Height measuring device of spring washer elasticity test

A technology of height measuring device and elasticity test, applied in the direction of measuring device, mechanical measuring device, using mechanical device, etc., can solve the problem of difference in measurement results, which can only be determined by human, and achieve small error, test accuracy and consistency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

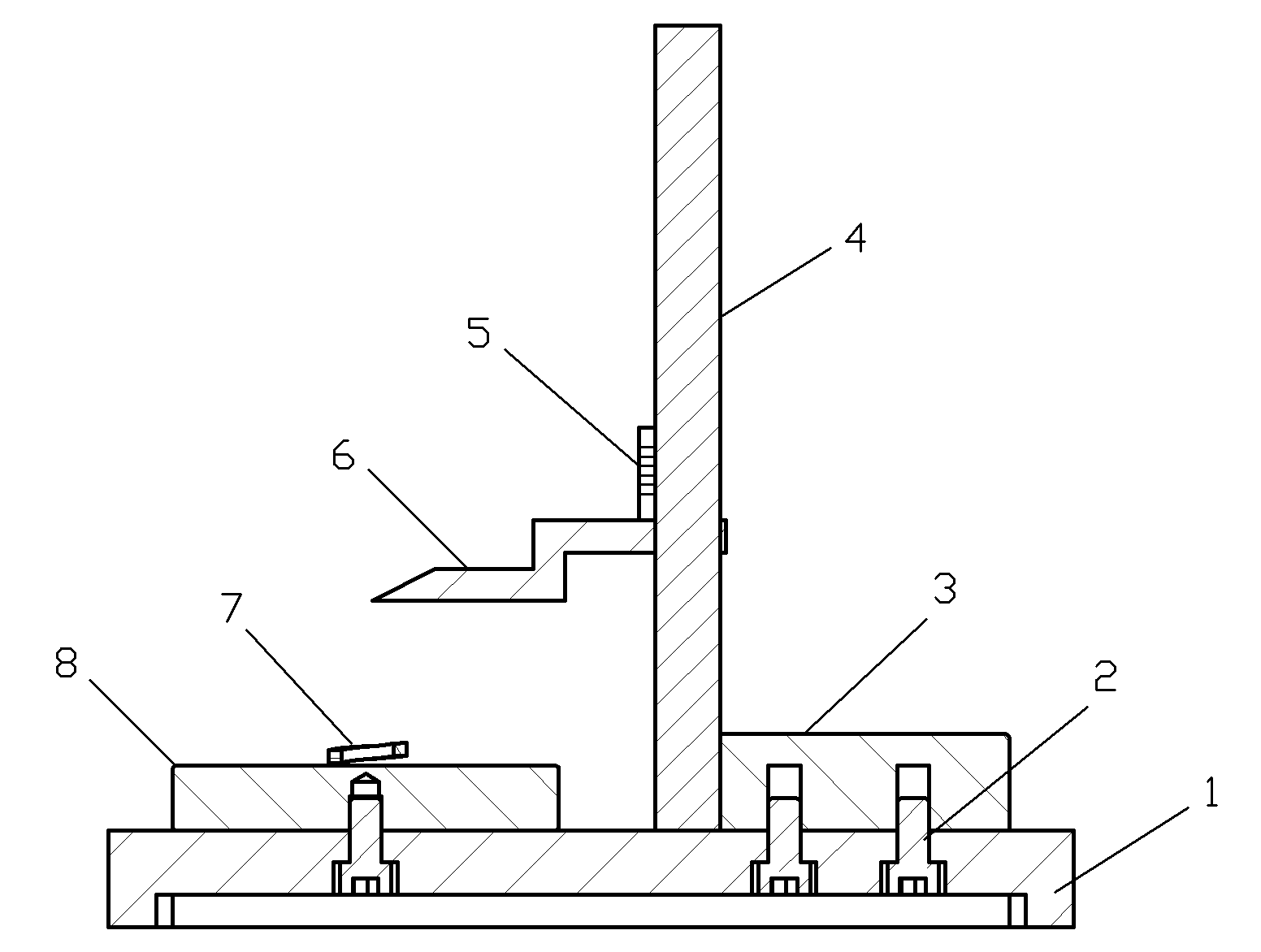

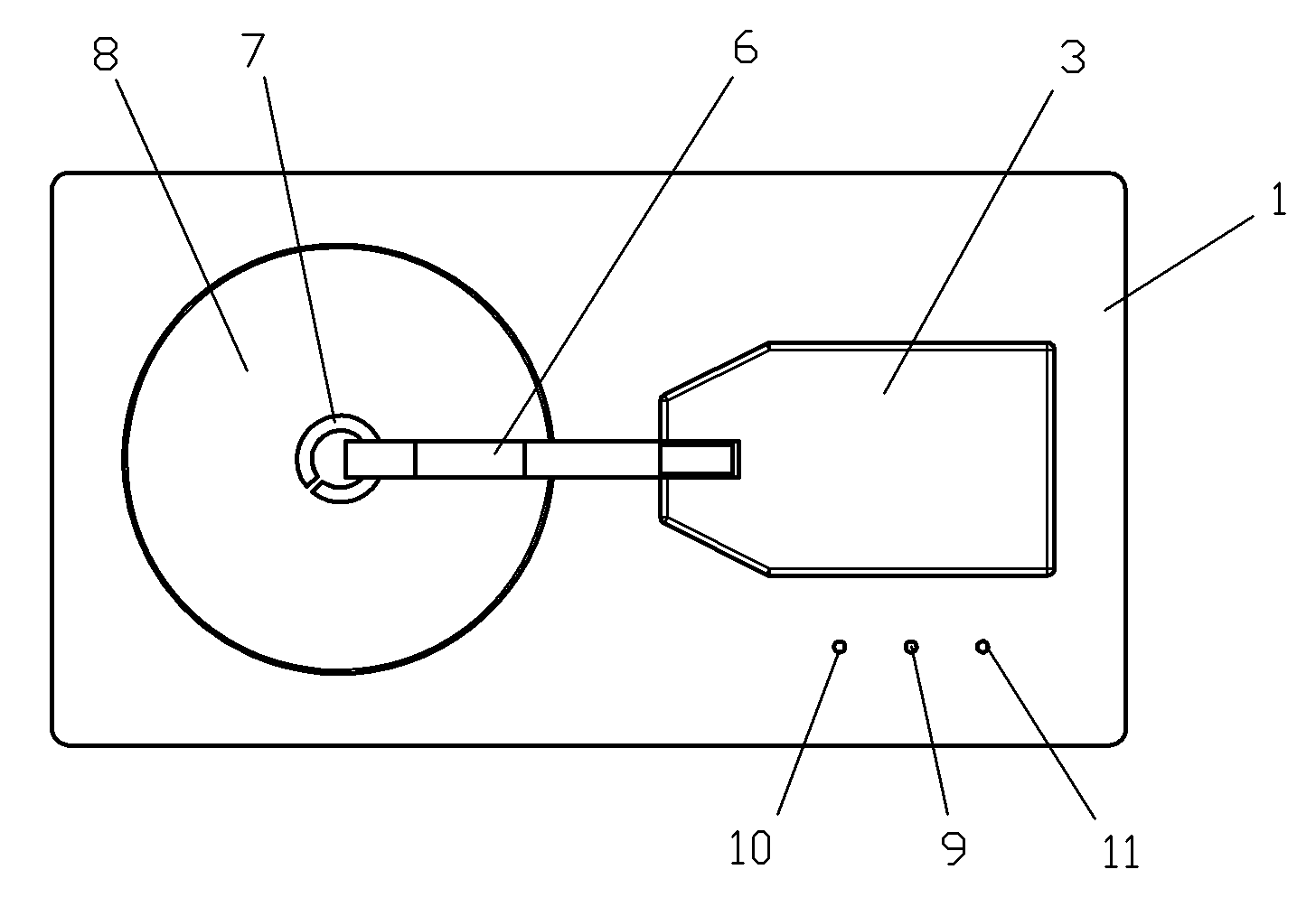

