Device for monitoring state of rotary bearing and diagnosing fault based on laboratory virtual instrument engineering workbench (Lab VIEW)

A fault diagnosis device and technology of slewing bearings, applied in electrical testing/monitoring, etc., can solve the problems of low diagnostic efficiency and reliance on professional knowledge of diagnostic experts, and achieve the effects of simple operation, friendly man-machine interface and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

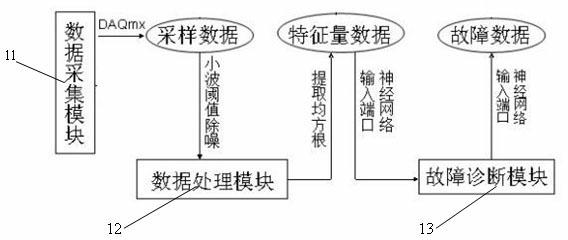

[0021] Embodiment 1: The LabVIEW-based slewing bearing state monitoring and fault diagnosis device proposed by the present invention uses a virtual instrument LabVIEW development platform which is a graphical programming system developed by NI Corporation. It is a powerful integrated development environment with a huge function library, which completely integrates communication with hardware such as GPIB, VXI, PCI and plug-in data acquisition cards.

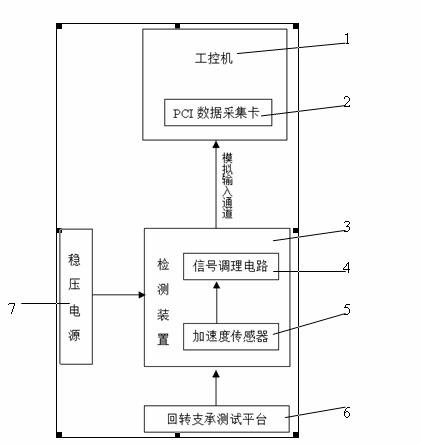

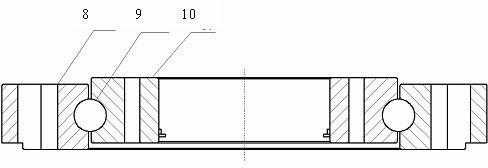

[0022] attached figure 1 It is a block diagram of the hardware structure of the present invention, including industrial computer 1, detection device 3 and voltage stabilized power supply 7, a PCI data acquisition card 2 comprising an analog input channel is provided in the industrial computer 1, and an acceleration sensor 5 and an acceleration sensor 5 are provided in the detection device 3. Signal conditioning circuit 4. The present invention takes the vibration acceleration of the slewing bearing as the monitoring parameter, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com