Patents

Literature

65results about How to "Guaranteed measurement efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

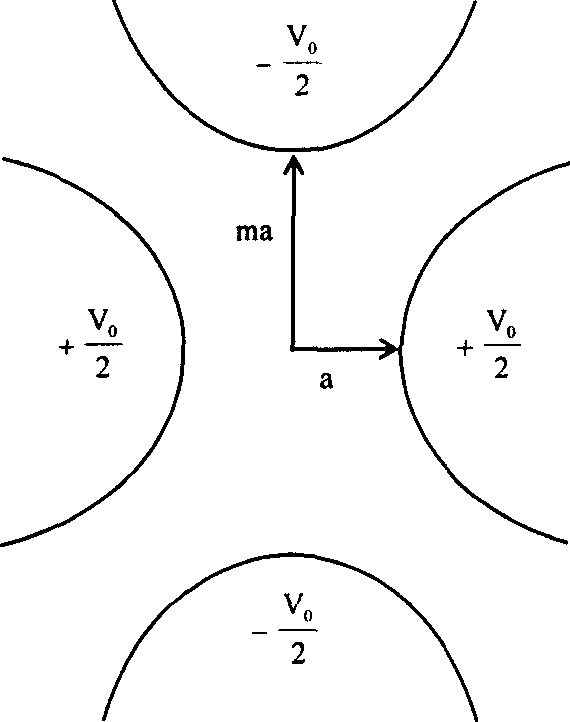

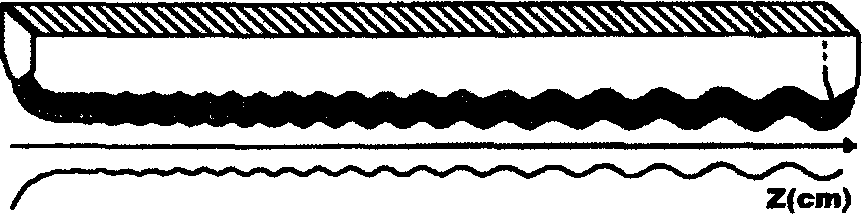

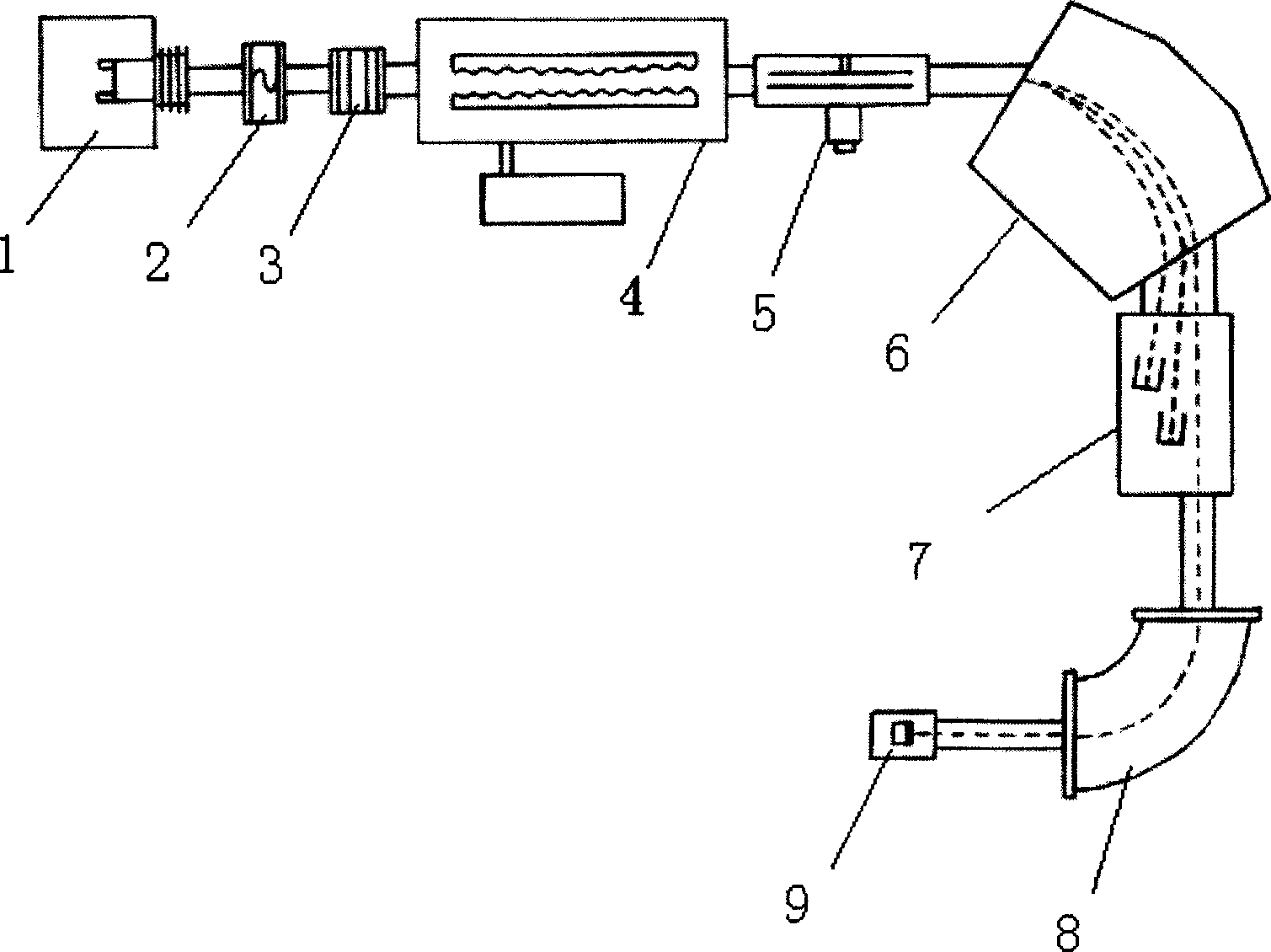

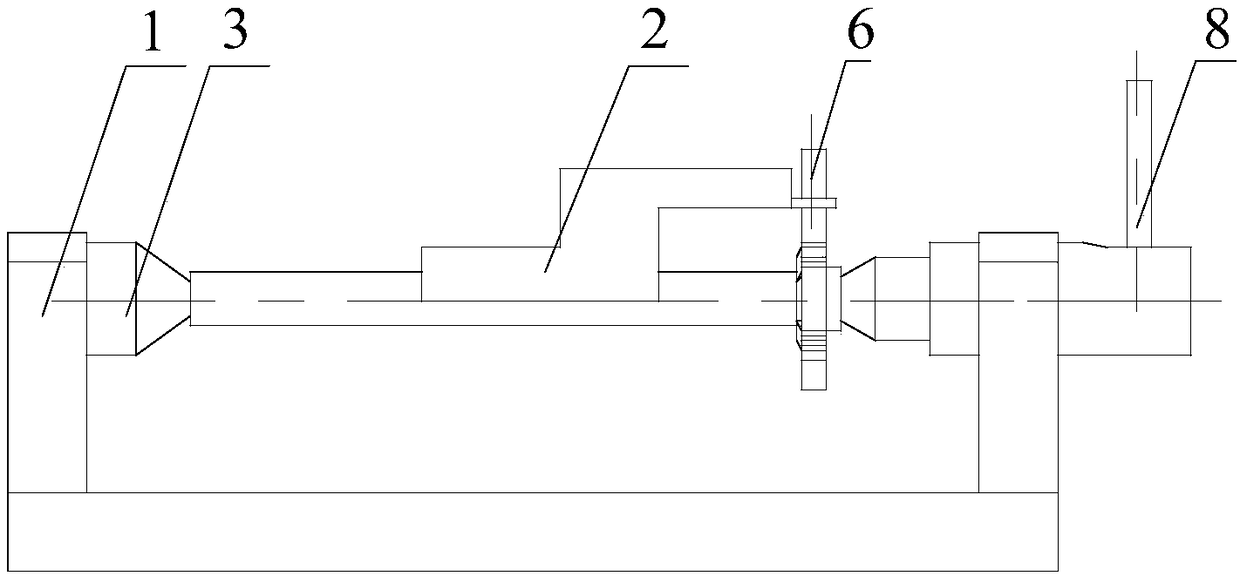

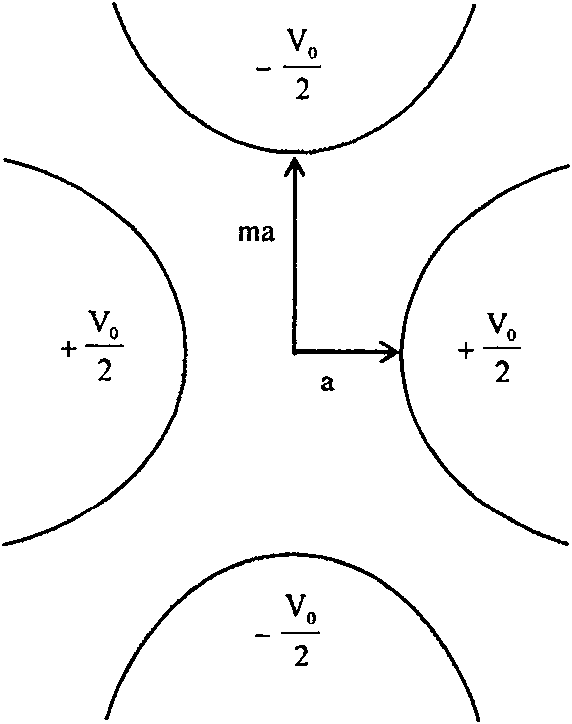

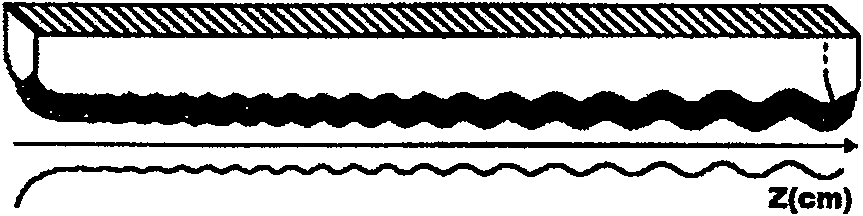

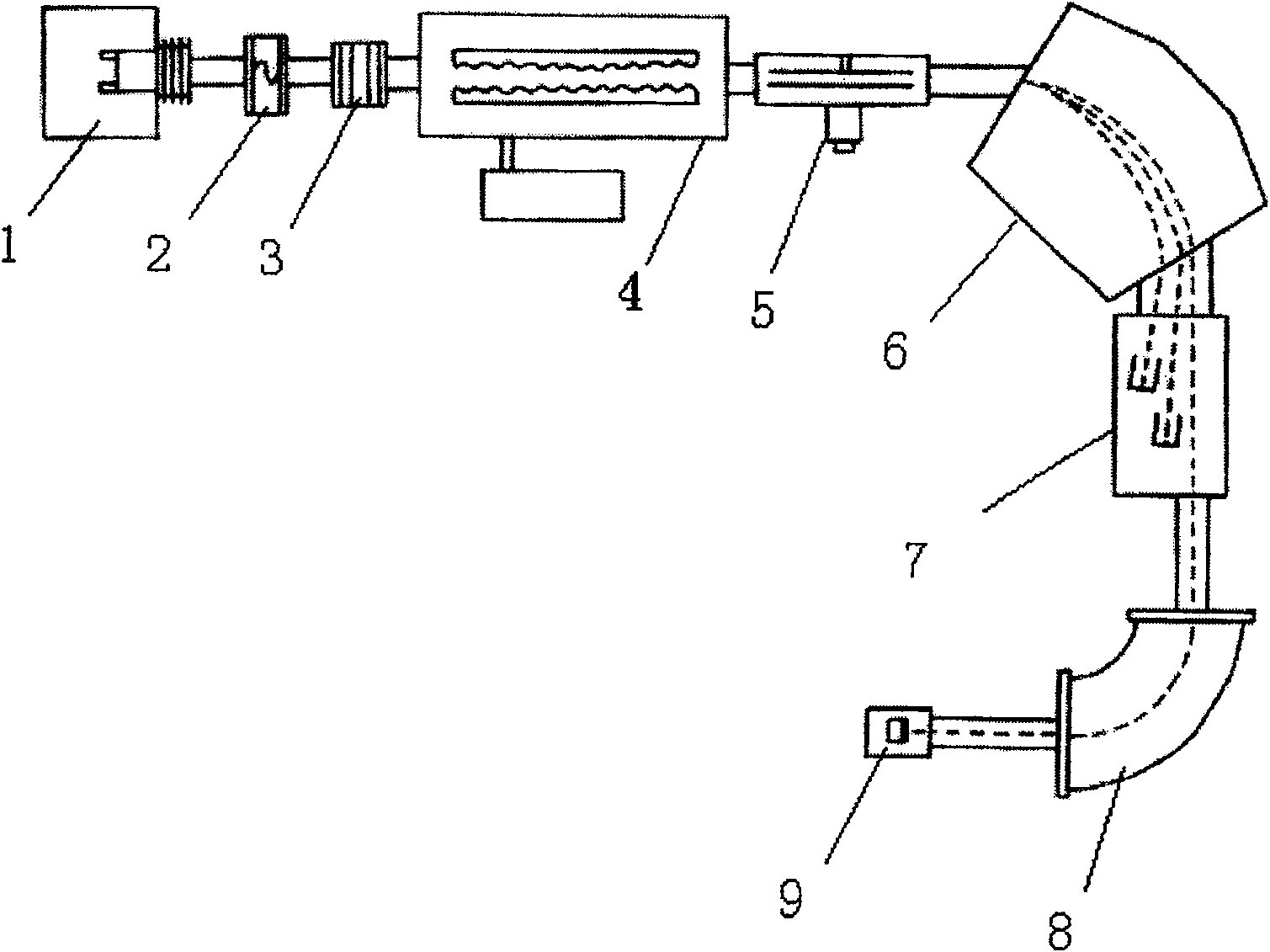

Mass spectrum equipment of accelerator, and method for measuring mass spectrum 14C of accelerator

InactiveCN1916622AEliminates cycle dryingImprove protectionStability-of-path spectrometersMaterial analysis by electric/magnetic meansHigh energyIon acceleration

A mass spectrum unit of accelerator consists of ion source, beam buncher, RFQ accelerator, electronic stripper, high energy analyzing system and detector. It is featured as connecting said unit and system in sequence; accelerating 14C, 12 C and 13C ion separately to be at certain energy for carrying out electronic lift off by R is not equal toQ accelerator in order to eliminate disturbance of molecular ion.

