Patents

Literature

45 results about "Human system interface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

“The human-system interface (HSI) is defined as the technology through which personnel interact with plant systems to perform their functions and tasks. Most plants have decent hardware and control systems installed and usually collect real-time information using Data Historians.

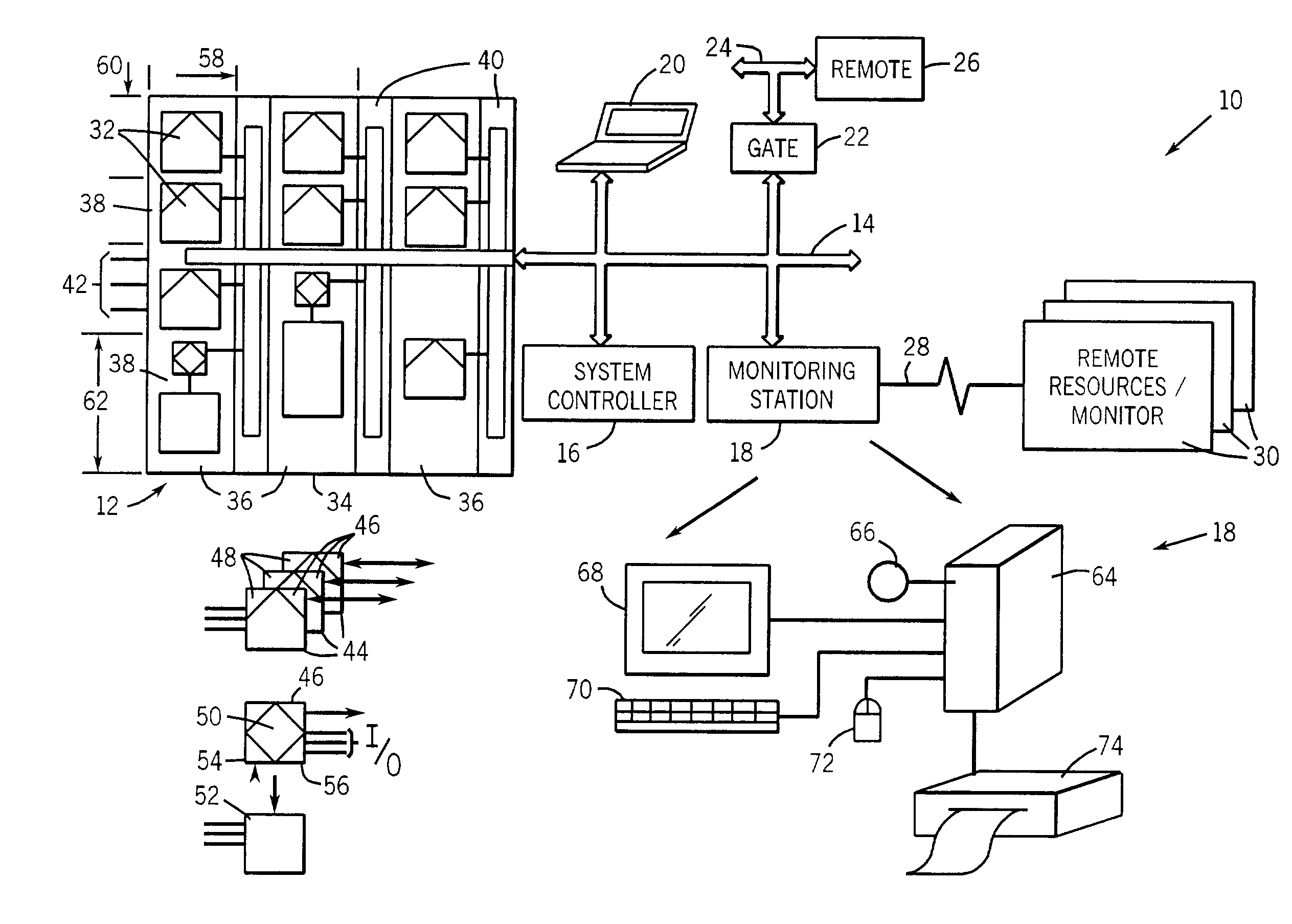

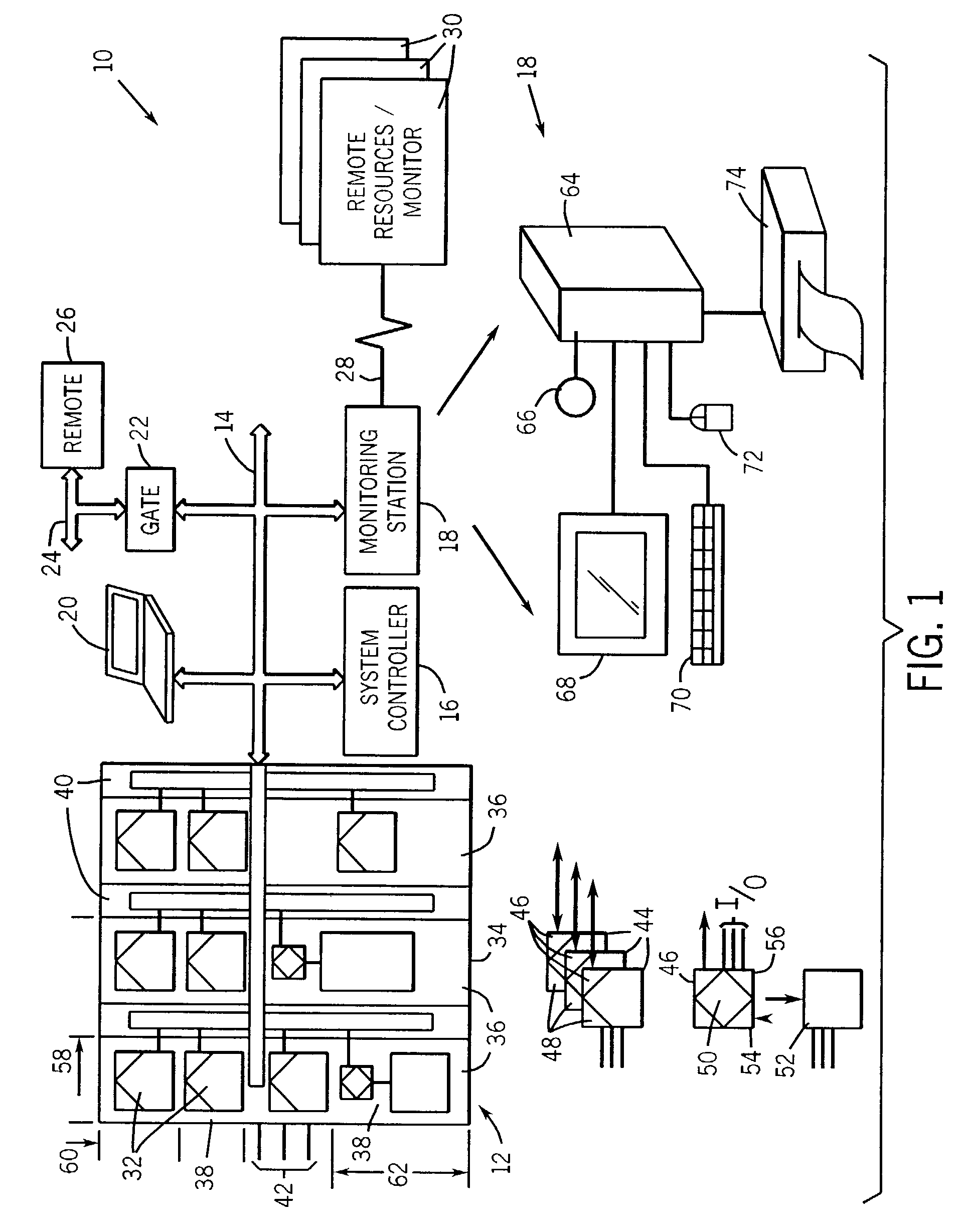

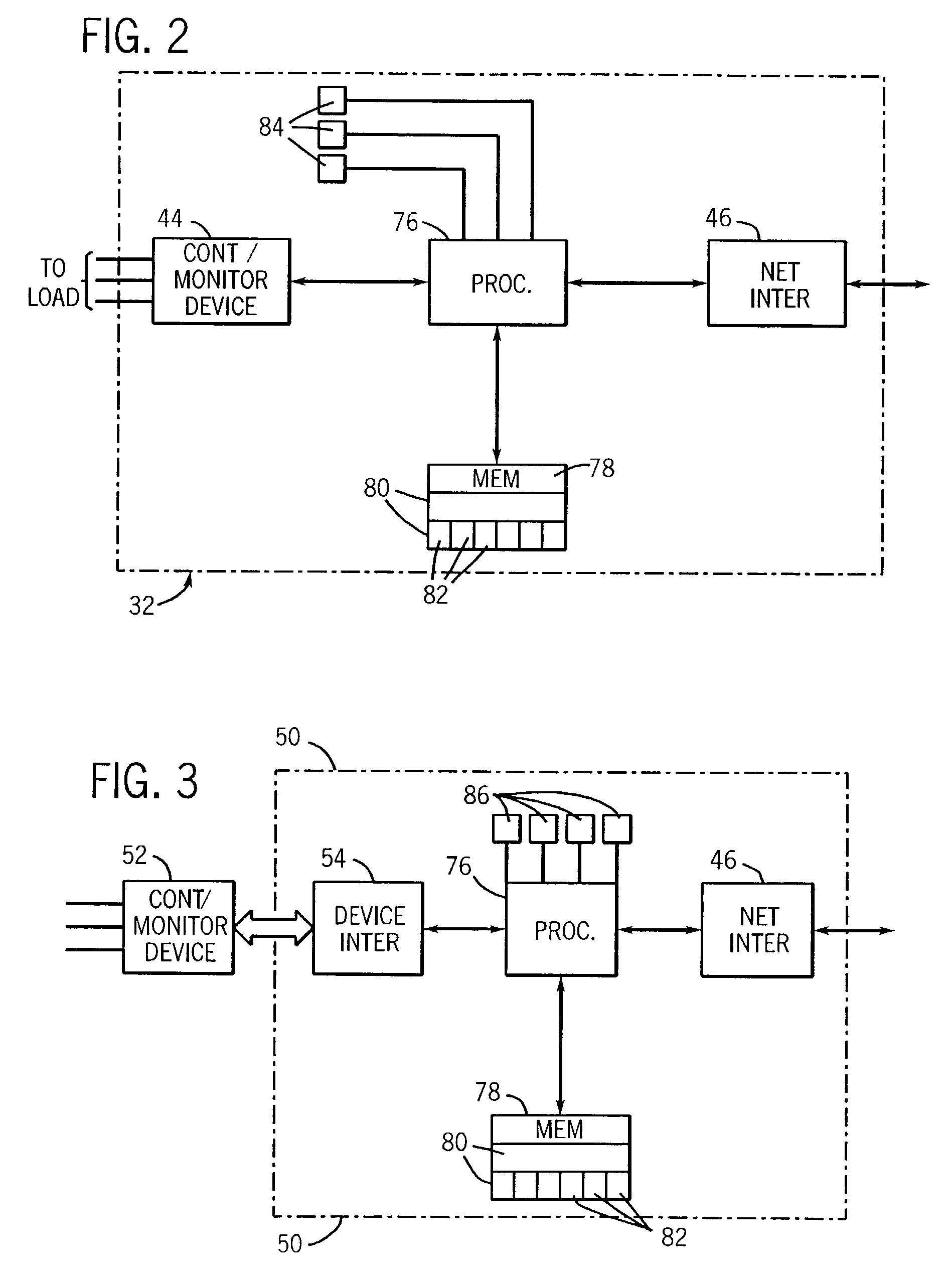

Industrial control and monitoring method and system

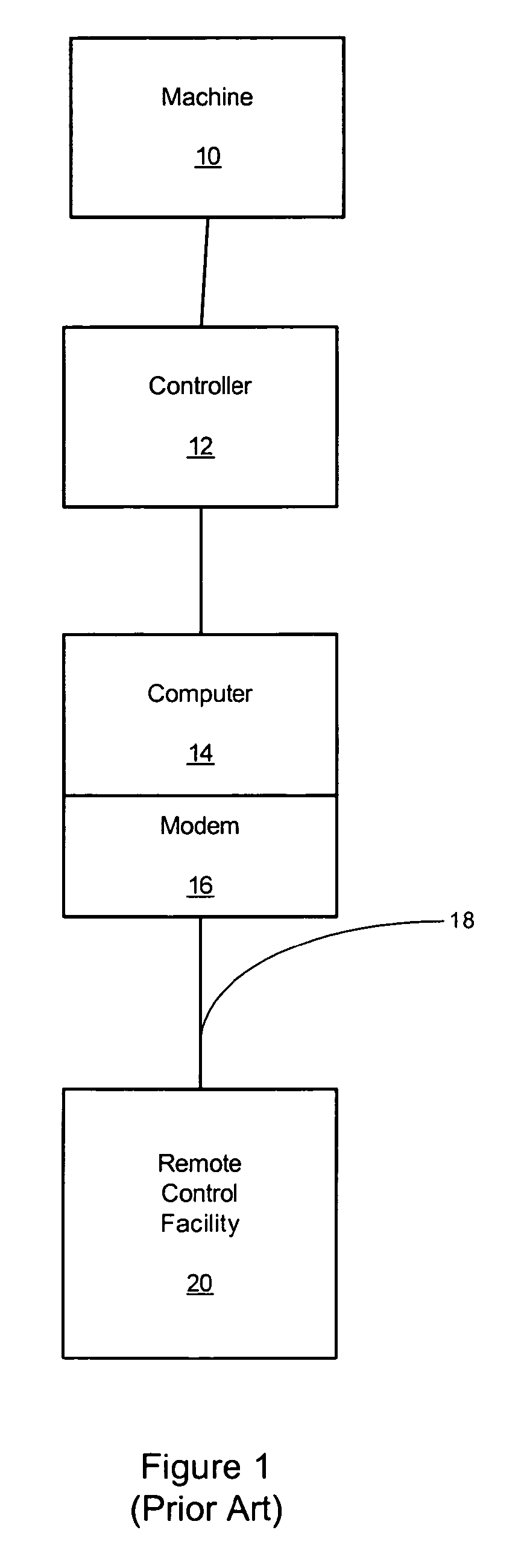

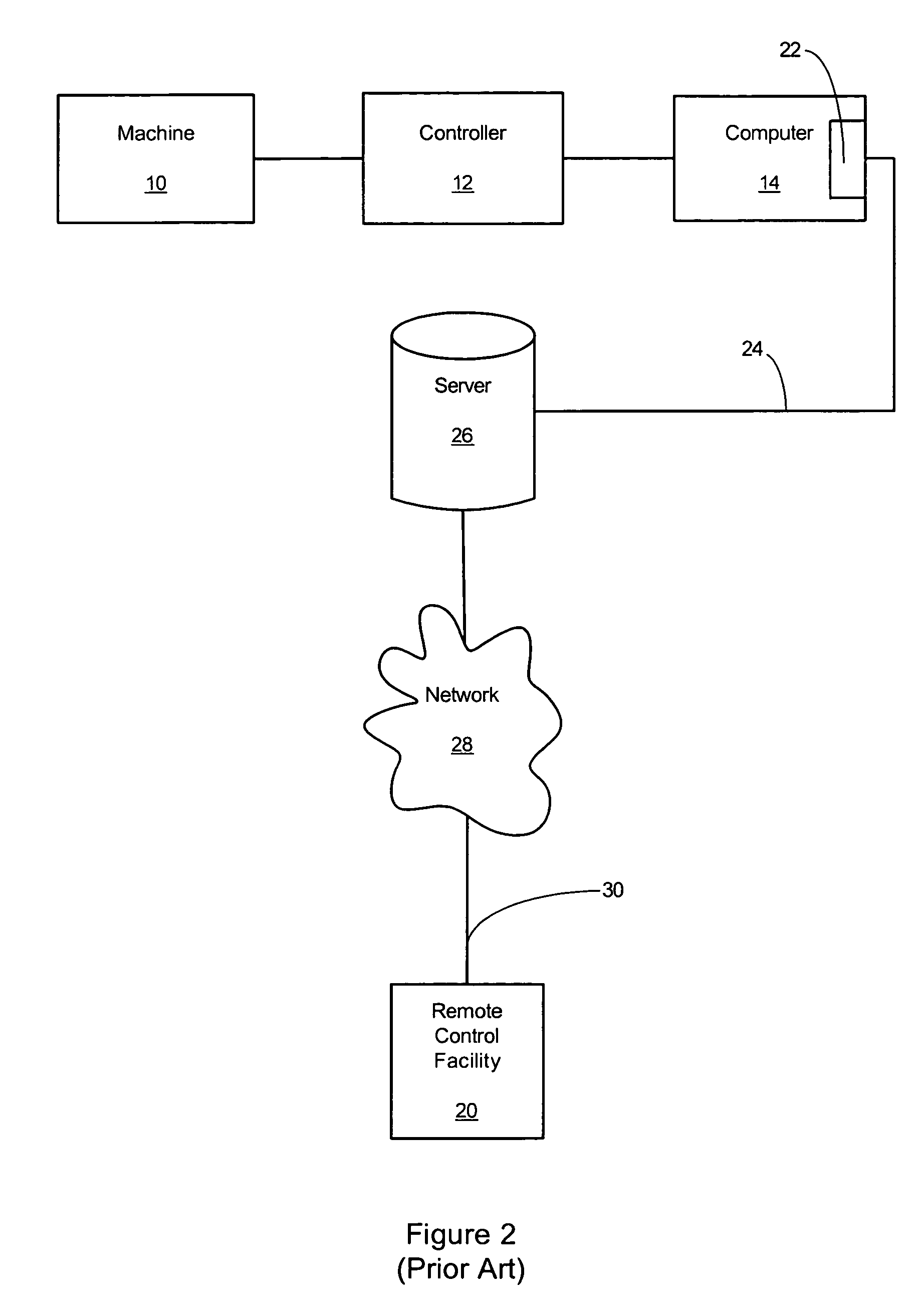

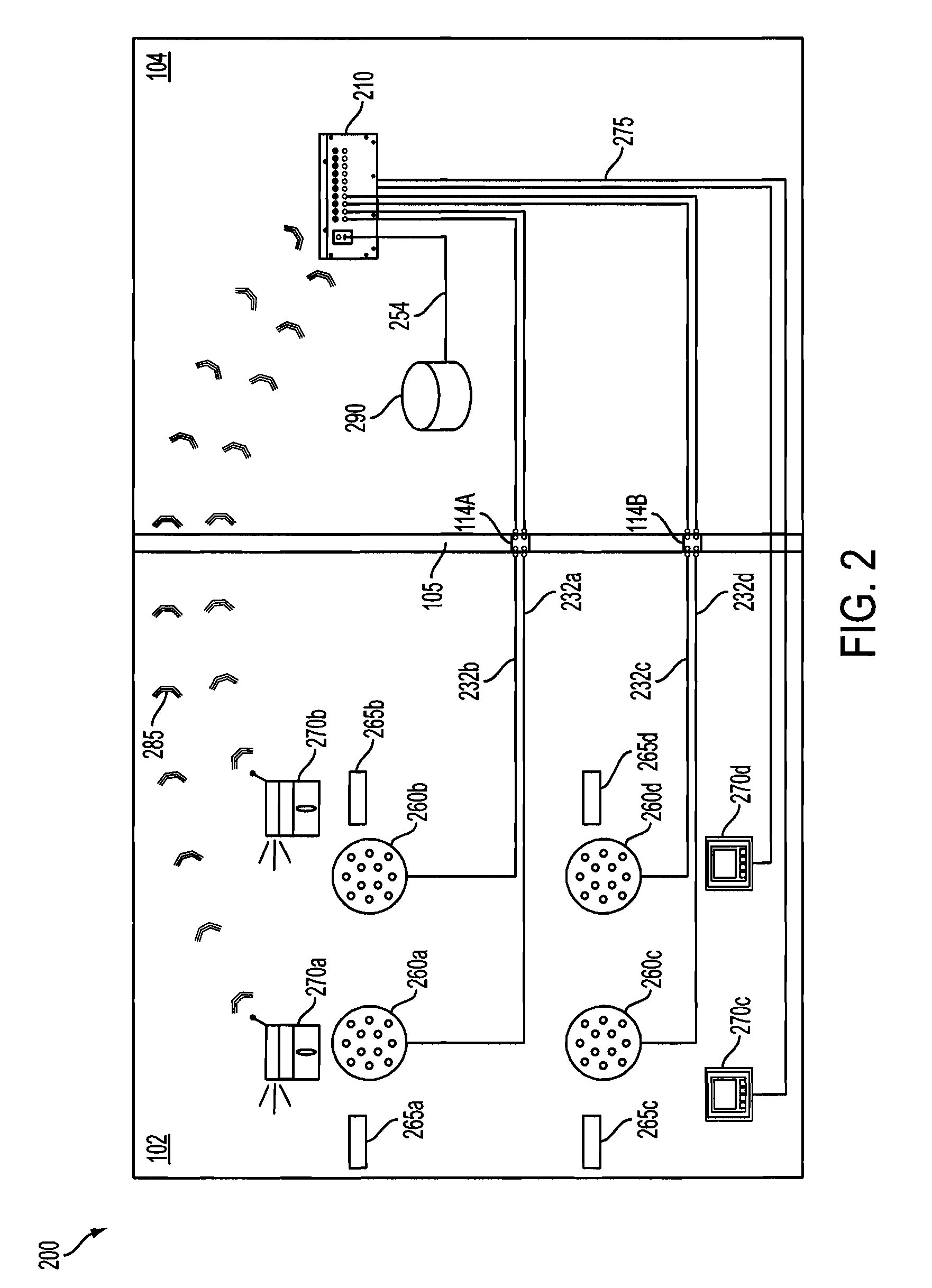

ActiveUS7092771B2Minimal programming effortGuaranteed uptimeComputer controlError detection/correctionMonitoring systemMotor control

A technique is provided for integrating human machine interfaces with control and monitoring systems. Control and monitoring systems may be integrated into a human machine interface to enable access to various systems including networked and programmable electrical components, such as components of motor control centers, and databases that including component, system designation data, configuration information, settings, and so forth. The database and components are accessed by execution of a program embedded in the human machine interface to provide desired information in response to selection of a particular physical component of the system. The information serves as the basis for an operator display through the human machine interface.

Owner:ROCKWELL AUTOMATION TECH

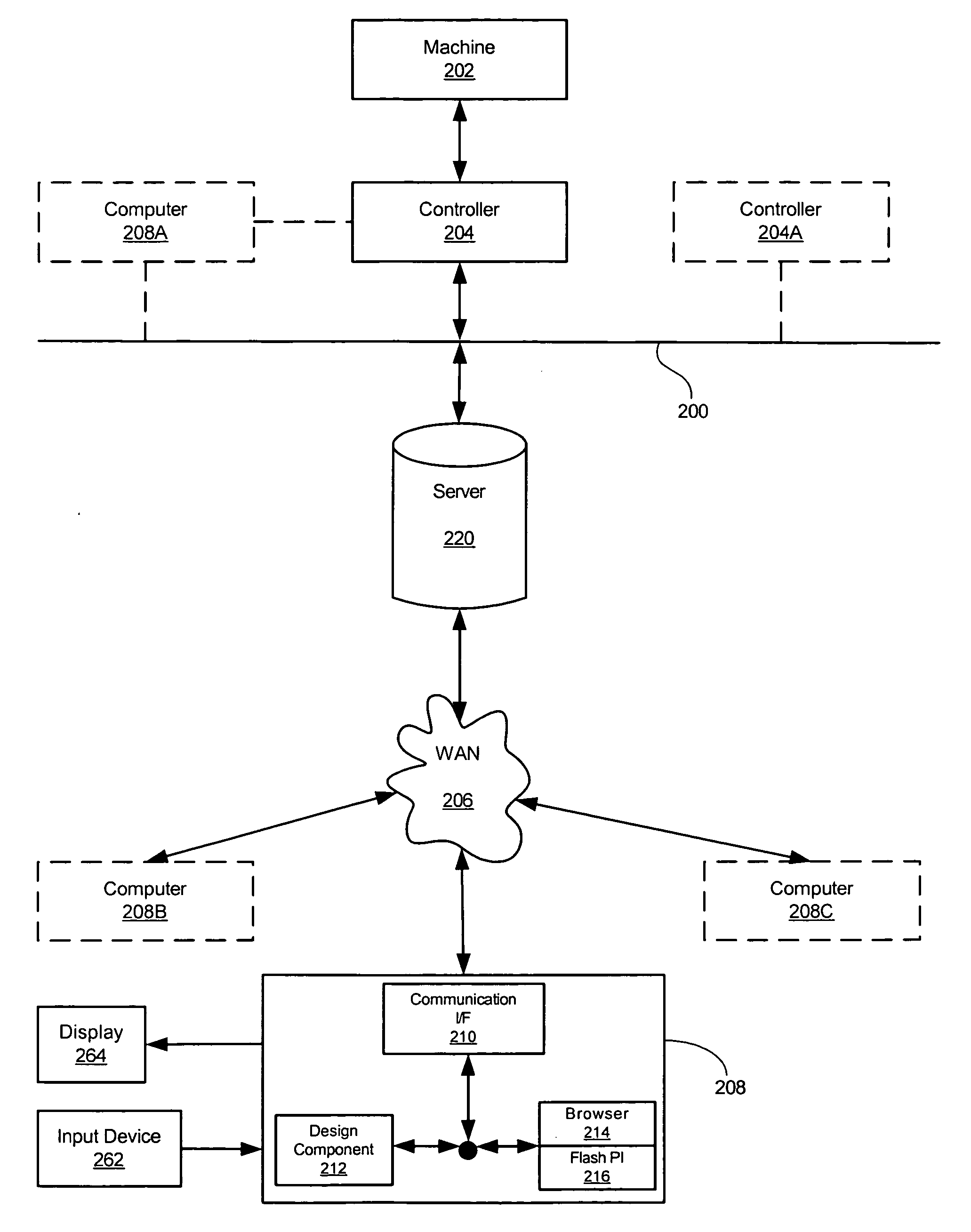

Human-machine interface system and method for remotely monitoring and controlling a machine

A system and method for providing a graphical human-machine interface (“HMI”) for a machine having controllable parts. The system and method implement an HMI in real time using a standard browser over a network. The system and method permits remote users to make modifications to the HMI and to the control status of the machine. Any subsequent modifications are transmitted to the machine and all remote users in real time. Thus, the system and method allow a remote user to effectively monitor and control machines and processes without the need for the operator to be physically present at the location where the machine or process is located or being performed.

Owner:PARKER HANNIFIN CORP

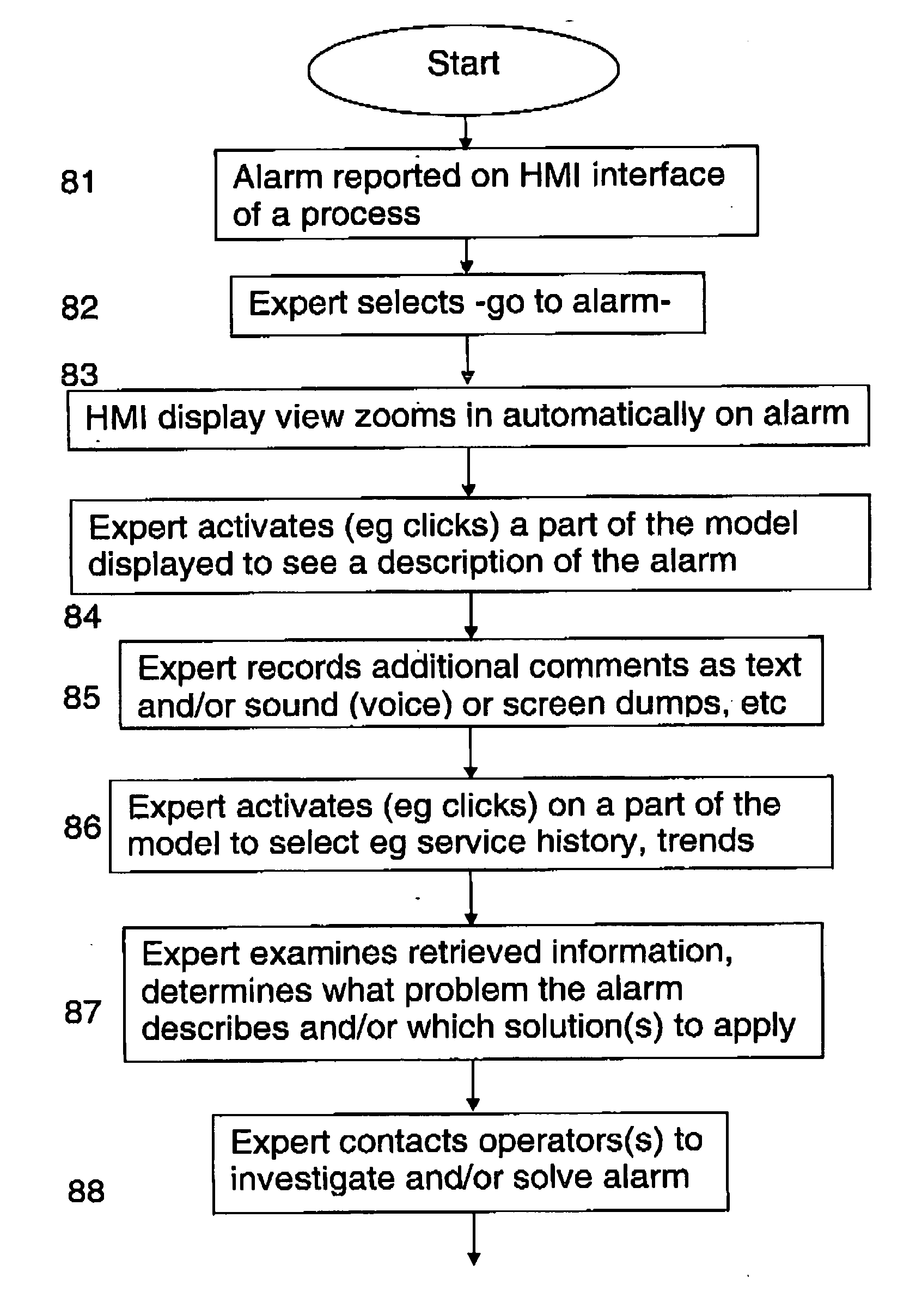

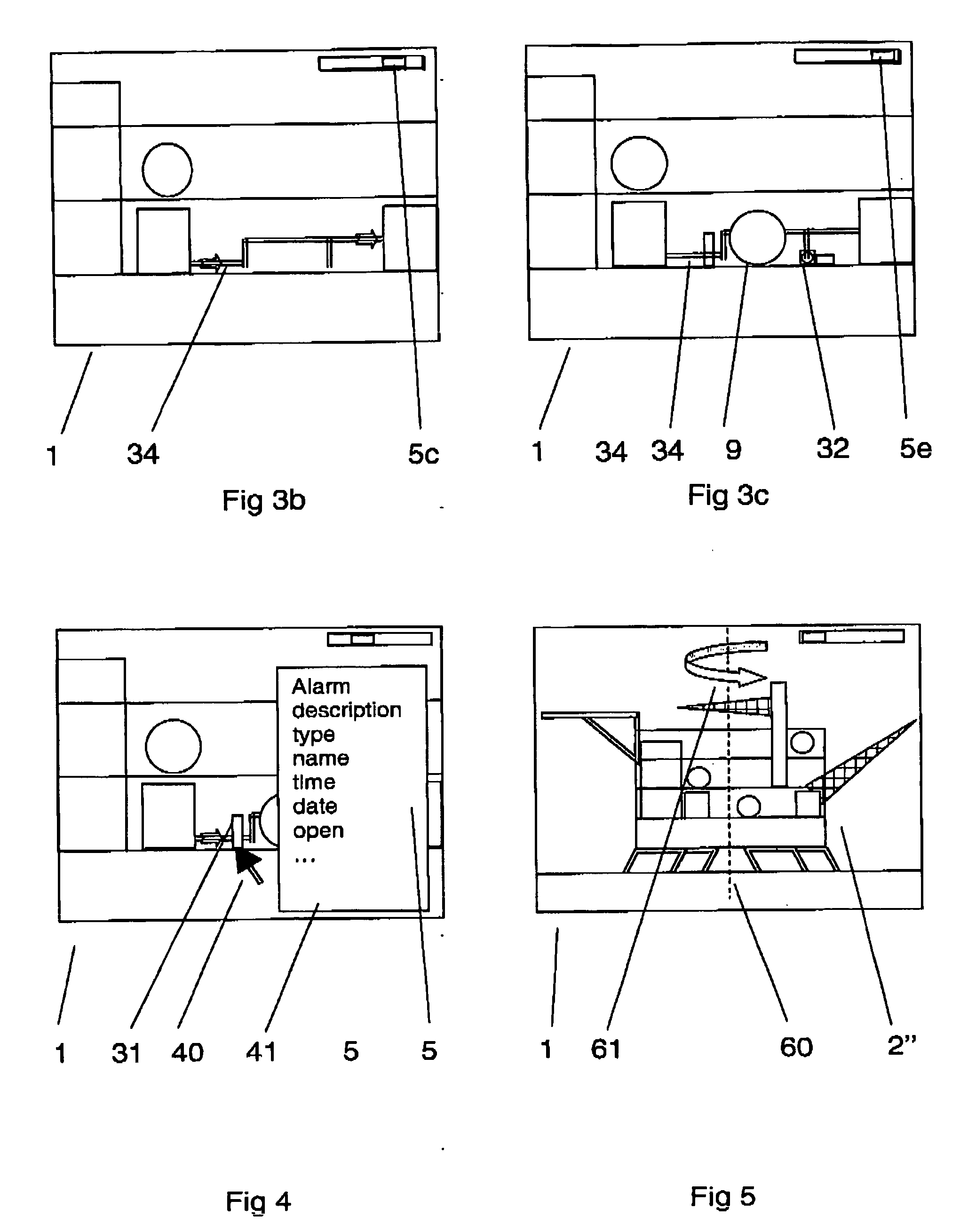

Human-machine interface for a control system

ActiveUS20060241793A1Efficiently presentedWay fastComputer controlSimulator controlControl systemMonitoring and control

A human-machine interface of a control system for monitoring and control of a process and including a computer generated model of the process. The process or a part or component of the process is displayed such that the model is arranged to map a point on the computer generated model to data held by the control system about the at least one part or component of the process. A method to monitor and control a process using the human-machine interface and a system including the interface are also described.