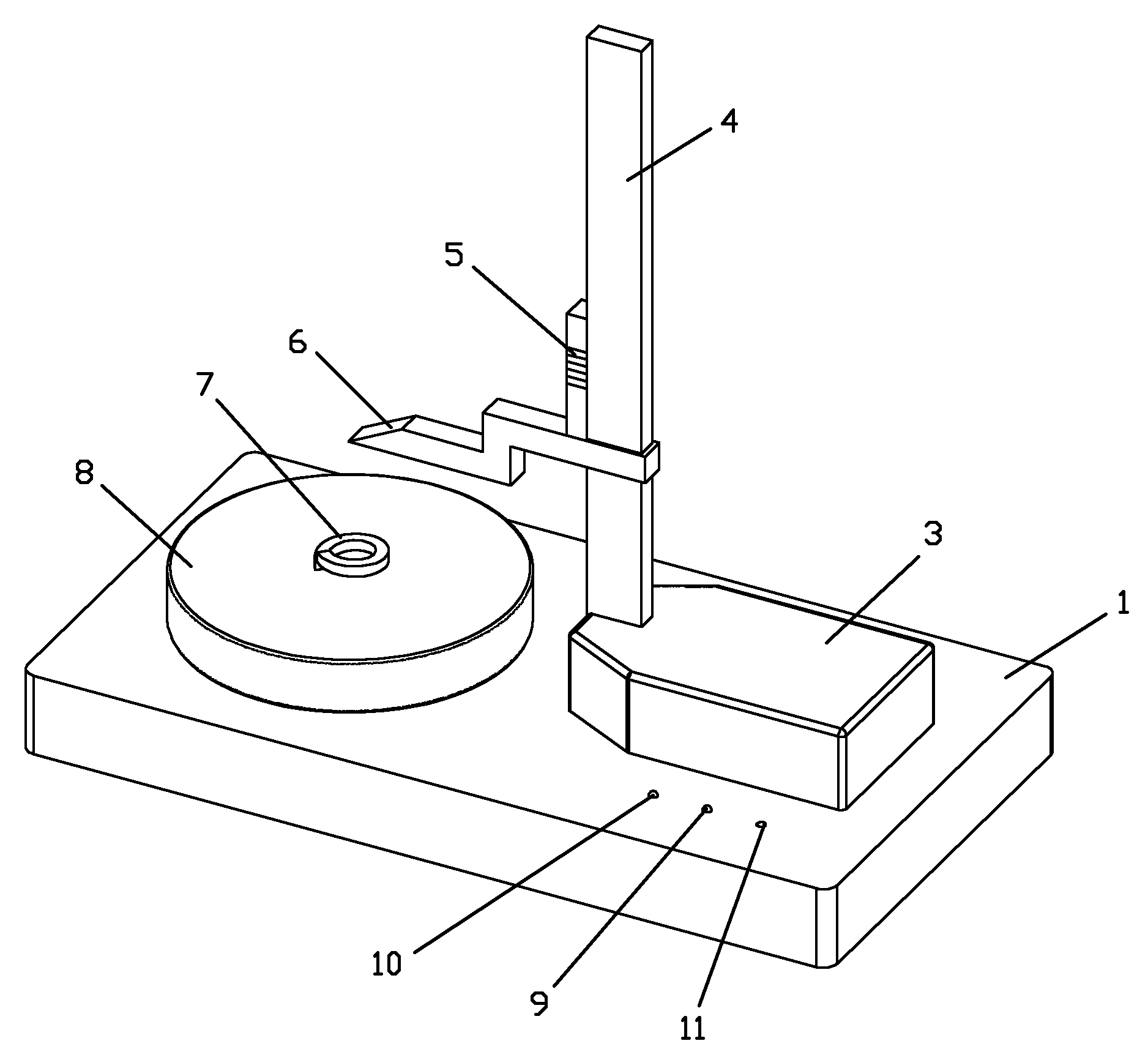

[0013] With reference to the accompanying drawings, the spring washer elasticity test height measuring device includes a height gauge, a base 1, a metal platen 8 and a control circuit, and the described height gauge includes a base 3, a scale 4, a vernier 6 and a fine-tuning device 5, and is characterized in that The metal platen 8 and the height gauge are fixed on the base 1 by screws 2, the vernier 6 is placed directly above the metal platen 8, and the base 1 is also provided with a contact indicator light 9 and a buzzer 11 and the power indicator light 10, the control circuit is electrically connected with the metal platen 1, the indicator light 9, the buzzer 11 and the power indicator light 10, and drives the described The contact indicator light 9 and the buzzer 11 conduct work.

[0014] refer to Figure 4 , the control circuit of the present invention comprises a switch K1, a switch K2, a resistor R1, a light-emitting diode LED1, a light-emitting diode LED2, a buzzer F ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com