Owner:PEKING UNIV

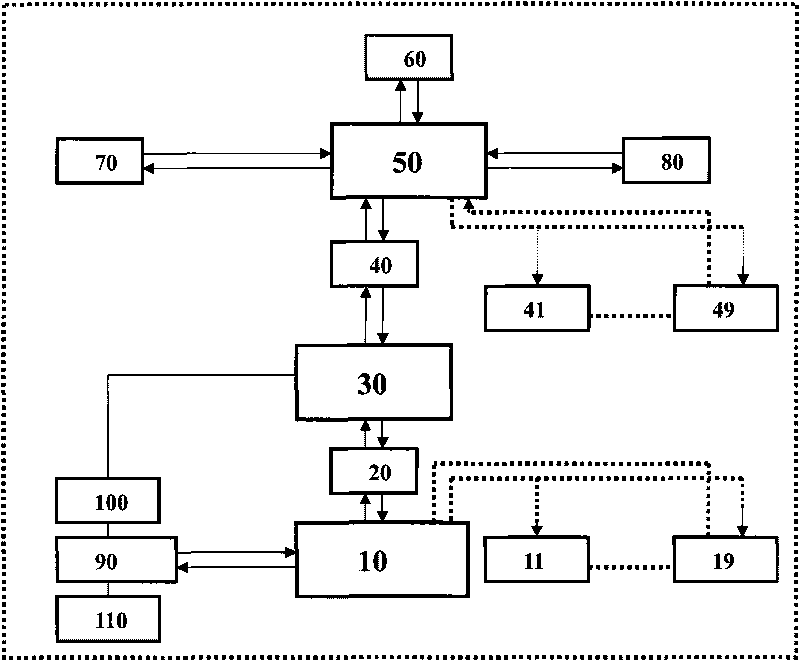

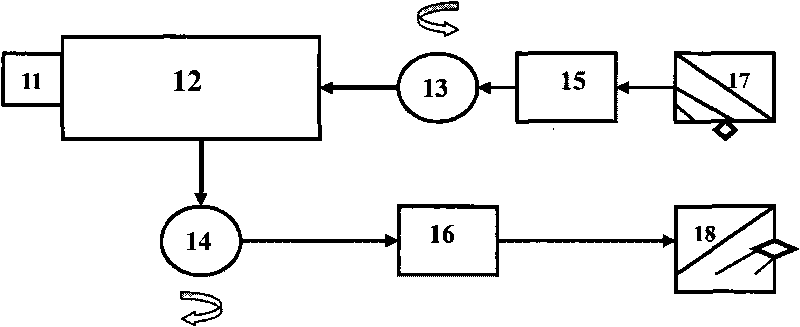

Microwave radar moisture sensor

InactiveCN101706459AGuaranteed separation effectGuaranteed measurement efficiencyMoisture content investigation using microwavesTransceiverMoisture sensor

The invention relates to a microwave radar moisture sensor, in particular to a contact / non-contact medium continuous or point sensing type microwave radar moisture sensor. The microwave radar moisture sensor comprises a probe, a signal channel, a signal processor (DSP), a TPS interface, a microprocessor (MCU), an I2C interface and a driving interface, wherein the output port of the probe is provided with an antenna, and the antenna can be provided with a holder and a filter scraper; the signal processor (DSP) and the microprocessor (MCU) are managed by respective software respectively; a pre-detected signal is connected with the driving interface through the probe, the signal channel, the signal processor, the TPS interface and the microprocessor (MCU); in addition, the probe, a polarization separator and a signal transceiver form a loop; and the antenna is arranged on one side or two sides of a detection medium. Because the microwave radar moisture sensor belongs to a multi-sensor system, correlated variables of the sensor are provided with enough interfaces, and other probes for temperature and electric conductivity can be connected with the signal processor through the I2C so as to finish moisture parameter correction.

