Grinding device

A technology for grinding and processing objects, which can be used in the direction of grinding machine parts, grinding/polishing equipment, grinding machines, etc., and can solve problems such as thickness deviation of semiconductor wafers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

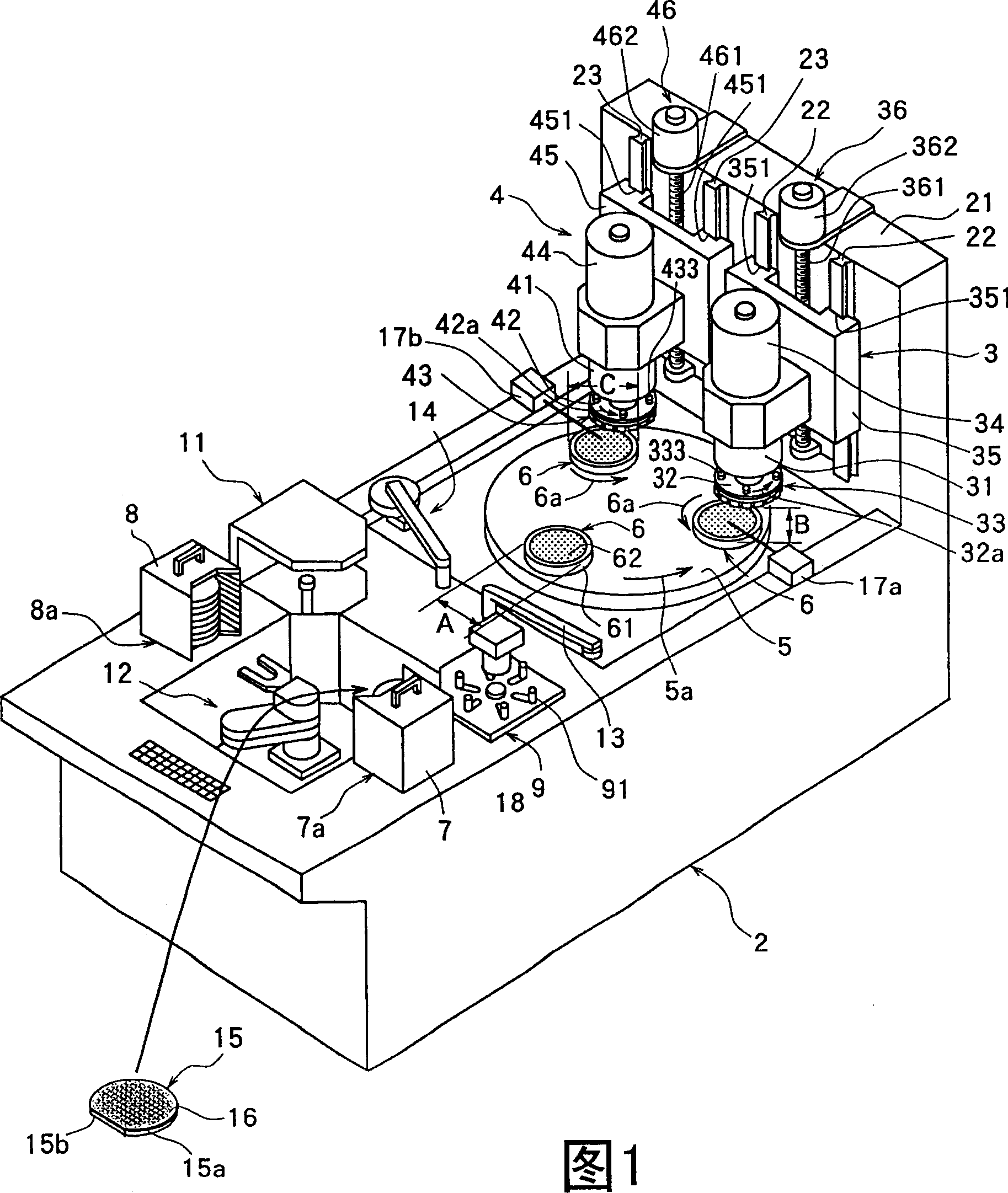

[0013] Hereinafter, preferred embodiments of the grinding device according to the present invention will be described with reference to the accompanying drawings.

[0014] Fig. 1 is a perspective view showing a grinding apparatus constructed according to the present invention.

[0015] The grinding device in the illustrated embodiment has a device housing 2 in the shape of a roughly cuboid. At the upper right end in FIG. 1 of the device housing 2, a stationary support plate 21 is erected. On the inner surface of the stationary support plate 21, two pairs of guide rails 22, 22 and 23, 23 extending in the vertical direction are provided. A rough grinding device 3 as a rough grinding mechanism is installed on one guide rail 22, 22 so as to be movable up and down; The fine grinding device 4 of the fine grinding mechanism.

[0016] Rough grinding device 3 has device housing 31, and the rough grinding wheel 33 that is installed on the wheel support 32 of the lower end of this dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com