Owner:ABB (SCHWEIZ) AG

Bridging human machine interface technologies in a process automation and information management environment

An industrial control and automation human machine interface (HMI) technology migration scheme is embodied in object management, graphics technologies, and namespace handlers for HMI applications. Newfeatures of the second technology are supported for HMI graphics while retaining the functionality of systems embodying the first technology, including the ability to export to the first technology,graphics developed and / or managed in the second technology. A combination of facilities is provided to accommodate both the first and second HMI graphics technologies: name space integration, graphicsrendering integration, and HMI application management integration.

Owner:AVEVA SOFTWARE LLC

Human-machine interface for a control system

ActiveUS7715929B2Way fastRelieve pressureComputer controlSimulator controlControl systemMonitoring and control

A human-machine interface of a control system for monitoring and control of a process and including a computer generated model of the process. The process or a part or component of the process is displayed such that the model is arranged to map a point on the computer generated model to data held by the control system about the at least one part or component of the process. A method to monitor and control a process using the human-machine interface and a system including the interface are also described.

Owner:ABB (SCHWEIZ) AG

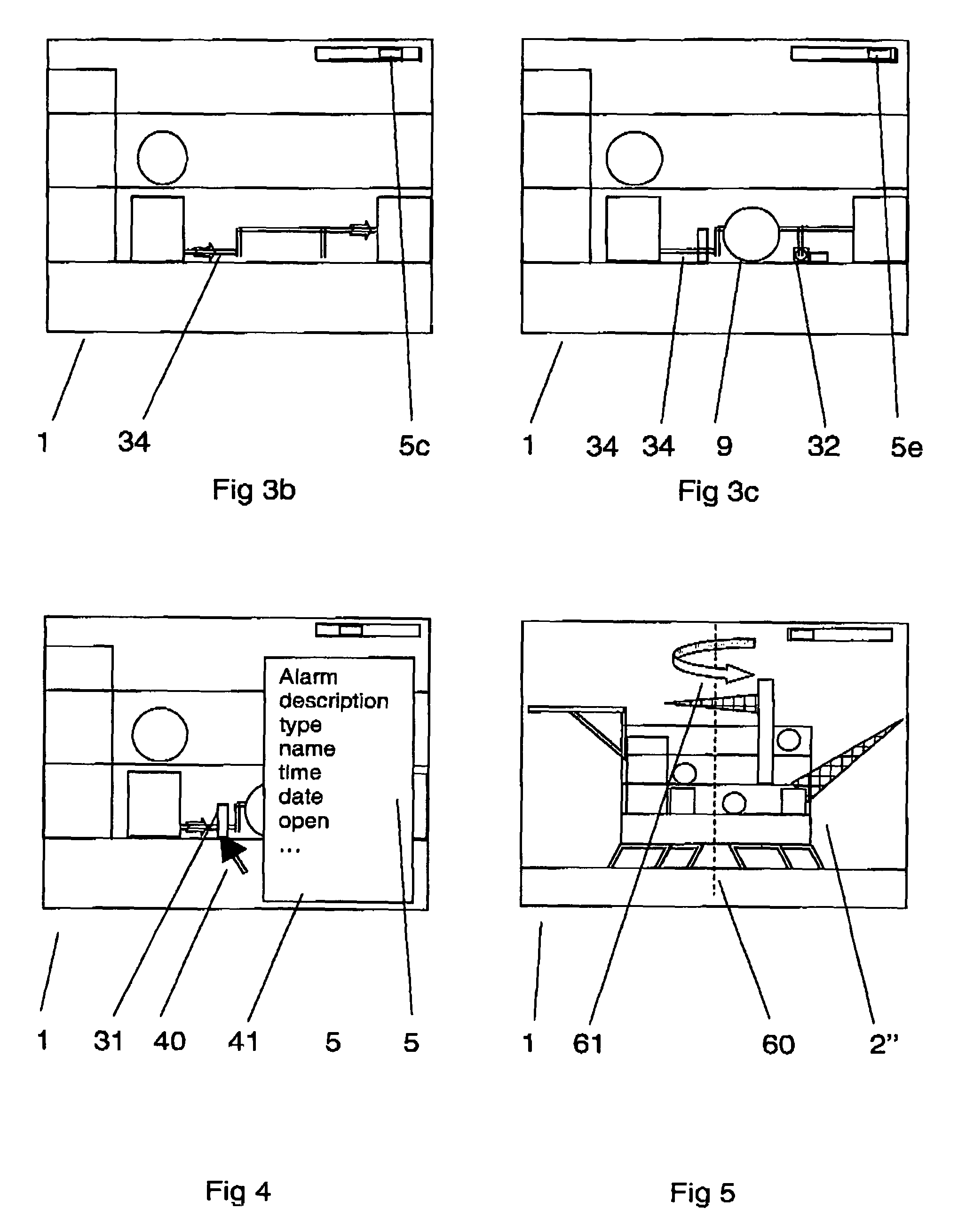

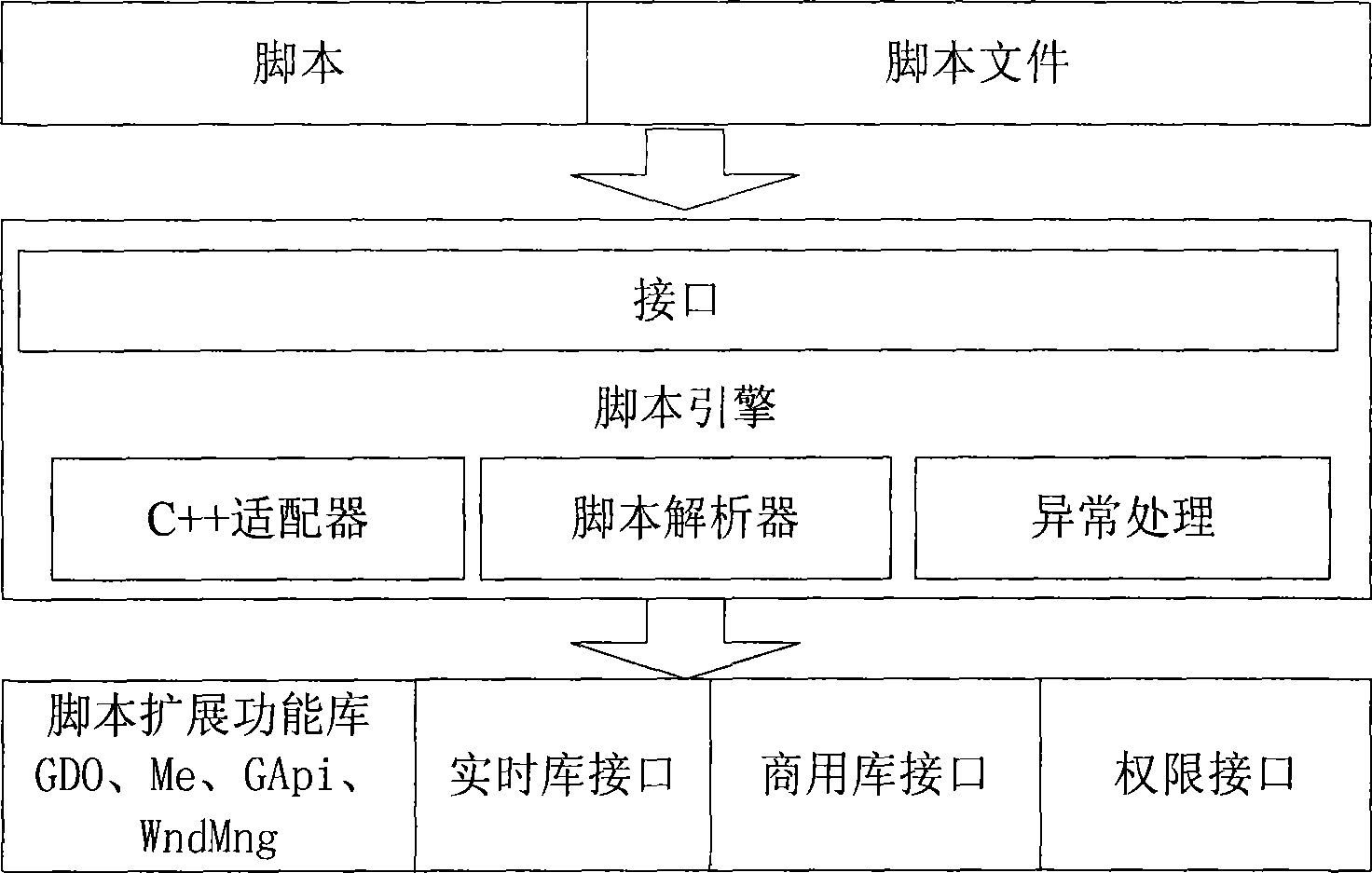

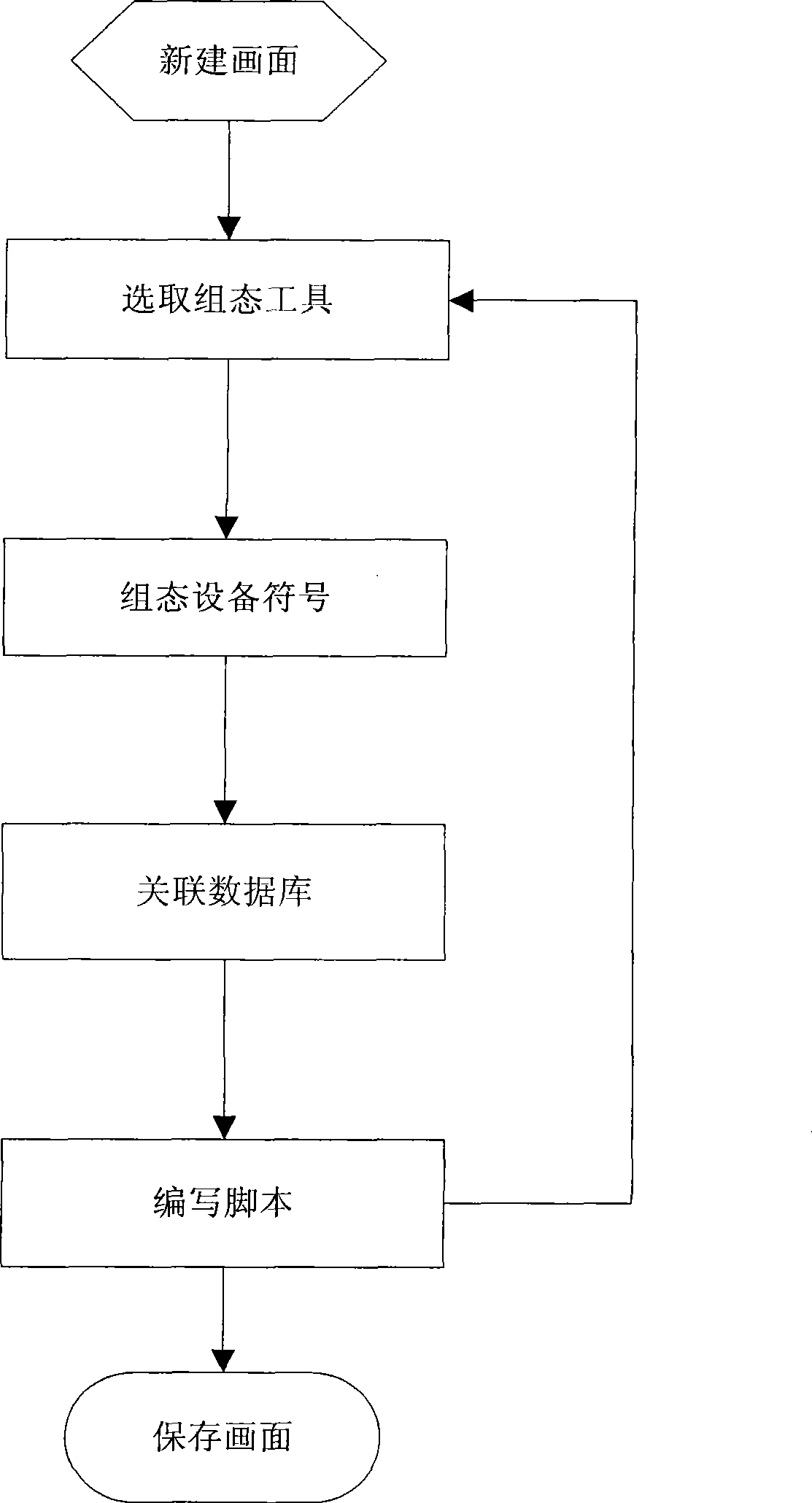

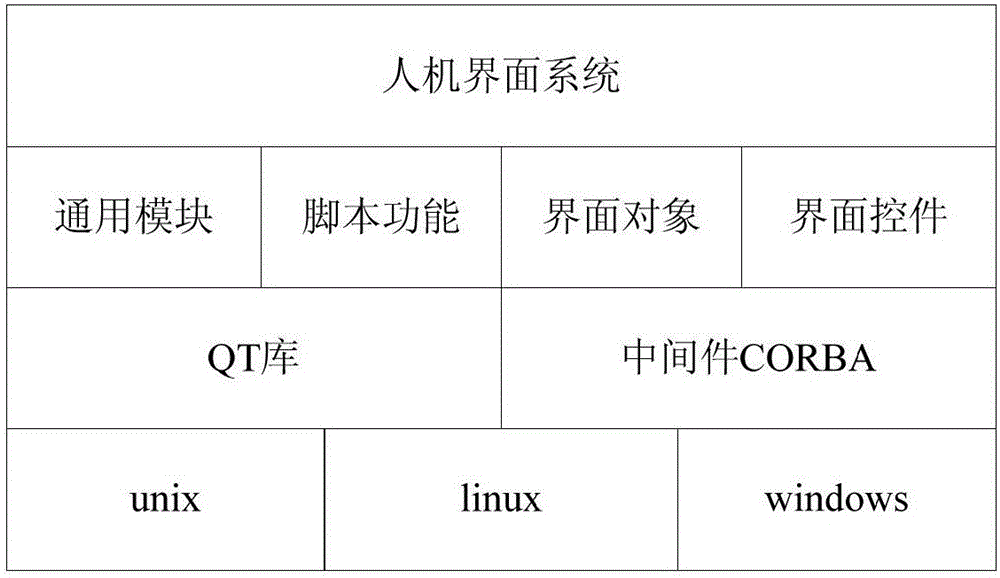

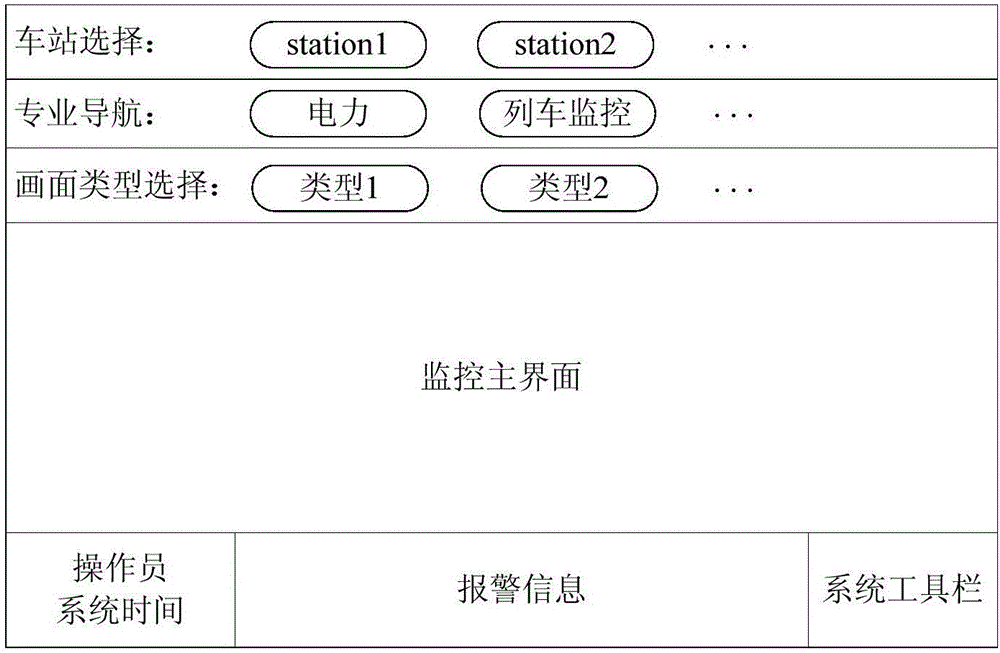

Synthesis monitoring cross-platform configuration human-machine interface system

InactiveCN101510151ATroubleshoot hardware platform issuesRealize resource sharingProgramme controlComputer controlGraphicsUnix

The invention discloses an integrated monitor cross platform configuration human-computer interface system, which comprises a server and a workstation, wherein the server and the workstation are internally provided with operating systems and a human-computer interface system framework; the human-computer interface system framework is characterized by being an MVC architecture and supporting the operating systems of Unix, Linux and Windows; the system also comprises a graphical component module encapsulated with a set of basal graphic objects in an inheritance way; a graphical control module encapsulated with a set of graphic interactive controls; and a script engine system which comprises a script engine module used for parsing the script, driving a script extended function library and dynamically executing the script and a script extension module used for accessing a real time database and a historical data base and judging authority. The integrated monitor cross platform configuration human-computer interface system realizes resource sharing and interconnection requirement, and solves the hardware platform problems of a hybrid platform and a heterogeneous platform of the integrated monitor system.