Owner:杨厚荣

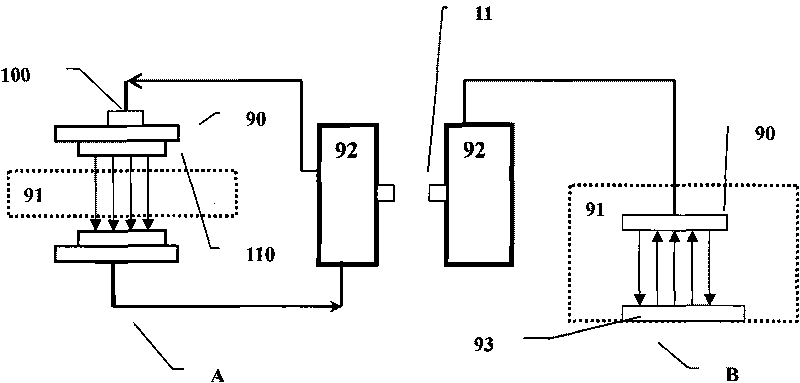

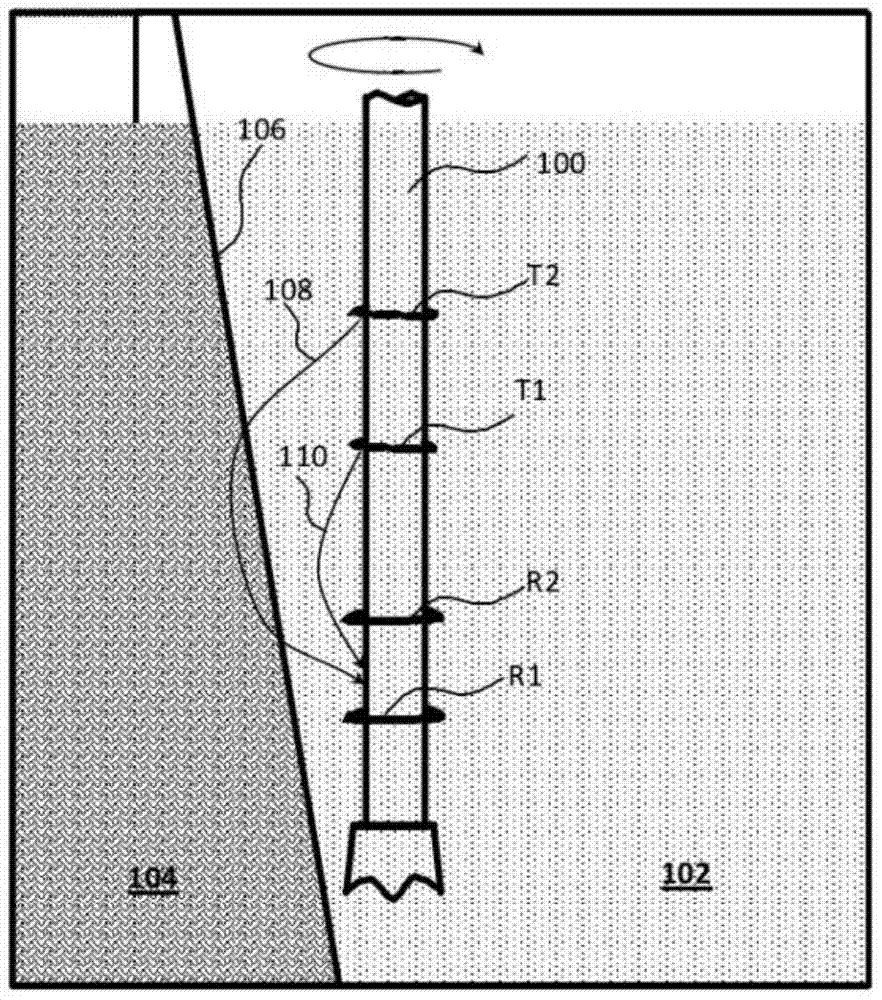

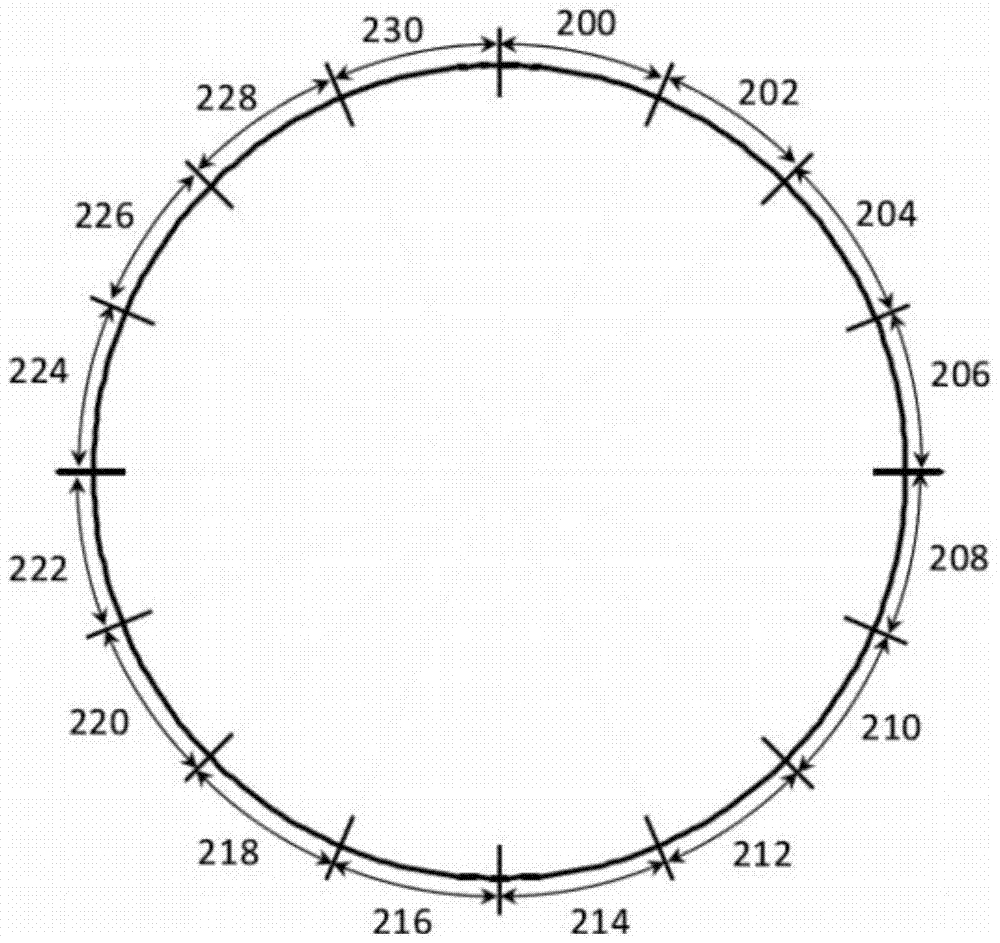

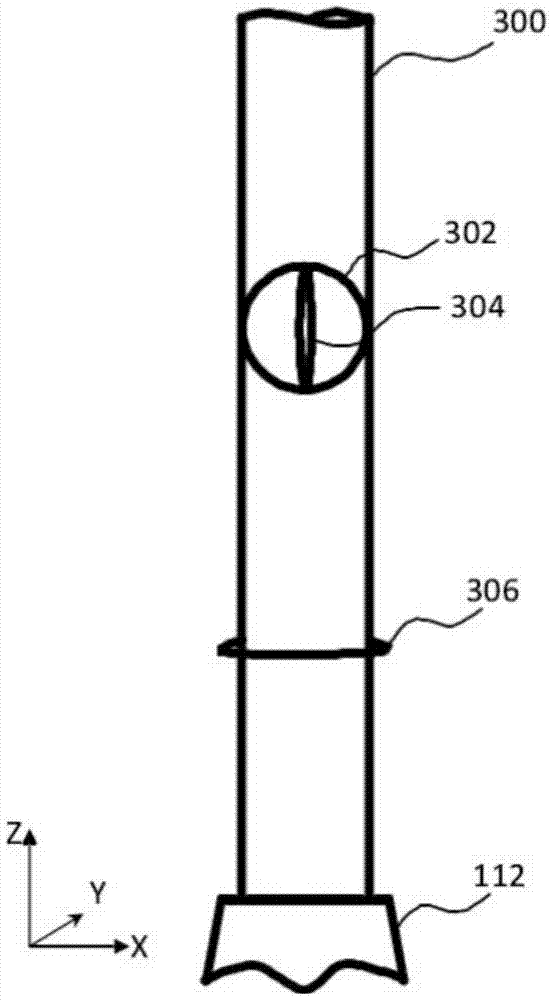

Method for detecting bed boundary

The invention discloses a method for detecting a bed boundary. The method includes the steps that a tool shell with a longitudinal axis is placed in a borehole, wherein a first transmitter, a second transmitter and a receiver are configured on the tool shell, and the directions of the devices are different; the magnetic torque of electromagnetic signals transmitted by the first transmitter and the second transmitter is modulated, then, the first transmitter and the second transmitter are made to send the electromagnetic signals at the same time, and total magnetic torque vectors of the electromagnetic signals are electrically rotated in the transmitting process; the receiver is used for receiving and measuring the modulated electromagnetic signals transmitted by the first transmitter and the second transmitter, and then the amplitude and the phase positions of the modulated electromagnetic signals are acquired; the direction and the position of the bed boundary are calculated according to the amplitude and the phase positions measured and acquired by the receiver. According to the method, the problem that a tool for measuring the directional resistivity can not meet practical work requirements is solved, and practicability of the devices is improved.

Owner:CNPC GREATWALL DRILLING ENG

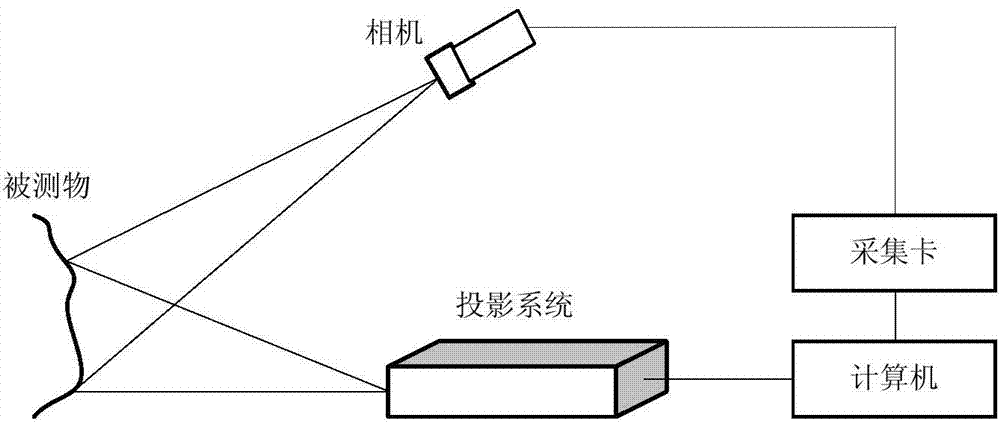

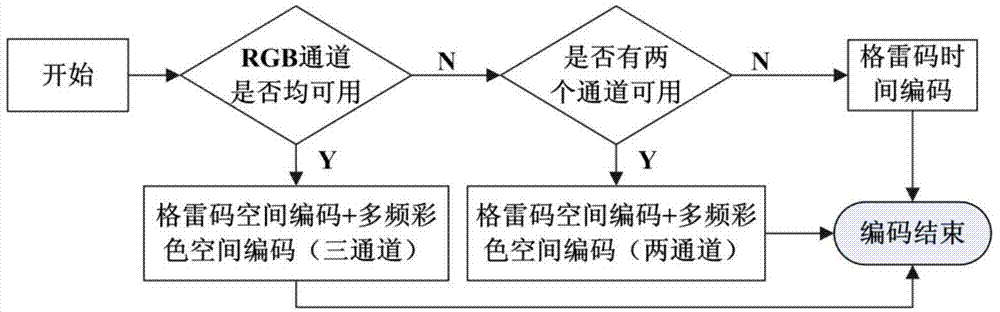

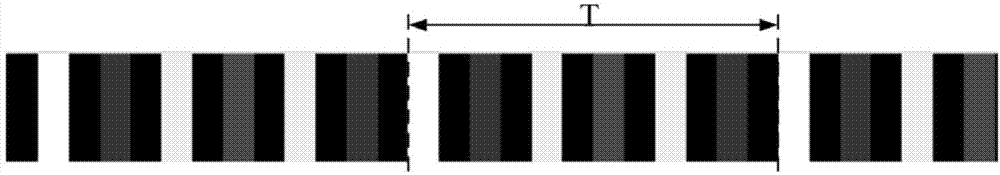

Optical three-dimensional profile measuring method of self-adaptation multi-frequency space-time color coding

ActiveCN104729427AGuaranteed measurement efficiencyReduce measurement errorUsing optical meansSpatial encodingDependability

Provided is an optical three-dimensional profile measuring method of self-adaptation multi-frequency space-time color coding. The method comprises the steps that firstly, a white image is projected on a to-be-tested object, a coding pass suitable for a surface reflection characteristic of the object is obtained through self-adaptation; and then, by using multi-frequency multi-color stripes to form a cyclical combined stripe, local space coding on the stripe is completed; finally, time coding is carried out on the cycle of the space coding by using Grey binary coding. A coded pattern is projected to carry out measuring on a profile, and three-dimensional profile data of a measured target are obtained. On the premise of guaranteeing the measuring efficiency, the problems of the color coding measuring precision and the decoding reliability are solved.

Owner:XI AN JIAOTONG UNIV

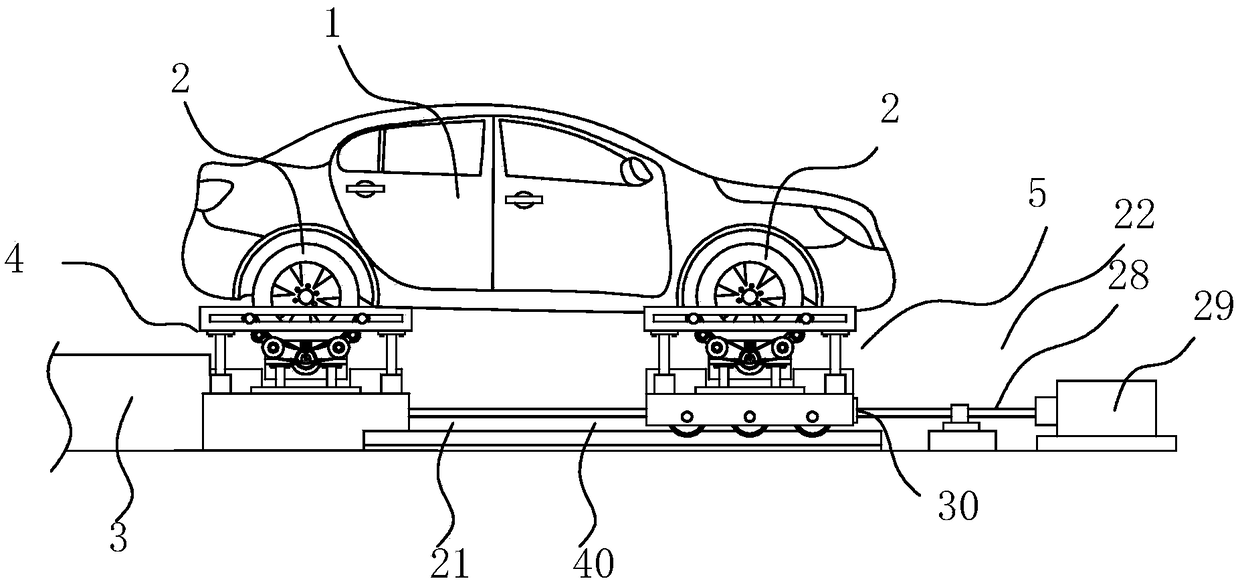

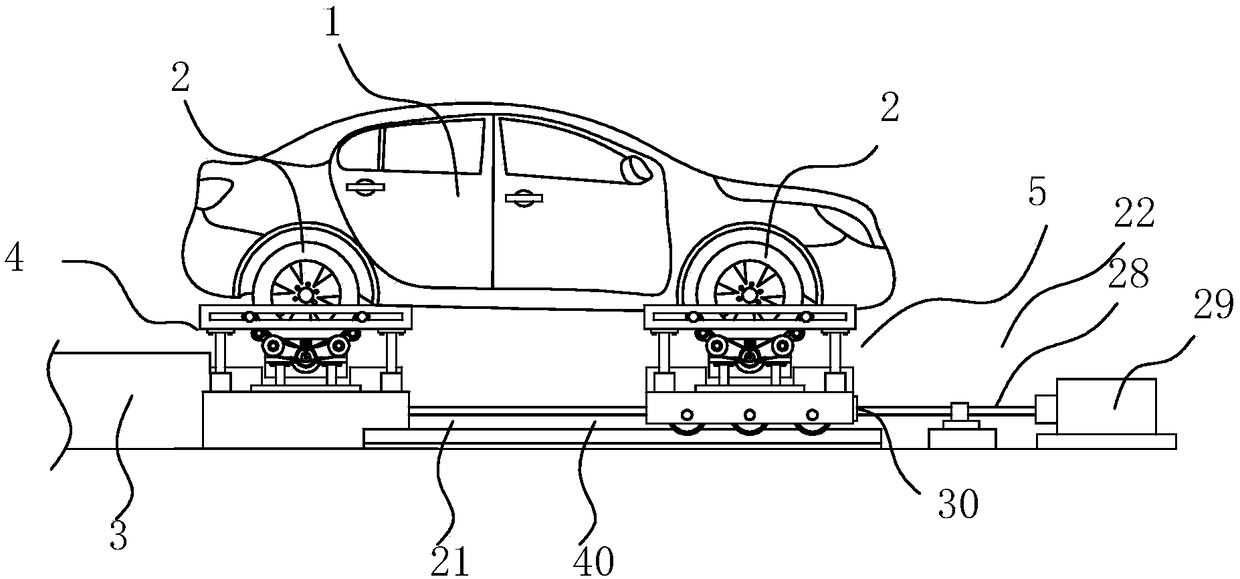

Automobile tread pattern depth automatic detection method

The invention discloses an automobile tread pattern depth automatic detection method. A laser distance measuring device measures tread pattern depth, a camera is used for shooting a lateral image of atire, and the tread pattern depth, tire image data and detection time accumulative data are sent to a server in real time; the server judges tread pattern depth data, and it is judged whether or notabnormal wear exists and hubs, rims, valve caps and the like are in good condition. An automatic tread pattern detection system has the advantages that the convenience degree of the operation is improved, and the system is conductive to achieving the real-time performance of the automatic operation and data transmission; the laser distance measuring device measures the tread pattern depth, the acquiring of data is quicker, and the measuring working efficiency and measuring precision are ensured.

