Multifunctional height gauge

A height gauge and multi-functional technology, applied in the field of measuring tools, can solve the problems of unrealistic measurement, lack of contact reference positioning and measurement position, complexity, etc., and achieve the effect of simple and fast assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

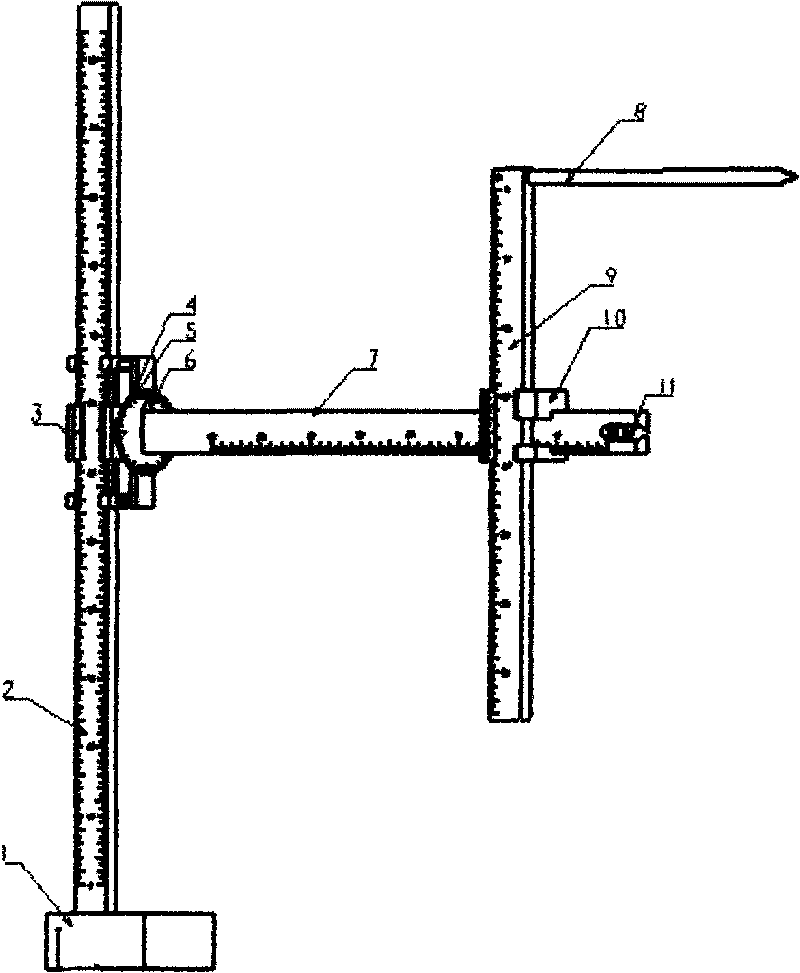

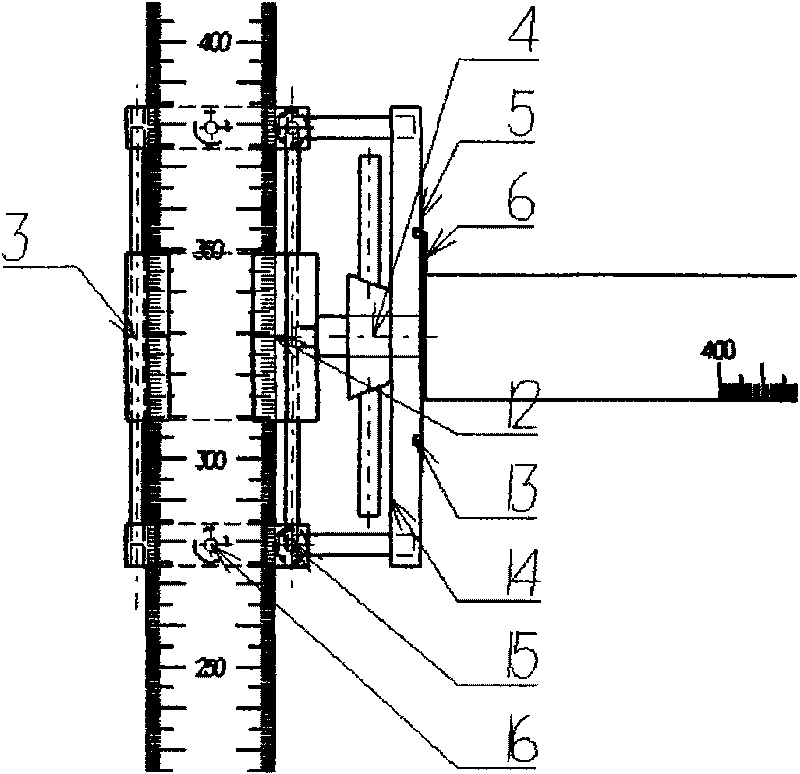

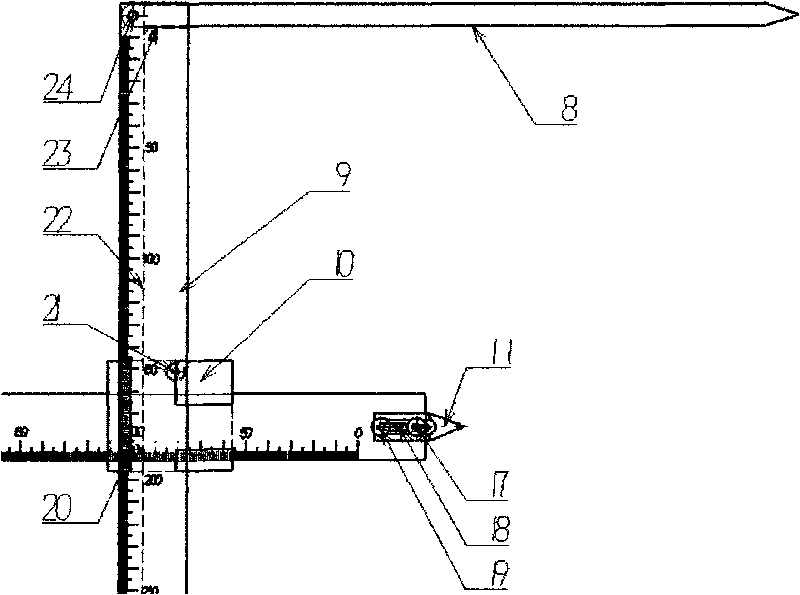

[0035] The structure and specific use of the height gauge of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0036] Such as figure 1 , 2 As shown, the multifunctional height gauge of the present invention includes: a base 1, a column 2, a composite sliding seat 3, a level 7, a level rotation locking mechanism 4, an angle dial 5, an angle dial mounting plate 14, a two-way Sliding seat 10, detection ruler 9, level ruler contact arm 11 and rotatable concealed contact arm 8. The composite sliding seat 3 is installed on the column and can slide up and down along the column, and is used to install the dial 5 and the level 7 to realize the height measurement on the column line, the fixing of the dial 5, the sliding up and down of the level 7 and the level 7 turns. The angle dial mounting plate 14 is connected with the compound sliding seat 3 by its upper and lower two supports, and is fastened together with the compound slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com