Special-shaped conductor part dimension measurement method

A measurement method and technology of parts, applied in the direction of measuring device, mechanical measuring device, angle/taper measurement, etc., can solve the problems of unsuitable mass production inspection, high requirements for equipment and personnel, and inability to extract the end points of dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

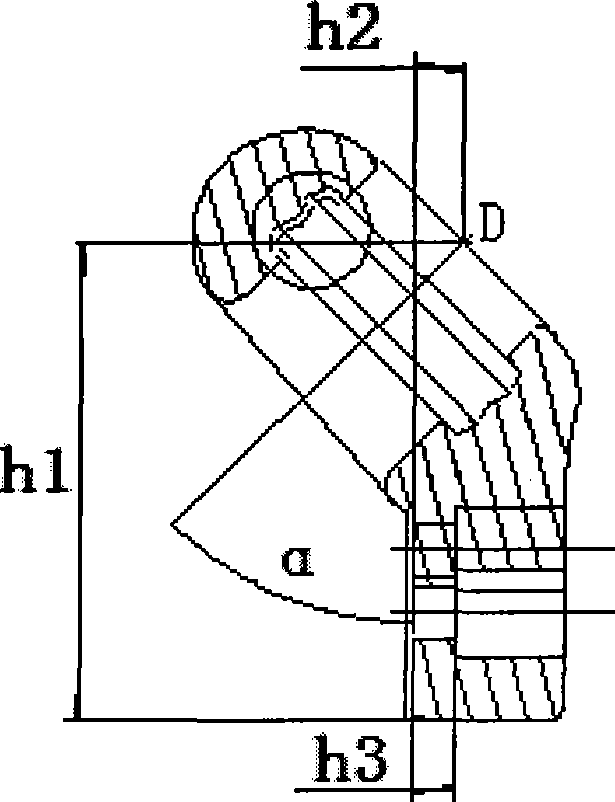

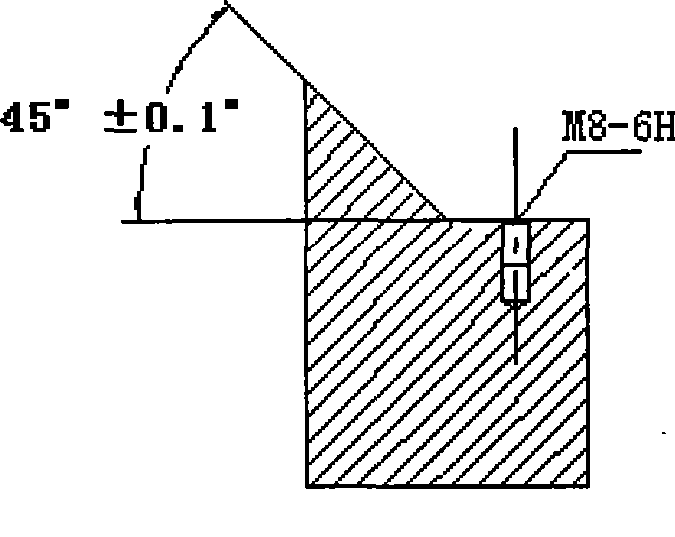

[0019] because figure 1 The reference hole of the tested part is , so if image 3 , Figure 4 As shown, three sets of mandrels of size series were first produced to meet the matching needs of different hole sizes.