Owner:NARI TECH CO LTD

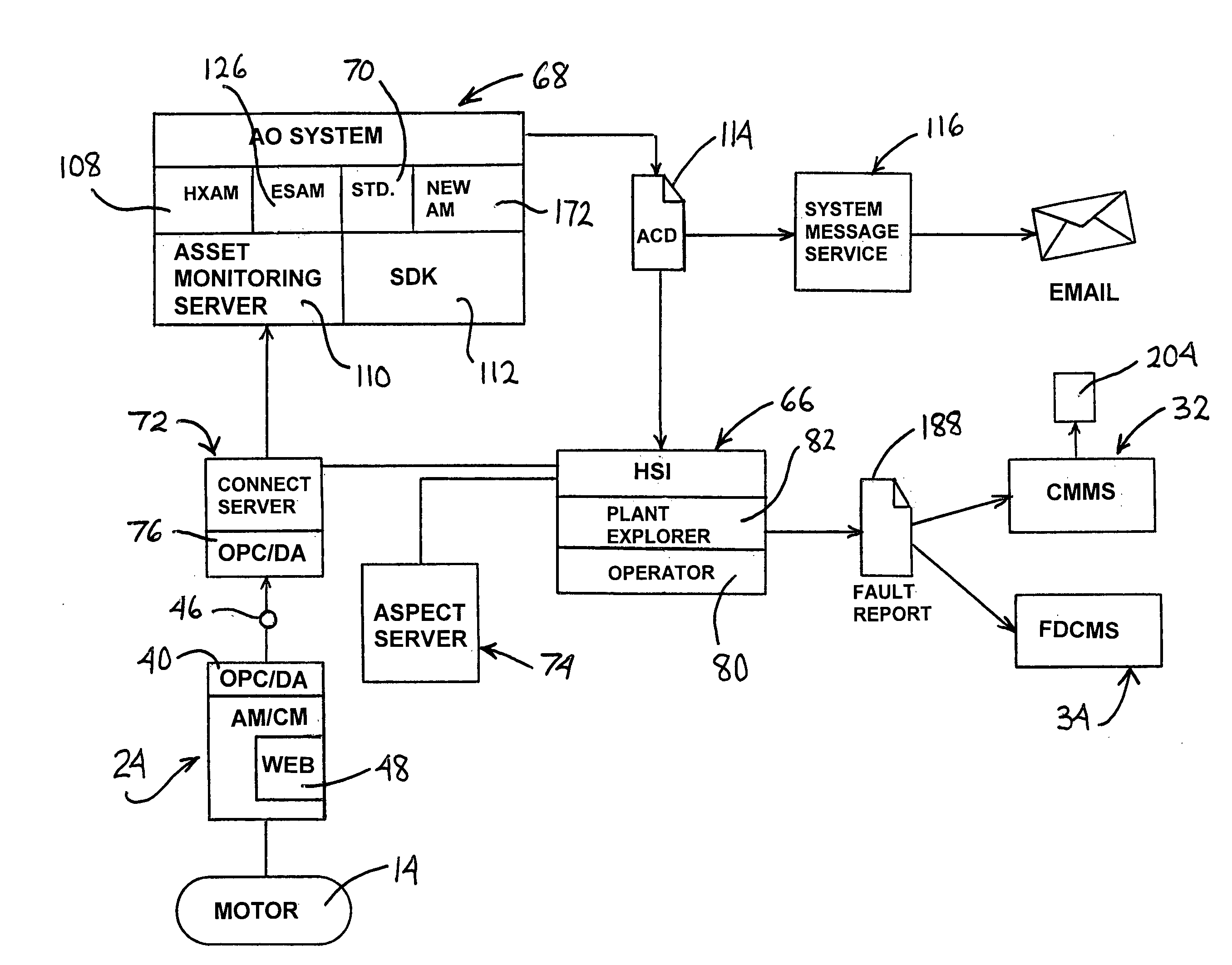

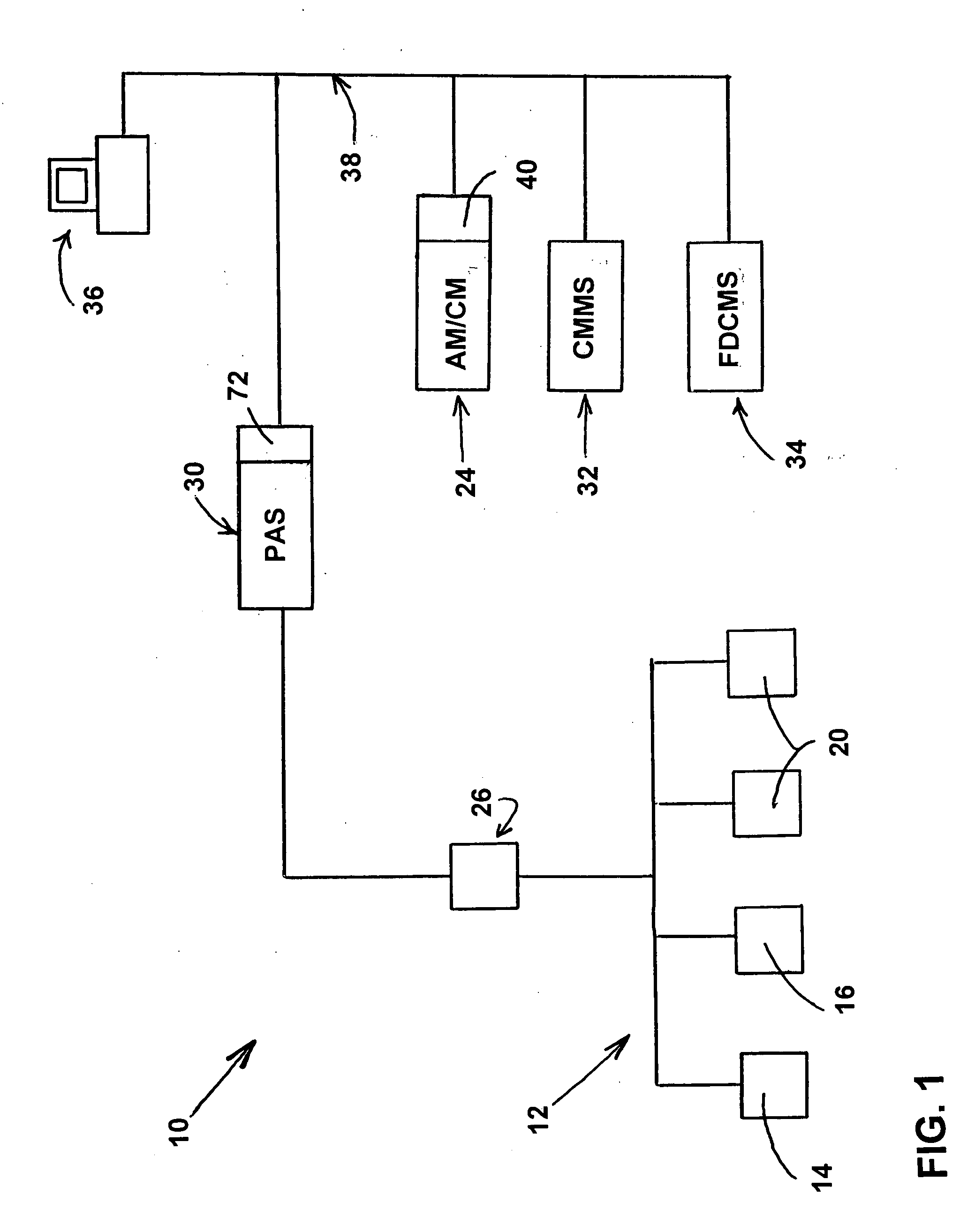

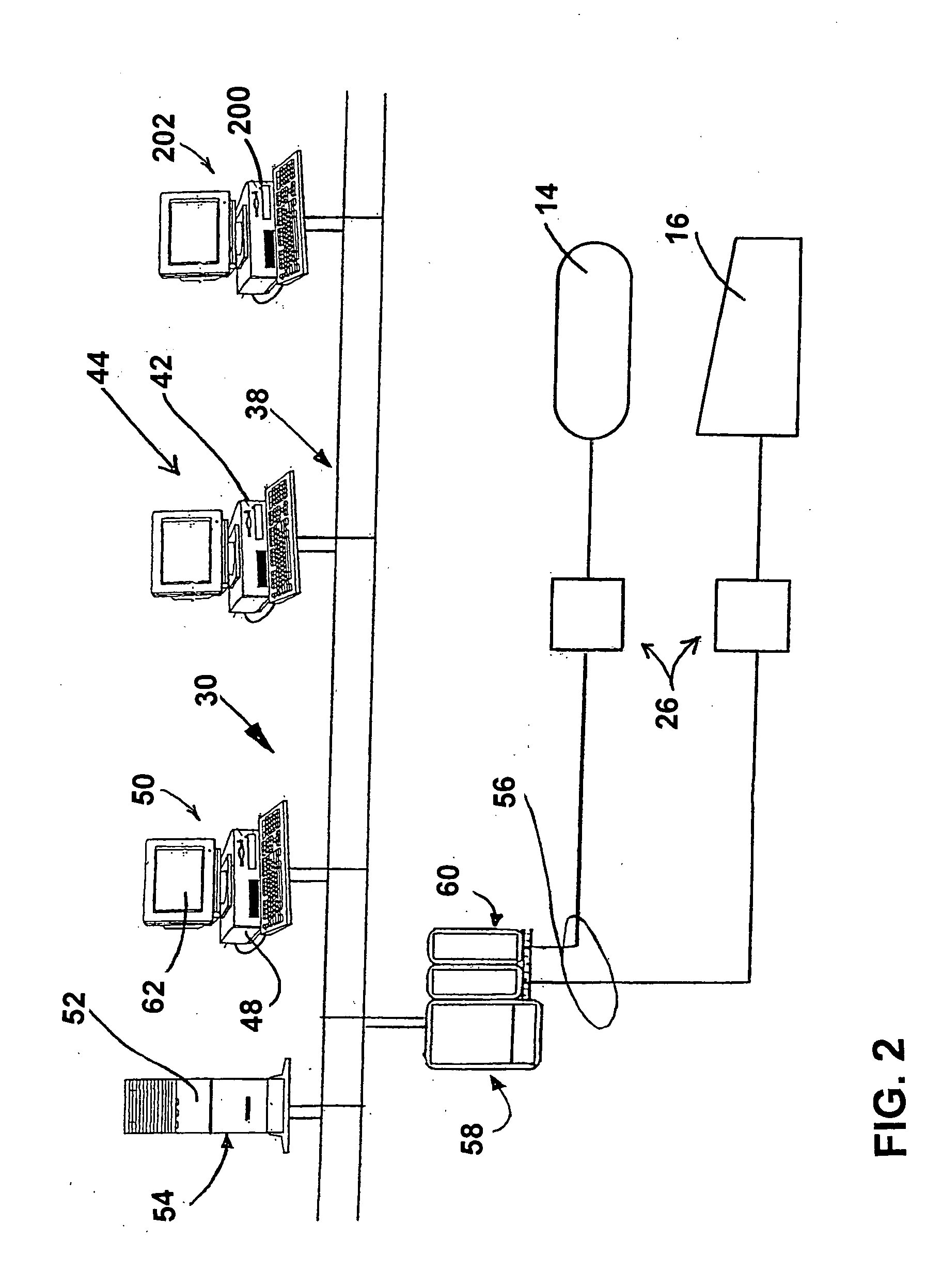

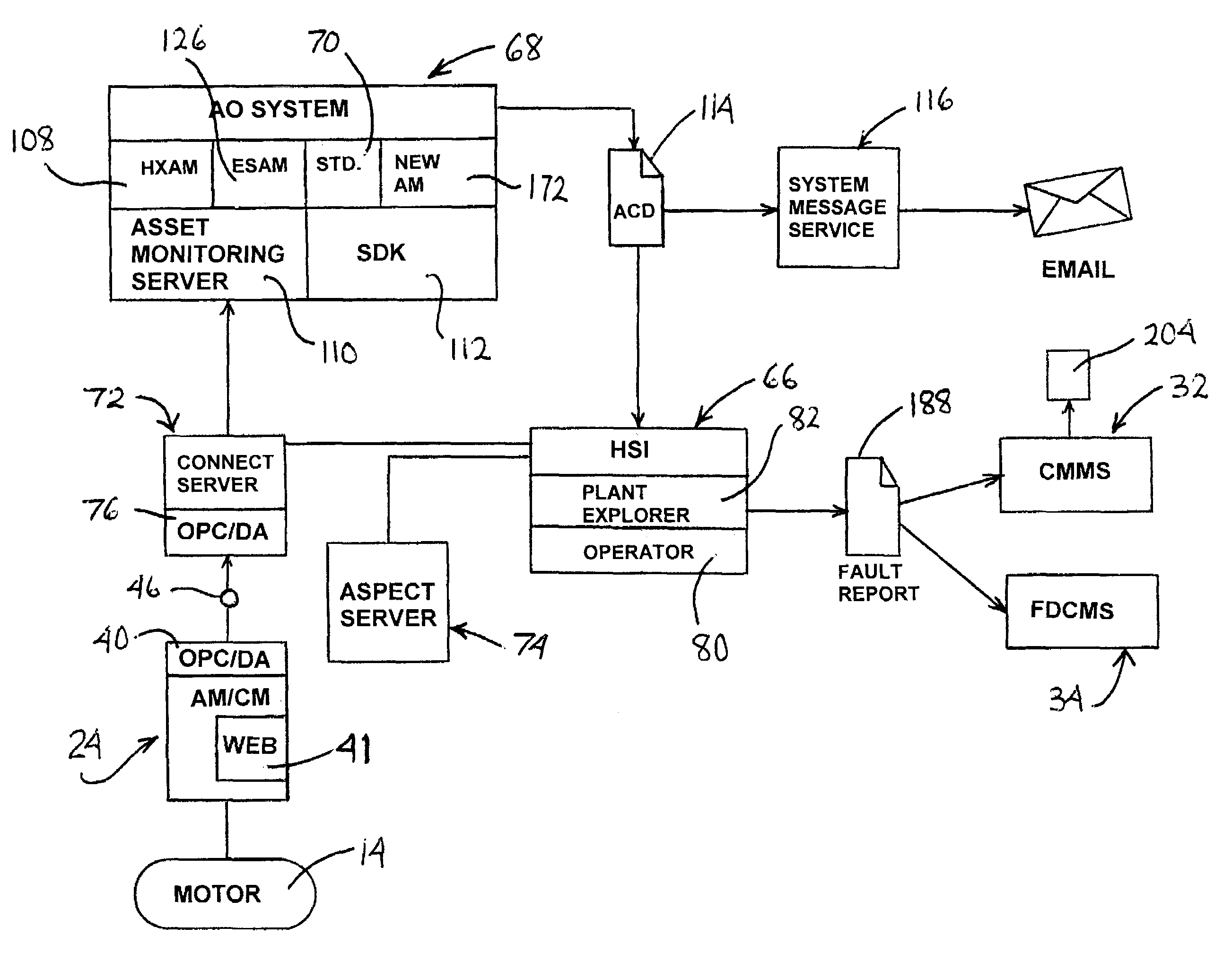

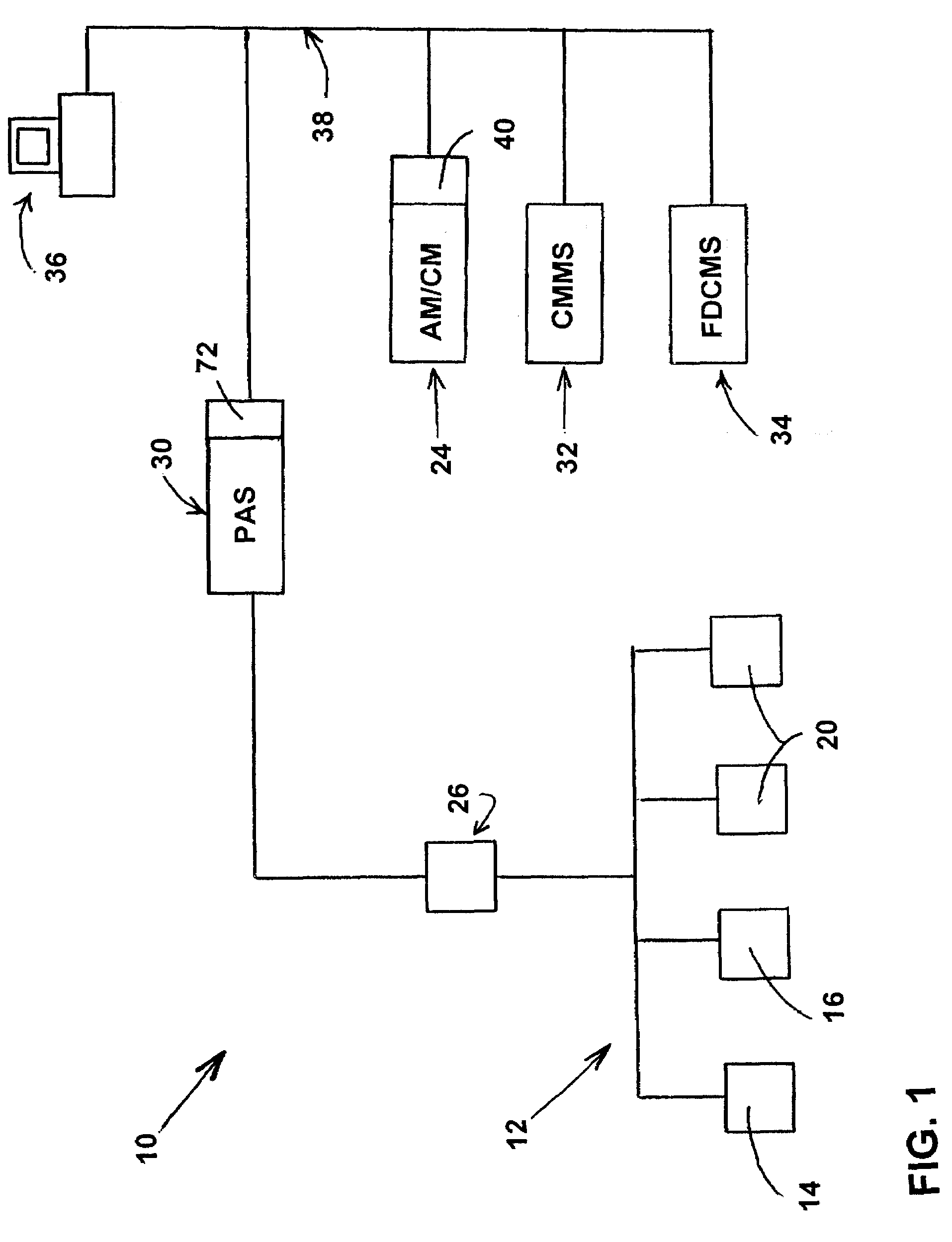

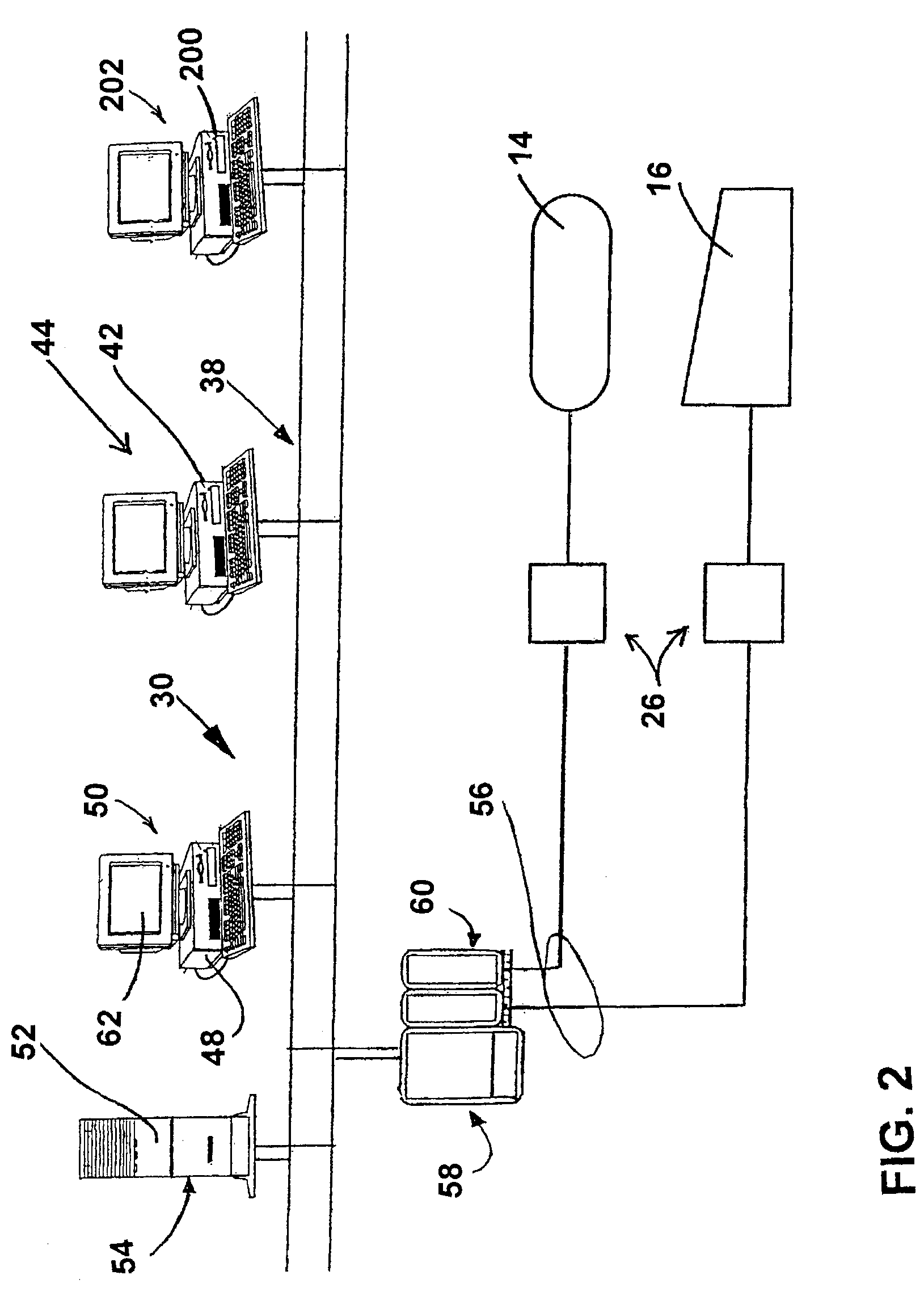

External status asset monitor

The present invention is directed to a system and method of monitoring assets of an enterprise using a stand-alone software system and a process automation software system. The stand-alone software system is operable to generate a web page about a condition of the asset and to transmit data items for the condition in a single data string. The data items include a status of the condition and a URL of the web page. The process automation software system includes a human system interface (HSI) and a generic asset monitor having a changeable condition table. The generic asset monitor may be modified to create a custom asset monitor specific to the asset. The custom asset monitor is operable to monitor the status of the condition and the HSI is operable to display the data items and the web page from the stand-alone software system.

Owner:ABB INC

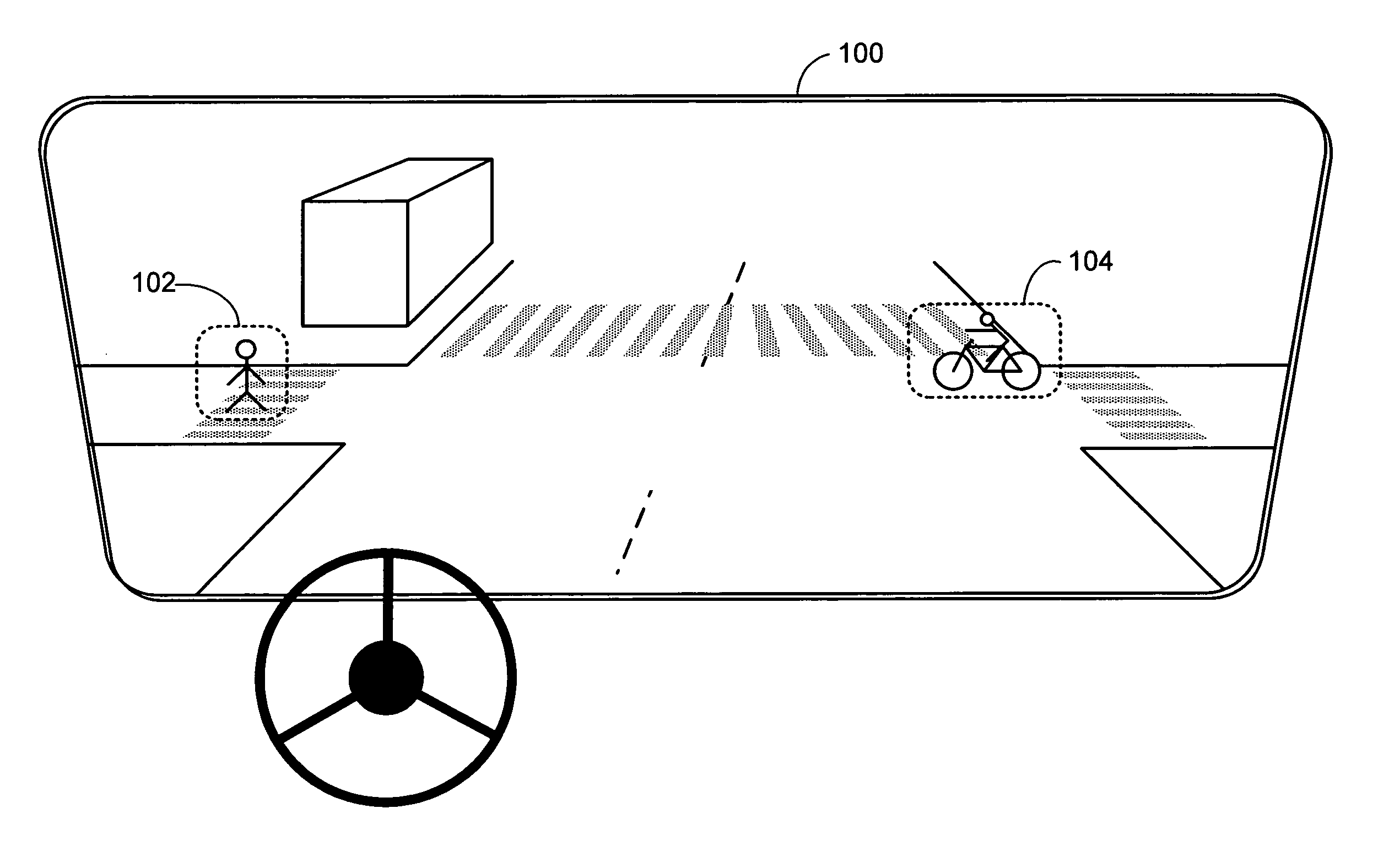

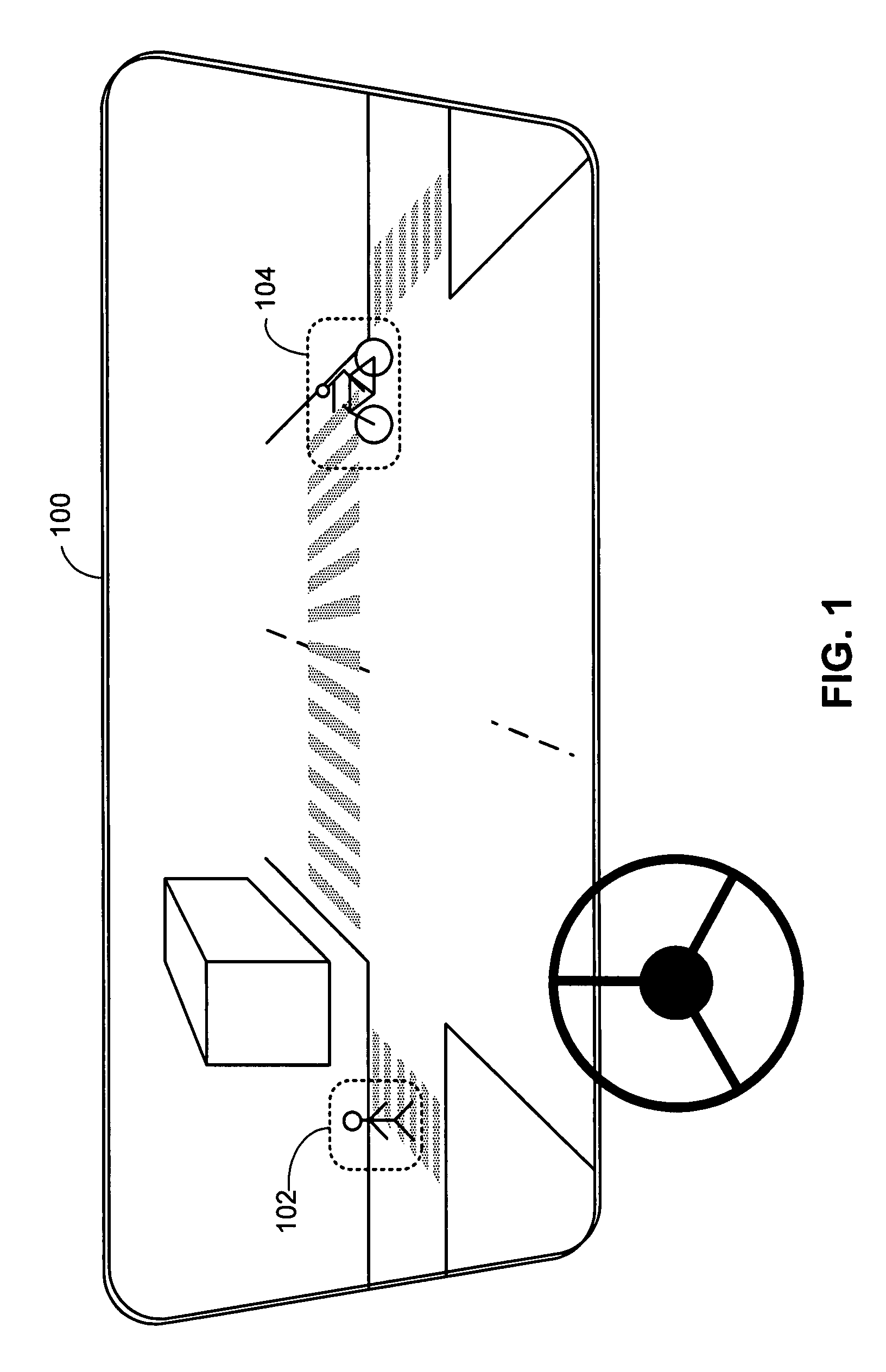

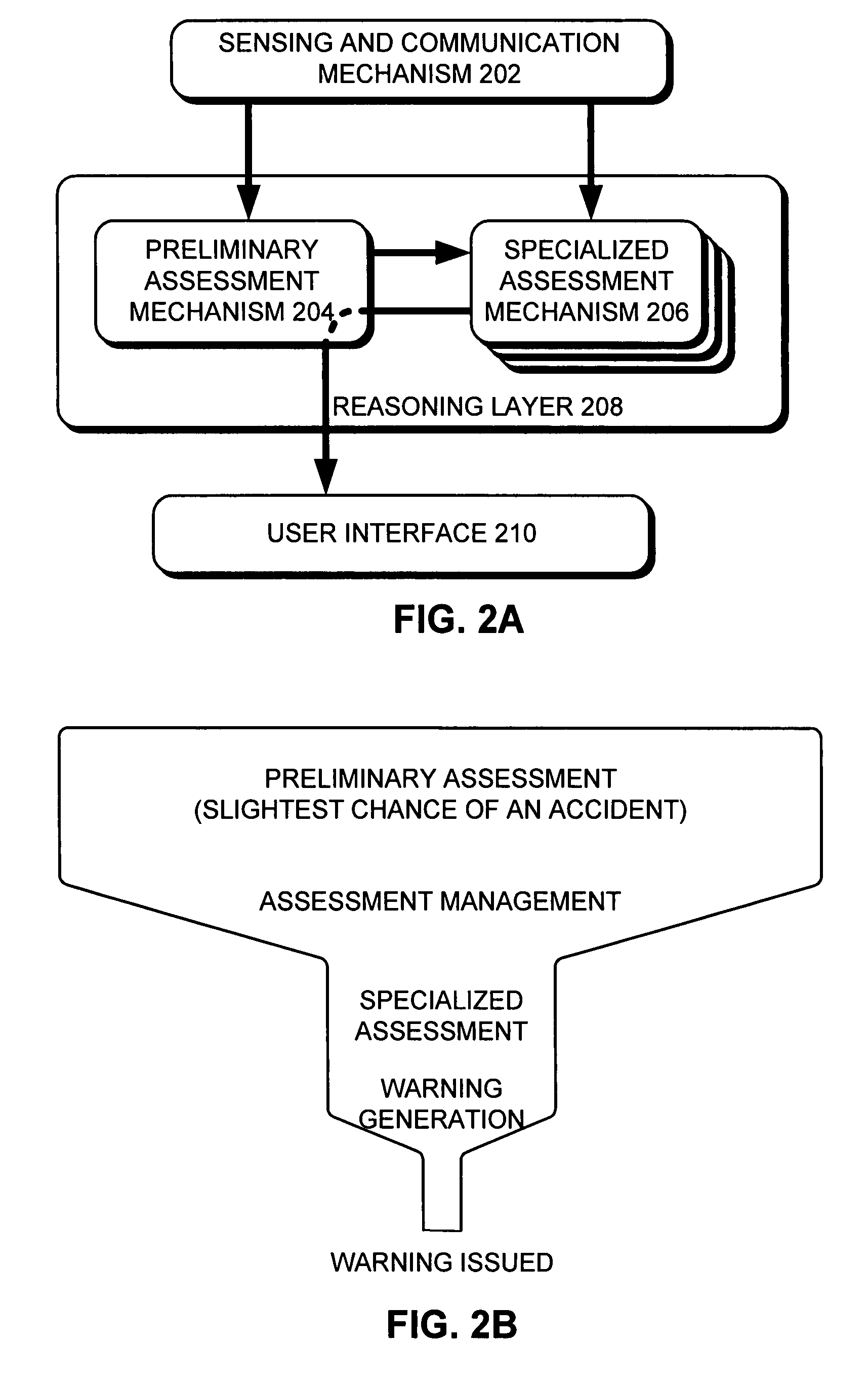

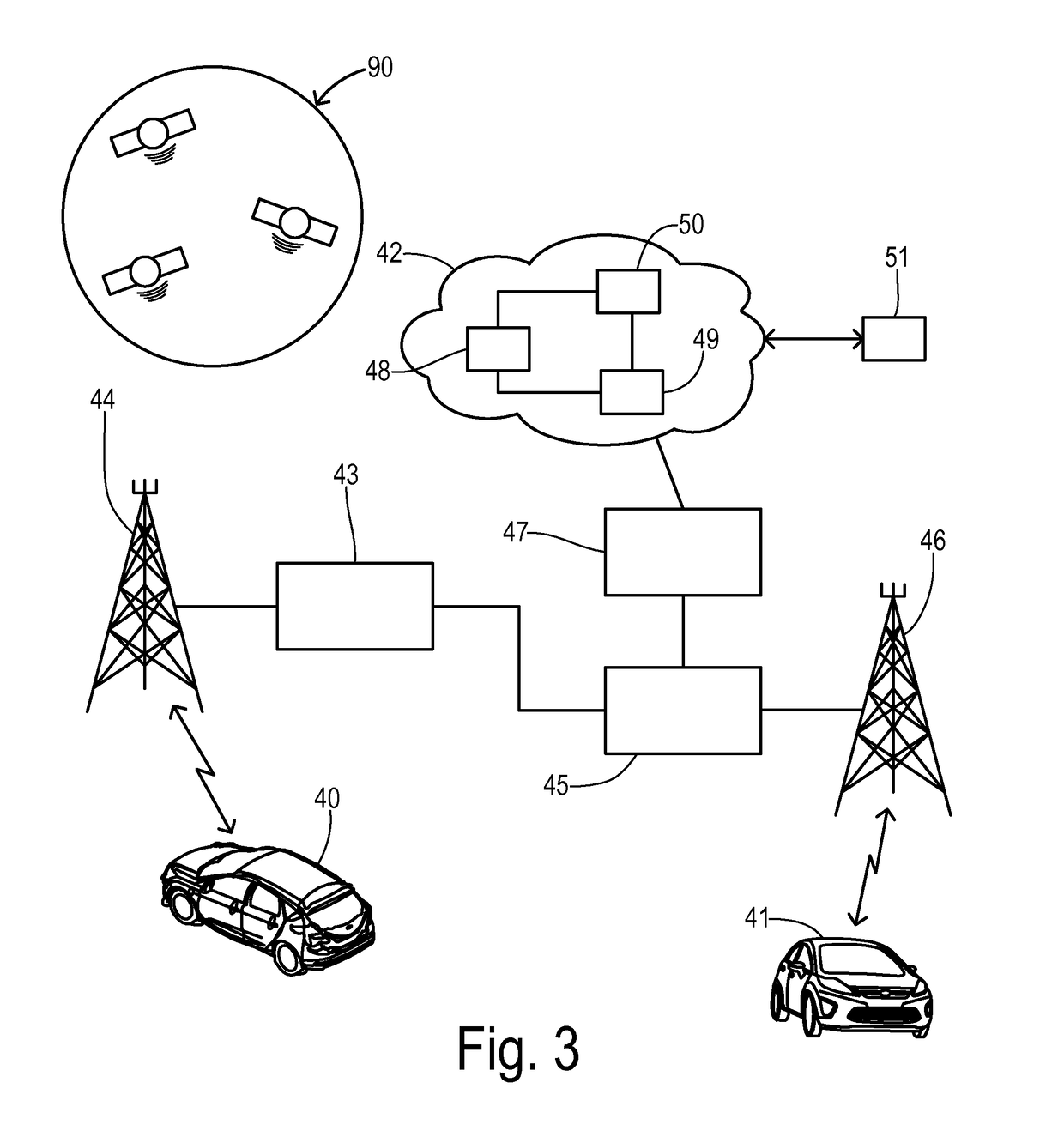

Human-machine-interface (HMI) customization based on collision assessments

ActiveUS7710248B2Facilitates collision warningAnti-collision systemsOptical signallingAlgorithmHuman system interface

One embodiment of the present invention provides a system that facilitates collision warning. During operation, the system receives information on one or more predicted collisions and determines a utility of issuing a warning for a predicted collision based on the received information. The system further schedules one or more warnings for the predicted collisions based on the utilities of issuing the warnings.

Owner:UATC LLC

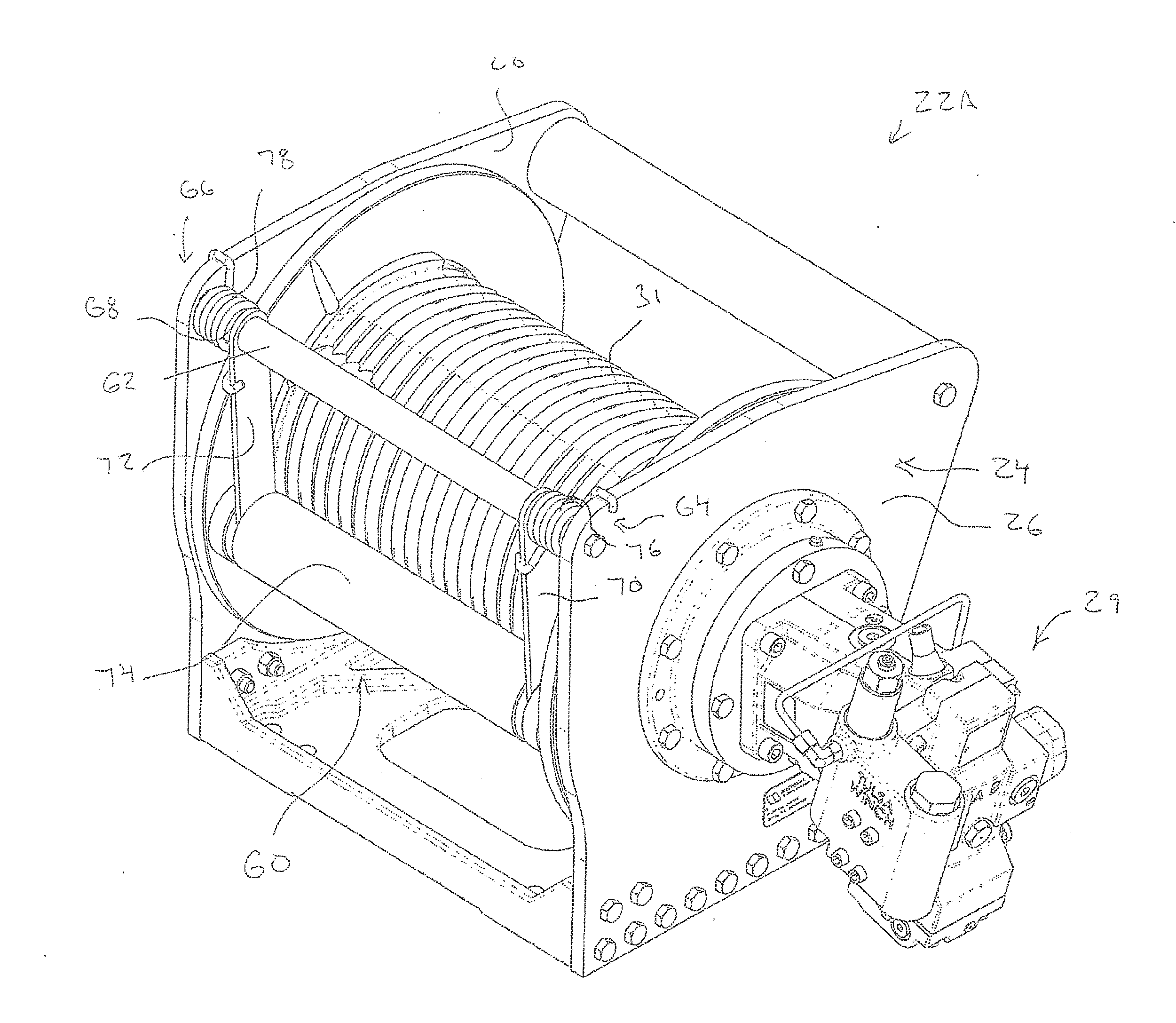

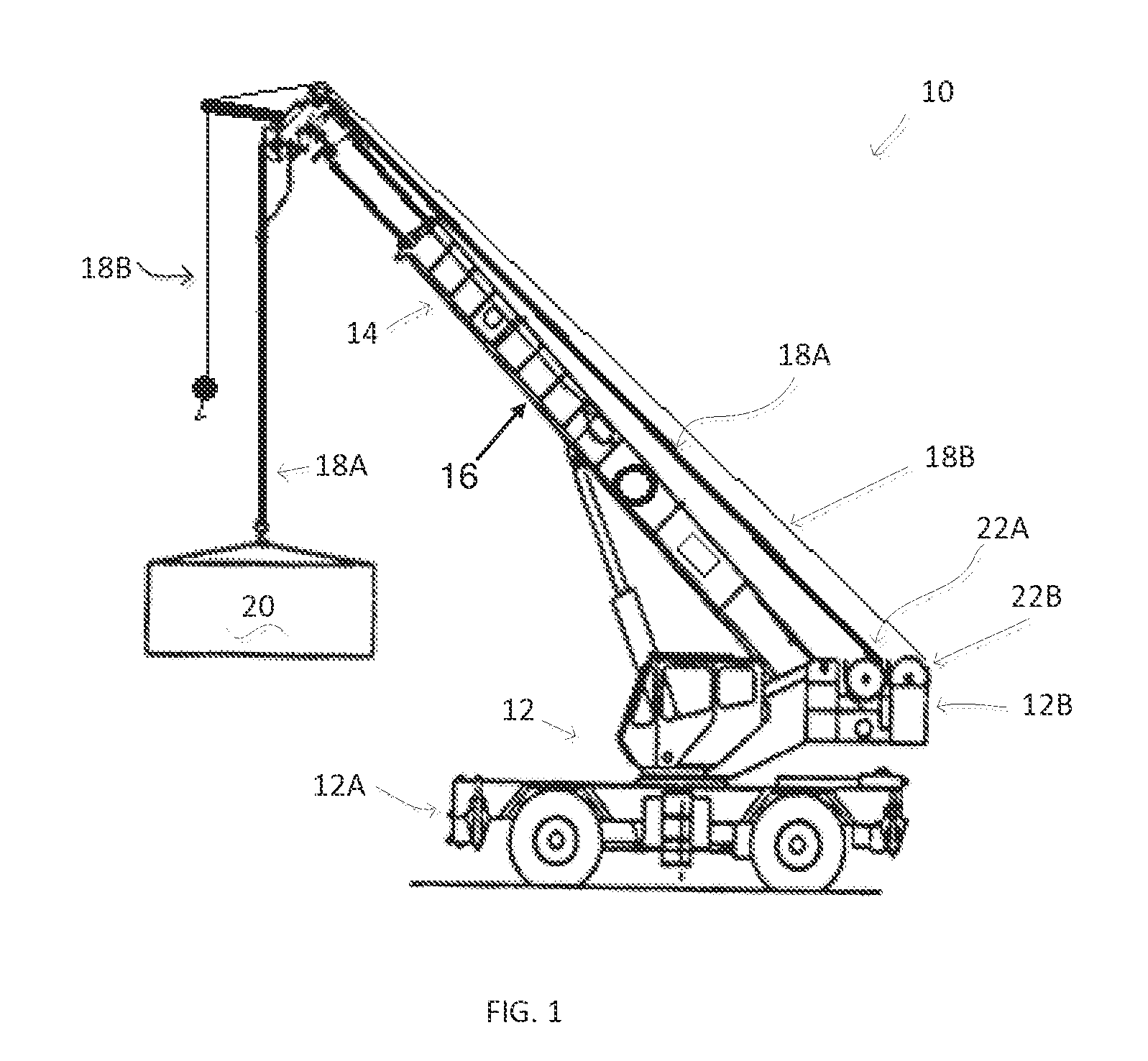

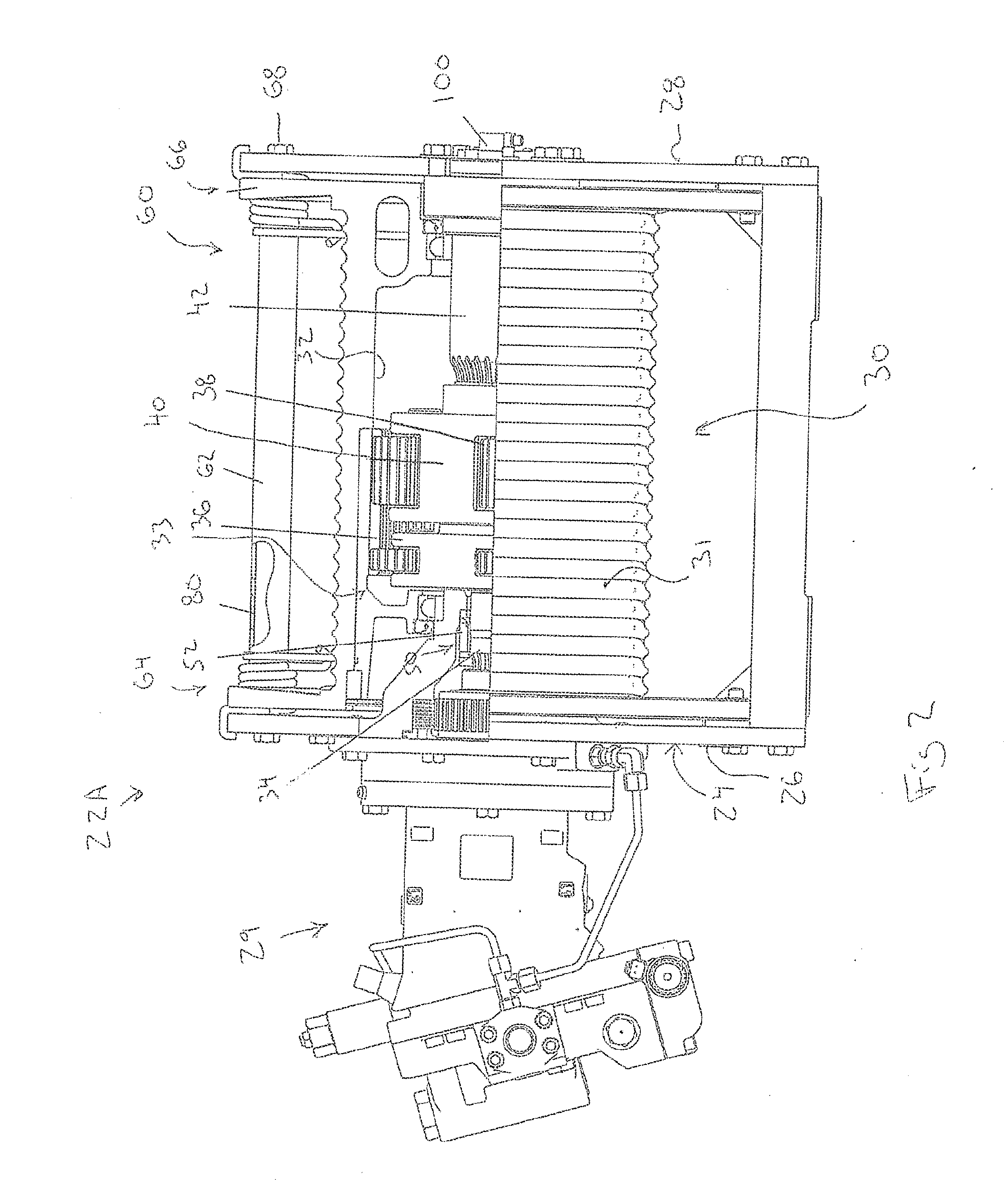

Embedded hoist human-machine interface

ActiveUS20150379783A1Registering/indicating working of machinesWork measurementMechanical engineeringHuman system interface

A cable drum receives a length of working cable that is wound in and out from the drum in response to powered rotation of the drum with an uppermost layer of working cable on the drum forming a working surface. A torque sensor in communication with the cable drum measures a torque applied to the cable drum due to tension on the working cable from a load. A drum height gauge is provided for measuring a height of the working surface of the cable on the cable drum. A processor receives the torque value from the torque sensor and the height of the working surface from the drum height gauge and computes a force applied to the length of working cable due to the load based on the torque and height of the working surface. The work performed by the cable may be calculated to assist in determining cable health.

