Handheld type heating cloth-cutting device

A heating device and hand-held technology, applied in textiles and papermaking, fabric edge trimming, textile material cutting, etc., can solve the problems of loose fiber at the trimming edge, weak connection, and poor wearing effect, so as to achieve poor wearing effect and avoid The effect of loose cutting fiber and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

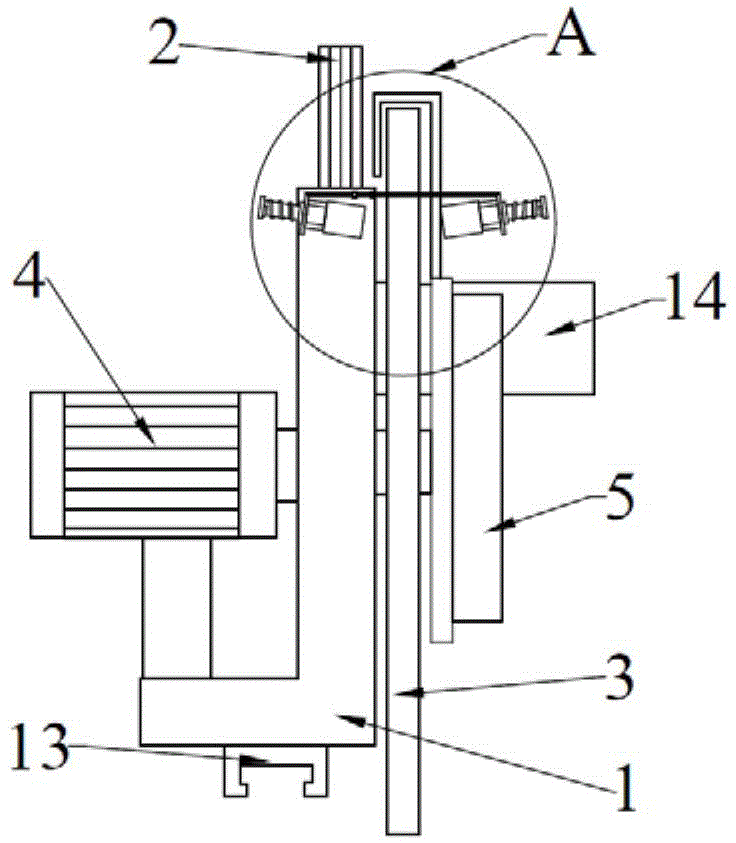

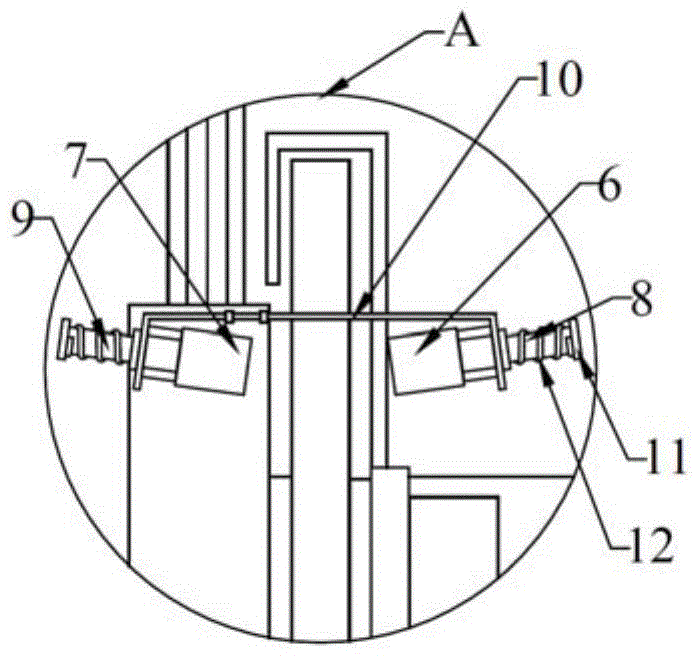

[0024] Such as Figure 1 to Figure 3 As shown, the embodiment is a hand-held heating cloth cutting device. The cloth cutting device includes a frame 1, a handle 2 is arranged on the frame 1, and a circular blade 3 is arranged on the frame 1 through a connecting piece. 3 is connected to the output end of the drive motor 4 through a transmission member, the drive motor 4 is used to drive the blade 3 to rotate, and the cloth cutting device also includes a heating device for heating the blade 3 .

[0025] In the present embodiment, the blade 3 is a circular blade, and the heating device includes an electric heating block 5 arranged on at least one side of the cutter, and the electric heating block 5 is fixedly arranged on the frame 1, and the electric heating block 5 and the frame 1 There is a gap between opposing faces.

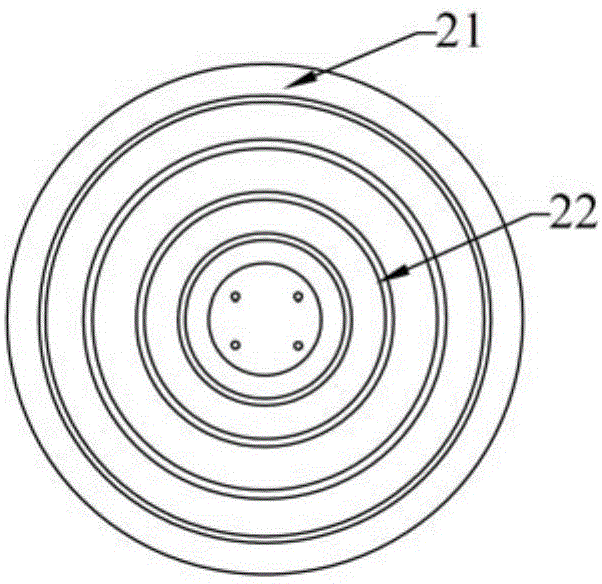

[0026] In this embodiment, the electric heating block 5 is circular, and the circular electric heating block 5 and the axis of the blade 3 are on the same stra...

Embodiment 2

[0033] Such as Figure 4 and Figure 5 As shown, the difference between Embodiment 2 and Embodiment 1 is that in Embodiment 2, the blade is an annular blade 15, and the heating device includes a soaking plate 16 that is arranged on the inner edge of the annular blade 15 and contacts each other. The soaking plate 15 The heating wire 17 used to heat the soaking plate 16 is arranged on the surface of the disk, and the center of the soaking plate 16 is provided with a through hole, which is connected with one end of the hollow transmission shaft 18, and the two ends of the heating wire 17 are respectively installed on the The electric wires in the hollow transmission shaft 18 are connected, and the hollow transmission shaft 18 is connected with the driving motor 4 through a transmission member.

[0034] In this embodiment, the soaking plate 16 includes a first plate body 19 and a second plate body 20 that are buckled, and the opposite surfaces of the first plate body 19 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com