Owner:SHANGHAI OCEAN UNIV

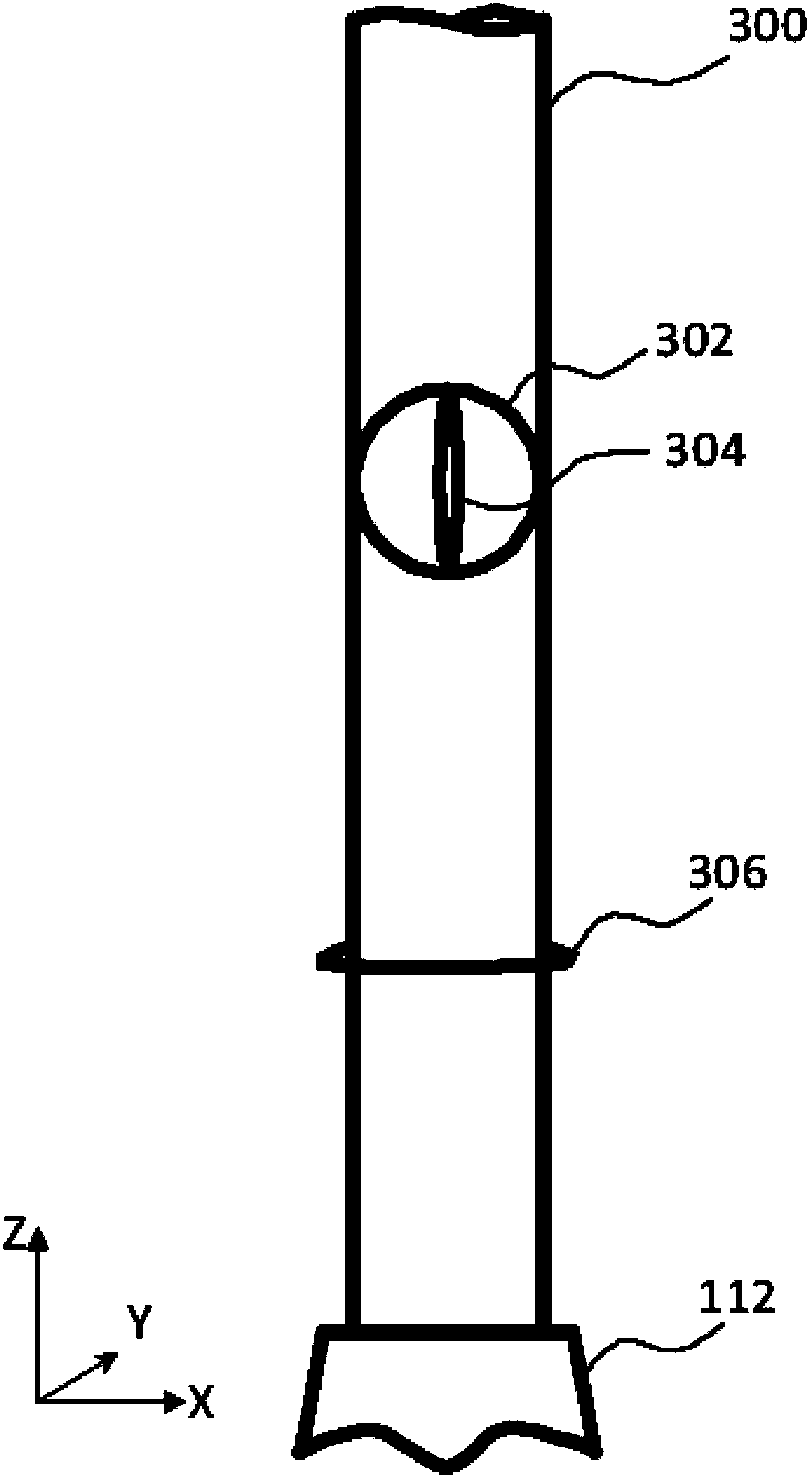

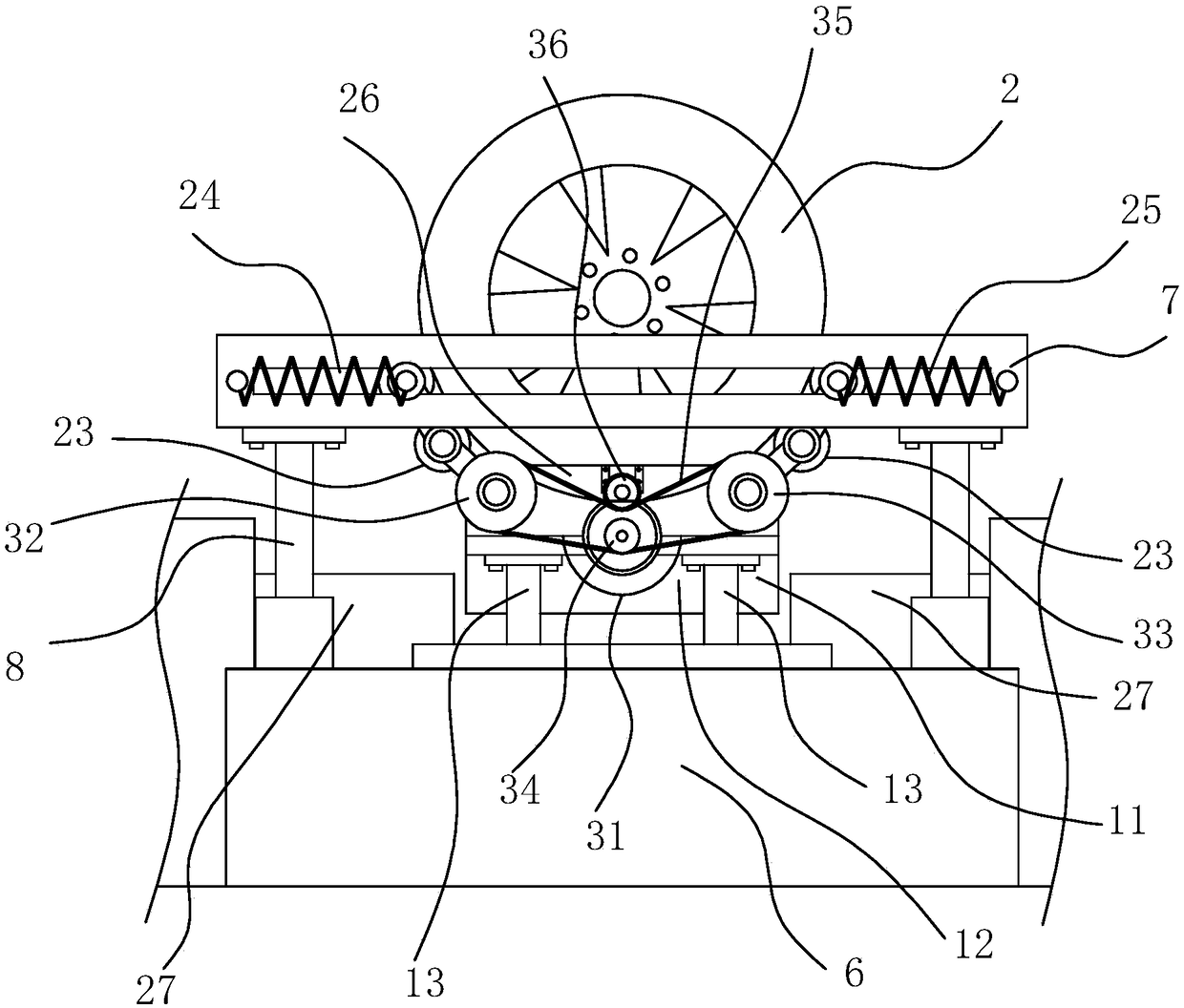

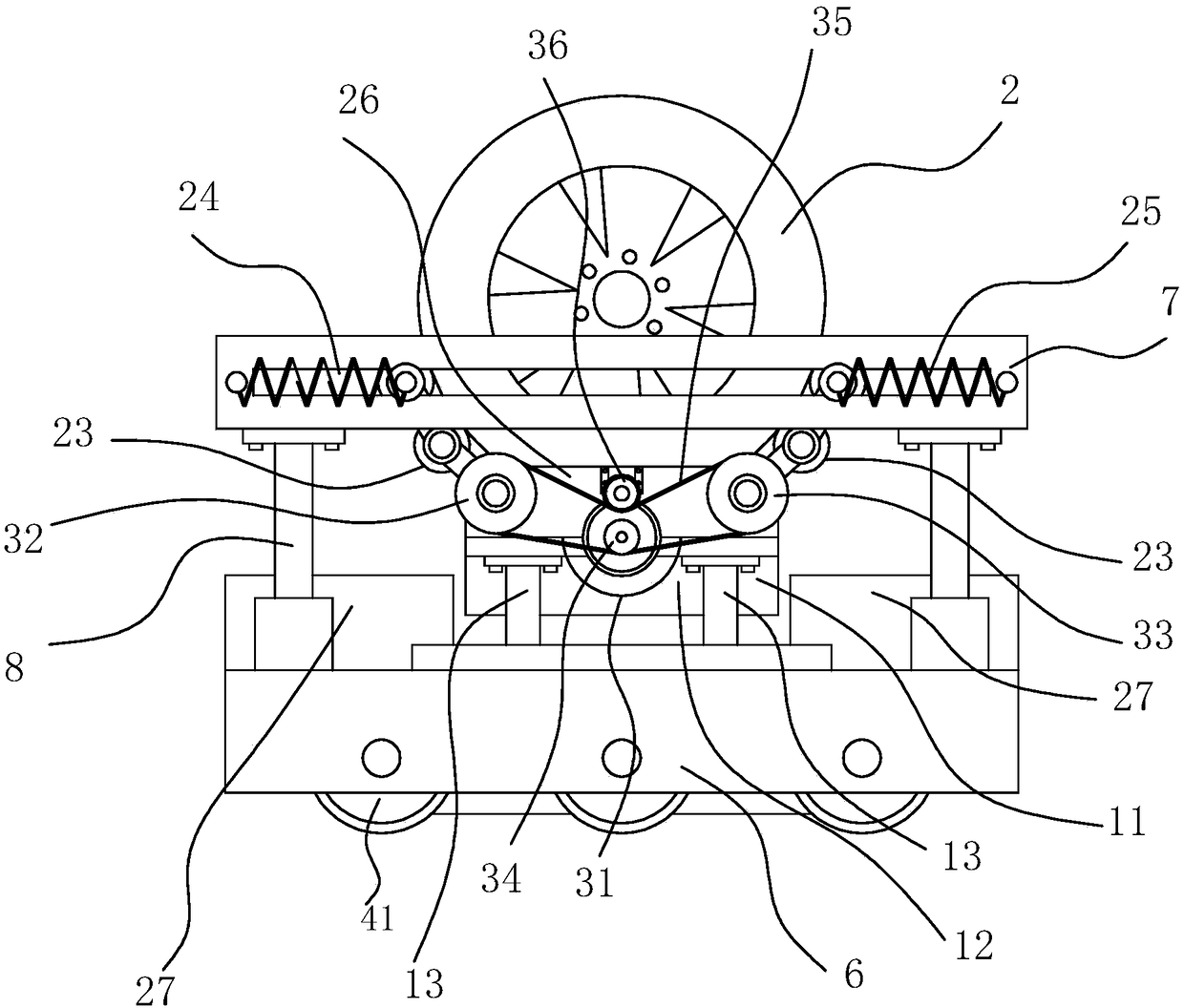

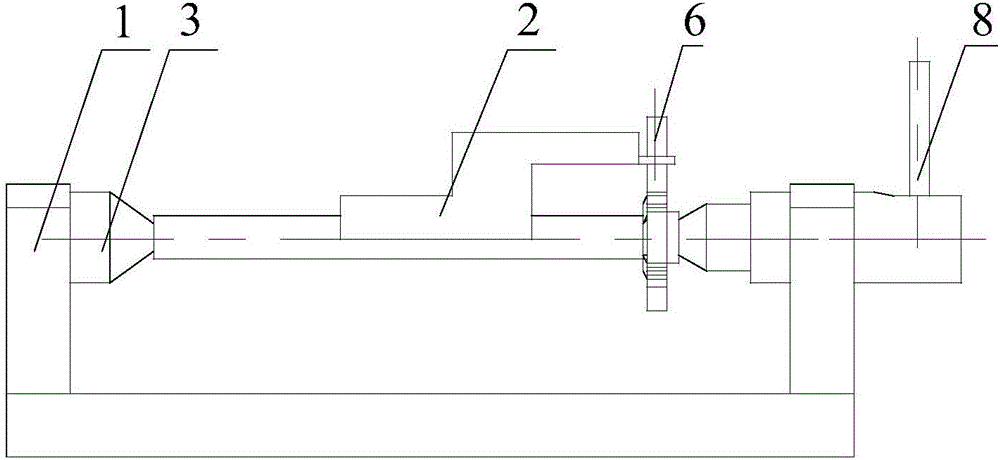

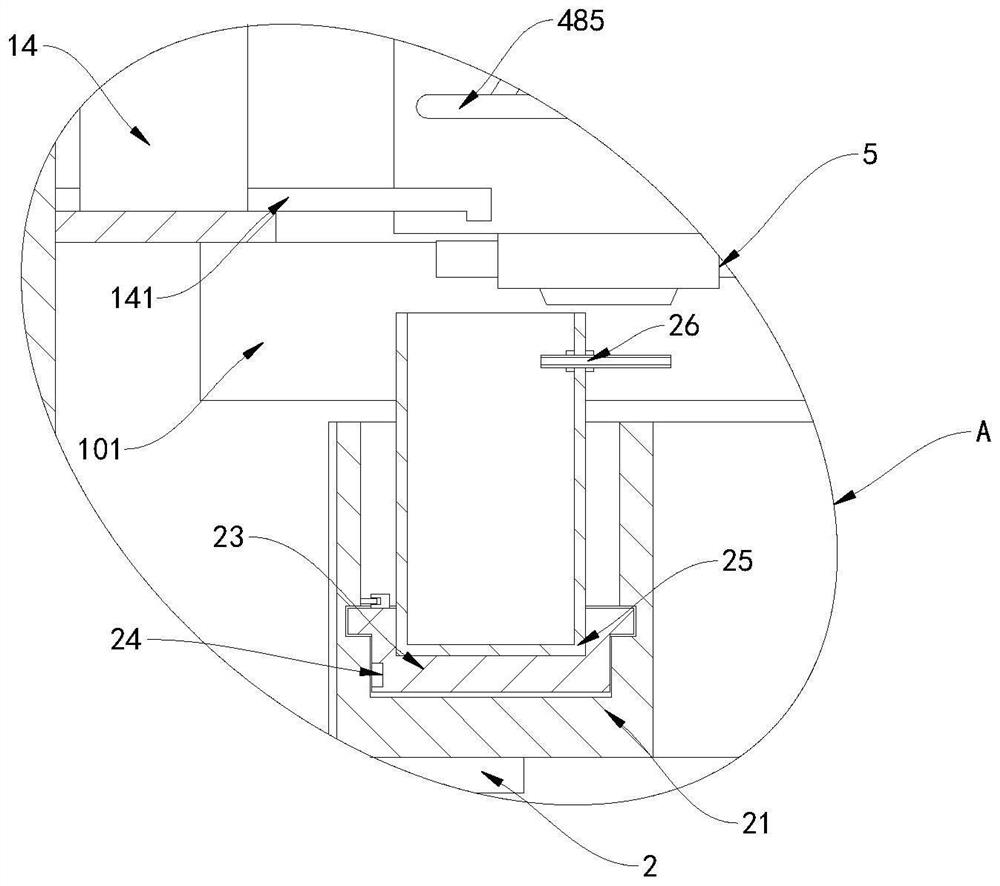

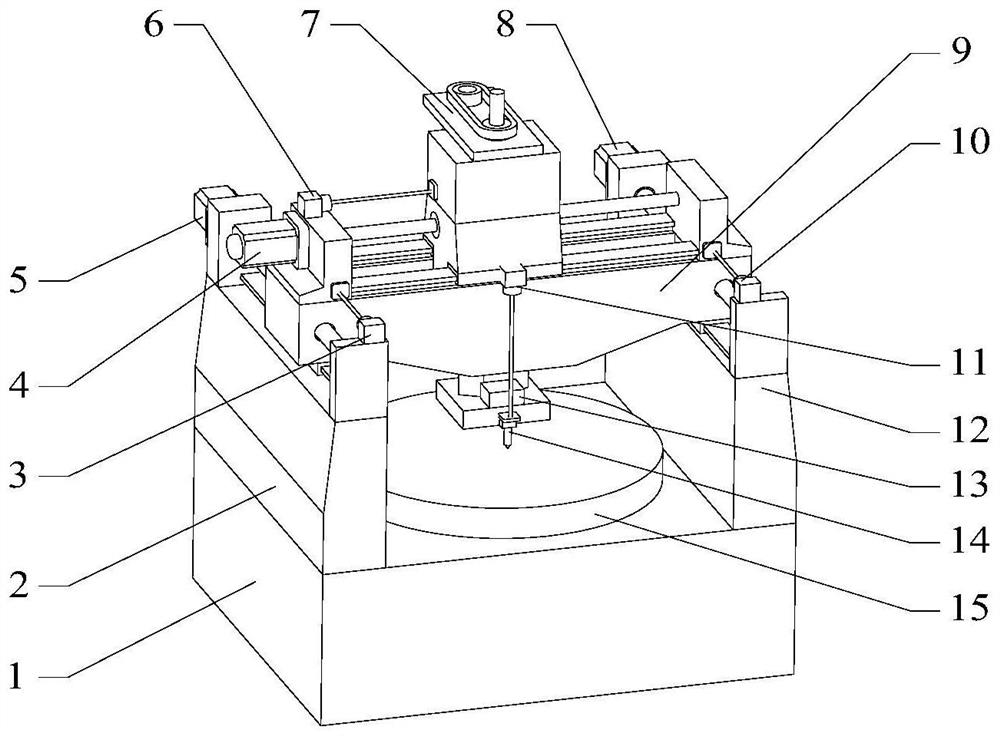

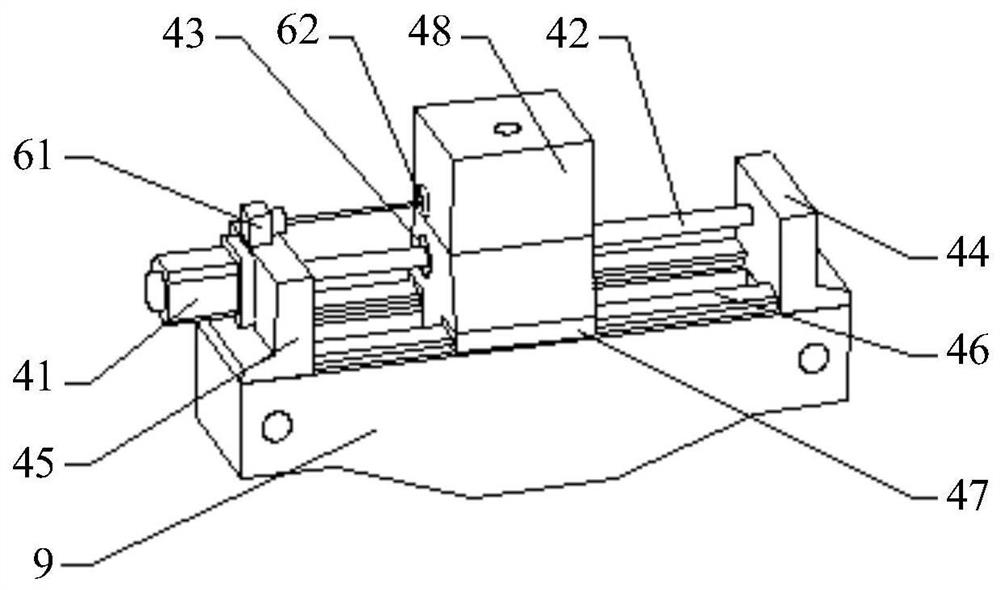

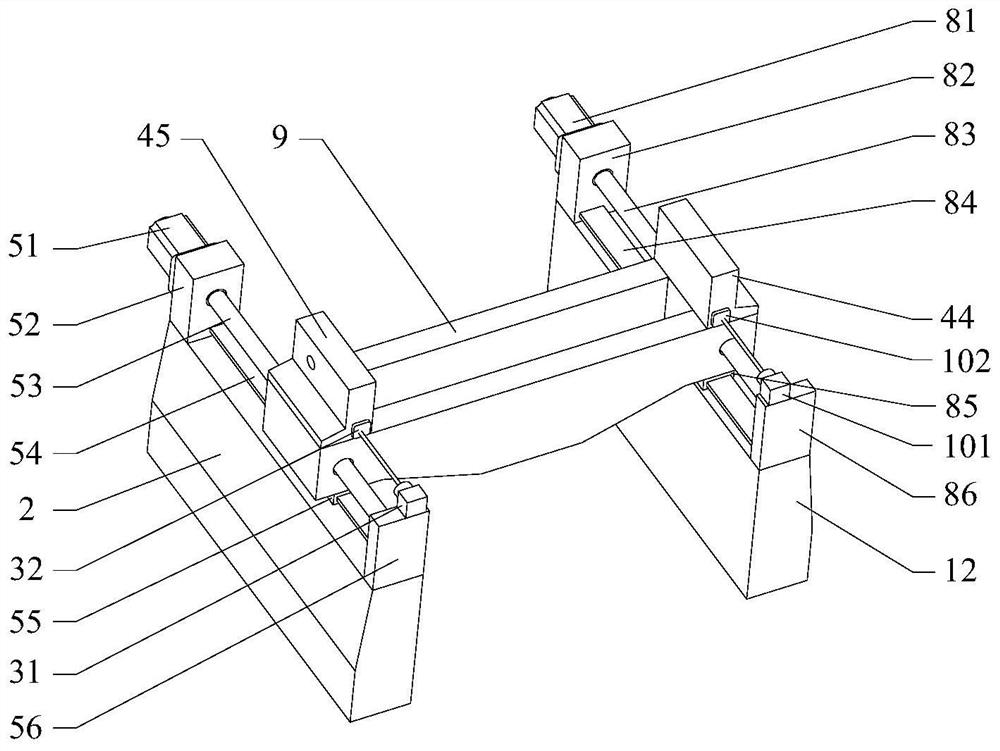

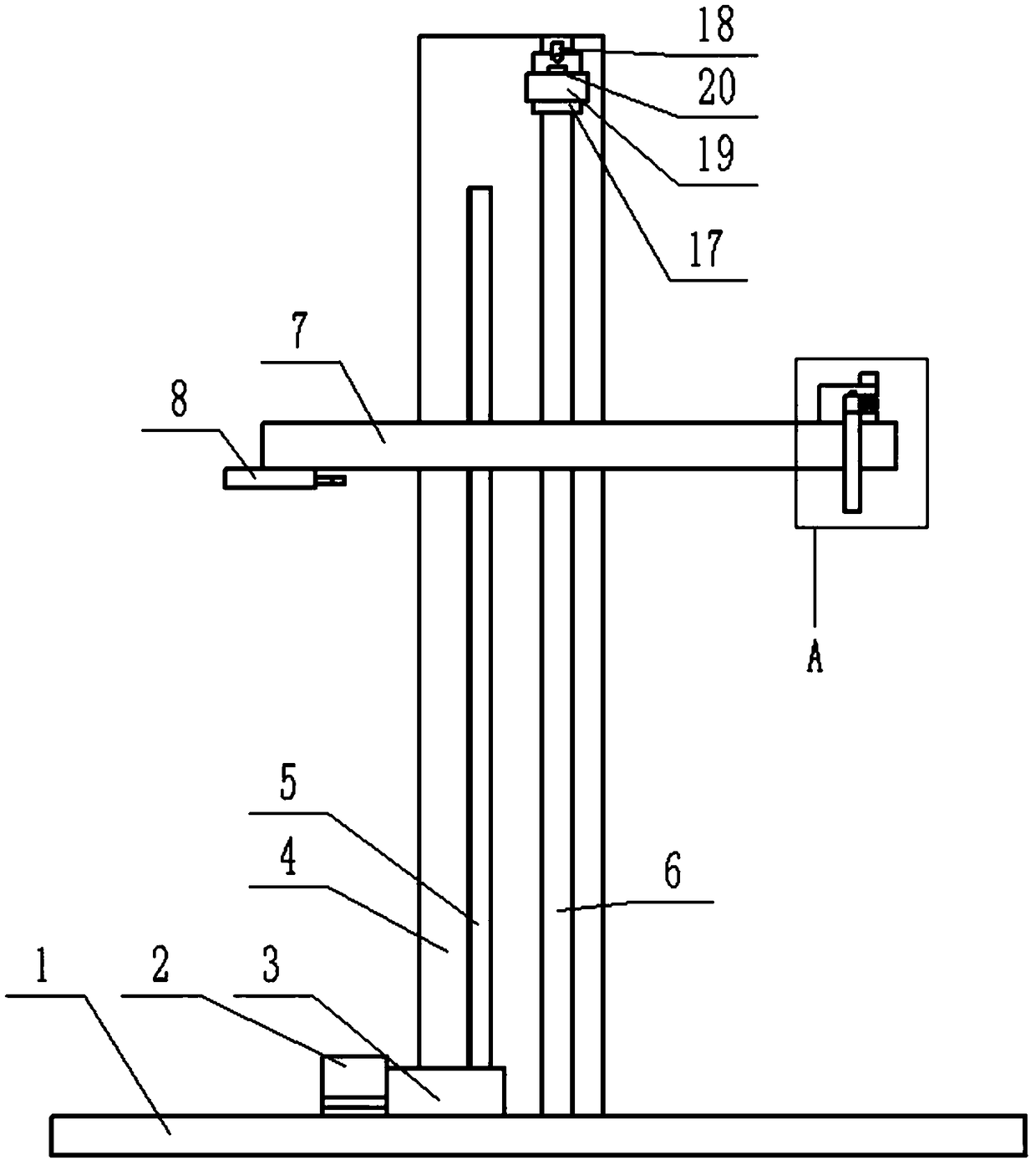

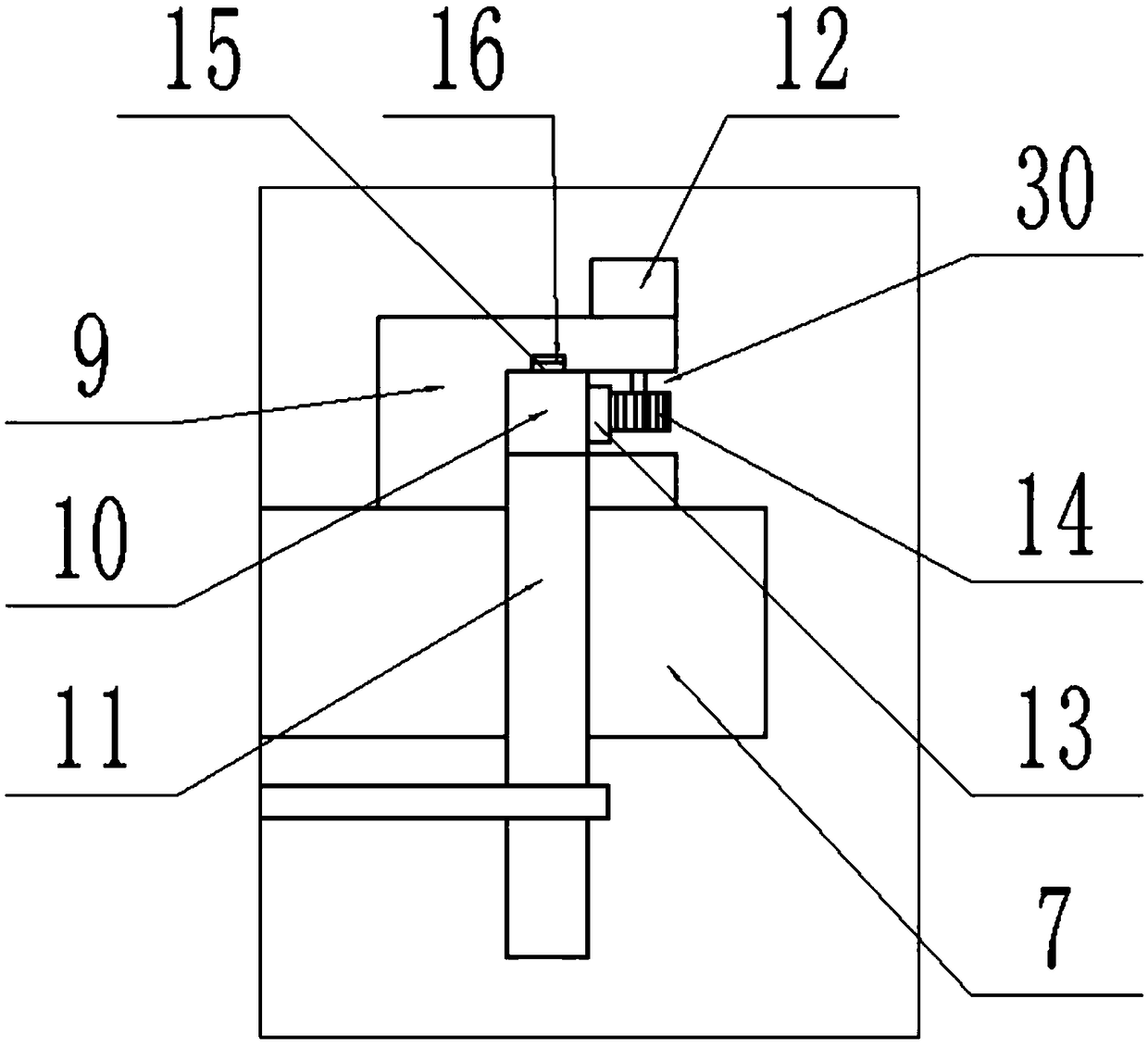

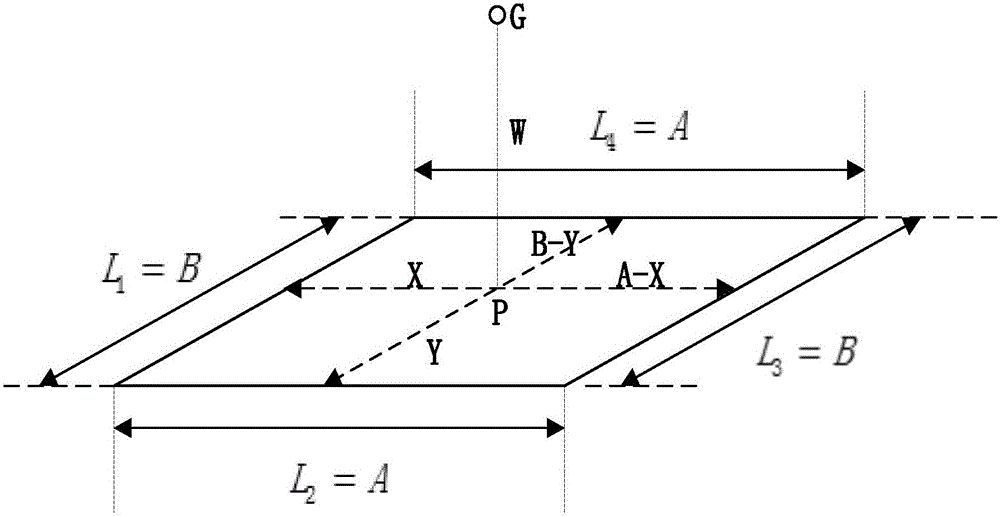

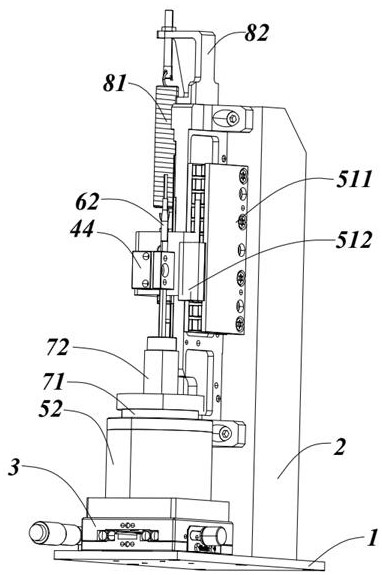

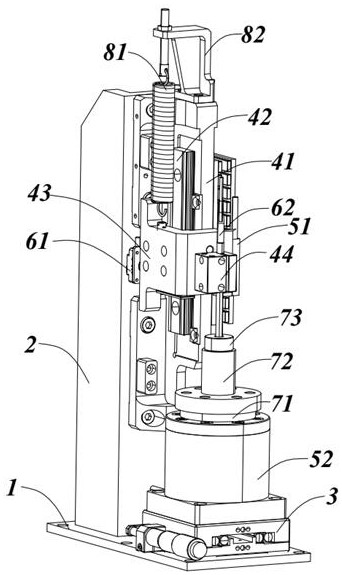

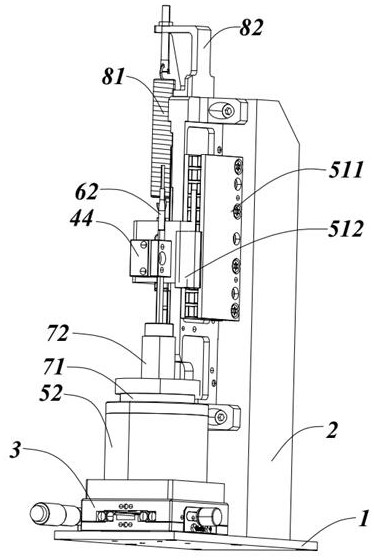

Device and method for measuring diameter of eccentric shaft of industrial robot joint decelerator

ActiveCN107255453AAccurate and reliable measurementsAutomate the measurement processUsing optical meansMeasurement deviceReduction drive

The invention discloses a device and method for measuring the diameter of an eccentric shaft of an industrial robot joint decelerator, and the device comprises a working platform, a central measurement vertical column, an upper tip unit, a lower tip unit, and a to-be-measured workpiece. The central measurement vertical column is disposed on the working platform, and the upper tip unit is connected with the central measurement vertical column through an upper tip moving sliding plate. The working platform is provided with a rotating tilt cylinder unit which is used for fixing the lower tip unit. The to-be-measured workpiece is clamped and located through the upper and lower tip units, and the upper tip moving sliding plate is provided with a staggered-type combined light curtain sensor measurement