Owner:TULSA WINCH INC

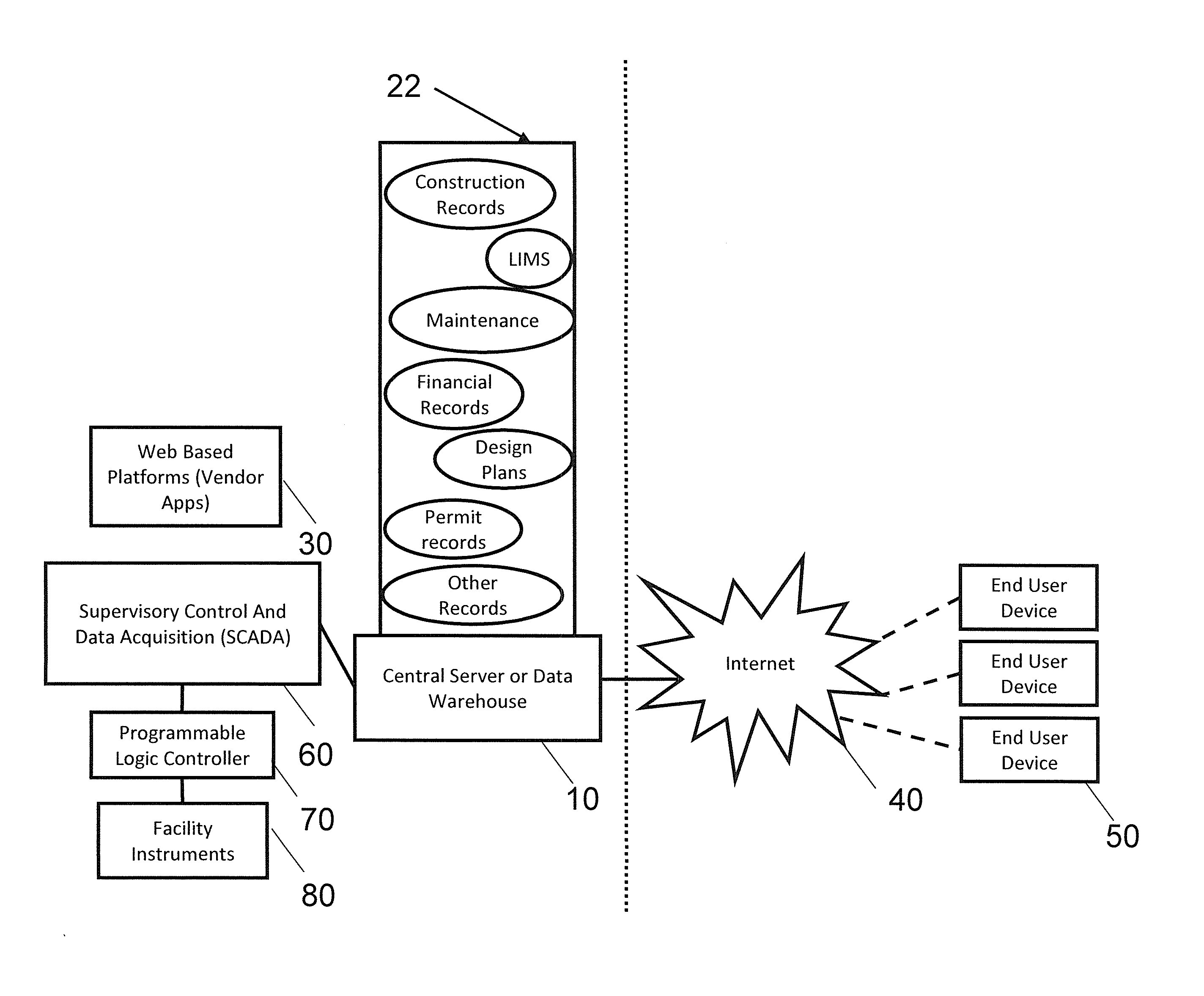

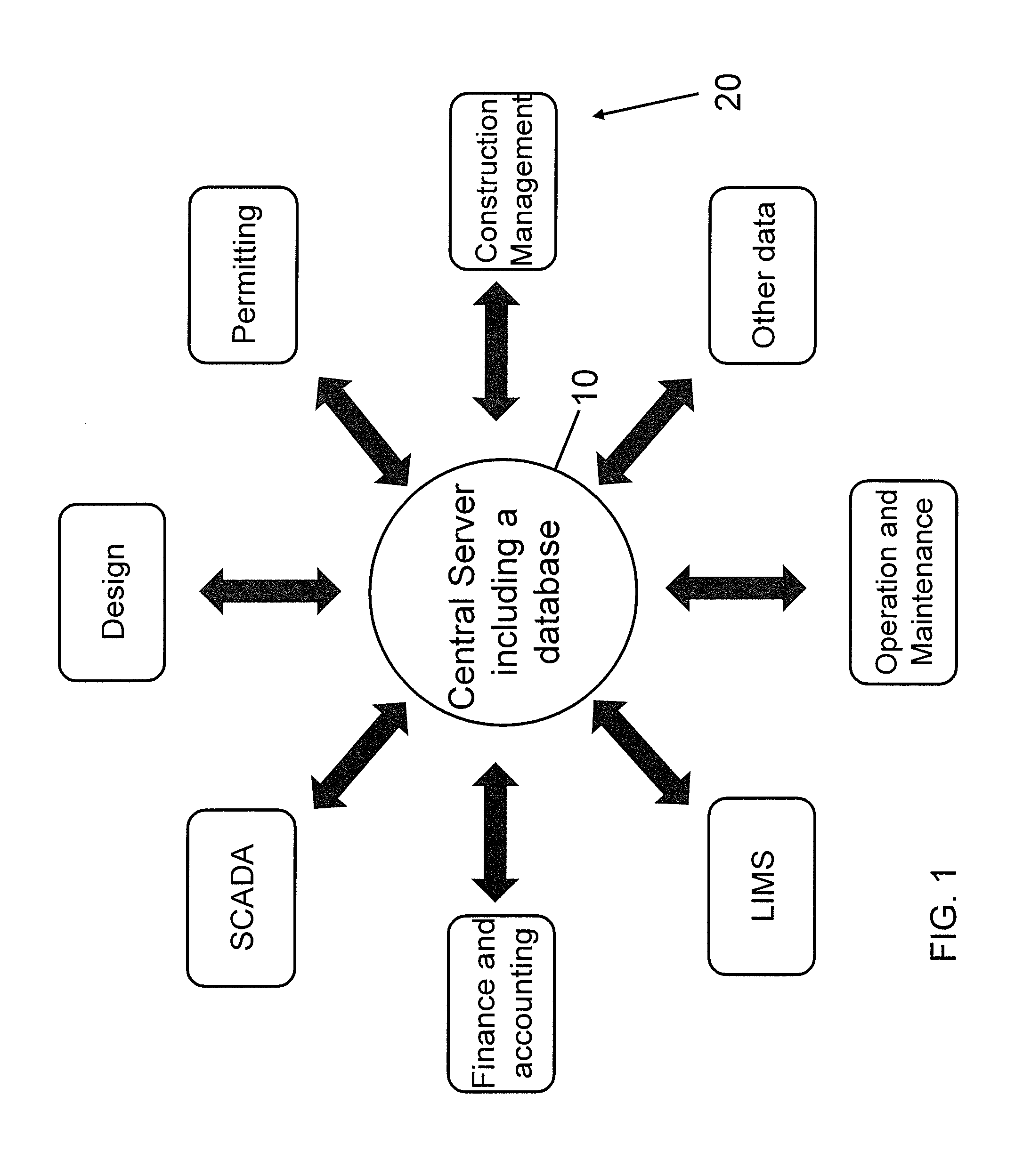

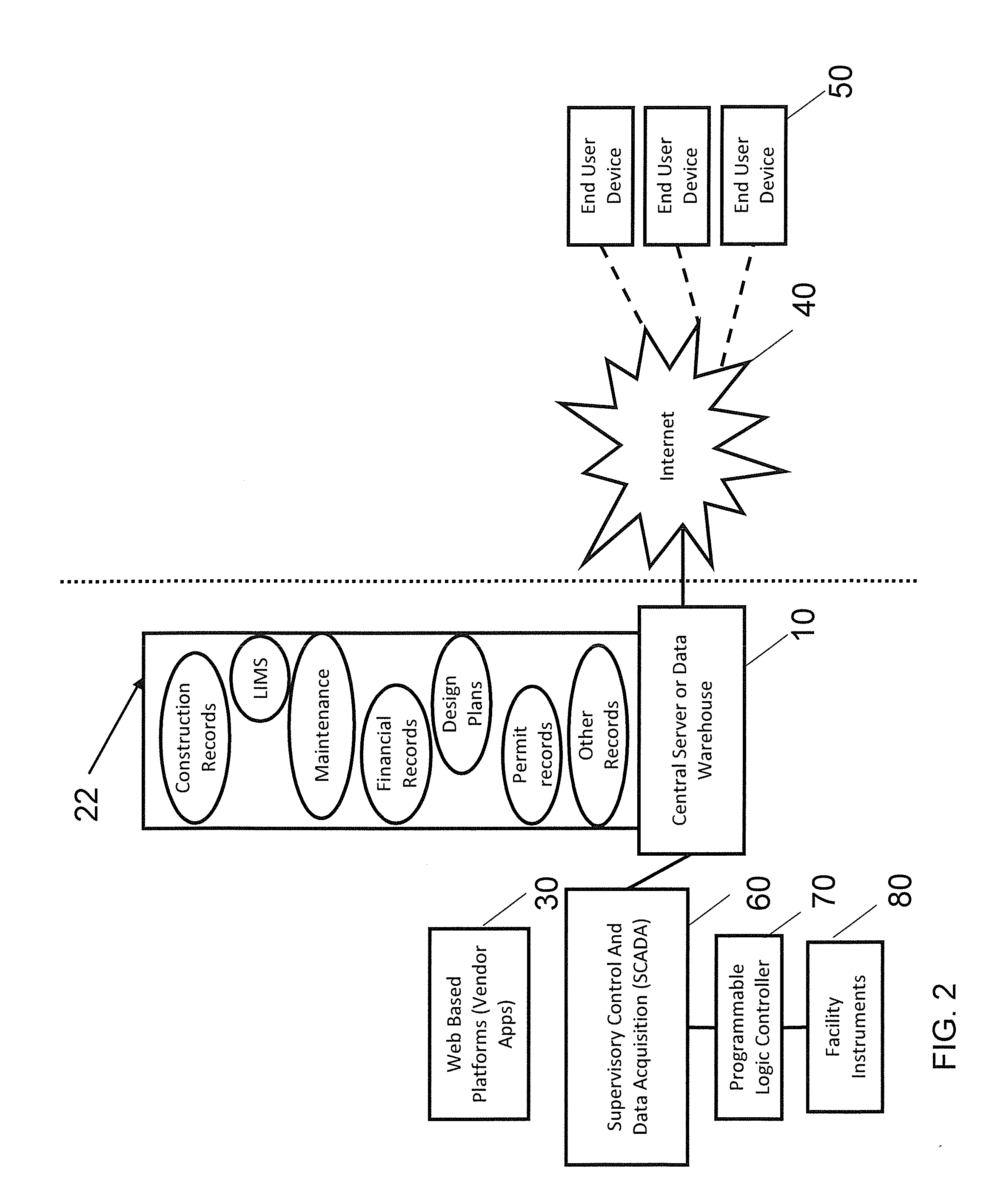

Remote access for water infrastructure management

InactiveUS20130079936A1Programme controlTesting/monitoring control systemsComputer terminalWater infrastructure

A system for remotely monitoring and controlling a plurality of water treatment facilities distributed over a wide area includes: a plurality of interfaces configured to receive status information from the facilities and to transmit commands to control the facilities; a database for storing the status information; and a human machine interface configured to transmit the status information to a remote terminal.

Owner:PERC WATER

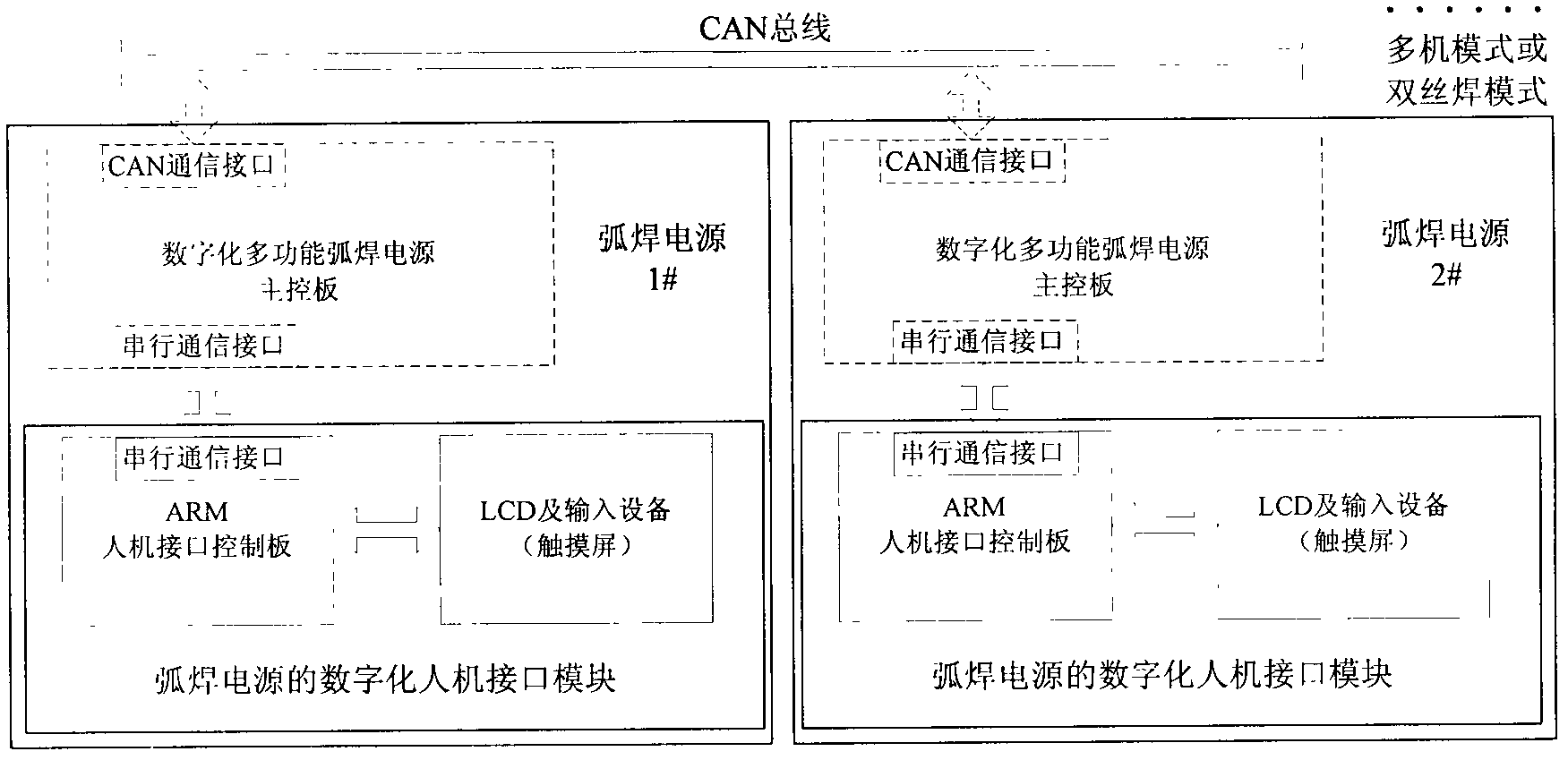

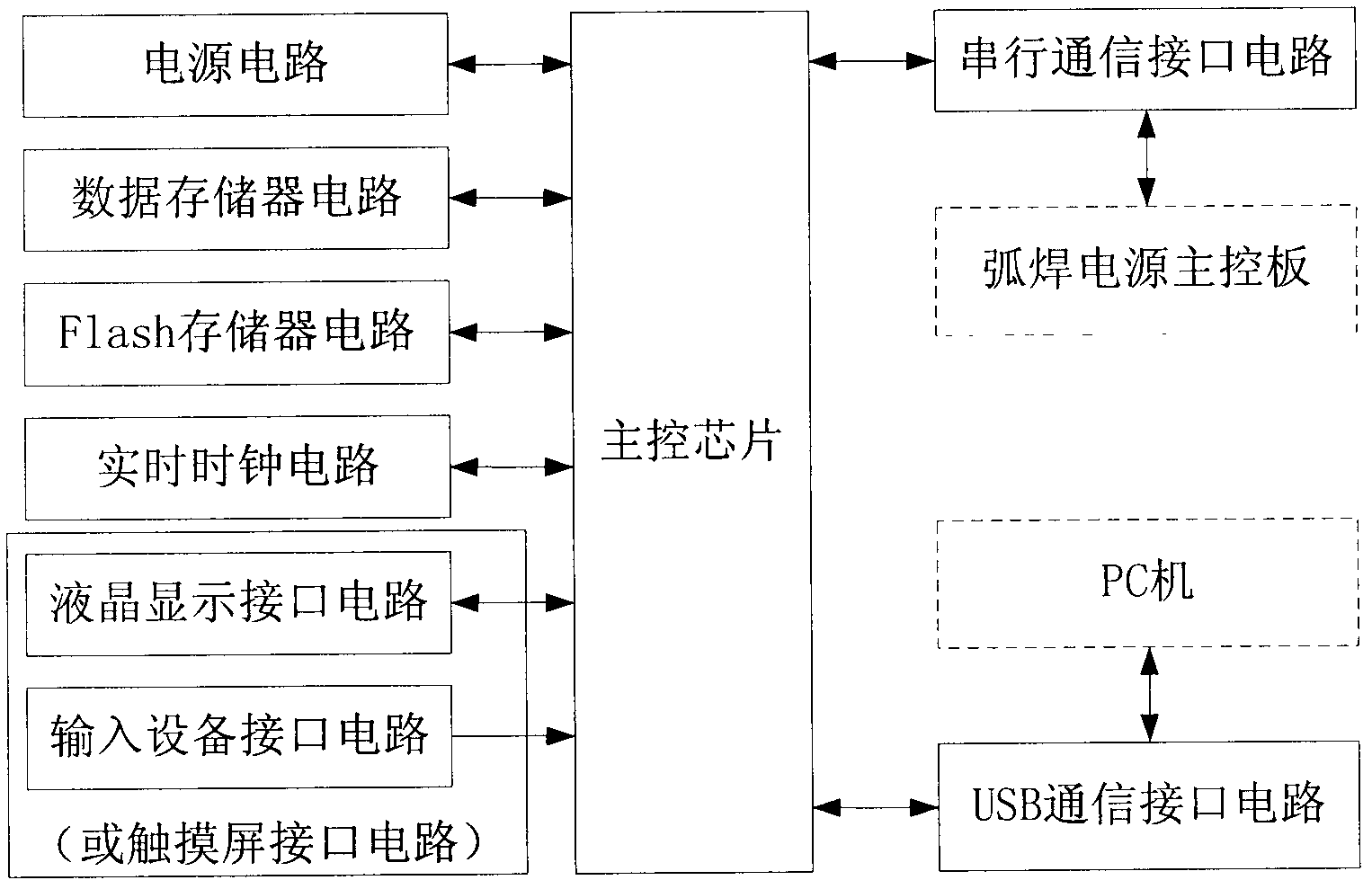

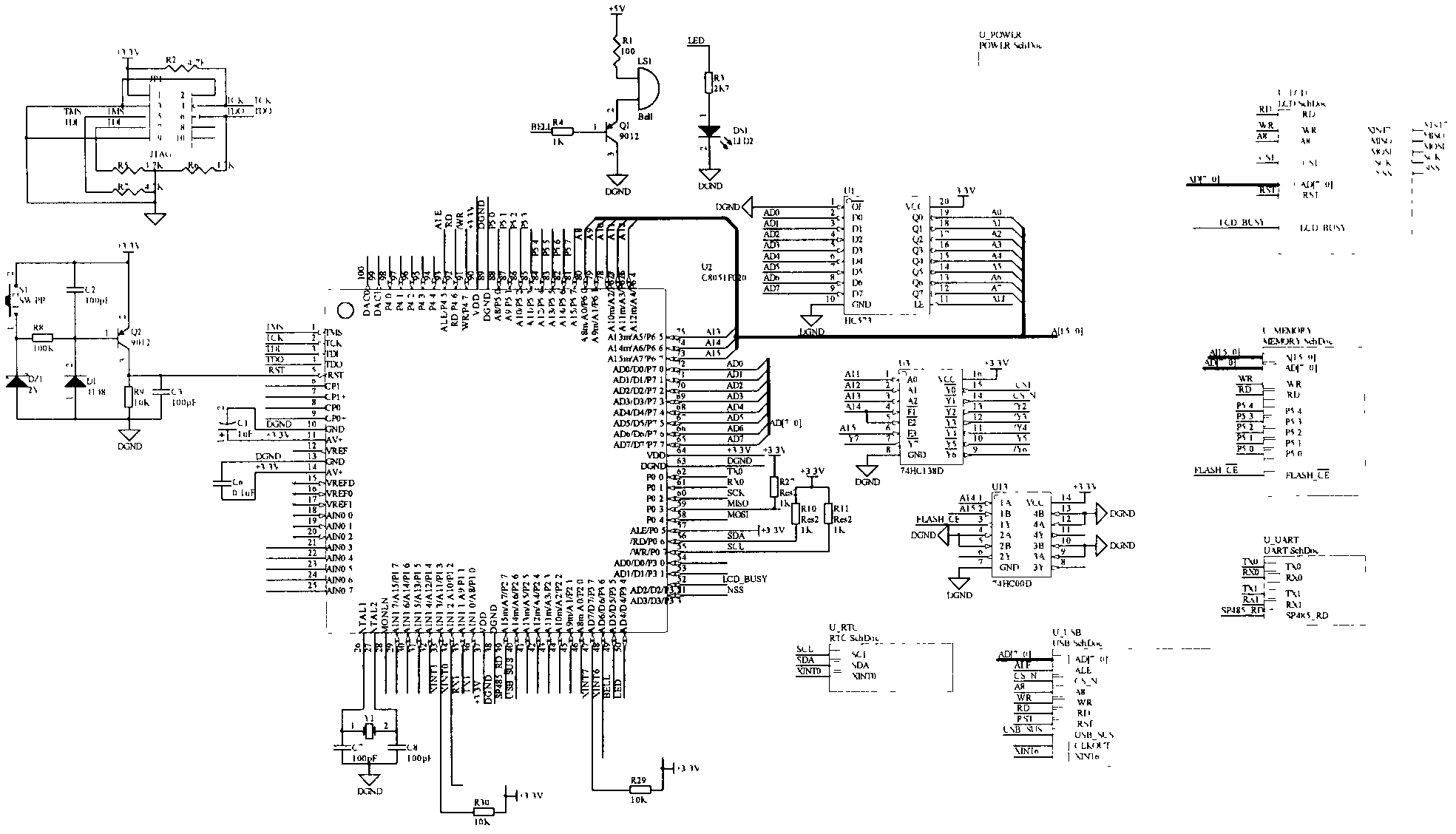

Digitized man-machine interface module of arc welding power source

The invention provides a digitized man-machine interface module of an arc welding power source, which is applied to the field of mechatronics. A hardware circuit is developed based on an embedded controller, adopts a modular design, and mainly comprises a main control chip, a liquid crystal display (LCD) interface circuit, an input equipment interface circuit, a serial communication interface (SCI) circuit, a data storage circuit, a Flash storage circuit, a real-time clock circuit and a universal serial bus (USB) communication interface circuit. The digitized man-machine interface module can be universally suitable for digitized multifunctional arc welding power sources, and carry out serial communication with the master control boards of the arc welding power sources, thus realizing multiple purposes with one machine; the digitized man-machine interface module ensures the response speed of a system; and meanwhile, a database is provided with revisability and extendibility, thus providing knowledge bases and man-machine interface support for a follow-up welding expert system.

Owner:AUTOMATIC ENG RES & MFG CENT GUANGDONG SCI ACAD

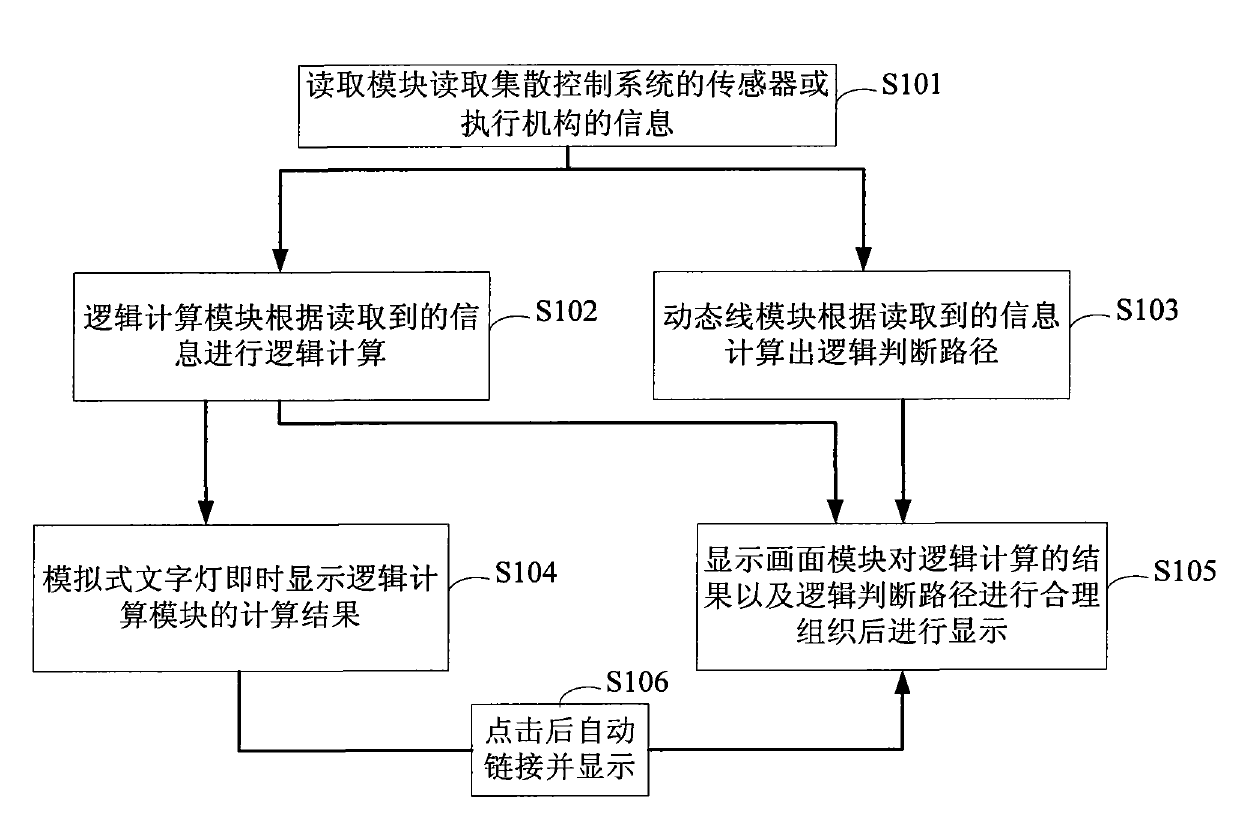

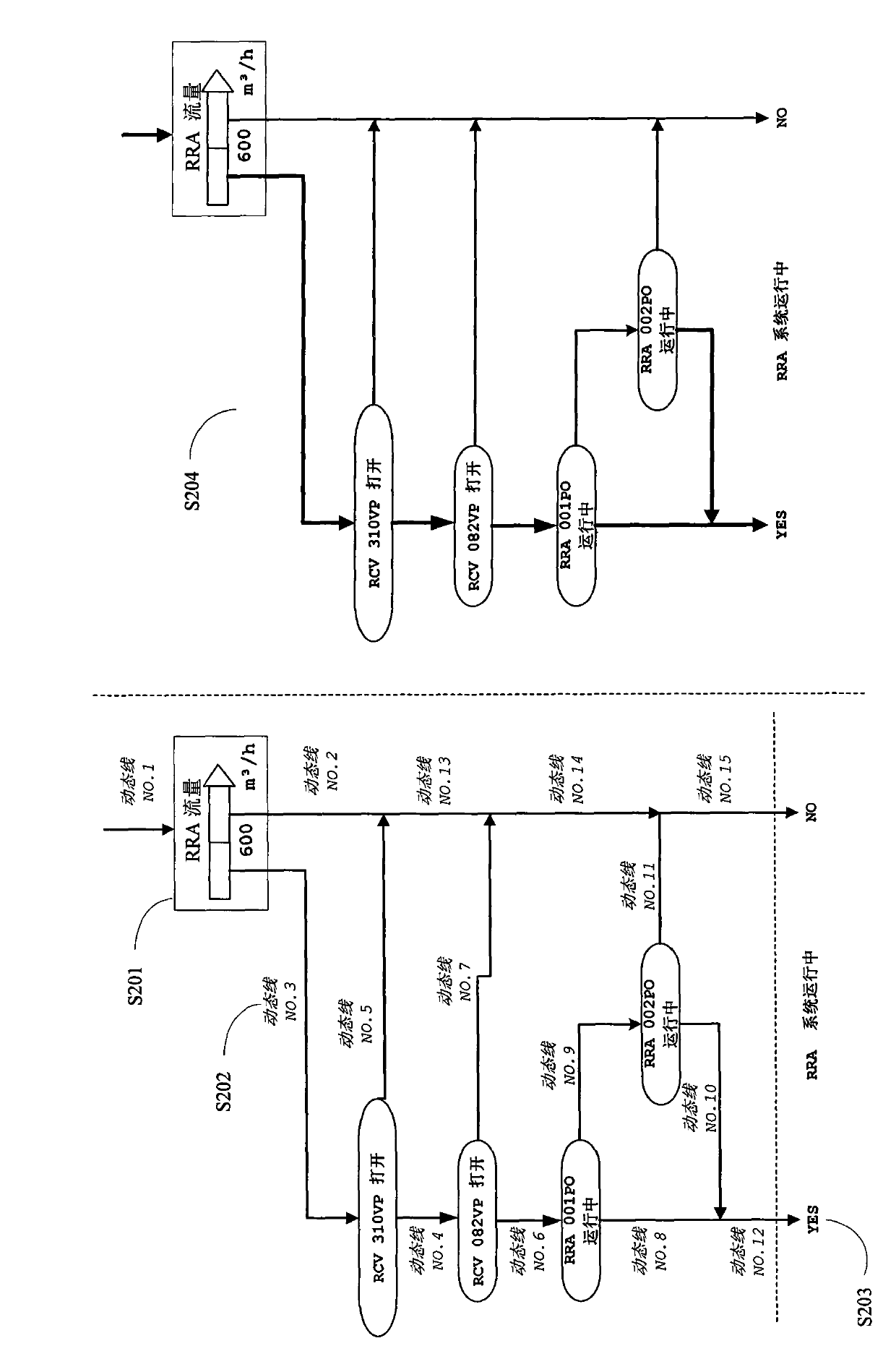

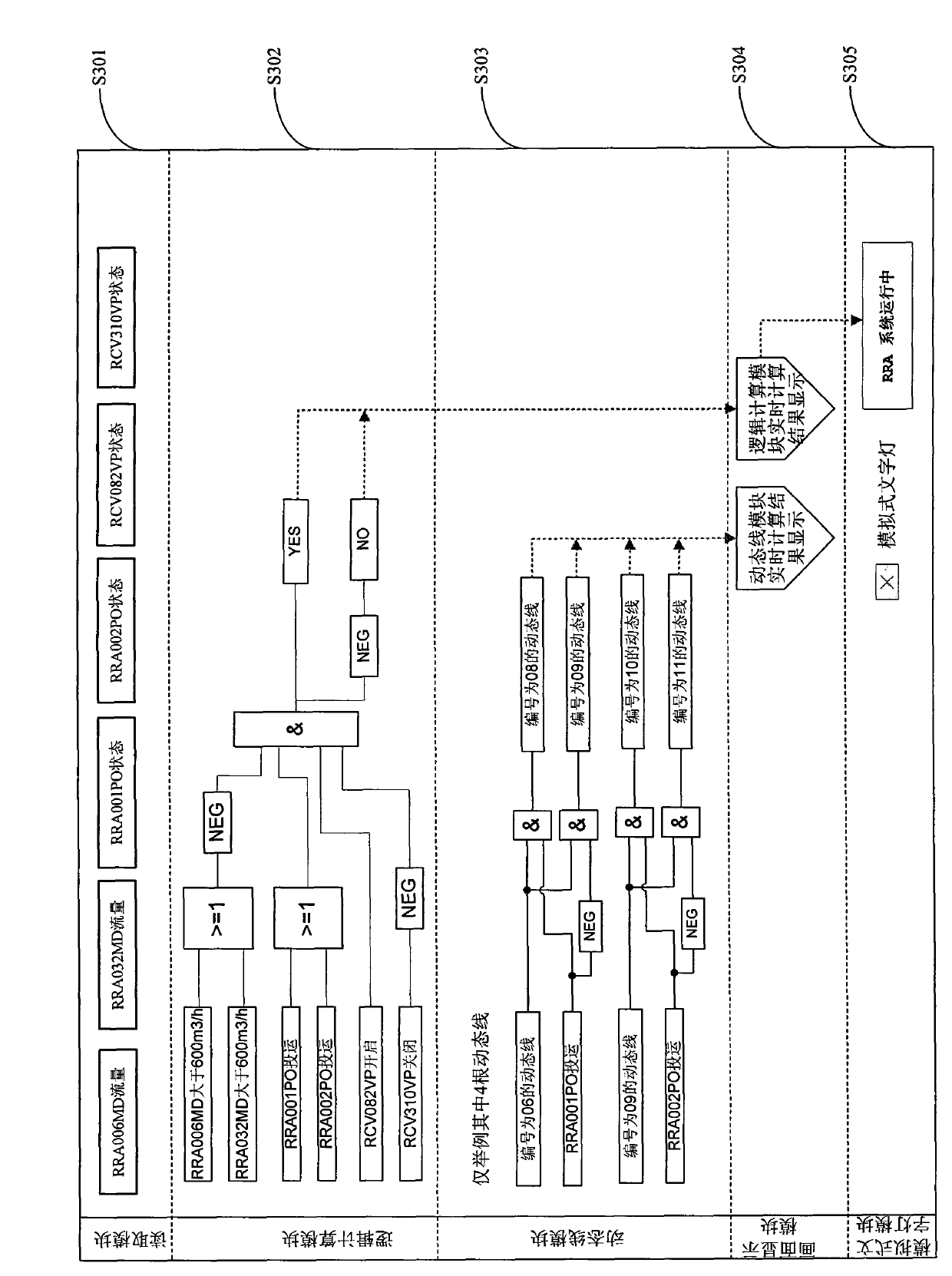

Method and system for computing and displaying under computerization accident condition in nuclear power plant

ActiveCN101770826AEasy to handleGuaranteed uptimePower plant safety arrangementNuclear energy generationPower stationRelevant information

The invention relates to a method and a system for computing and displaying under the computerization accident condition in a nuclear power plant, wherein the method comprises the following steps: S1, a reading module reads the information of a sensor or an actuating mechanism of a distributed control system; S2, a logic computation module logically computes according to the read information; S3,a dynamic line module works out a logical decision path according to the read information; and S4, a display frame module reasonably organizes the logical calculated result and the logical decision path so as to be displayed. By logically computing a great deal of related information under a complicated condition, the invention provides accurate conclusion and detailed computational process for operators, utilizes the advantages of the computer control technology and the human-machine interface of an advanced master-control room to the maximum extent, and greatly improves the analysis and judging ability of the operators on complicated conditions under the accident condition; and meanwhile, the work load and the psychological pressure of the operators are relieved, and thereby the accident handling capacity and the safe operation level of the power station are improved.

