Limiting and adjusting mechanism for forming lug holes of lug winding machine

An adjustment mechanism and earphone technology, which is applied in the field of fully hydraulic earphone rolling machines, can solve the problems of affecting the quality of ear rolling and the effect of pressing is not obvious, and achieve the effects of high position reliability, precise position adjustment and repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

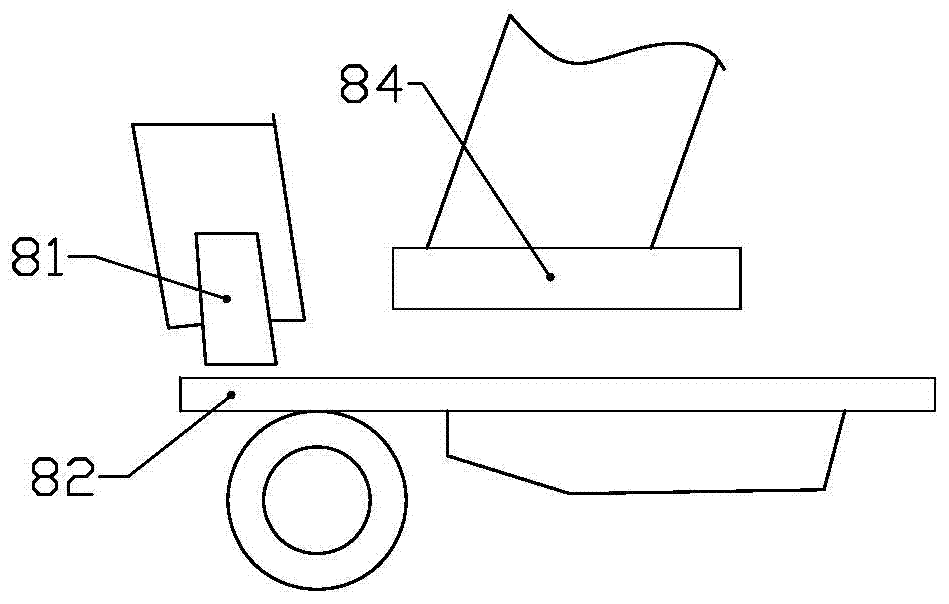

[0023] The ear hole forming limit adjustment mechanism of the roll earphone is installed in the roll earphone, and its main function is to compress the sheet material for the ear rolling operation, so as to facilitate the ear rolling process.

[0024] In the same roll of earphones, in the process of ear rolling for different batches of sheet materials with different thicknesses, it is necessary to adjust the initial position and the pressing position of the ear hole forming limit adjustment mechanism in order to obtain a reasonable pressing force. At present, the use of oil cylinder is used for compression. In this simple compression mechanism, the piston in the oil cylinder is not at the bottom of the cylinder, and the force of compression is completely guaranteed by the pressure of hydraulic oil. Due to the hydraulic pressure and its compressibility , so that the pressing force fluctuates, which further affects the quality of the rolled ears.

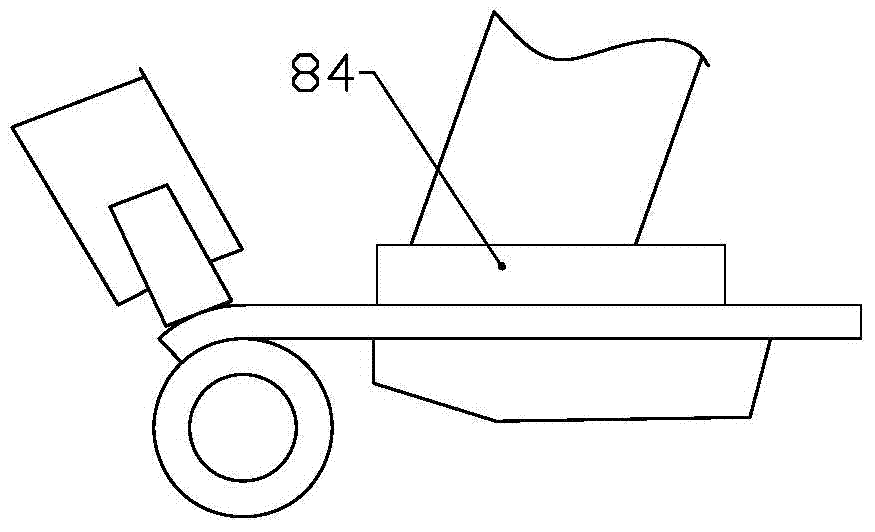

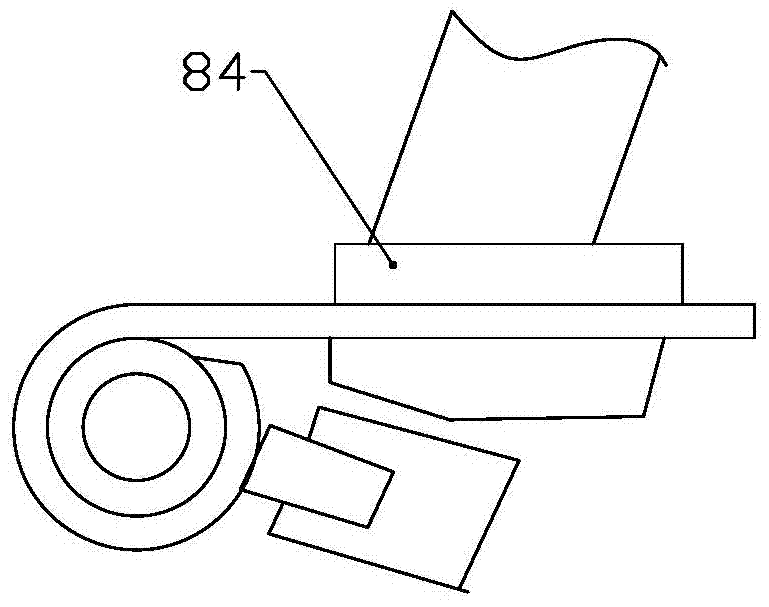

[0025] Such as Figure 5 to F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com