unit for measurement. The device employs a non-contact shaft diameter measurement method based on a light curtain sensor, can achieve the automatic measurement of the diameters of a plurality of types of eccentric shafts without the adjustment of the mechanical structure, and meets the demands of the measurement of the diameters of the plurality of types of eccentric shafts in the industrial production.

Owner:XI AN JIAOTONG UNIV

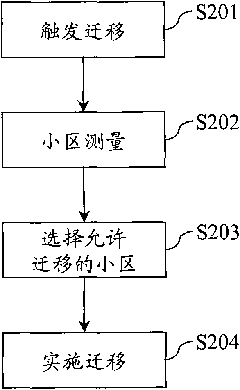

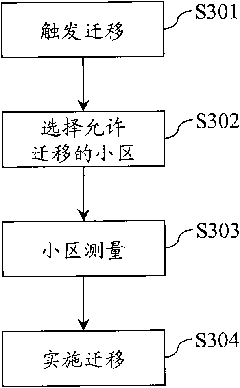

Realization method for selective migration in shared network

InactiveCN101801022ALighten the measurement burdenAddresses the lack of migration controlWireless communicationComputer scienceUser equipment

The invention is suitable for the mobile communication field, providing a realization method for selective migration in a shared network, which is used for user equipment to migrate between the shared network and a home network. The method comprises the following steps: A. selecting subdistricts allowable to migrate; B. measuring the subdistricts; and C. selecting the subdistrict meeting migration conditions to implement migration. According to the shared network region access control information, the invention filters the adjacent subdistrict lists, thereby greatly reducing the measurement load of UE, ensuring business quality and measuring efficiency, improving successful rate of the migration, while solving the defect that Shared CN is probably incapable of carrying out migration control when PS domain is in a connecting state.

Owner:HUAWEI TECH CO LTD

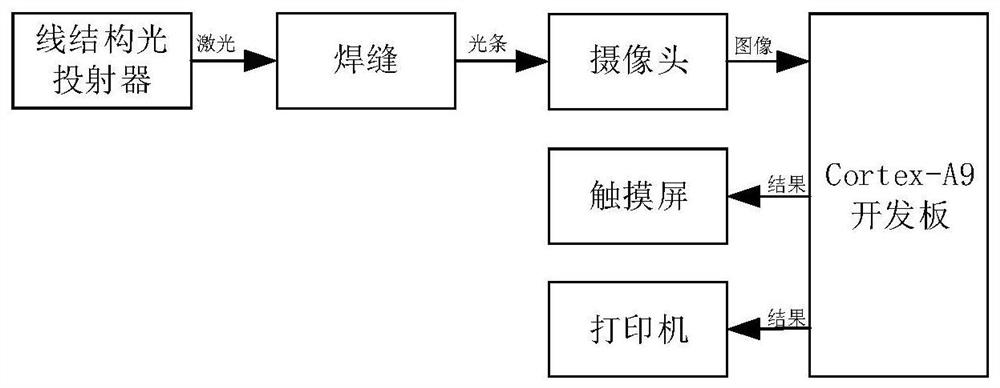