Owner:中广核工程有限公司 +1

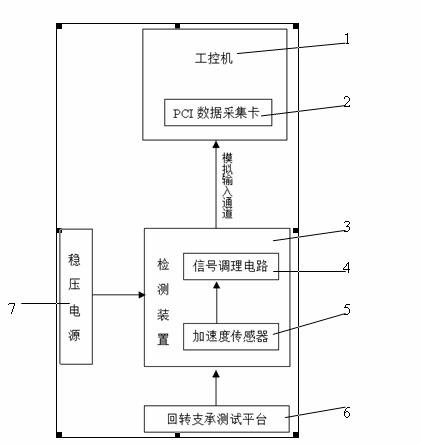

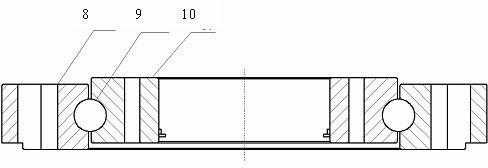

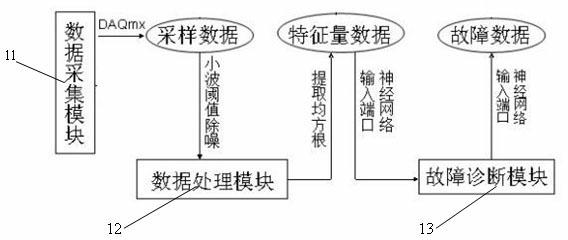

Device for monitoring state of rotary bearing and diagnosing fault based on laboratory virtual instrument engineering workbench (Lab VIEW)

InactiveCN102183951AImprove reliabilityFriendly man-machine interfaceElectric testing/monitoringEngineeringProcedural approach

The invention relates to a device for monitoring the state of a rotary bearing and diagnosing a fault based on a laboratory virtual instrument engineering workbench (Lab VIEW). The device comprises an industrial personal computer, a detection device, a stabilized-voltage supply, a data acquisition module, a data processing module and a fault diagnosis module; the industrial personal computer is provided with a programmable communication interface (PCI) data acquisition card including a simulated input channel; the detection device is provided with an acceleration transducer and a signal conditioning circuit; the signal conditioning circuit is used for amplifying and filtering signals picked up by the acceleration transducer and the like; the data acquisition module is used for inputting acquired signals into the industrial personal computer by a program, editing a data acquisition (DAQmx) driving program in the Lab VIEW, controlling sampling frequencies of the signals, inputting and outputting and the like; the data processing module comprises denoising display, storage and characteristic extraction of the signals, and is used for removing the interference of noise, extracting time-domain and frequency-domain characteristic quantity of the signals and preparing for fault diagnosis; the fault diagnosis module is used for obtaining fault information according to extracted characteristic data of the rotary bearing, outputting a diagnosis result and processing suggestions. The device has the advantages of simple structure, high openness, good real-time performance, friendly human-computer interface, no need of diagnostician participation and higher reliability, and can be used for automatically identifying the fault of the rotary bearing.

Owner:TONGJI UNIV

External status asset monitor

The present invention is directed to a system and method of monitoring assets of an enterprise using a stand-alone software system and a process automation software system. The stand-alone software system is operable to generate a web page about a condition of the asset and to transmit data items for the condition in a single data string. The data items include a status of the condition and a URL of the web page. The process automation software system includes a human system interface (HSI) and a generic asset monitor having a changeable condition table. The generic asset monitor may be modified to create a custom asset monitor specific to the asset. The custom asset monitor is operable to monitor the status of the condition and the HSI is operable to display the data items and the web page from the stand-alone software system.

Owner:ABB INC

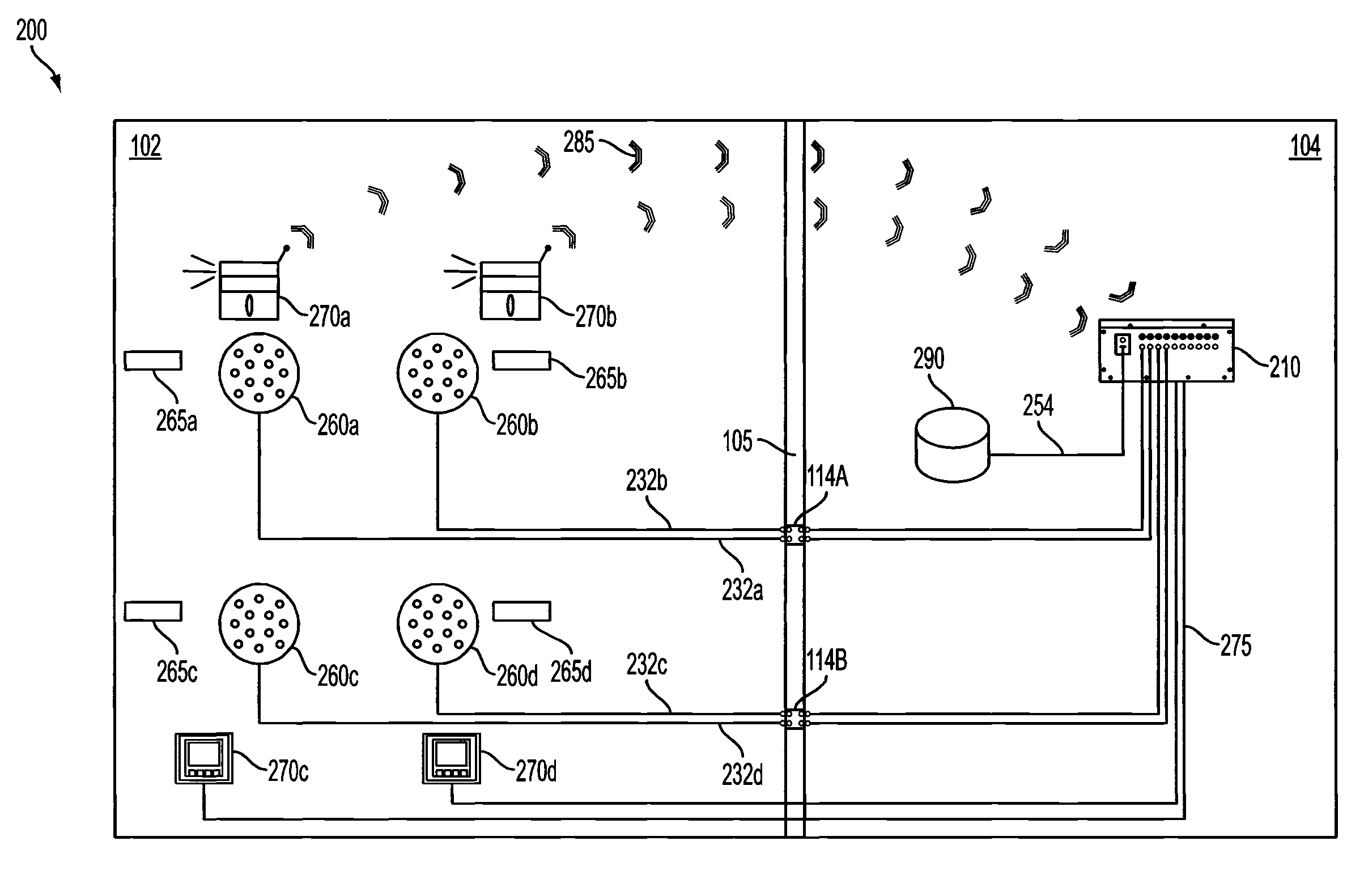

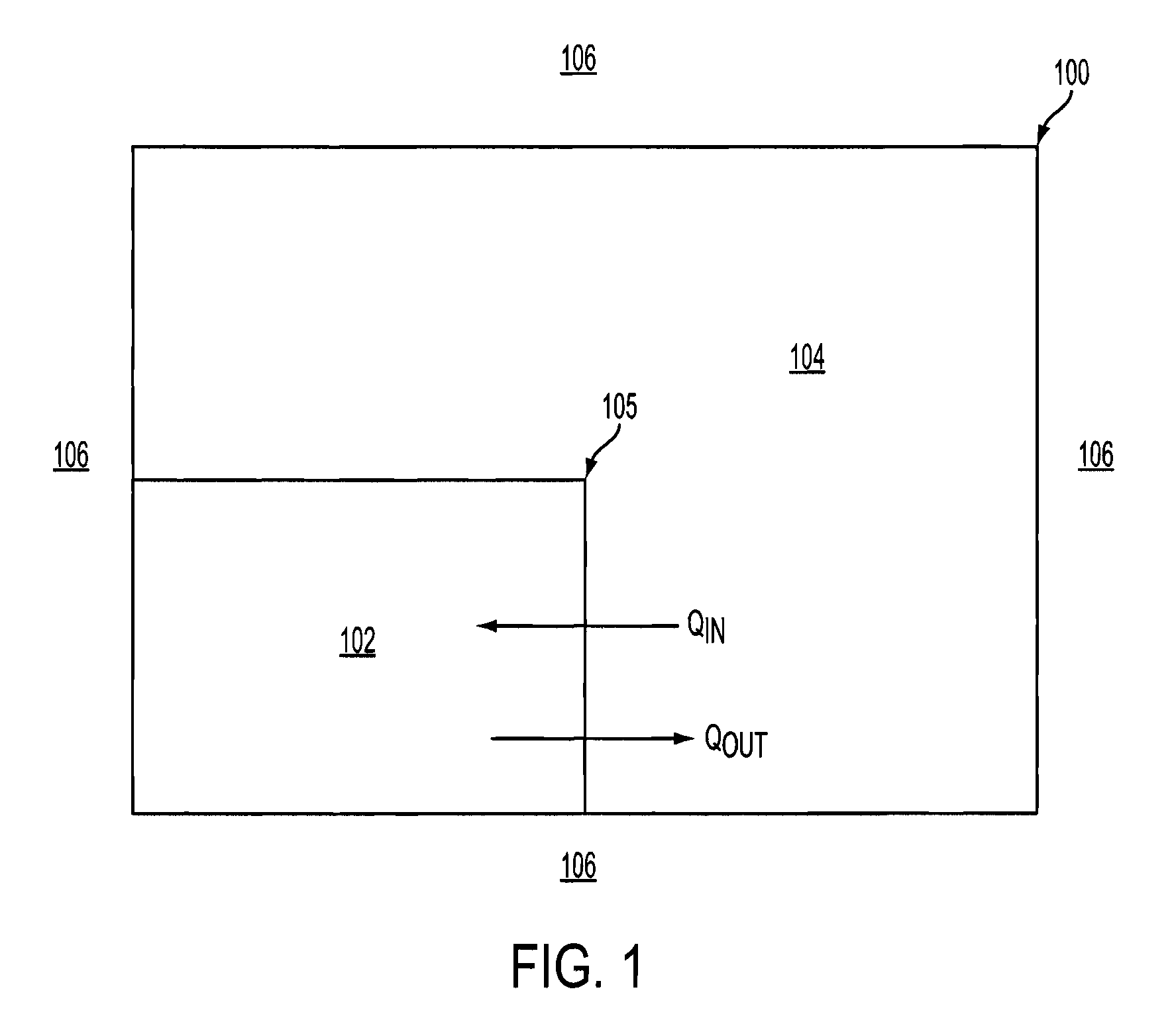

Programmable logic controller-based control center and user interface for air sampling in controlled environments

ActiveUS9285792B2Simple configurationIncrease flexibilityMeasurement of fluid loss/gain rateSamplingProgrammable logic controllerDisplay device

In accordance with an aspect of the present invention there is provided a system for sampling air at multiple locations in a controlled environment. The system includes one or more air sampling devices configured to monitor and test a volume of air within a controlled environment. A control center including a programmable logic controller (PLC) is configured to monitor and control the one or more air sampling devices. One or more touch panel displays are connected to the control center and provide a human-computer interface between the control center and users.

Owner:VALTEK ASSOC INC

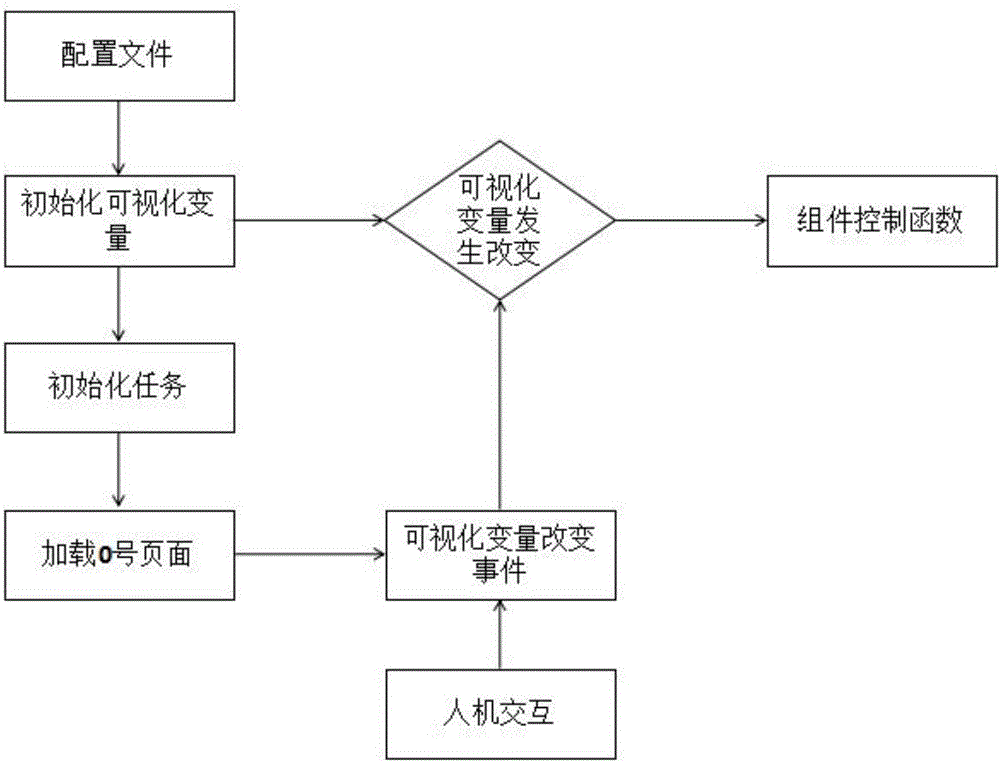

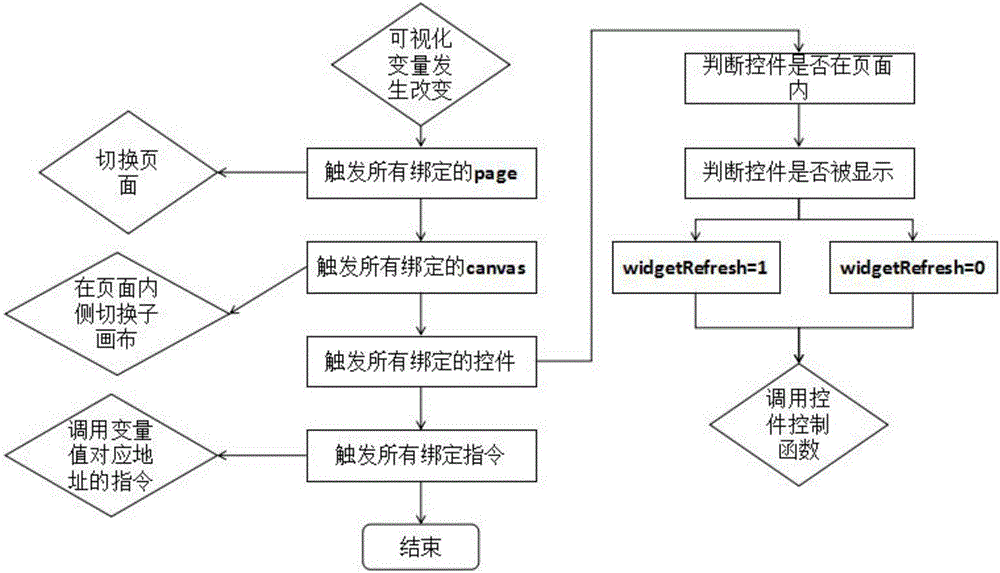

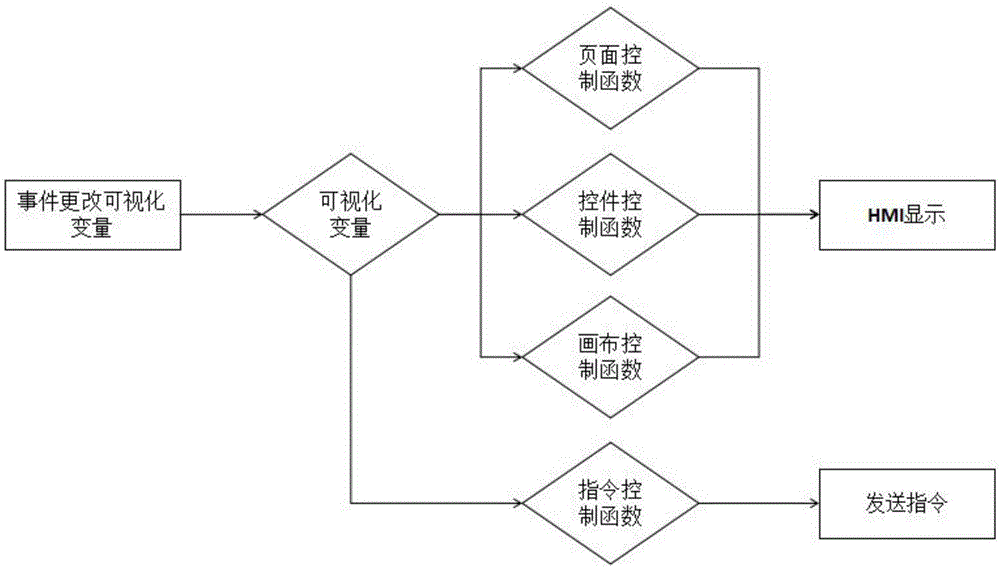

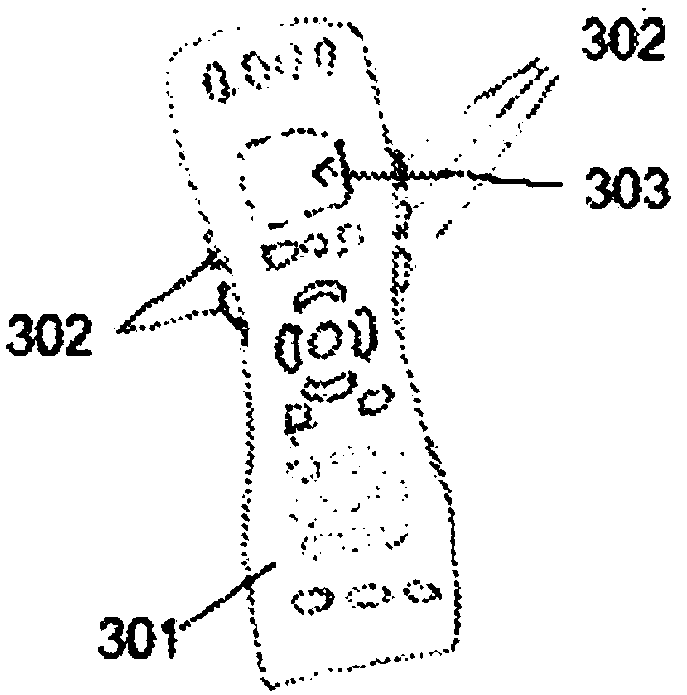

Method and system for interrelating components based on visual variables by human-machine interface

ActiveCN106802804AFacilitate communicationRealize interconnectionSoftware engineeringSpecific program execution arrangementsMan machineSimulation

The invention discloses a method and a system for for interrelating components based on visual variables by human-machine interface. The method includes binding visual variables to controls when a configuration file is generated for users; initializing the visual variable; initializing all tasks, loading pages, and refreshing drawing; waiting for change of event occurrence of visual variables by human-computer interaction when the visual variables is changed; triggering all the bound components; invoking control function; the system comprising a drawing assembly visual variables; the visual variables implementing the component interconnection model and triggering the change events of the visual variables. The method for interrelating components based on the visual variables by human-machine interface is characterized in that the method realized by binding visual variables and components in the man-machine interface; through the visual variables connecting the various components, the various components are coordinated and among the various components and components can easily communicate with the outside world; the development process of the whole interface does not need to introduce the process of writing code.

Owner:合肥速显微电子科技有限公司

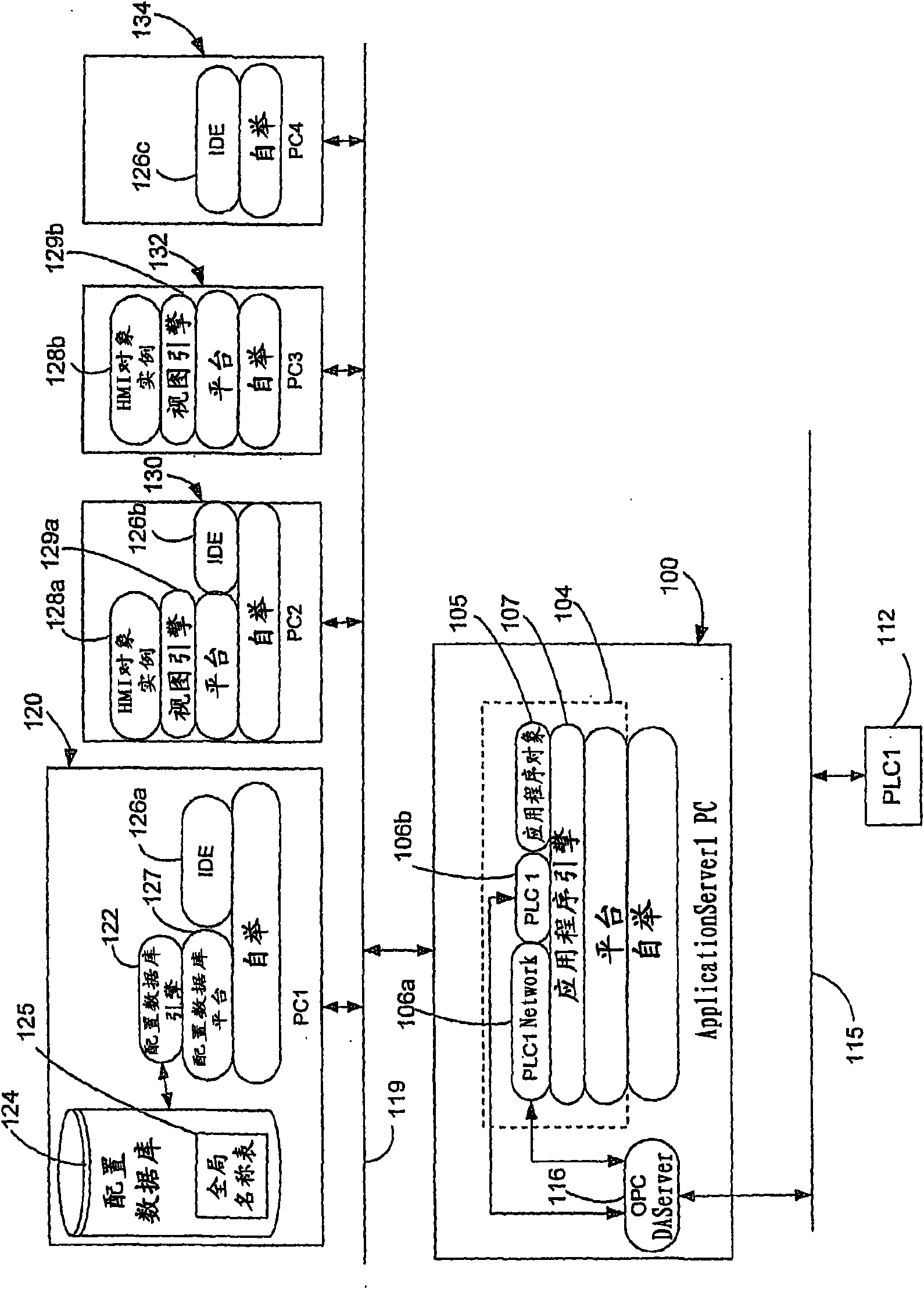

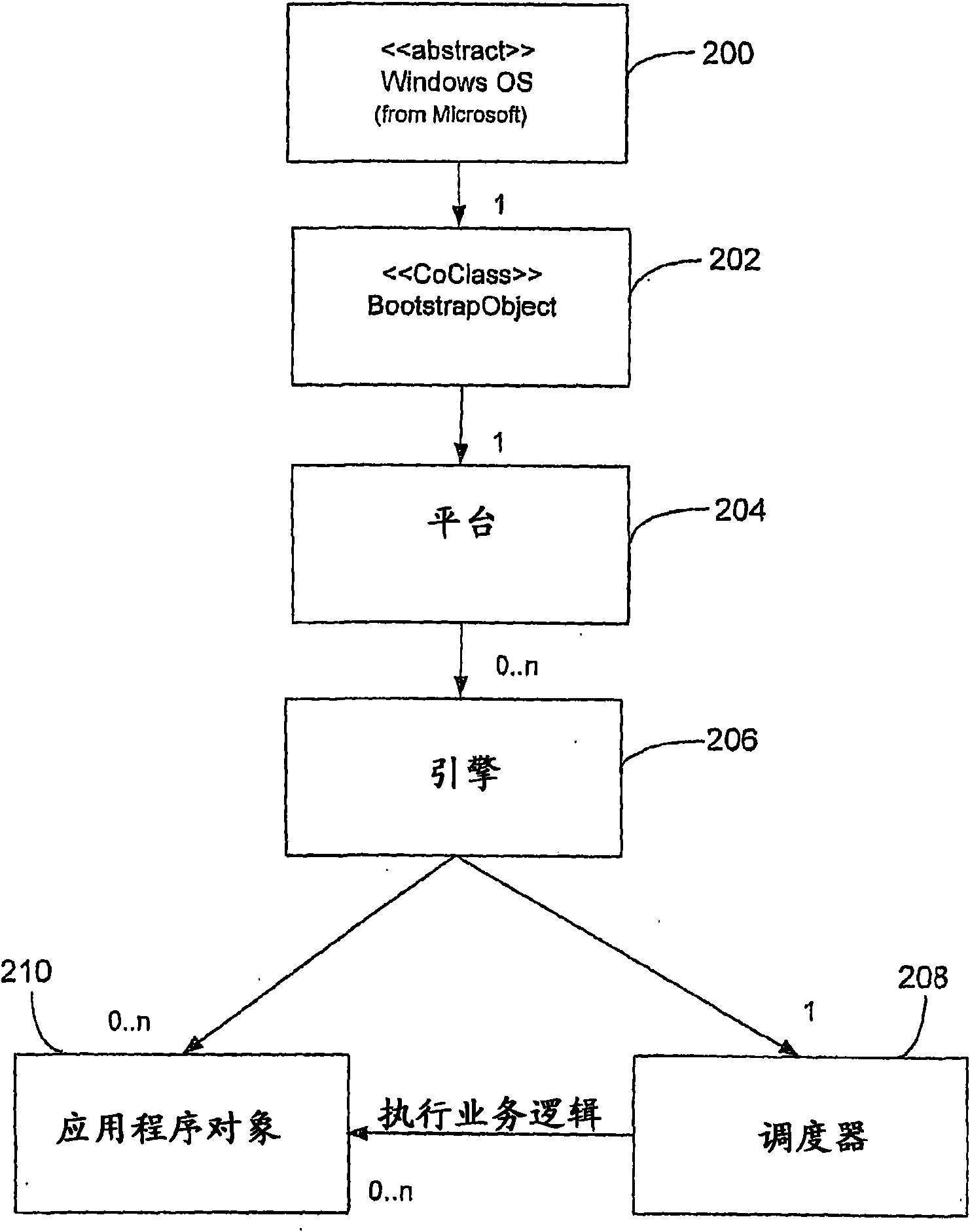

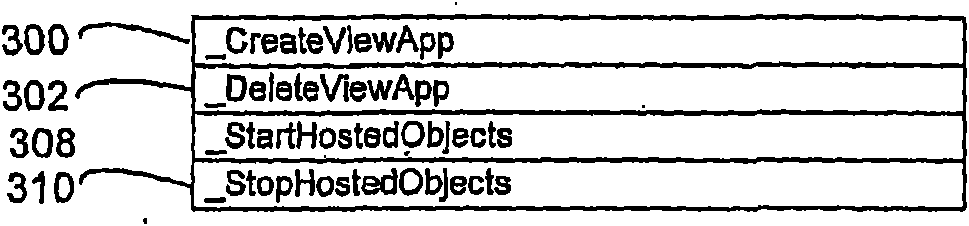

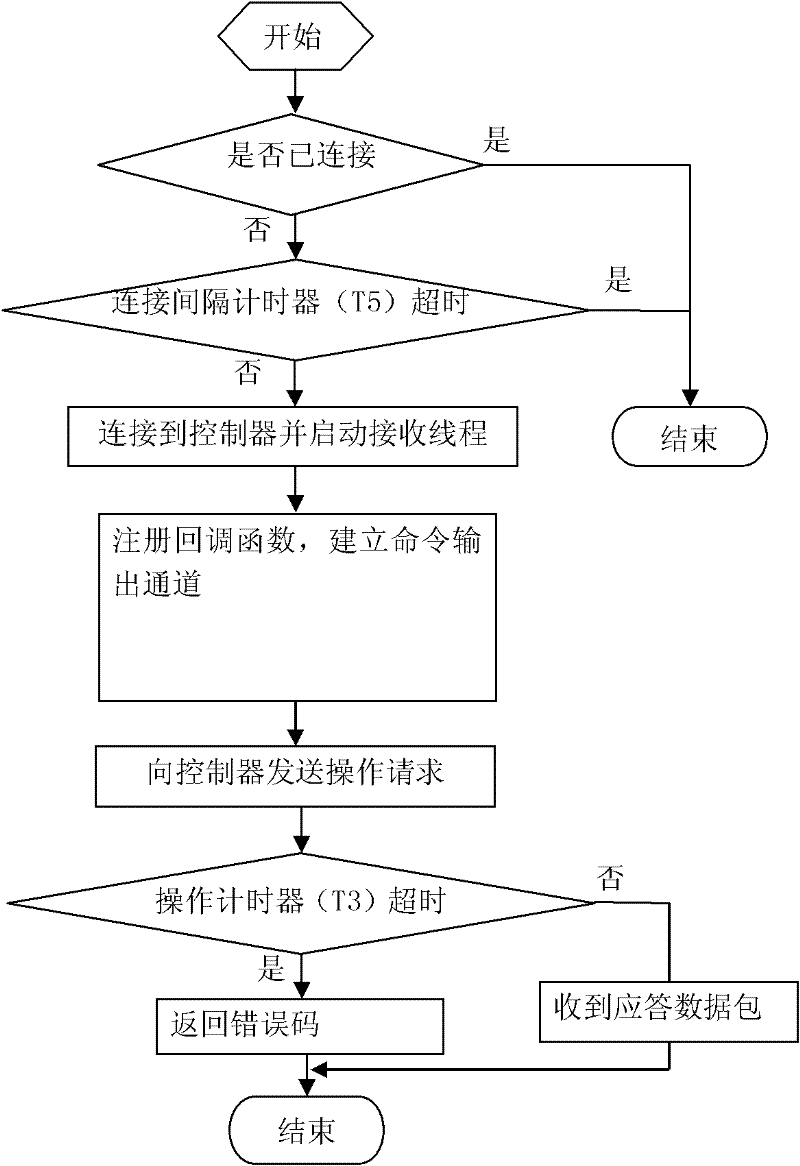

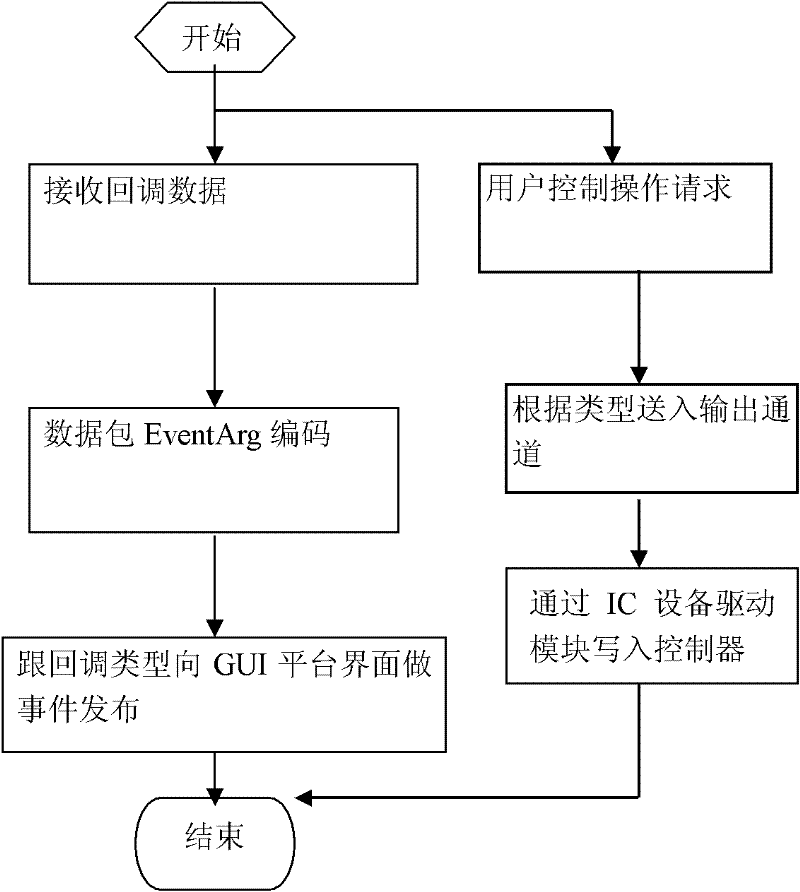

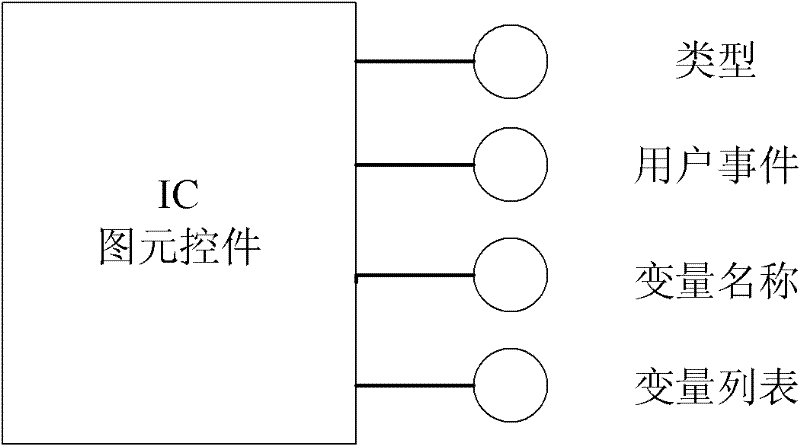

GUI (Graphical User Interface) platformization realization method orienting to IC (Integrated Circuit) equipment control software