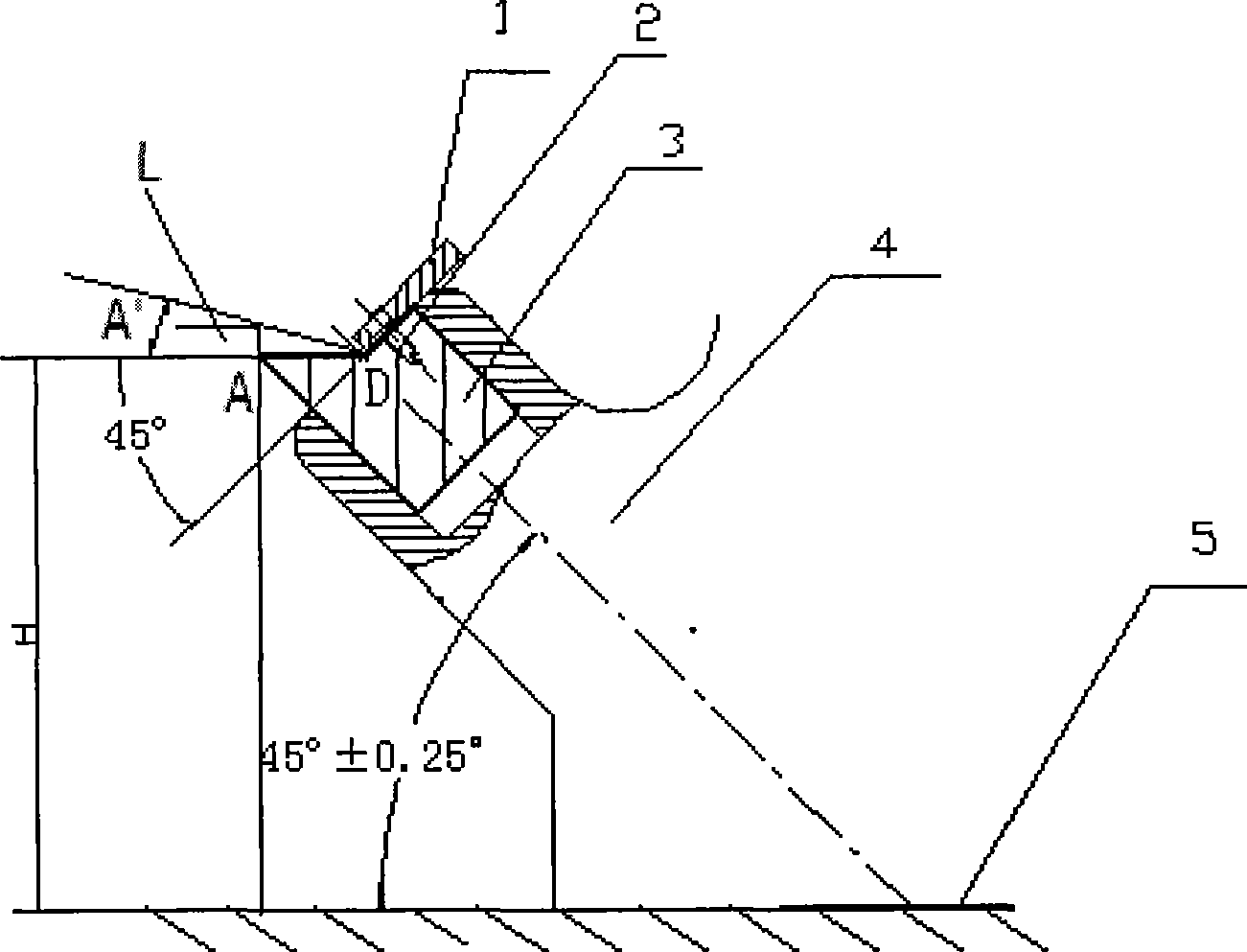

[0020] Such as figure 2 As shown, place the part 4 on the detection platform 5, clean the Φ53 inner hole of the workpiece 4, first measure the diameter and depth of the hole, select the appropriate mandrel 3, and make the fit clearance as small as possible. Use screws 2 to fasten the limiting plate 1 to the M8 screw holes on the mandrel 3 . Then insert the mandrel 3 in the direction shown. After aligning the intersection line 6 of the two planes of the mandrel with the height gauge, move the probe of the height gauge close to the intersection line to measure the dimension H, and then move the probe of the height gauge to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com