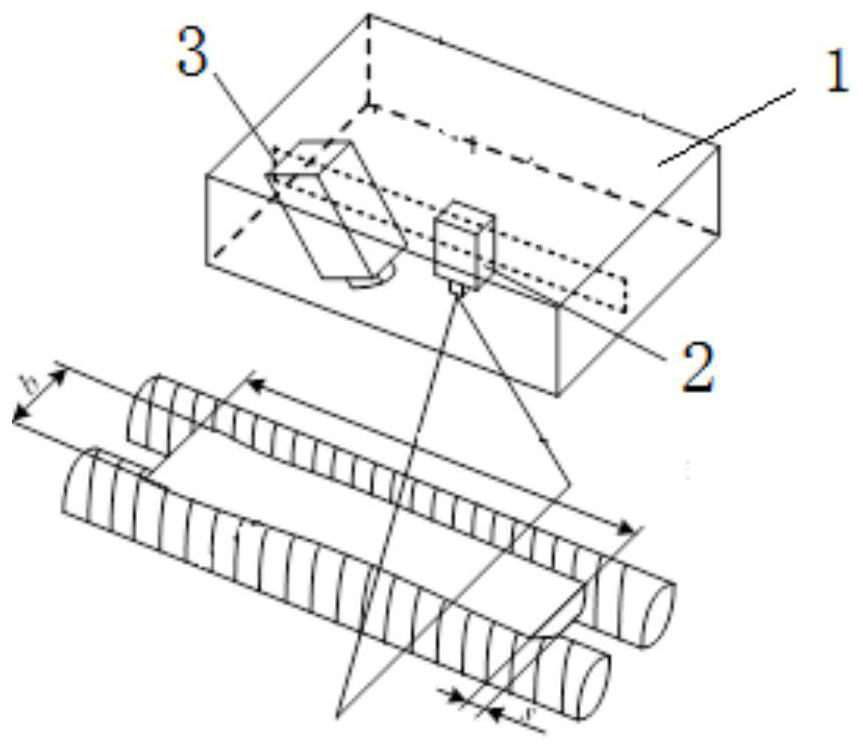

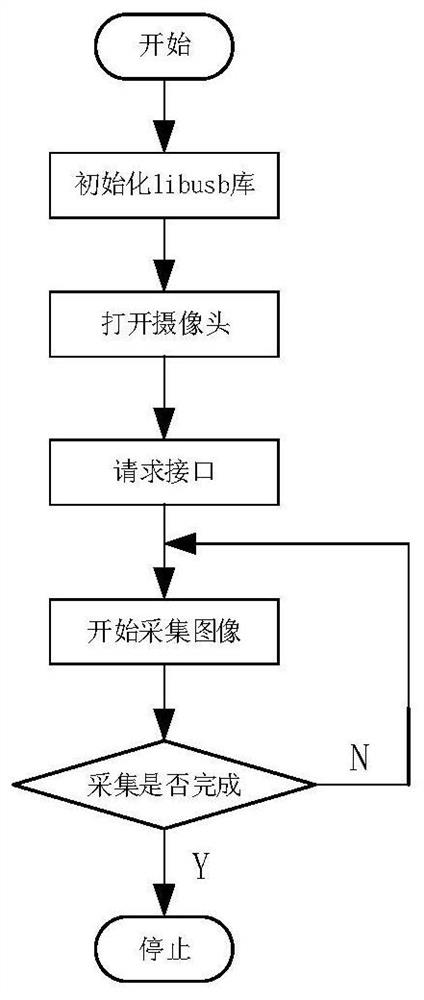

Device and a method for detecting geometric parameters of steel bar weld joint

PendingCN112037189AGuaranteed measurement accuracyGuaranteed measurement efficiencyImage enhancementImage analysisGradationEngineering

The invention provides a device and a method for detecting geometric parameters of a steel bar weld joint. The method comprises the following steps: acquiring a weld joint image in real time; preprocessing the obtained weld joint image, carrying out binarization processing on the weld joint image, and extracting a light bar center of the preprocessed weld joint image by adopting a gray scale square weighted threshold gravity center method; converting a coordinate system of the obtained weld joint image to obtain a relationship between an image coordinate system and a world coordinate system; based on the relationship between the image coordinate system and the world coordinate system and the image data statistics of the weld joint, obtaining the length, width, thickness and saturation of the weld joint; and outputting a result. By processing a structured light strip image, a sub-pixel precision strip center line can be extracted, a precise intersection line of structured light and a target is obtained, intersection line turning point coordinates can be used as target feature point pixel coordinates, and the measurement precision and efficiency are ensured; the invention further provides a device for obtaining the weld joint parameters based on the line-to-line structured light, and the detection efficiency, accuracy and consistency can be improved.