ActiveCN102455910AImprove cluster monitoring capabilitiesIncrease the level of automationSoftware engineeringSpecific program execution arrangementsGraphical user interfaceControl system

The invention relates to a GUI (Graphical User Interface) platformization realization method orienting to IC (Integrated Circuit) equipment control software. The GUI platformization realization method comprises the following steps of: developing corresponding IC equipment driving modules and drawing a GUI platform interface according to the characteristics of IC equipment of different manufacturers; connecting a monitoring host and a controller of the IC equipment by using the IC equipment driving modules to form a communication network; reading data in the controller by the IC equipment driving modules and mapping the data onto a general data layer of a GUI platform; and performing display, control and exception handling on the data in real time by the GUI platform interface by using the data layer, thereby realizing the GUI platformization of the IC equipment control software. According to the invention, a cross-platform mechanism is realized, the cluster monitoring capacity of wafer manufacturing equipment is enhanced, the requirements of the user on flexibly configuring a human-computer interface of a corresponding control system can be met, the entire production process is ensured to be rapidly configured in a short time, and thus, the requirement for starting the production in advance is guaranteed.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Integrated design method of human-machine interface of trolley car integrated operation dispatching system

InactiveCN106815018ARealize managementEasy to handleData processing applicationsSpecific program execution arrangementsObject oriented technologyElectric power

The invention discloses an integrated design method of a human-machine interface of a trolley car integrated operation dispatching system. The method comprises the following steps: encapsulating a basic object of a pattern by means of an object oriented technology by adopting standard C++ and QT; encapsulating an interactive control of the pattern by means of the object oriented technology by adopting standard C++ and QT; adopting a script language meeting an ECMA-262. Standard; and expanding a QT object to realize intercommunication of a QT local object and a script object. The interface formed by the design integrates different service application functions, for example, automatic monitoring of the trolley car, a power monitoring system, a broadcasting system, a passenger information system, a closed circuit television system, an electromechanical monitoring system and an access control system and provides a software platform which integrates operation monitoring, operation management and dispatch and command for operation dispatching staff, so that the trolley car, the machine and the electricity are uniformly monitored and managed on one human-machine interface platform.

Owner:NARI TECH CO LTD +1

Apparatus and method for hybrid type of input of buttons/keys and "finger writing" and low profile/variable geometry hand-based controller

InactiveCN108027705AManual control with multiple controlled membersDetails for portable computersHybrid typeHuman–robot interaction

A methods and apparatus of hand based "hybrid" input (human computer interface) allowing compact, efficient, even single-handed operable symbol and character input methods that do not rely on vision and utilizing skills user already have. Also about a new kind of dynamic / shape-transformable human-machine interaction means (methods and apparatus / controllers) ~ Variable Geometry hand-based controller, for providing on-demand, (Ergonometric and) change-able (transformable) interface for user's hand to interact with, thus provide more flexible / versatile way of interaction and possibly simulating (including the user experience) a variety of (hand-based) controllers / devices, so that user can have more than one way of interaction without need to switch to other controllers.

Owner:肖泉

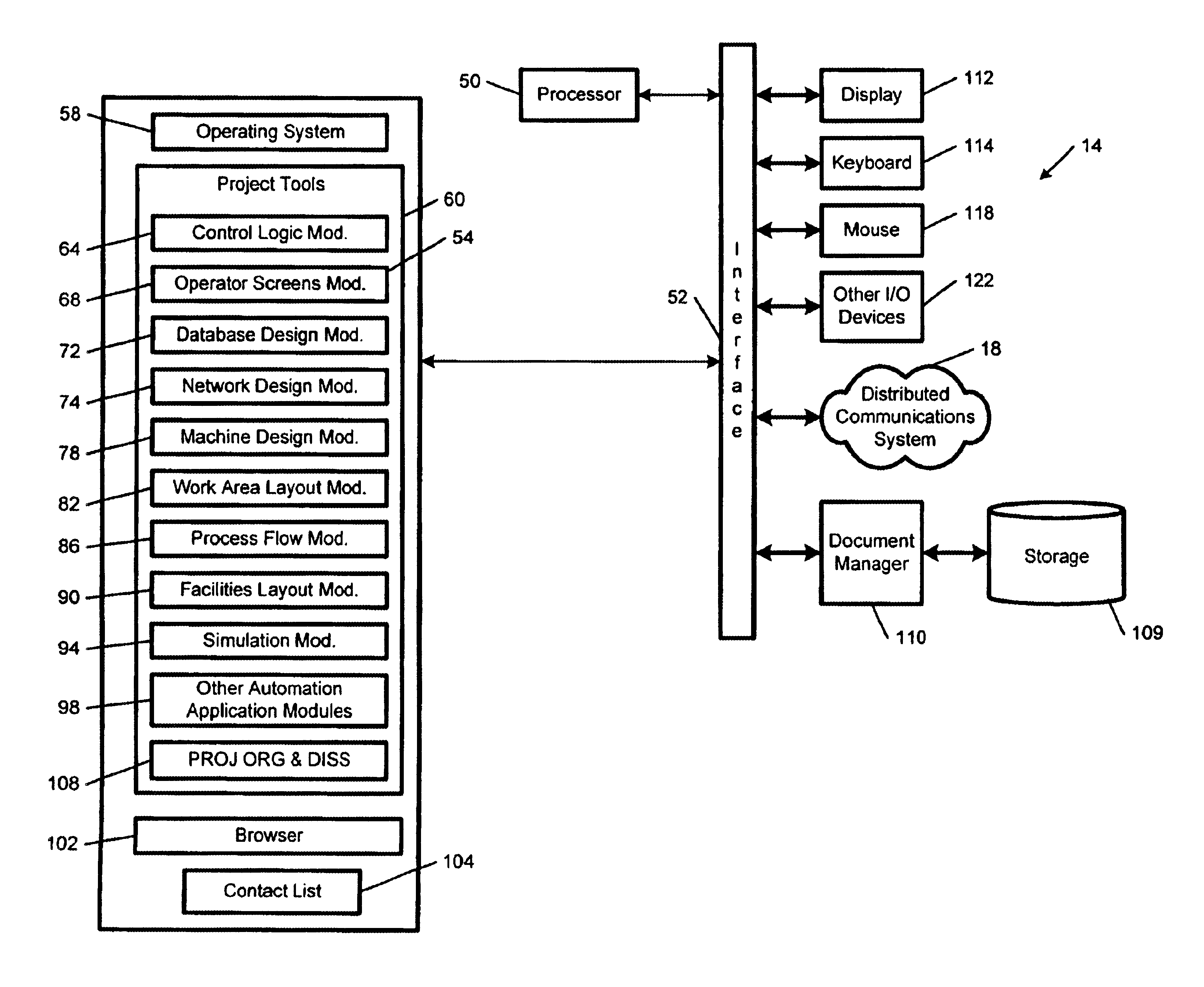

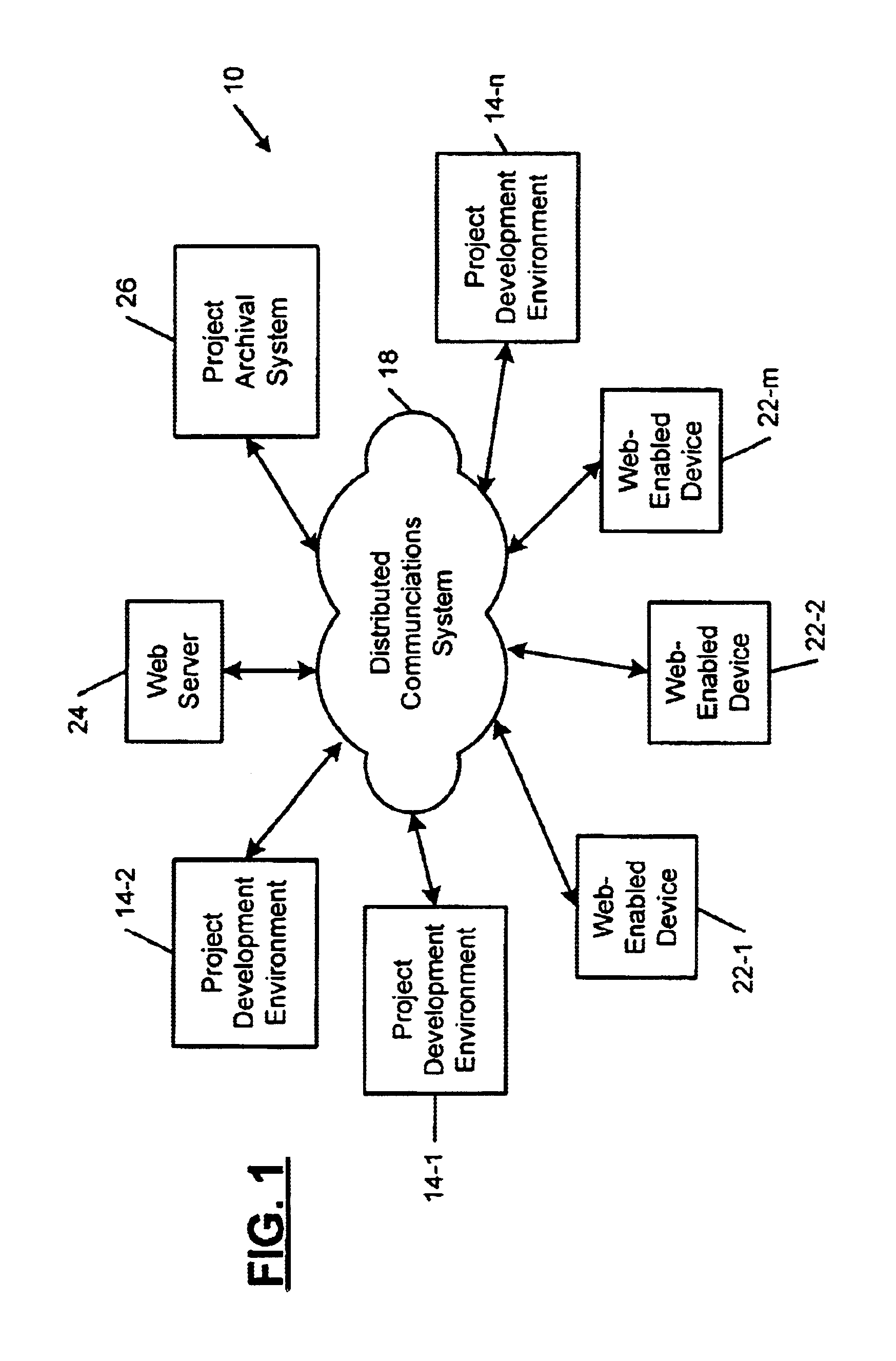

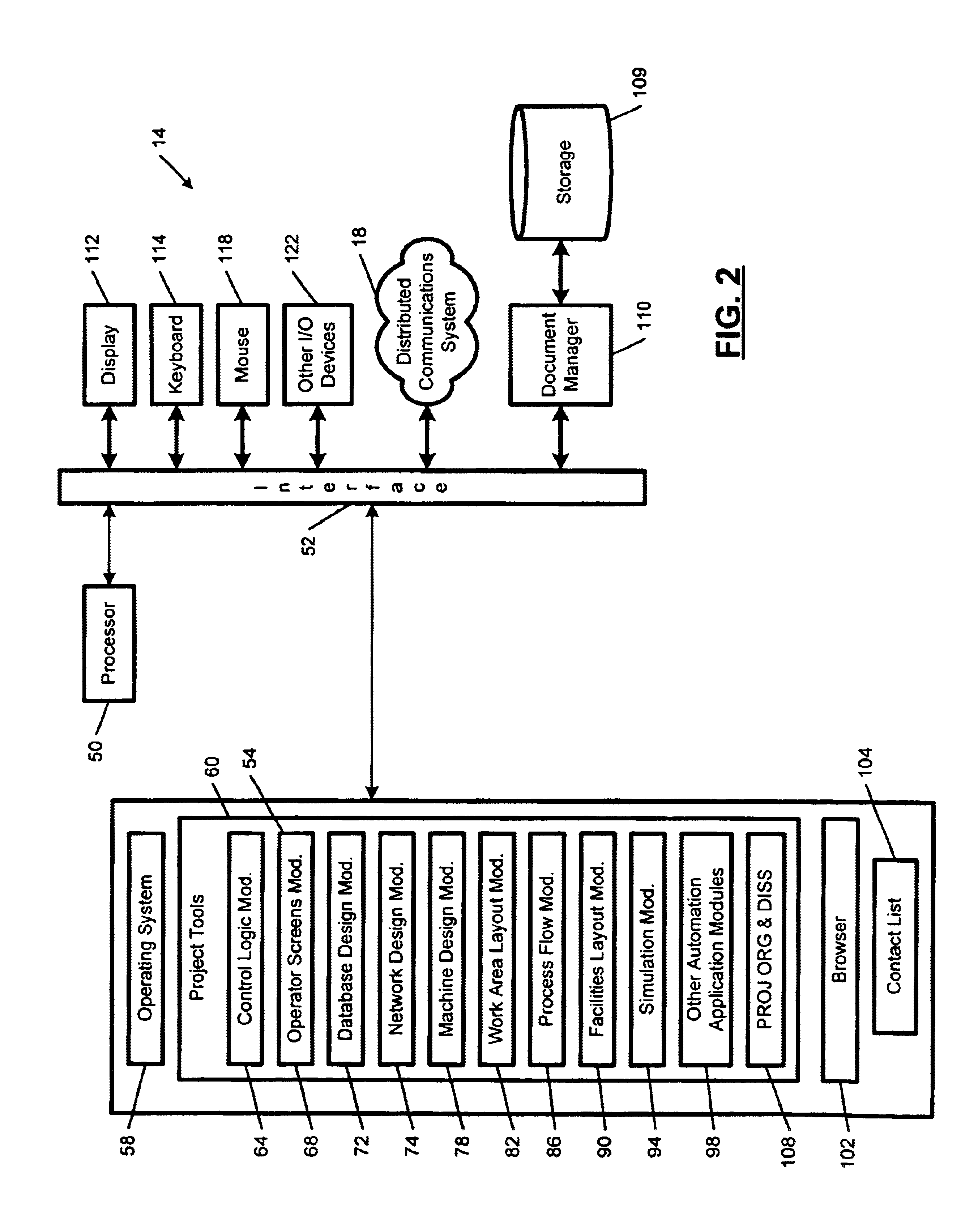

Project organization and dissemination system for machine programming and control systems

A project organization and dissemination system for a machine programming and control system includes a project development environment that communicates with a distributed communications system. The project development environment includes project tools for designing project elements. The project tools include a control logic module that generates and edits flowchart project elements that include flowchart blocks and contain control logic for operating a device to further a process. A project archival system communicates with the distributed communications system and stores the project elements. A web enabled device communicates with the distributed communications system and allows remote access to the project elements. Other project elements include human machine interface (HMI), databases, network layout, electrical and electromechanical devices, spatial arrangement, process logic and flow, and / or facility layout and design.

Owner:PHOENIX CONTACT SERVICES

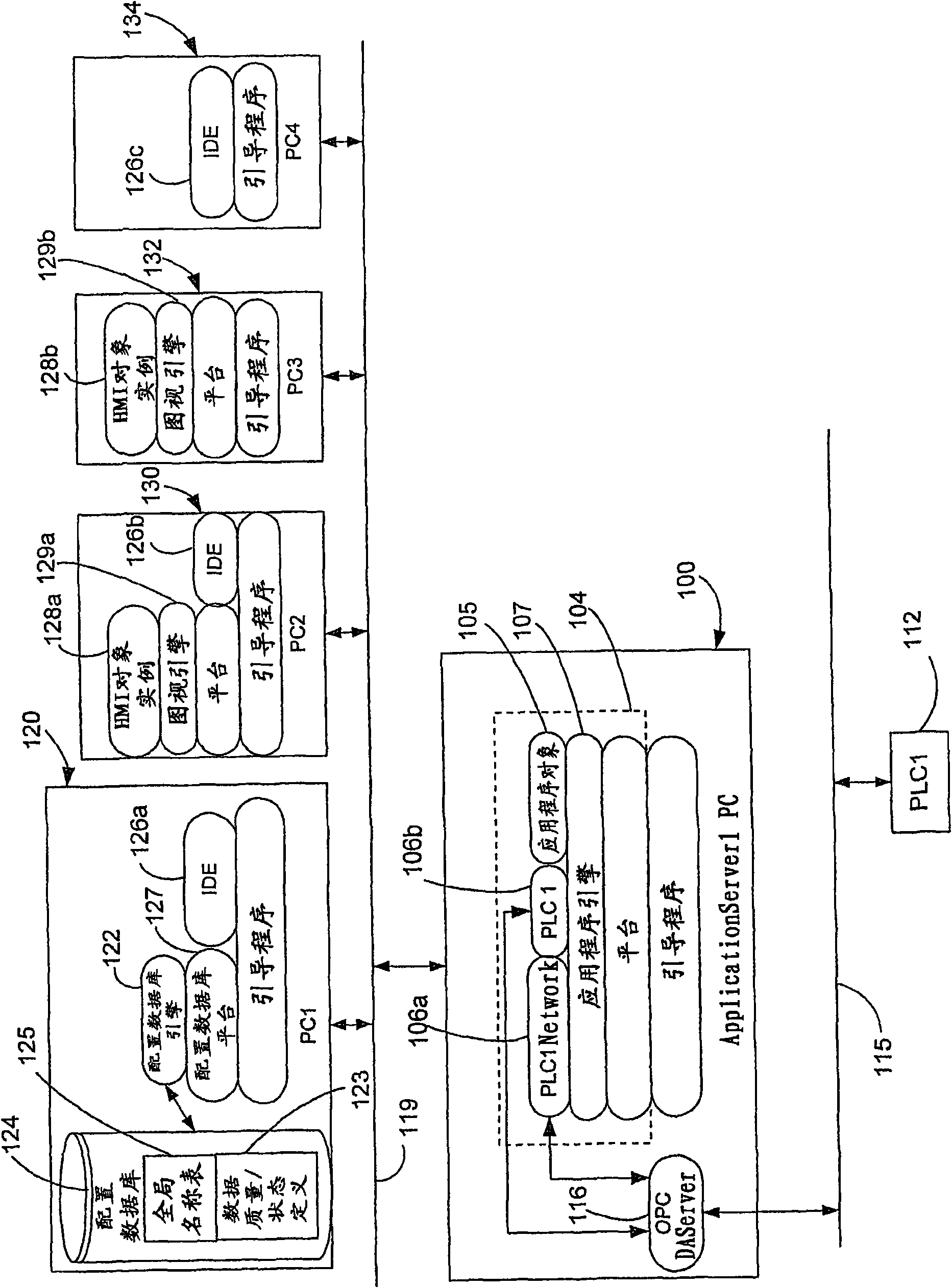

Data quality and status behavior for human machine interface graphics in industrial control and automation systems

An industrial control and automation human machine interface (HMI) technology is disclosed that includes a centralized definition of data quality and status behaviors for graphical elements. The centralized definition is thereafter applied to every graphical element that is linked to a data value for which status is maintained / provided. Centrally configured data quality and status indication behaviors are incorporated across entire HMI applications and even sets of HMI applications in a system to inform an operator of the data quality and / or status of read / written data through globally defined data status animation behavior. The centrally defined behaviors are distributed to all nodes on a system and incorporated in live applications without shutting down the applications to update their behavior definition. A status graphic element type. The status graphical element examines a designated data variable and displays a picture or icon indicating the quality or status of the data.

Owner:AVEVA SOFTWARE LLC

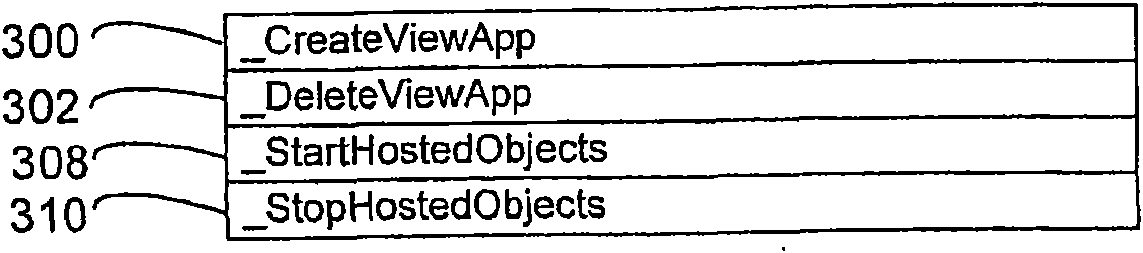

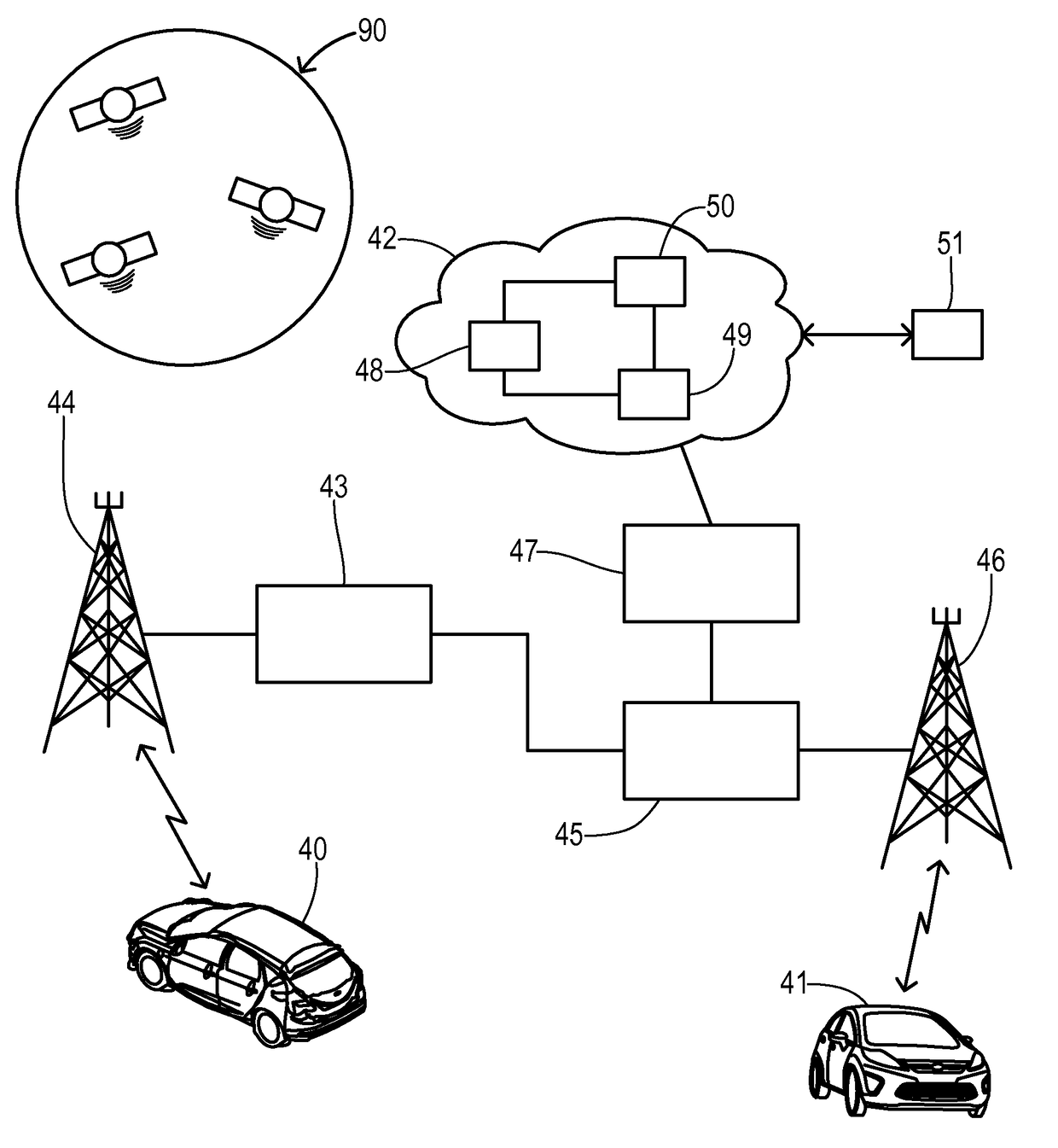

Adaptive control of automotive HVAC system using crowd-sourcing data

ActiveUS9849751B2Lighting and heating apparatusRoad vehicles traffic controlMobile vehicleCrowd sourcing

A motor vehicle comprises an HVAC system including a climate control circuit coupled to onboard sensors, a human-machine interface, and climate actuators. The actuators are responsive to respective command parameters generated by the control circuit in response to the sensors and the human-machine interface. A wireless communication system transmits vehicle HVAC data to and receives crowd data from a remote server. The control circuit initiates a request for crowd data via the communication system to the remote server, wherein the request includes peer parameters for identifying a vehicle environment. The control circuit receives a response via the communication system from the remote server. The response comprises crowd data and at least one weight indicating a confidence level associated with the crowd data. The control circuit generates at least one command parameter using a set of fuzzy rules responsive to the crowd data and the weight from the response.

