Plunger type equal-liquid-level pressure amorphous strip maker

An amorphous belt-making machine and plunger-type technology, which is applied in the field of belt-making equipment for manufacturing amorphous alloys or amorphous nanocrystalline soft magnetic alloys, can solve problems such as equipment debugging, not yet running, and unstable roll gaps. , to achieve the effect of maintaining uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

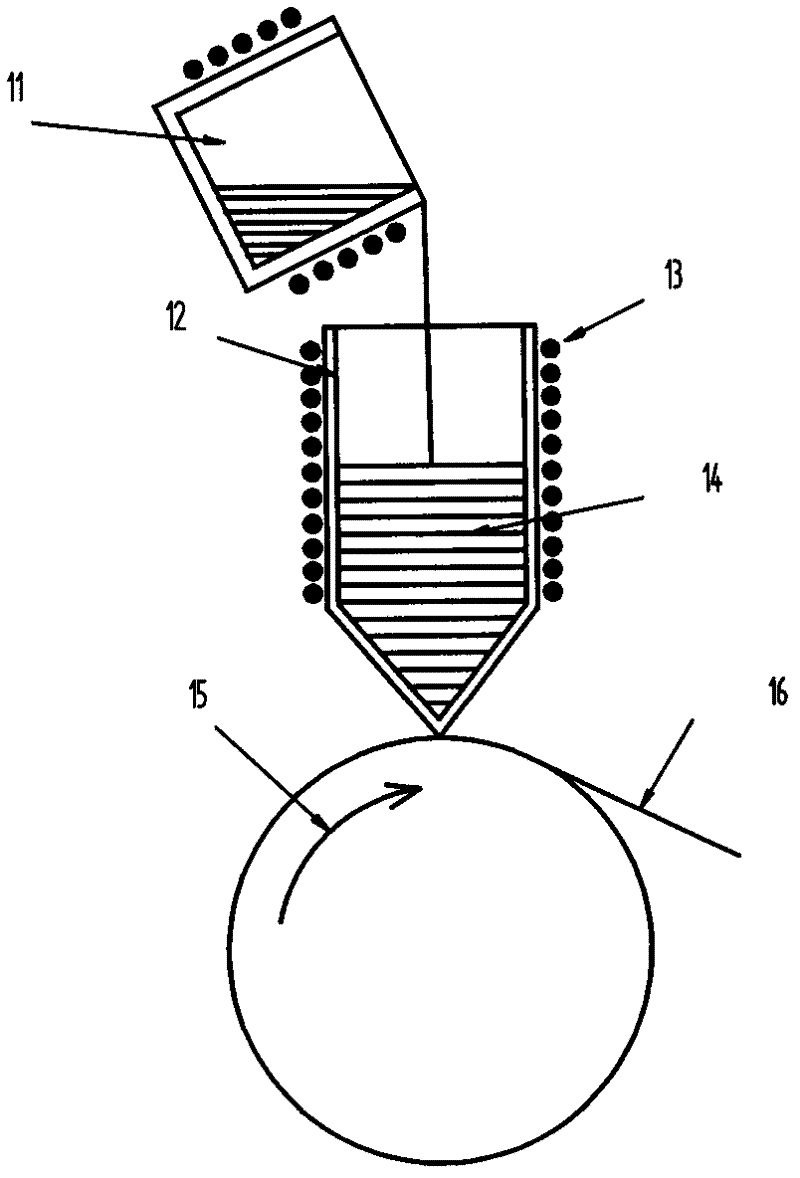

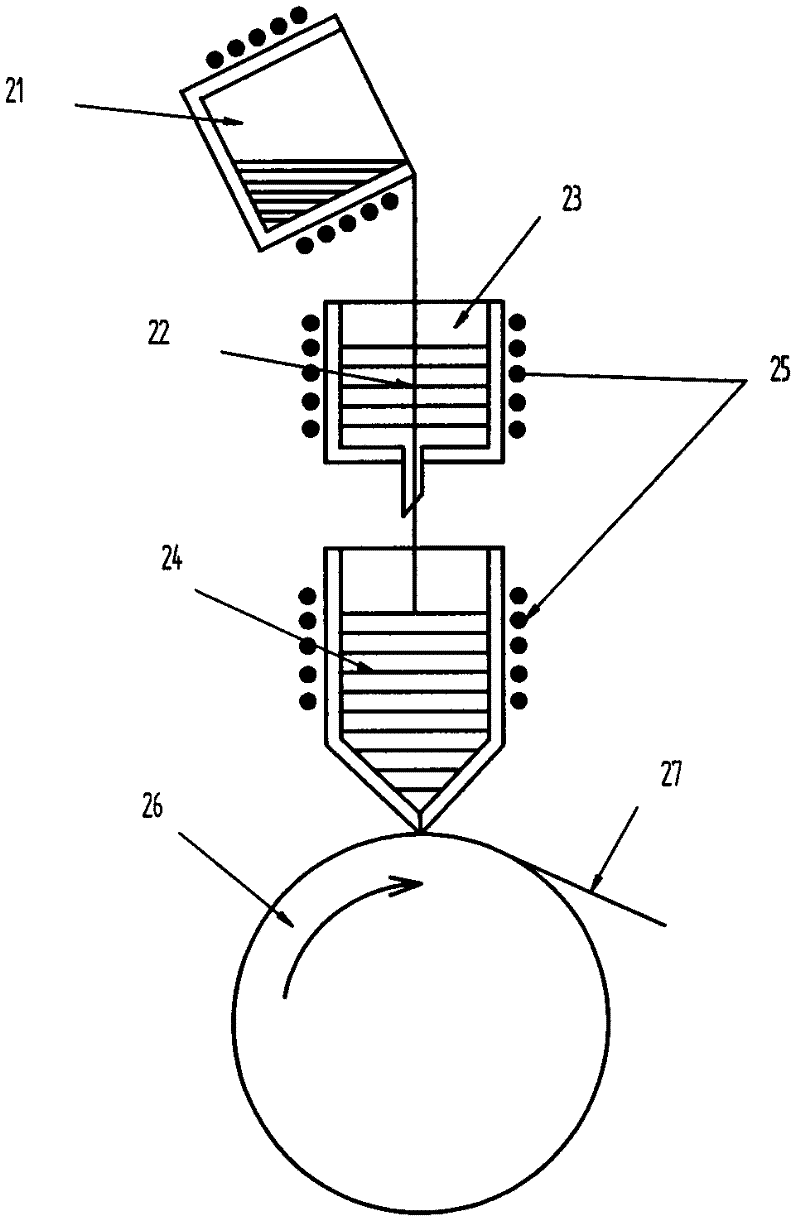

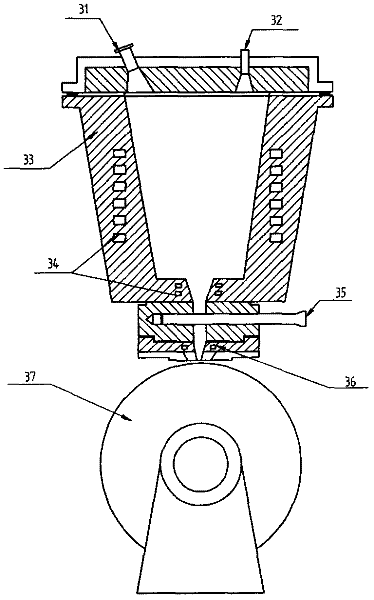

Image

Examples

specific Embodiment 1

[0055] Device parameters

[0056] Non-vacuum induction furnace: loading capacity 200kg

[0057] Nozzle package parameters: volume 12x16x45cm material: silicon carbide

[0058] Nozzle material: BN

[0059] Stopper rod: made of wood sticks with moderate density, baked at 200 degrees Celsius for 48 hours, coated with silicon melt + zircon powder, and then baked at 200 degrees Celsius for 48 hours, size: φ11x50cm

[0060] Cooling roll material: CrZrCu Size: φ60x20cm

[0061] Cooling water pressure: 1.8MPa

[0062] Spray tape grade: 1K107

[0063] Master alloy composition Cu1.3Si7.72B1.99Nb5.5Fe

[0064] Design spray tape size thickness 25μm width 20mm

[0065] Nozzle size mouth slit width 0.5mm length 20mm

[0066] Cooling roll speed 32m / s

[0067] Operation: Manual

[0068] Inspection: water pressure, cooling roll speed, stopper rod displacement, intermediate frequency power supply for furnace turning action

[0069] Furnace loading: make 200kg master alloy less than 8c...

specific Embodiment 2

[0079] Spray tape grade: 2605S-2

[0080] Master alloy composition: Si5.14B2.65Fe

[0081] Density: 7.18g / cm 3

[0082] Design spray tape size: 25μm wide 100mm

[0083] Nozzle size: nozzle width 0.5mm length 100mm

[0084] Cooling roll speed: 32m / s

[0085] Operation: Manual

[0086] Related operations are the same as spraying 1K107

[0087] Regarding the difference:

[0088] The pouring temperature is 1380°C

[0089] Nozzle liquid level control 42cm

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com