Bevel gear tooth thickness measurer

A technology of bevel gears and measuring instruments, applied in the field of machinery, can solve problems such as not reflecting the actual backlash of gear pair meshing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

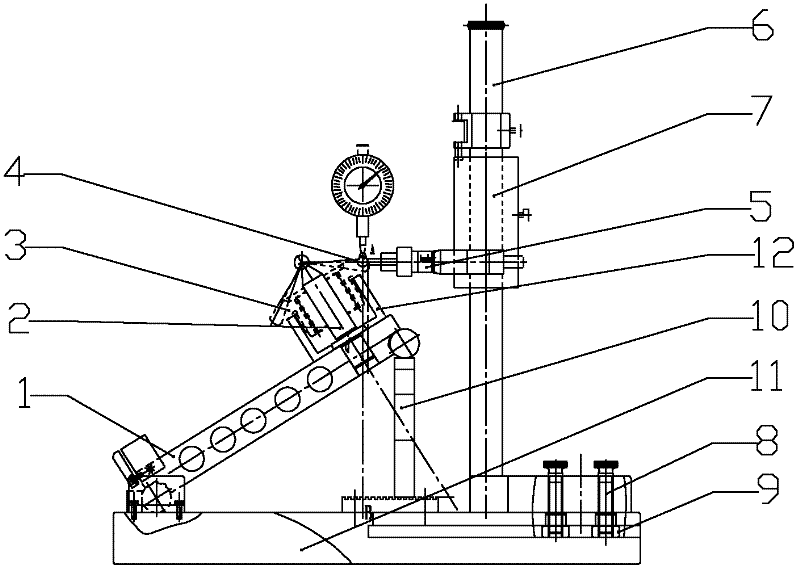

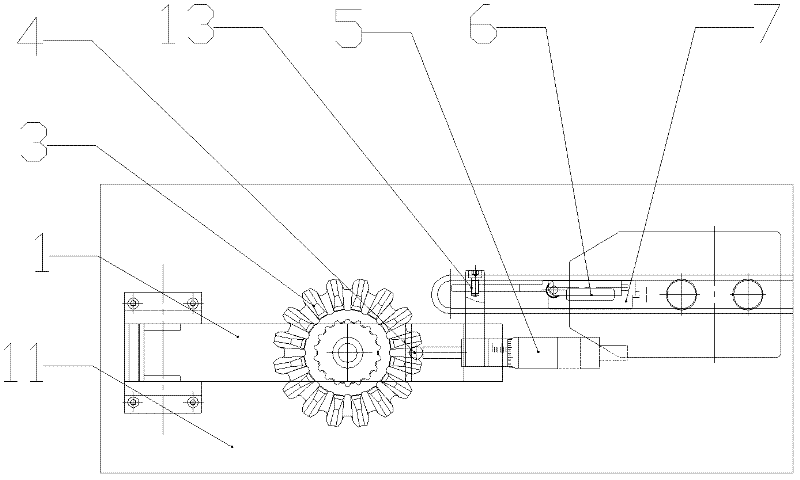

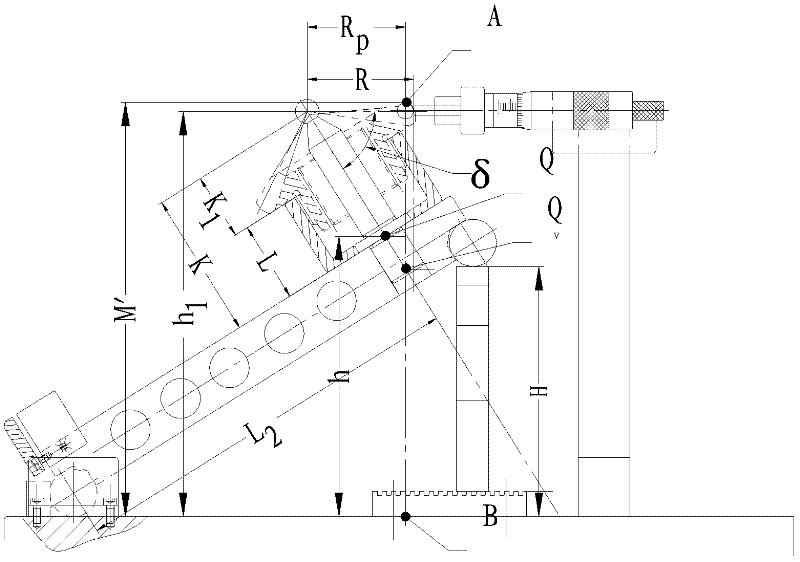

[0054] like figure 1 , 2 , 3, the bevel gear tooth thickness measuring instrument is mainly composed of a sine gauge 1 (with a mandrel 2), a right-angle curved ruler with a micrometer sleeve and a reading device 5, a height gauge 6, a gauge block 10, a steel ball 4, and a micrometer 5 (the ruler frame, measuring anvil and locking device have been removed).

[0055] The worktable of the bevel gear tooth thickness measuring instrument is roughly rectangular, and the sine gauge 1 and the right-angle bending ruler are respectively installed at both ends of the workbench, and the installation angles of the sine gauge 1 and the right-angle bending ruler are parallel to each other; The right-angle curved ruler and the workbench are moved through the clearance fit of the guide groove and the guide key, and are positioned by the knurled bolt 8 and the T-nut 9; the upright part of the right-angle curved ruler is a height gauge 6, and the height gauge 6 An adjustment sleeve 7 is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com