Owner:FORD GLOBAL TECH LLC

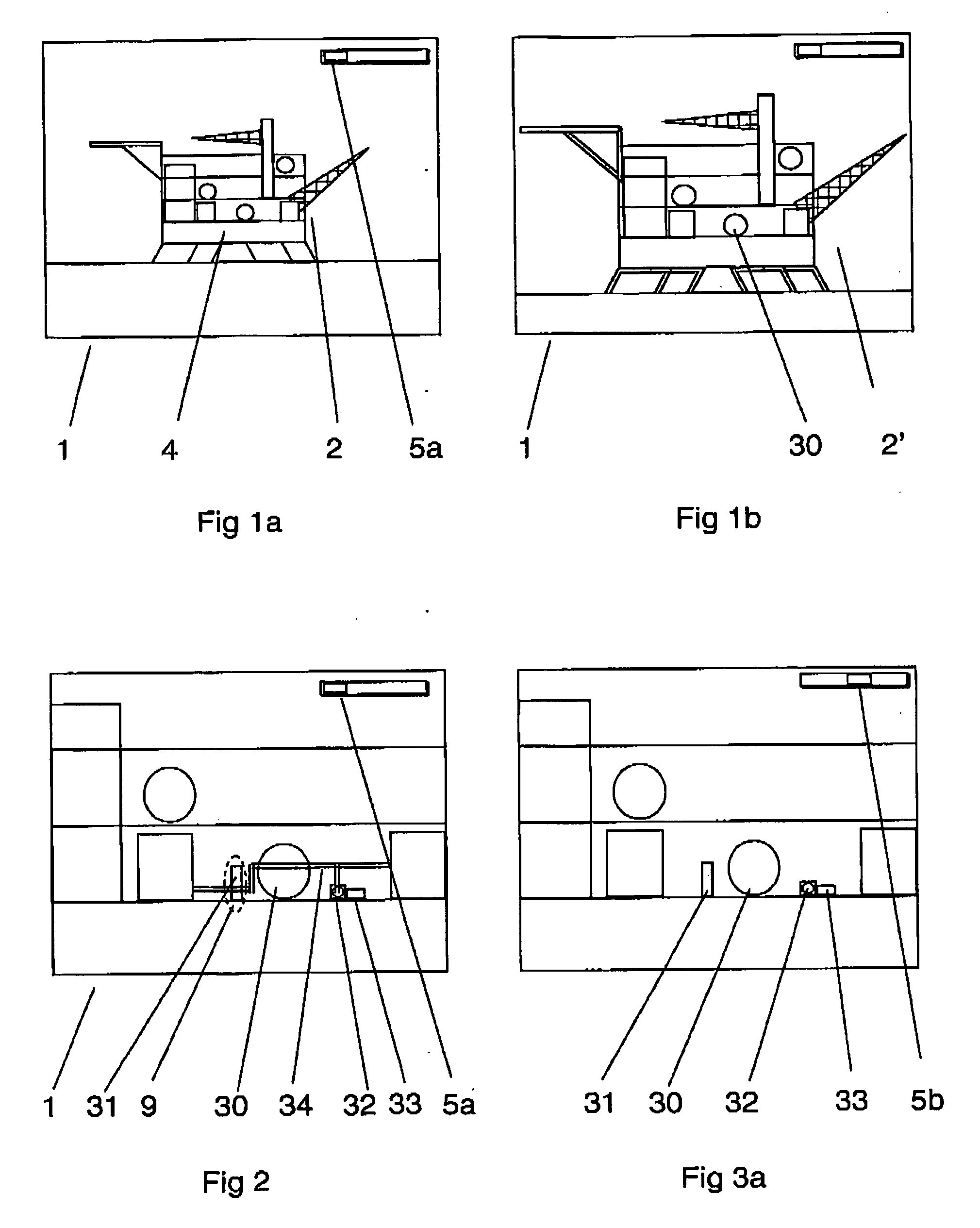

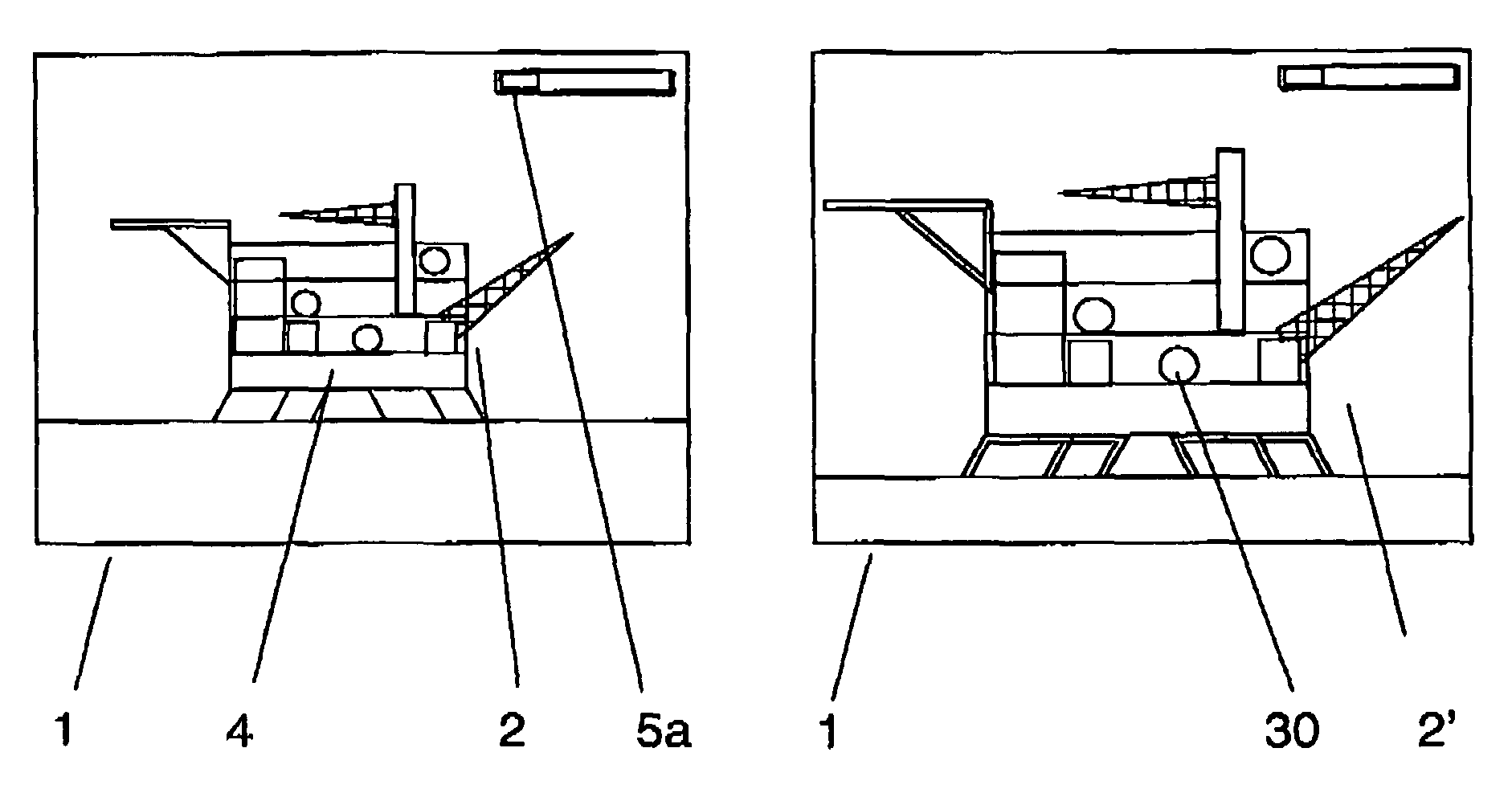

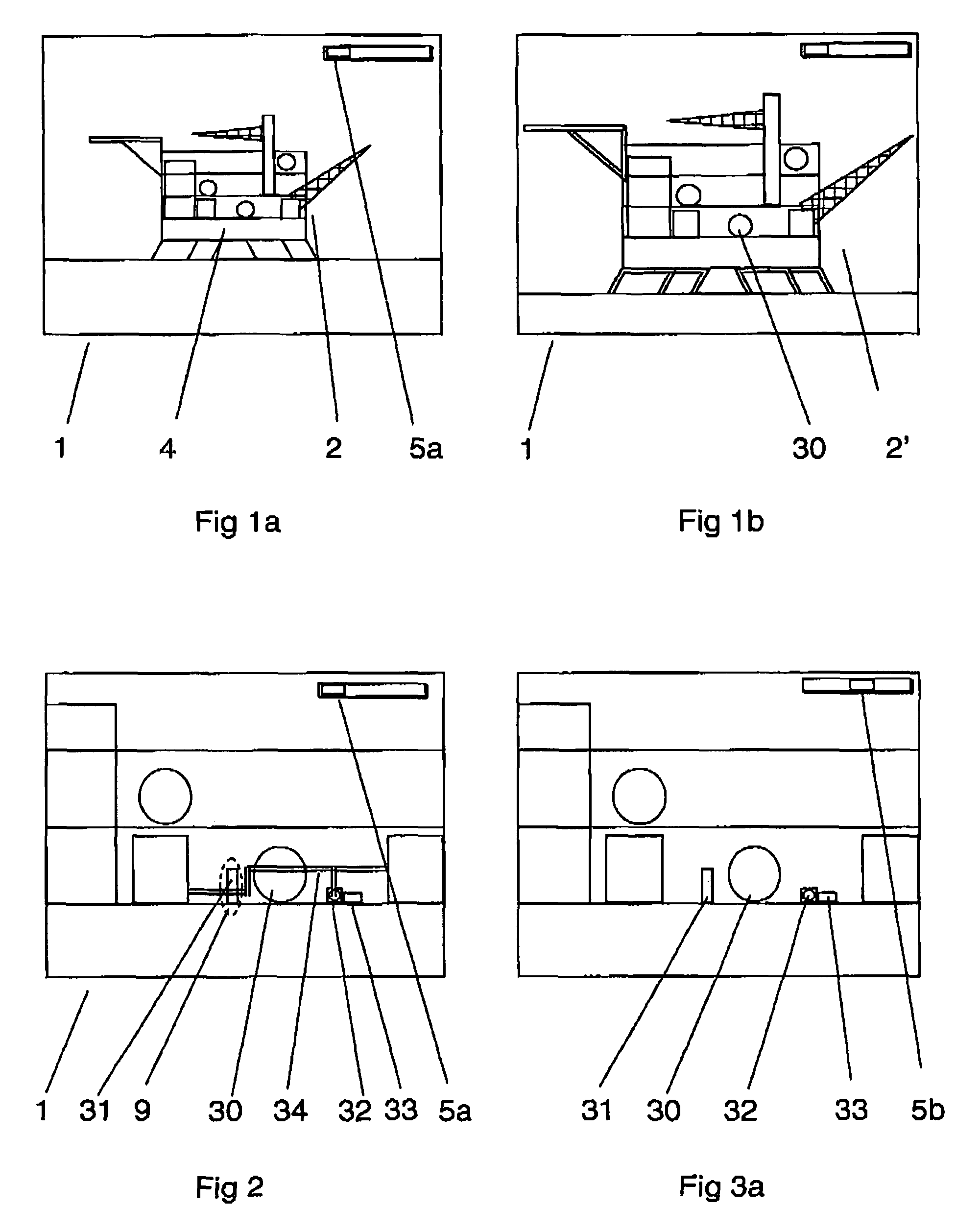

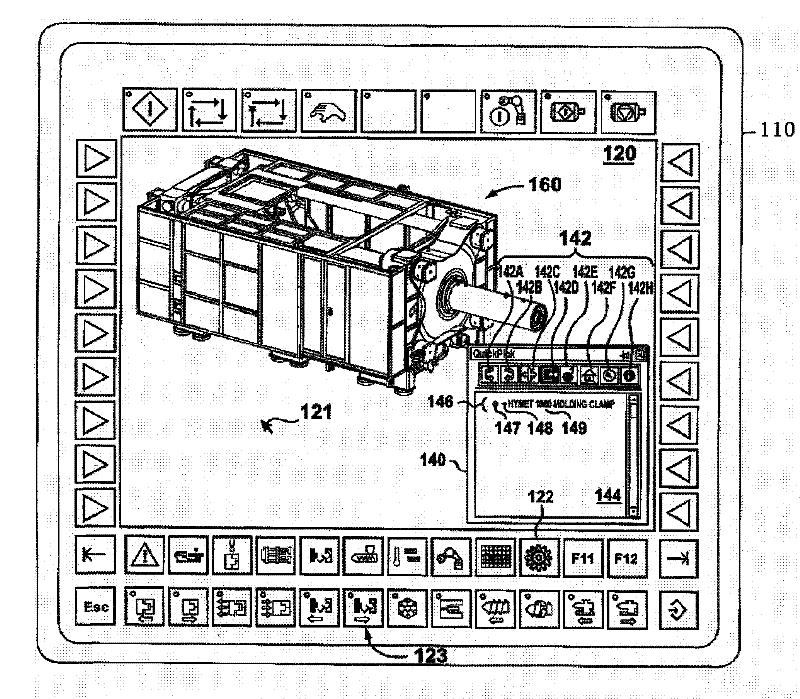

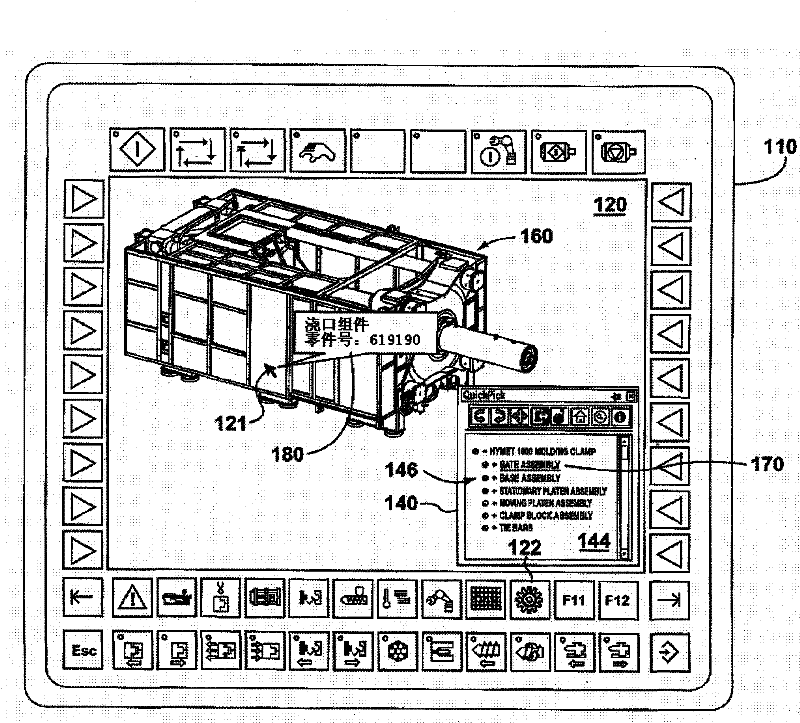

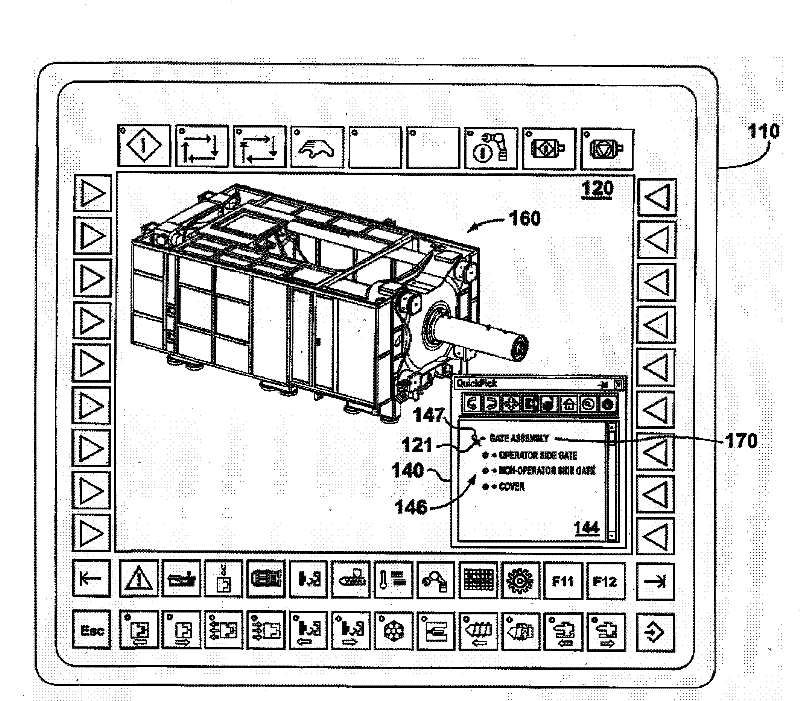

A method for displaying a virtual model of a molding system, and part information for a selected entity model, on a display of a human-machine interface of a molding system computer

Embodiments of the present invention teach a human-machine interface of a molding system computer for displaying a virtual model of a molding system and part information for a selected entity model on a display of a human-machine interface of a molding system computer, amongst other things.

Owner:HUSKY INJECTION MOLDING SYST LTD

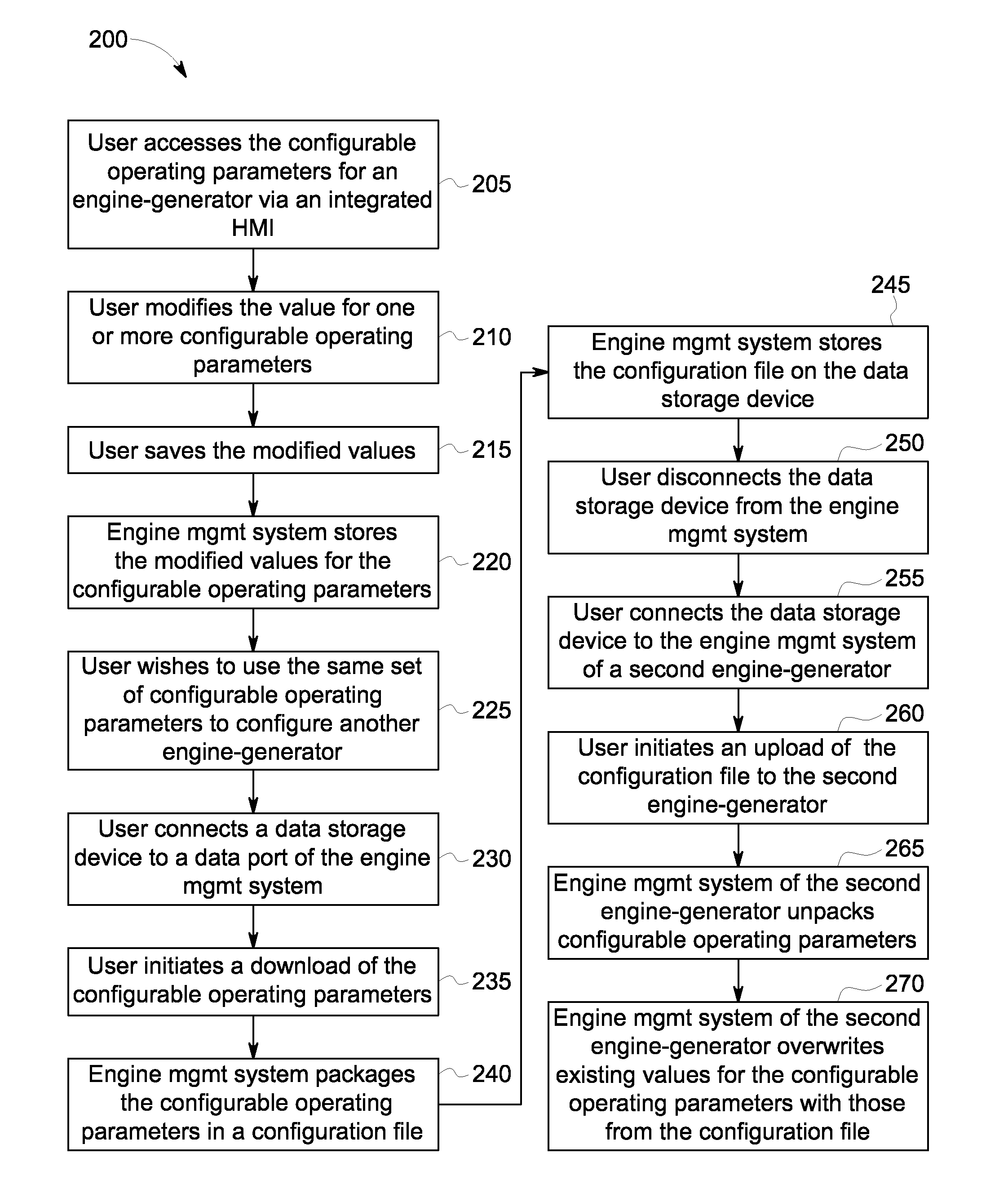

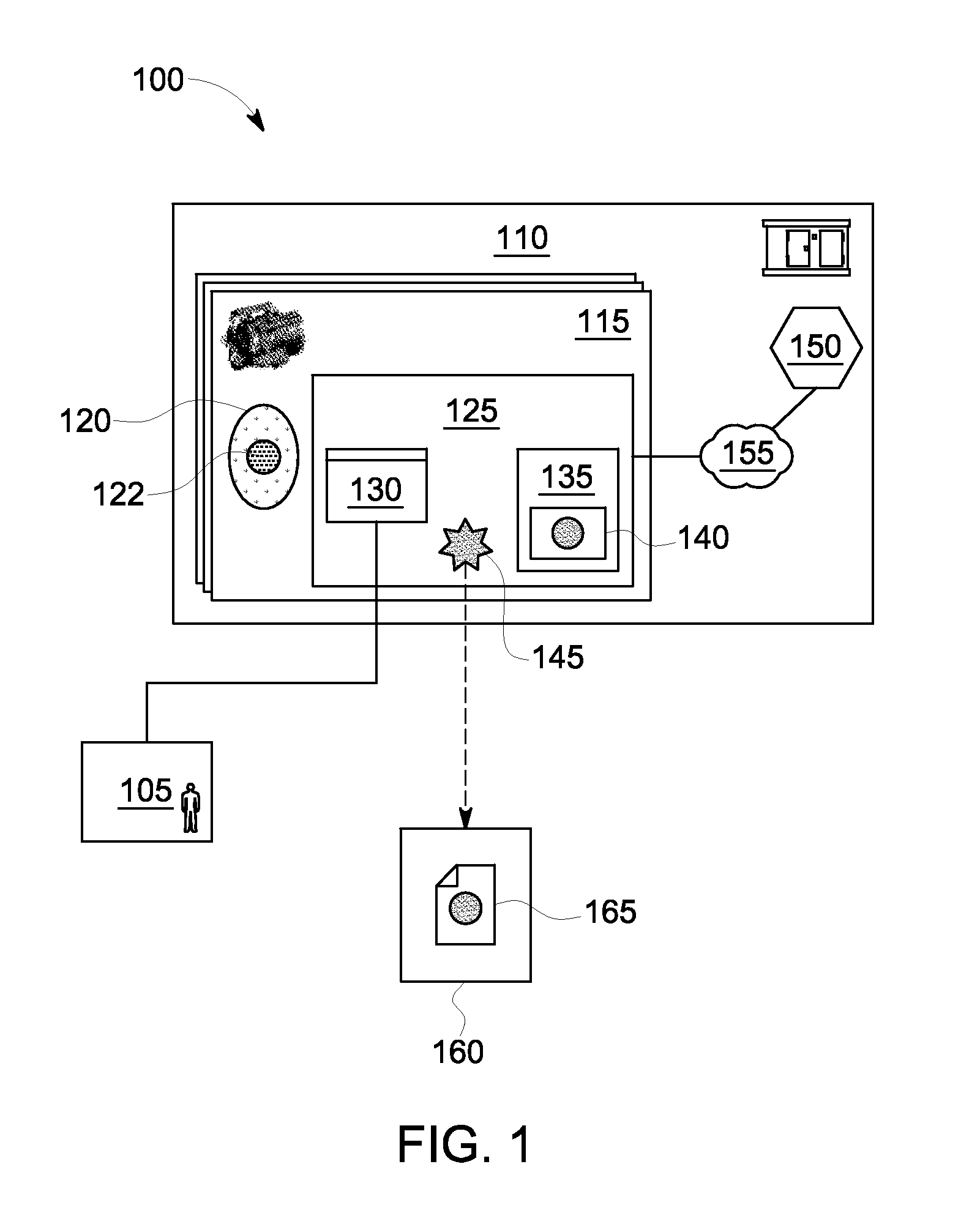

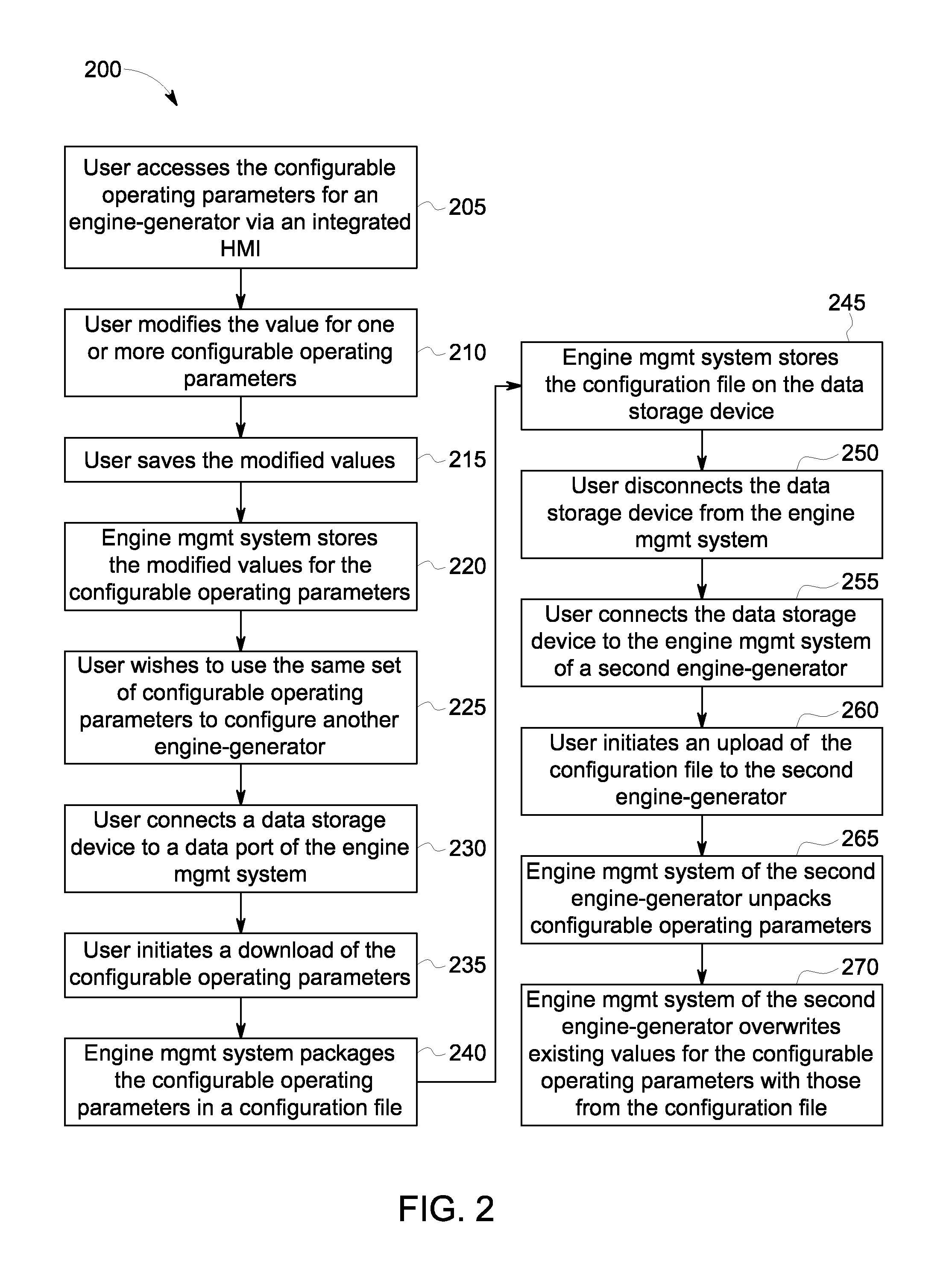

System, method, and computer program for an integrated human-machine interface (HMI) of an engine-generator

InactiveUS20130173095A1Easy to modifyAffect operationDigital data processing detailsElectric motor startersPower cycleNetwork link

In one embodiment, an engine management system (EMS) can use a human machine interface (HMI) to modify operating parameters of a set of engine generators controlled by an engine control unit (ECU). The HMI can permits authorized users to adjust a plurality of operating parameters of the engine generators in accordance with an authorization level of the authorized users. The ECU can be a standalone system operable independent of the EMS. A communication network (e.g., ARCnet) can link the EMS to the ECU, wherein the changes of the operating parameters input via the HMI are maintained over a power-cycle of the EMS. Further, changes of the operating parameters input via the HMI can be maintained even when communications over the communication network linking the engine.

Owner:GE GLOBAL SOURCING LLC

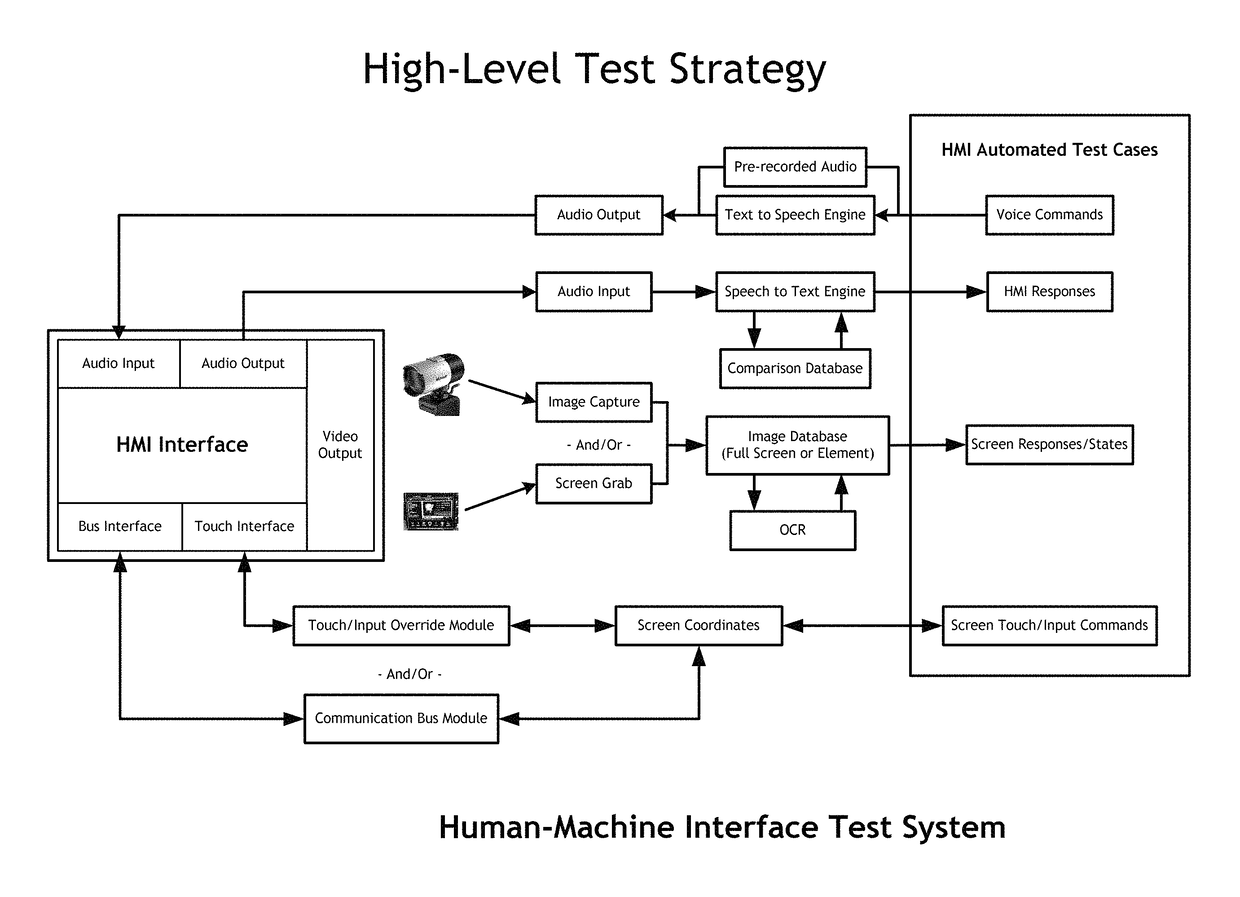

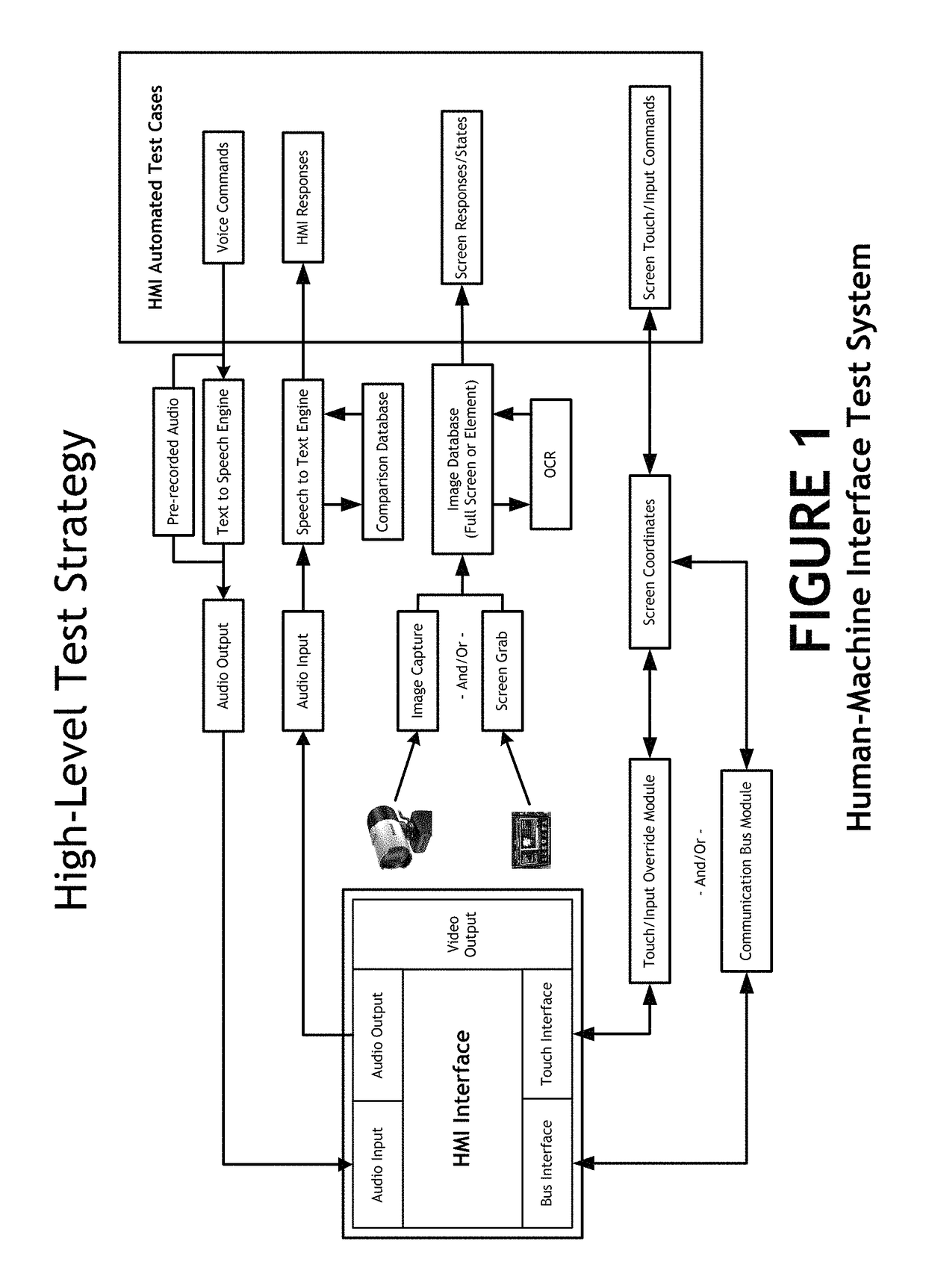

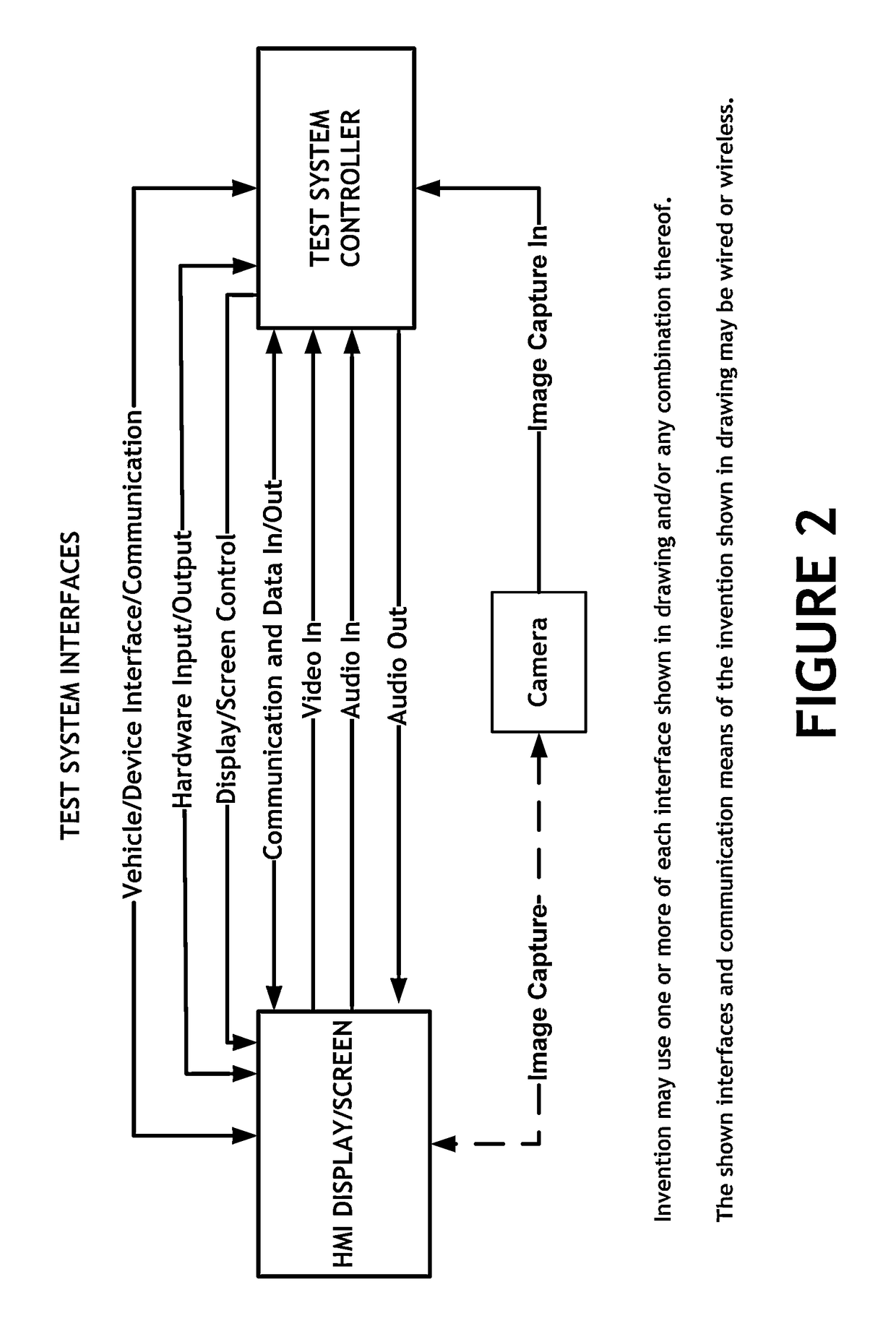

Human-machine interface test system

ActiveUS9940223B2Complete testFully testedComputer controlSoftware testing/debuggingComputer hardwareHuman interaction

The human-machine interface test system enables the automated testing of vehicle interface systems and consumer electronics devices, replacing testing and validation that previously had required human interaction. The human-machine interface device (HMI test object or device under test) does not need to be altered (via hardware or software modifications or additions) to be able to be tested using the human-machine interface test system. The HMIts involves the automated audio input generation and output analysis, visual verification of a display screen with graphics and texts display, including touch and gesture interface control and feedback, external device interface, as well as data logging for communication between the HMI device and the rest of the system, that will replace the testing and validation that previously required human interaction. The HMIts provides more accurate and reliable results from the conducted tests, increasing repeatability and consistency in a controlled environment, while significantly decreasing test time.

