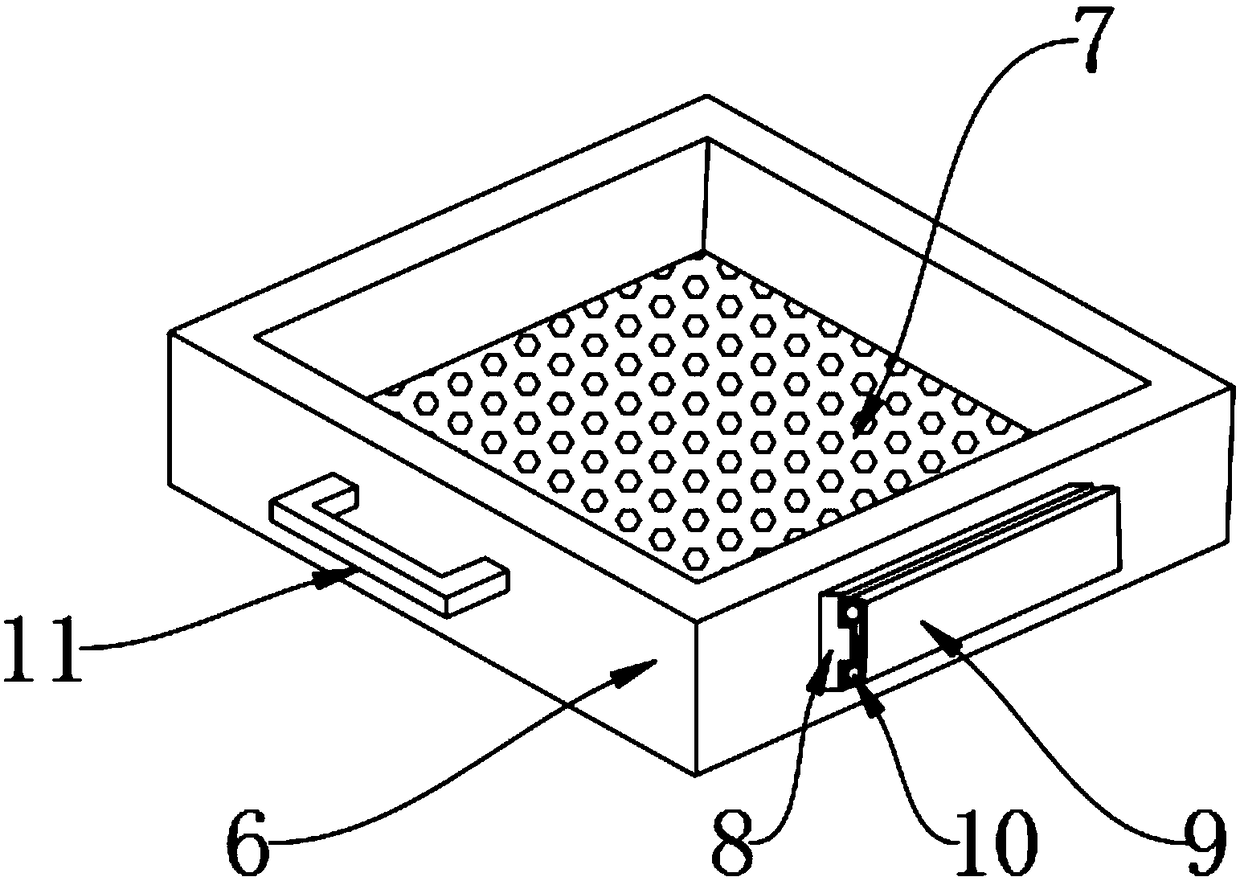

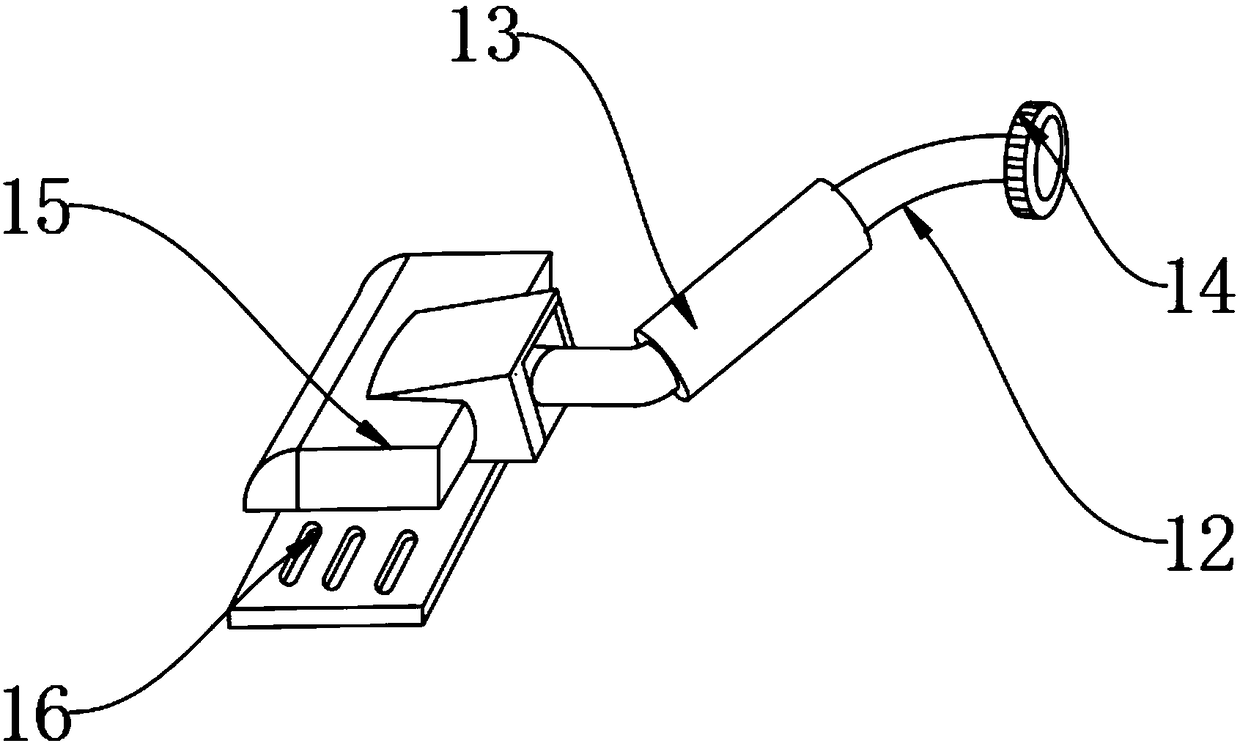

[0025] Example: such as Figure 1-5 As shown, the present invention provides a technical solution, a textile waste collection device for chemical fiber cloth, including a metal casing 1, in order to avoid rust and corrosion on the inner and outer surfaces of the metal casing 1, the inner and outer surfaces of the metal casing 1 are coated with Anti-rust paint, coarse filter screen 2 is installed on the top surface of the metal casing 1, a top cover 3 is installed on the top of the metal casing 1, a protective cover 4 is installed on one side of the metal casing 1, and an anti-rust filter is installed on the inner bottom of the metal casing 1. Grinding liner 5 and anti-wear liner 5 are equipped with a waste collection box 6 on one side, and a fine filter screen 7 is installed at the bottom of the waste collection box 6, and an inner fixed rail 8 is installed on one side of the waste collection box 6, and the inner fixed rail 8 One side is equipped with outer fixed rail 9, and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com