Wafer surface inspection apparatus and wafer surface inspection method

a technology of surface inspection and wafer, which is applied in the field of surface inspection apparatus and wafer surface inspection, can solve the problems of contaminating the wafer, reducing the detection sensitivity, and the phenomenon of destruction of foreign particles by laser irradiation has begun to emerge, so as to prevent the reduction of detection sensitivity and increase the density of energy of irradiated laser

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]The inspection method and the inspection apparatus of the present invention are applicable to a flat plate-shaped subject to be inspected, such as a semiconductor wafer, a glass substrate for a liquid crystal panel, a disk substrate and the like. In the following, embodiments of the present invention will be described with reference to the drawings, taking a semiconductor wafer as an example.

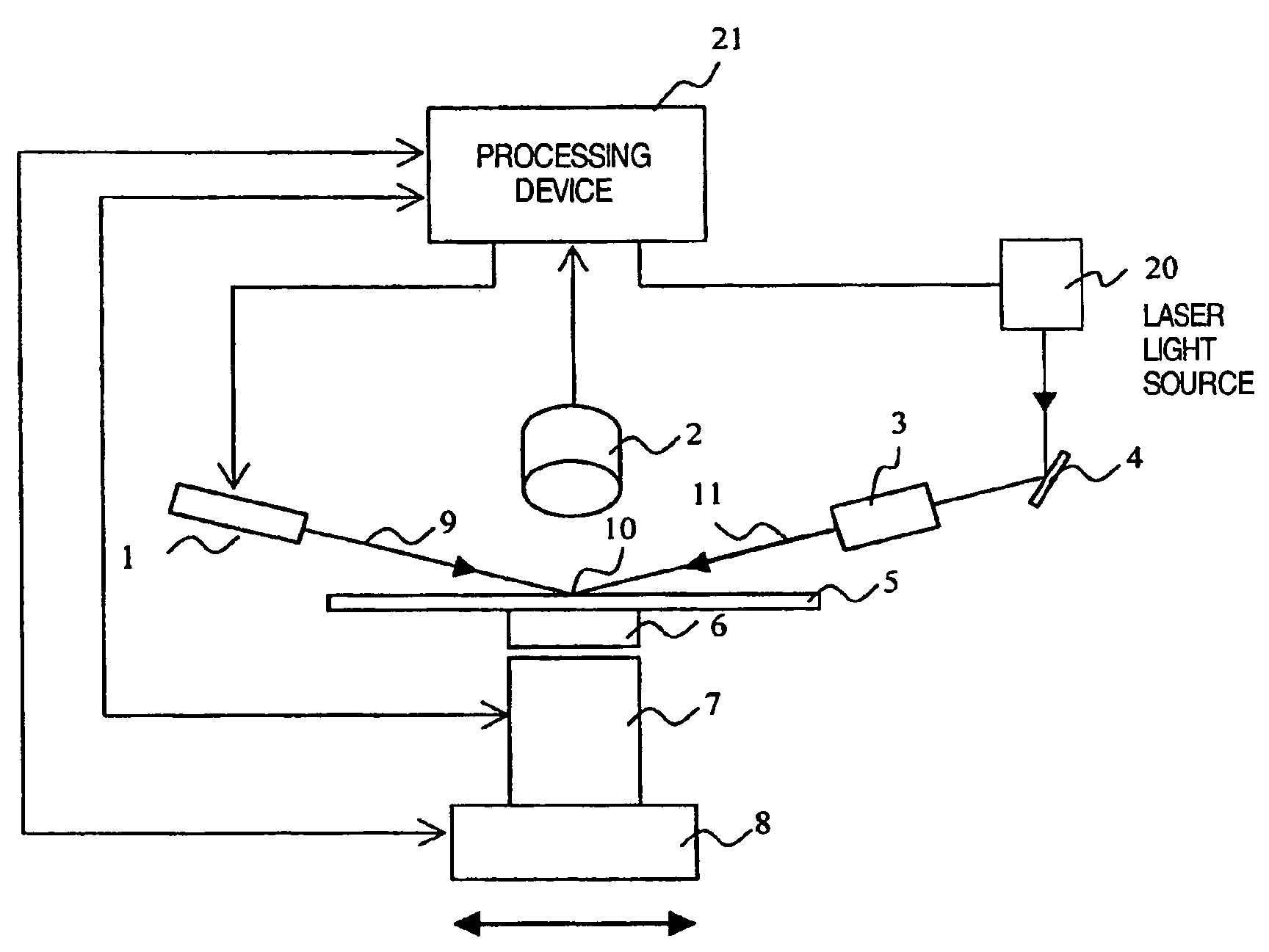

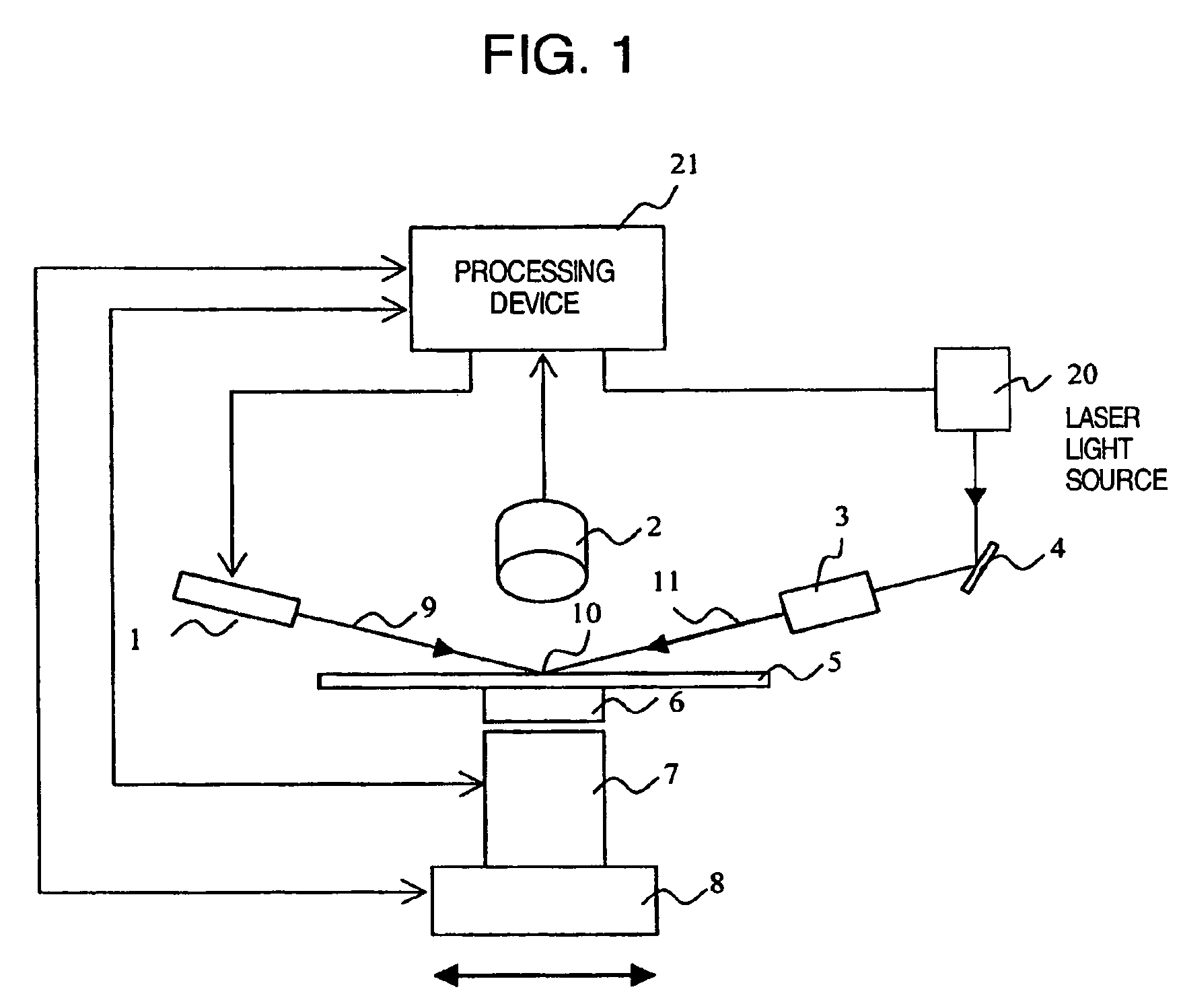

[0020]FIG. 1 shows a schematic configuration of a foreign particle inspection apparatus of the present invention incorporating gas spraying means (gas spraying unit).

[0021]A semiconductor wafer 5 that is the subject to be inspected is rested on an inspection table 6, serving also as holding means (holder) or vacuum suction means (vacuum suction device), and is clamped or held with vacuum. A scanning stage 8 is mounted with an air spindle motor 7 to which inspection table 6 is attached, and is capable of generally horizontal movement backwards and forthwards in an axial direction. Air spind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield | aaaaa | aaaaa |

| sensitivity | aaaaa | aaaaa |

| irradiation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com