Owner:CHANGAN UNIV

Electric scanning method and device for formation interface detection

InactiveCN103670389AHigh precisionSolve problems that cannot meet actual work needsBorehole/well accessoriesElectricityEnvironmental geology

Owner:BITSWAVE SUZHOU

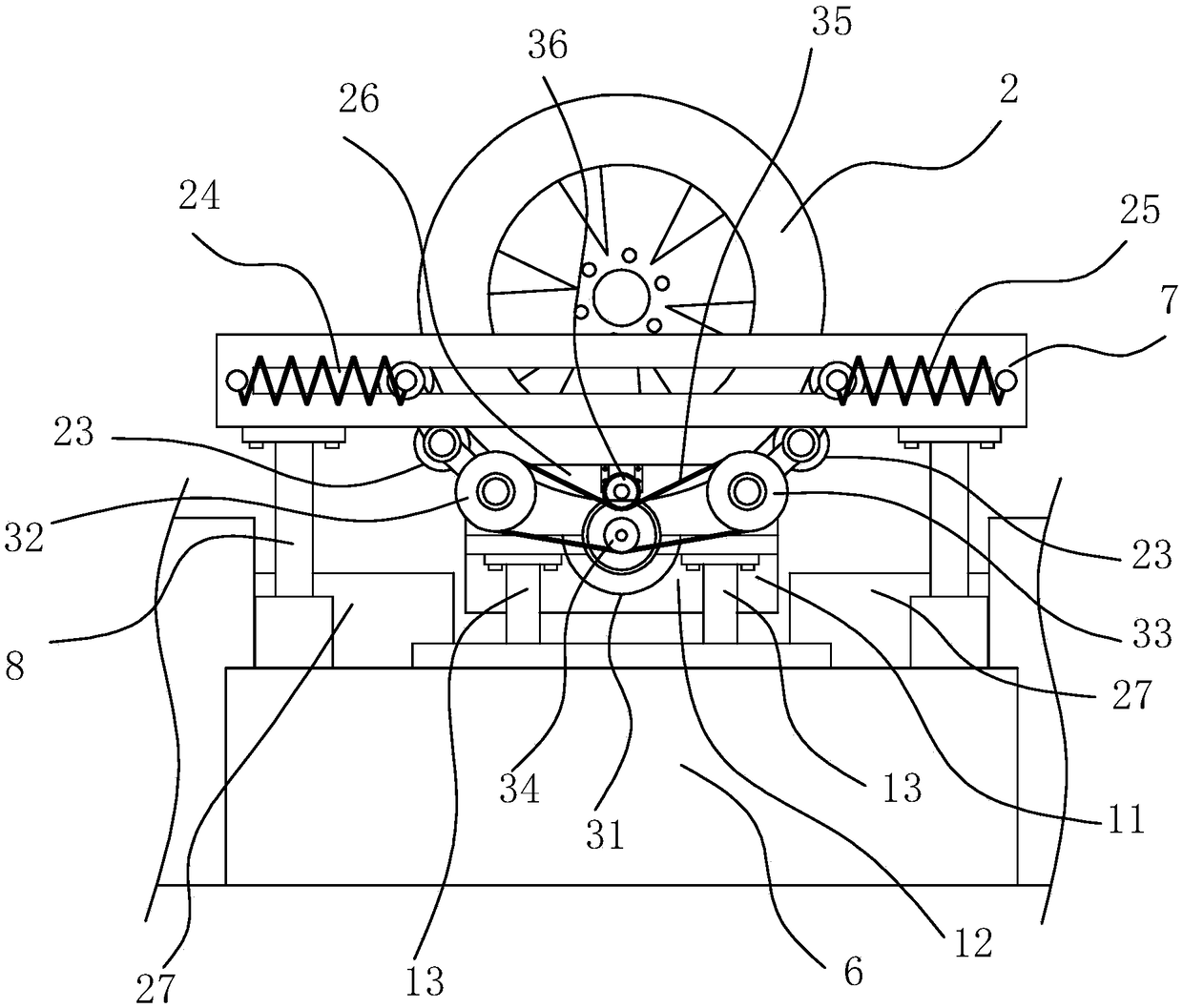

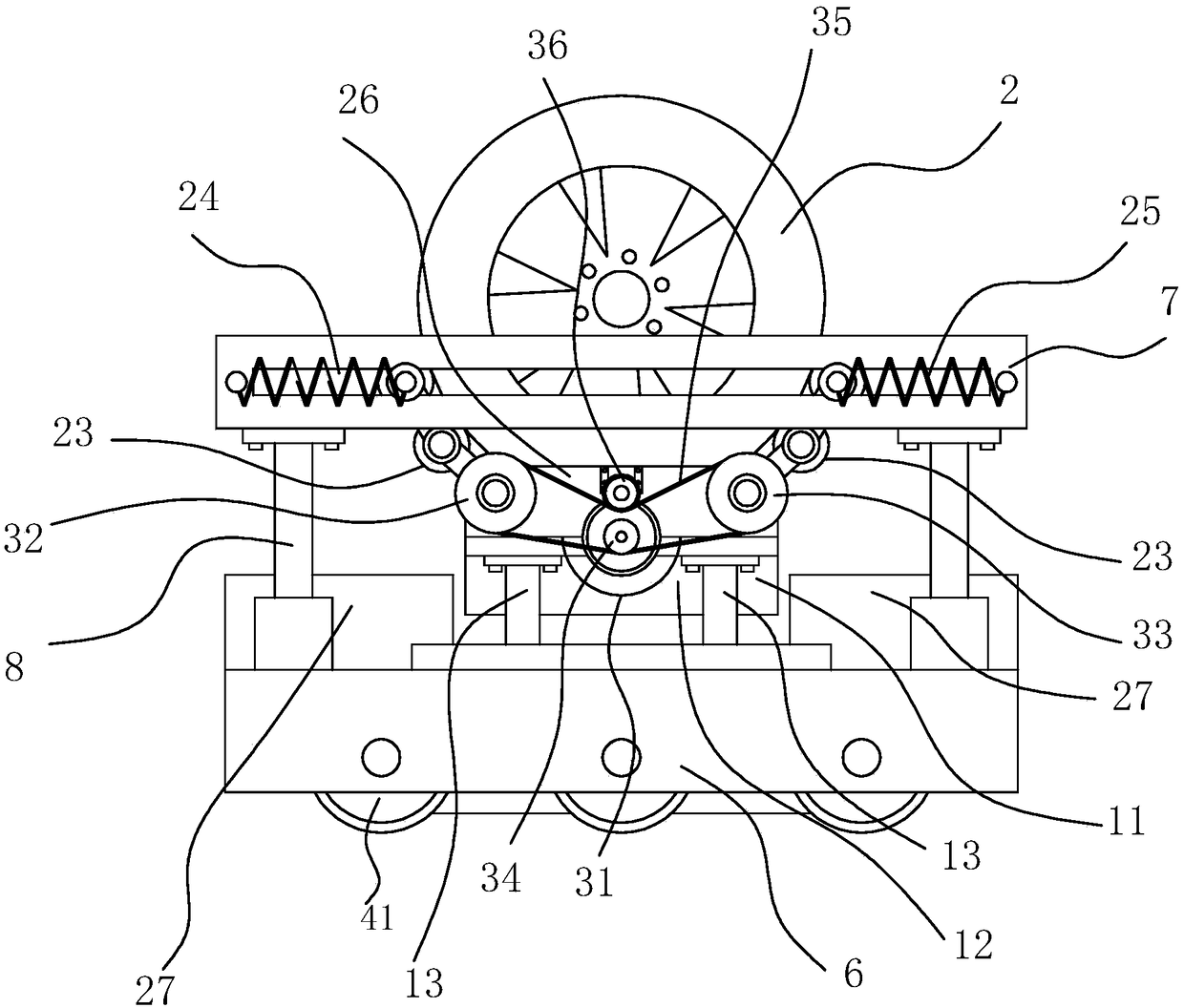

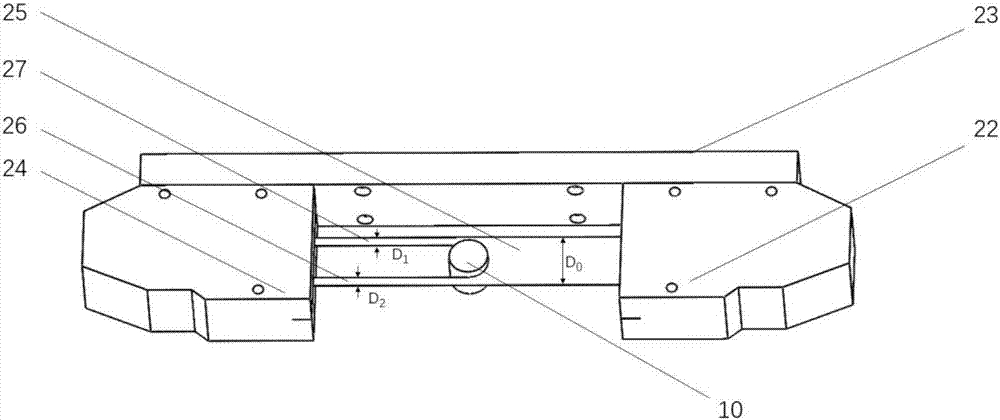

Automatic tire tread pattern depth measurement and detection method

ActiveCN108534705AImprove convenienceSpeed blockUsing optical meansVehicle tyre testingTreadNeutral position

The present invention discloses an automatic tire tread pattern depth measurement and detection method. The method comprises the following steps that: a first detection device is provided with a putting steel plate in advance to allow the steel plate to cover a rolling shaft of the first detection device, a vehicle travels from a base surface from left to right, the front wheel of the vehicle runsover the steel plate, then passes through the first detection device and runs over a second detection device, when the vehicle wheel presses the two rolling shafts at the innermost side on the seconddetection device, manual stop of the vehicle is performed, the vehicle is switched to a neutral position, a hand brake is released, at the same time, the wheel can perform automatic movement front and back, the wheel at the right side is supported by left and right rolling shafts, and the wheel can achieve centring arrangement with the second detection device. The automatic tire tread pattern depth measurement and detection method avoid the problems that tire tread pattern data is collected by manual operation one by one to cause slow measurement speed, large labor input and low efficiency.