Owner:FEV NORTH AMERICA INC

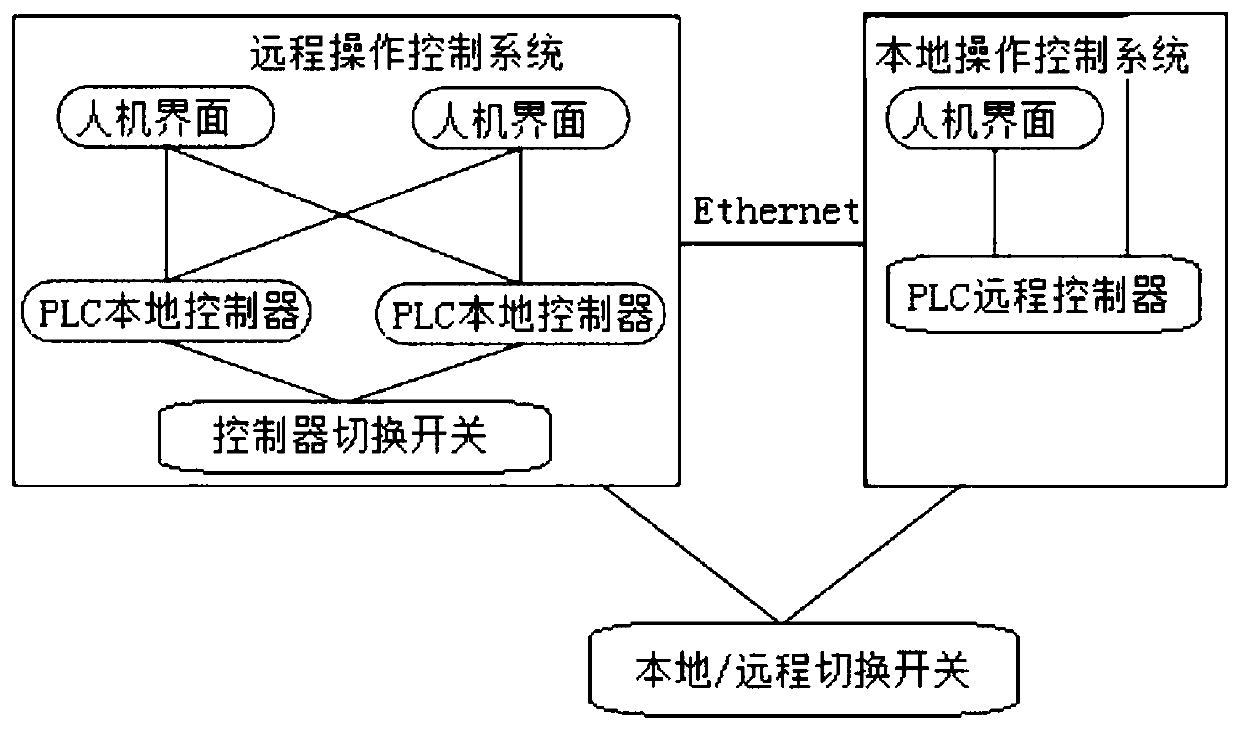

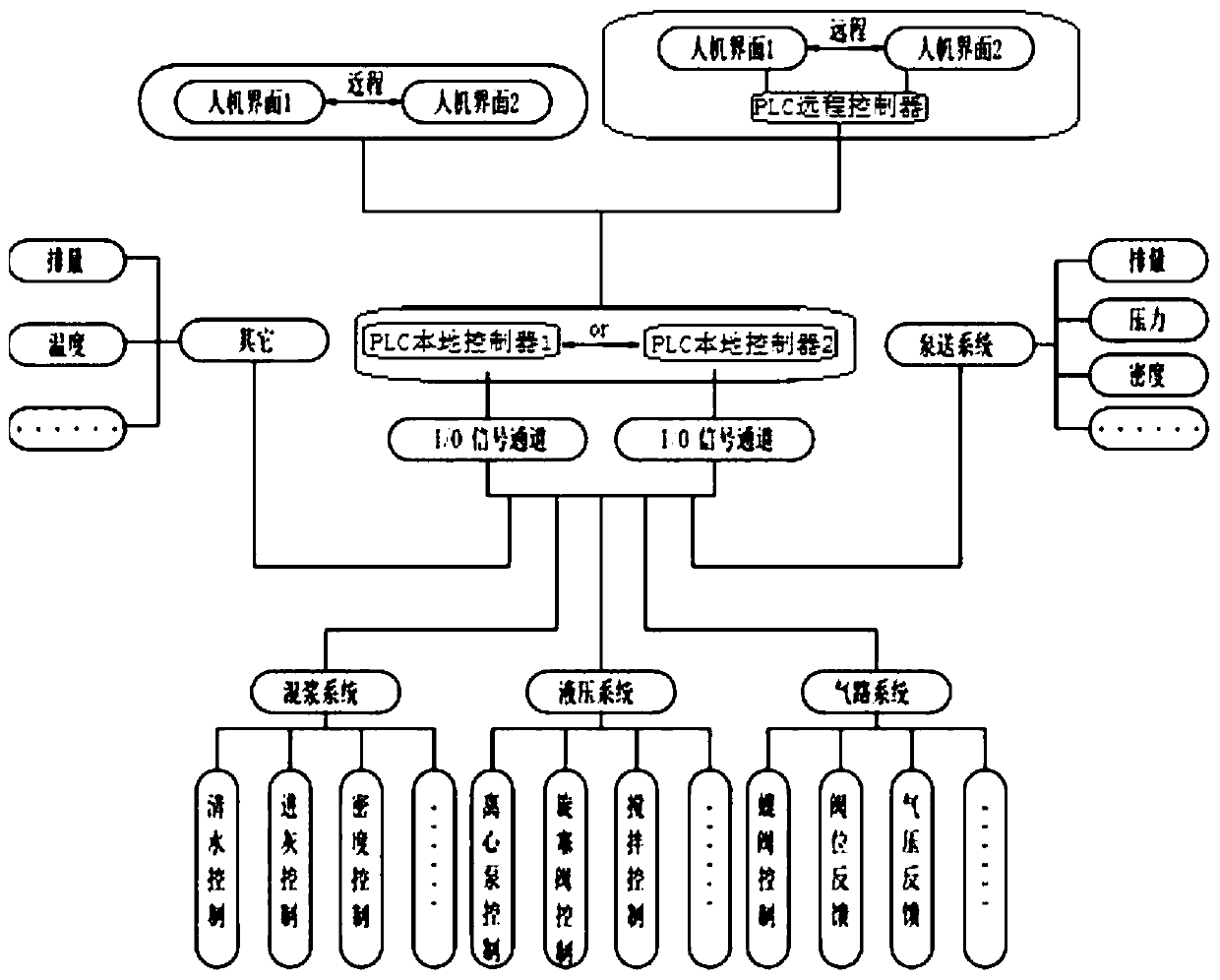

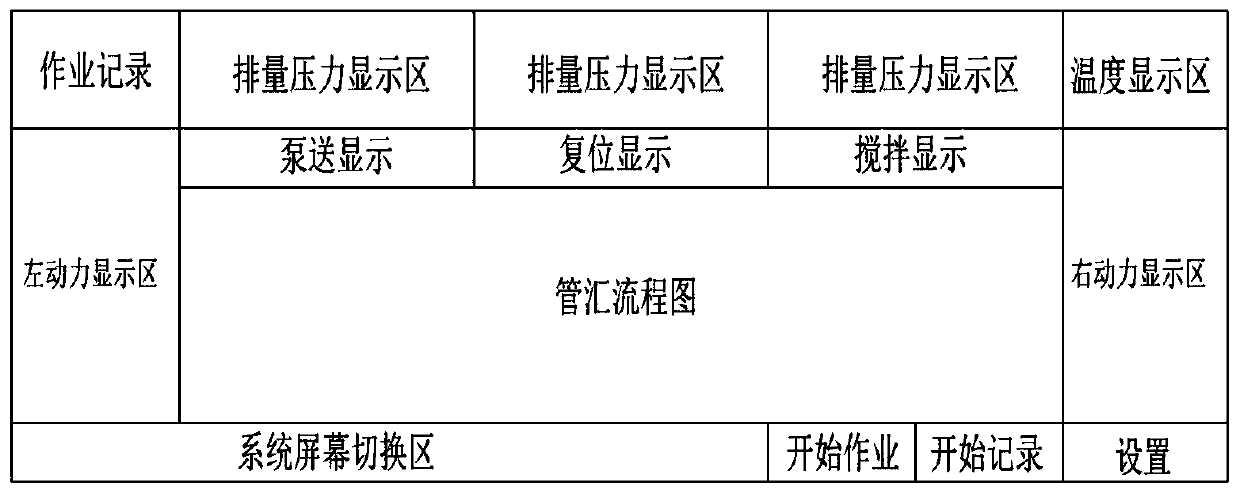

Local-remote full-process control system for cementing equipment

InactiveCN110244651AImprove reliabilityAchieve homeworkProgramme control in sequence/logic controllersControl systemRemote control

The invention provides a local-remote full-process control system for cementing equipment, and the system comprises at least a remote operation control system and a local operation control system connected via an Ethernet, wherein the remote operation control system comprises at least a PLC remote controller and a remote human-machine interface connected thereto, the local operation control system comprises at least a PLC local controller and a local human-machine interface connected thereto; and the PLC local controller is respectively connected to and controls a mixing system, a hydraulic system, a pneumatic system, a pumping system and other monitoring systems. The local-remote control system provided by the invention provides more operation options for the cementing equipment, and the two systems are backed up and independent of each other to ensure that the normal operation can be realized by switching the systems in the case of an error occurring in a certain control system, thereby improving the reliability of cementing equipment.

Owner:四机赛瓦石油钻采设备有限公司

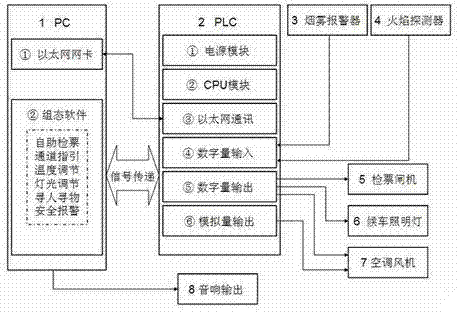

Automated management system for waiting places

InactiveCN103676897AEasy to useEasy to manageProgramme total factory controlOutput deviceAir conditioning

An automated management system for waiting places comprises a PC (Personal Computer), a PLC (Programmable Logic Controller), a smoke alarm, a flame detector, a ticket gate, a waiting lighting lamp, an air conditioning fan and a sound output device, wherein an Ethernet card and a configuration software have already been installed in the PC; a power supply module, a CPU (Central Processing Unit) module, an Ethernet communication module, a digital quantity input module, a digital quantity output module and an analog quantity output module are arranged in the PLC. Through different human-machine interface operations in the unified management system, the monitoring functions of self-service ticket checking, channel guiding, room temperature regulating, light control, people and object seeking and safe alarm can be realized, thus the flexibility of daily use and high efficiency of management in the management system are improved, meanwhile the system can effectively help workers in a waiting room to realize humanized guest service, and the passenger satisfaction degree is increased.

Owner:NANJING COMM INST OF TECH

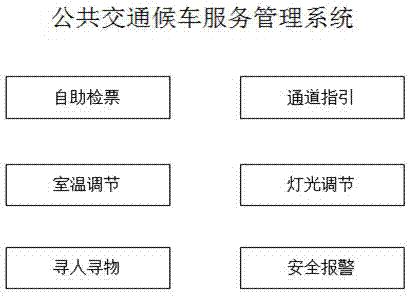

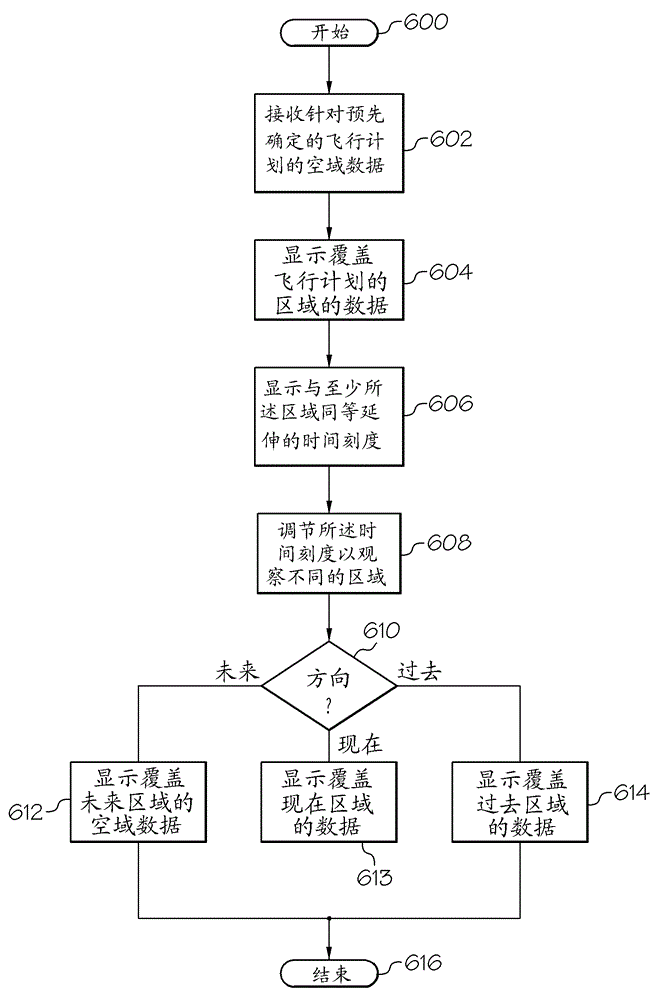

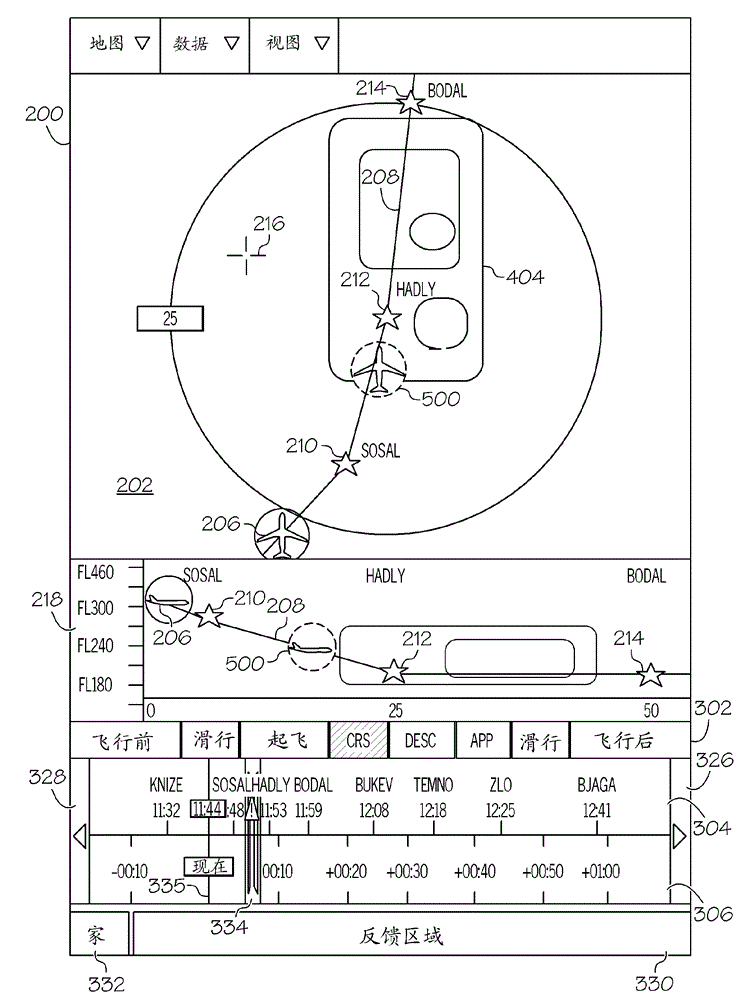

A system and method for providing enhanced HMI navigation

InactiveCN105303893ANavigation instrumentsInput/output processes for data processingDisplay deviceComputer science

A method and apparatus is provided for enhancing an HMI (Human Machine Interface) mechanism to include continuous, sequential, and time-based navigation capabilities. Airspace data associated with a flight plan is received, and the airspace data associated with a region of the flight plan is displayed. A time scale substantially coextensive with the region is also displayed. To view a future region of the airspace, the time scale on the display is moved in a first direction, and to view a previous region, the time scale on the display is moved in a second, substantially opposite direction.

Owner:HONEYWELL INT INC

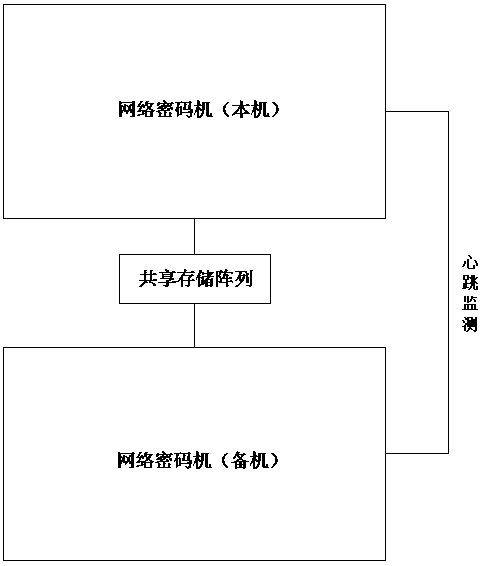

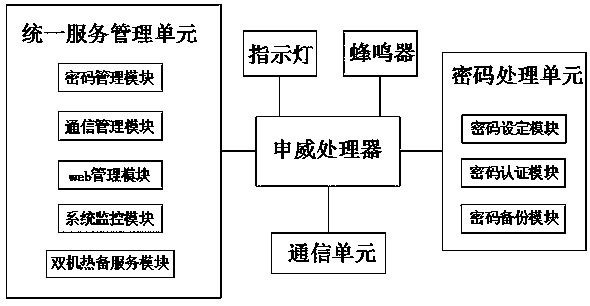

Management service system for network cipher machines

InactiveCN109672684AEnsure safetyMeet management needsData switching networksCommunication unitManagement unit

The invention provides a management service system for network cipher machines, comprising two network cipher machines and a shared storage array, wherein the two network cipher machines are respectively connected to the shared storage array, and are connected through a cable used for heartbeat detection; the network cipher machines are internally provided with a microprocessor, a communication unit, and a unified service management unit for configuring and managing the network cipher machines; the network cipher machines are provided with an indicator light and a buzzer; and the microprocessor is respectively connected to the communication unit, the unified service management unit, the indicator light and the buzzer. The invention comprises a front-end web interface and a background processing service, and provides a friendly human-machine interface, which can meet the management requirements of the network cipher machines, and provides a convenient and efficient management configuration system.

Owner:SHANDONG CHAOYUE DATA CONTROL ELECTRONICS CO LTD

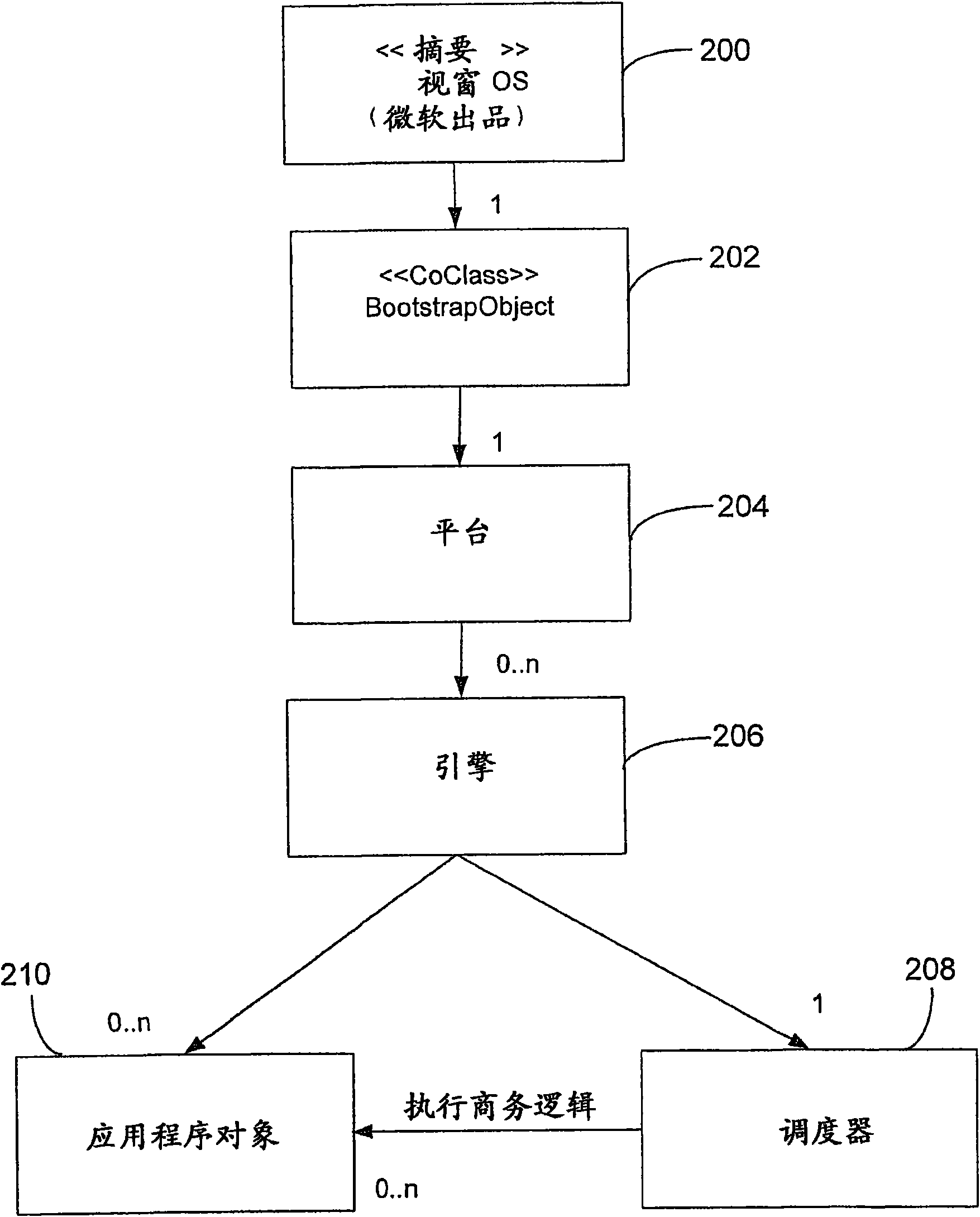

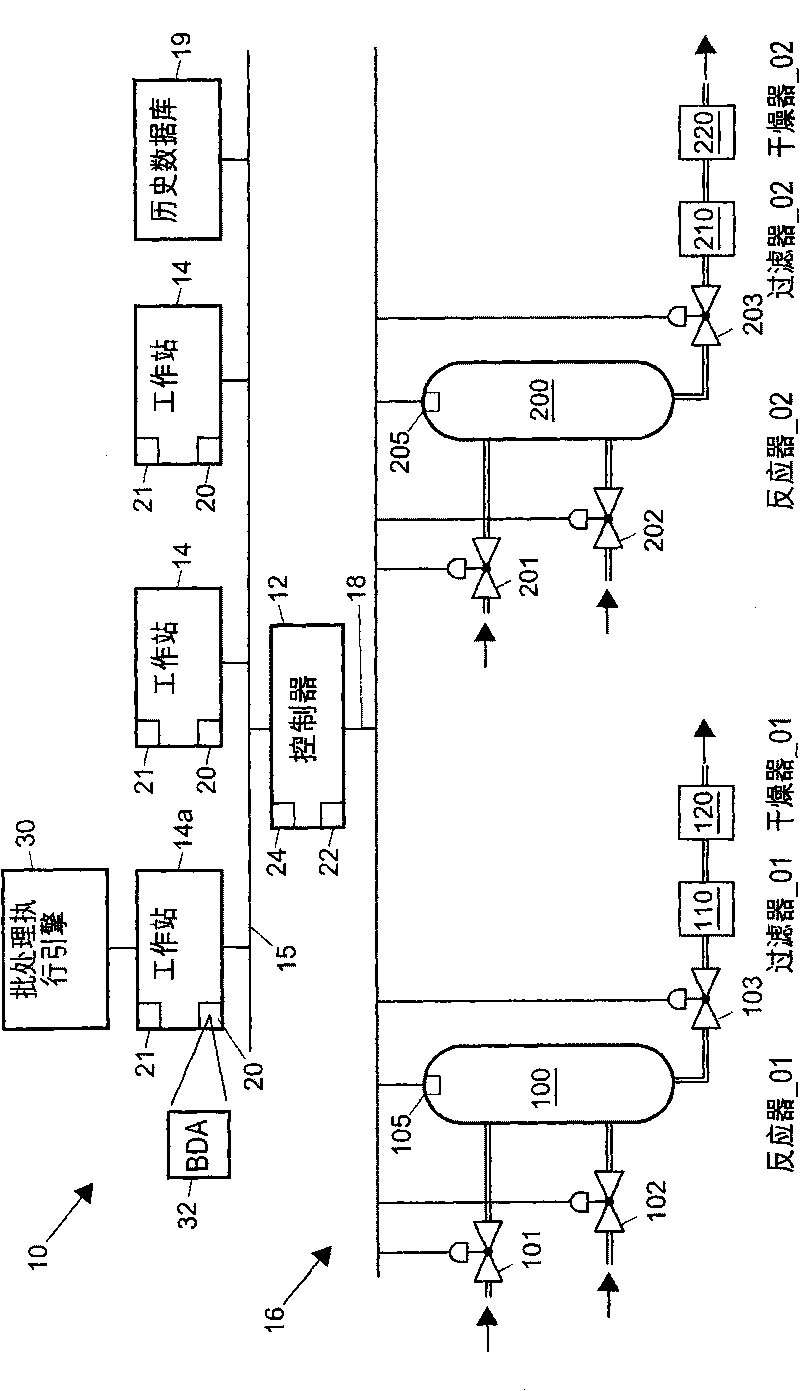

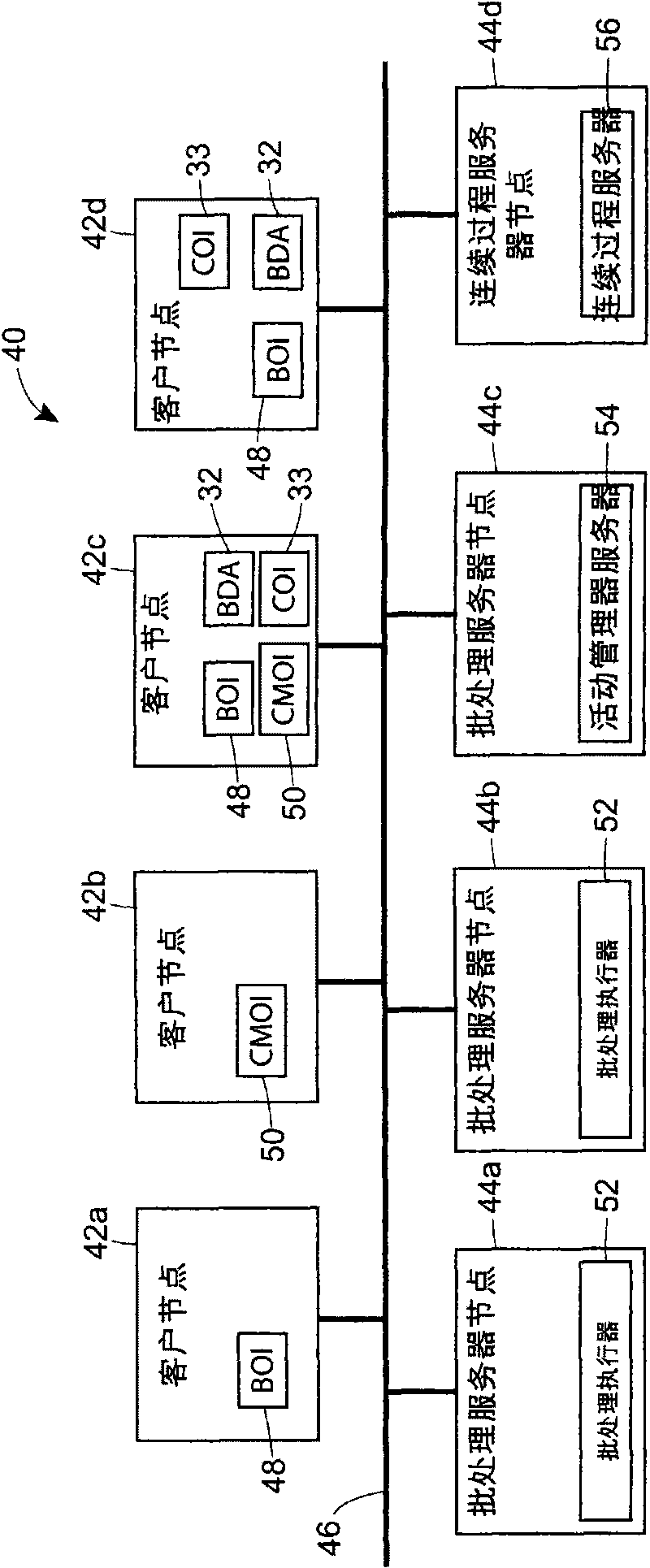

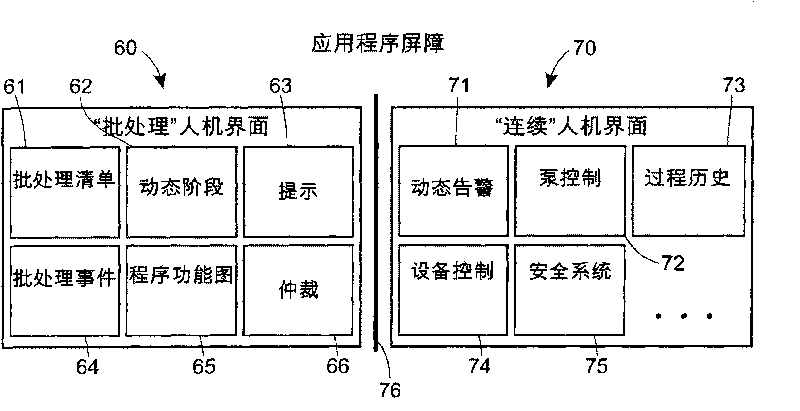

Complete integration of stand-alone batch operator interface capabilities into generic human machine interface using componentized objects

ActiveCN101713986ATotal factory controlInput/output processes for data processingOperator interfaceUser input

The present invention relates to complete integration of stand-alone batch operator interface capabilities into generic human machine interface using componentized objects. Systems and methods for providing an integrated HMI application for monitoring and interacting with both batch and non-batch processes in a process plant are disclosed. A plurality of independent stand-alone software objects defining various batch process interface views are embedded within a non-batch process control interface application. A blackboard service is provided for storing batch control data used by the various stand alone software objects. The blackboard service may be adapted to communicate with a batch control server to receive batch control data for populating the various batch interface views with data relating to various batch processes being carried out in the process plant and to send instructions for controlling the various batches input by users via the various batch interface views. When executed by a processor, the stand alone software objects defining the various batch interface views read data from and write data to the blackboard service to communicate data between batch process interface views and preserve contextual information between interface views to allow efficient and intuitive navigation between batch process interface views.

Owner:FISHER-ROSEMOUNT SYST INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com