Owner:宁波公运车辆检测有限公司

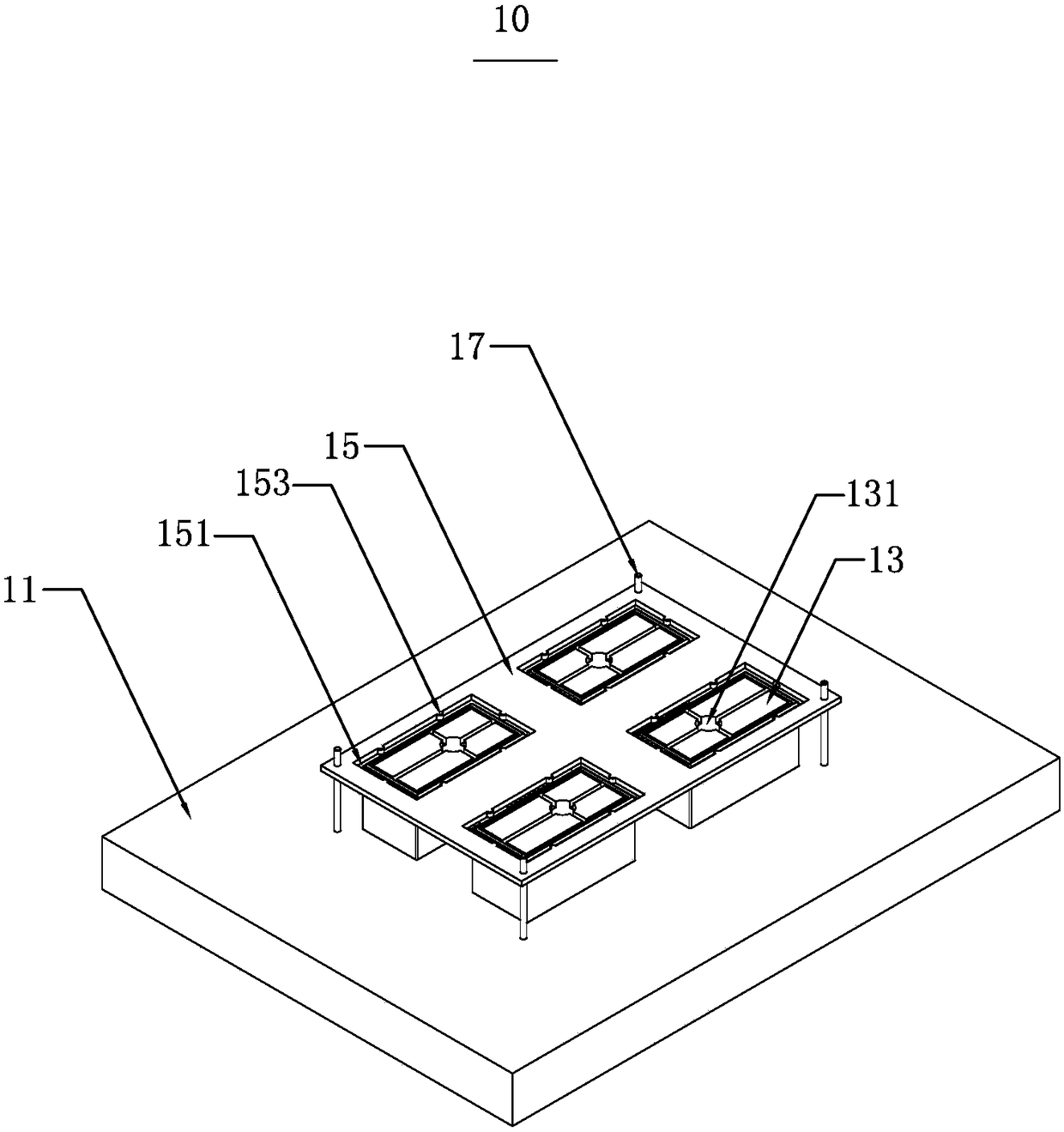

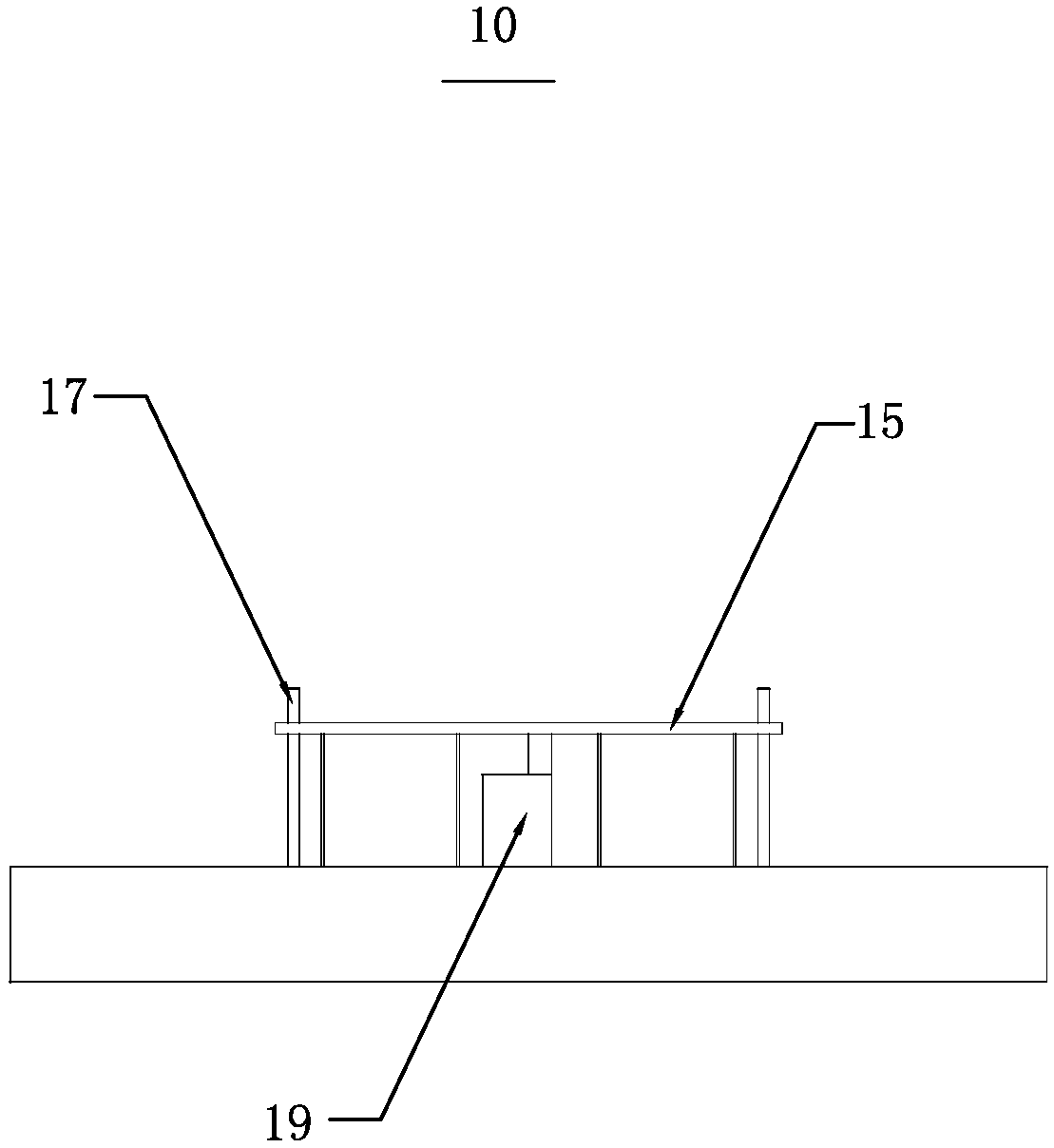

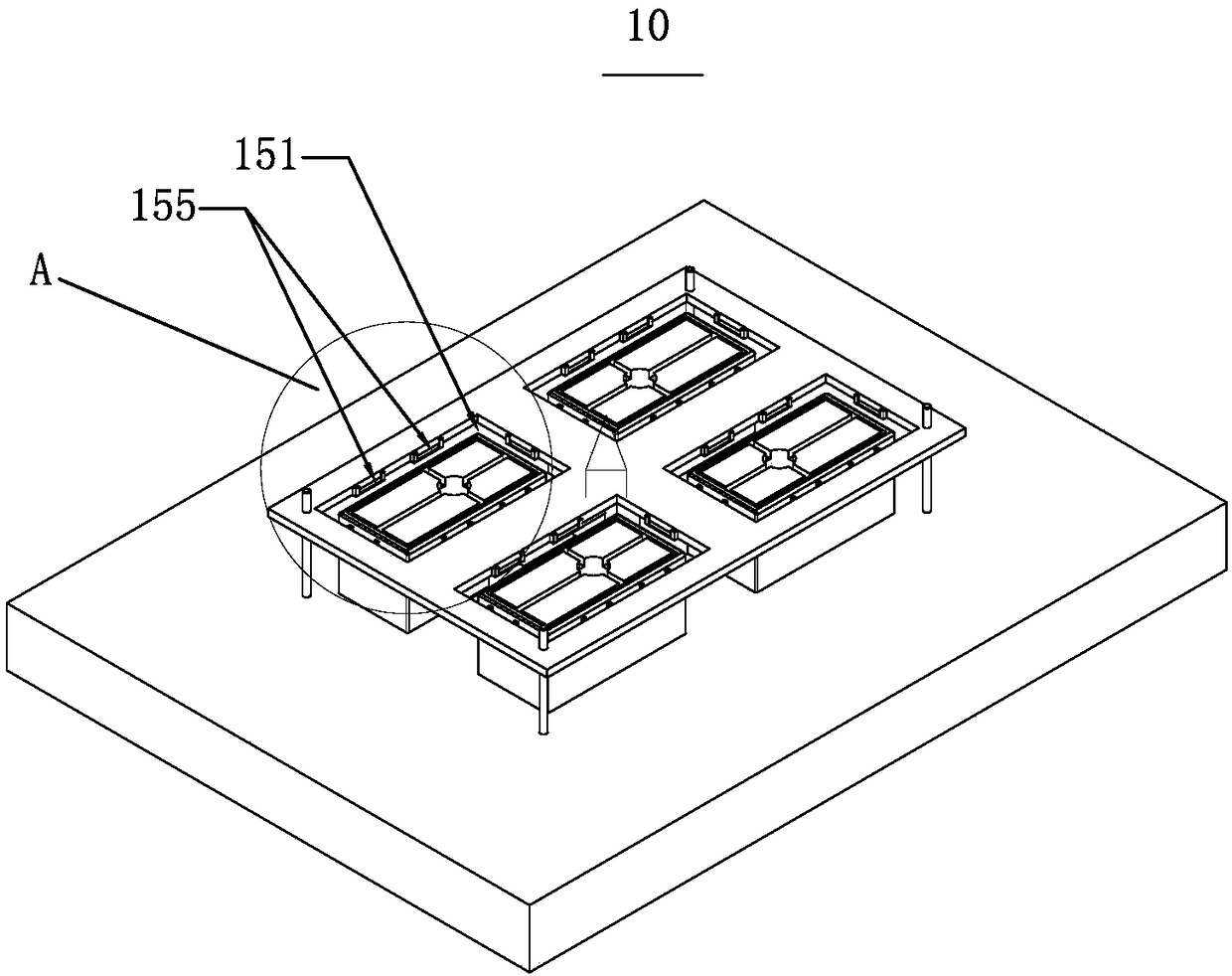

Positioning tool, and 3D curved surface glass detection system and method

ActiveCN108088652ASolve the detection speed is slowImprove detection accuracyOptical apparatus testingEngineering

The invention relates to the technical field of 3D curved surface glass detection, in particular to a positioning tool, a 3D curved surface glass detection system and method. The positioning tool comprises a plurality of object carrying tables and a positioning plate, the plurality of object carrying tables are used for bearing a plurality of 3D curved surface glass to be detected, and a pluralityof openings are formed in the position, corresponding to the object carrying table, of the positioning plate, the size of each opening is larger than that of the object carrying table, and the side wall of each opening is provided with a protrusion used for positioning the 3D curved surface glass borne by the object carrying table. The positioning tool, and the 3D curved surface glass detection system and method can be used for simultaneously positioning a plurality of pieces of 3D curved surface glass, so that the plurality of pieces of glass can be detected at one time in the detection process of the 3D curved surface glass, and the detection speed and the detection precision are greatly improved.

Owner:KAYMAO TECH SHENZHEN

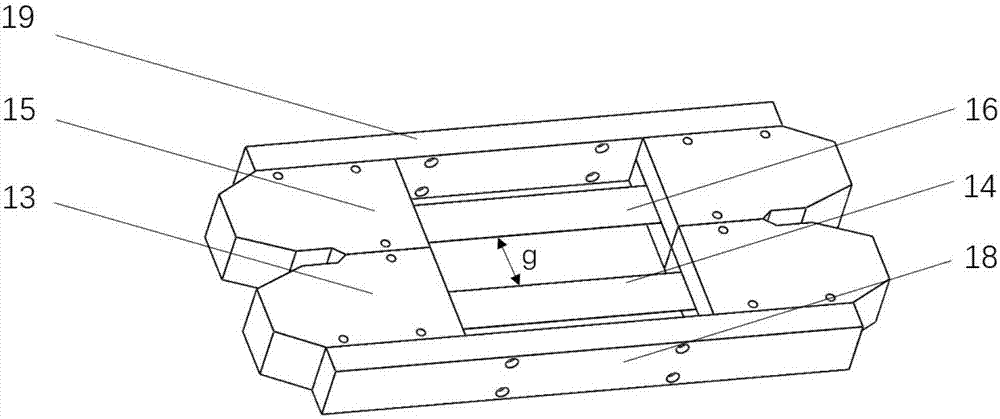

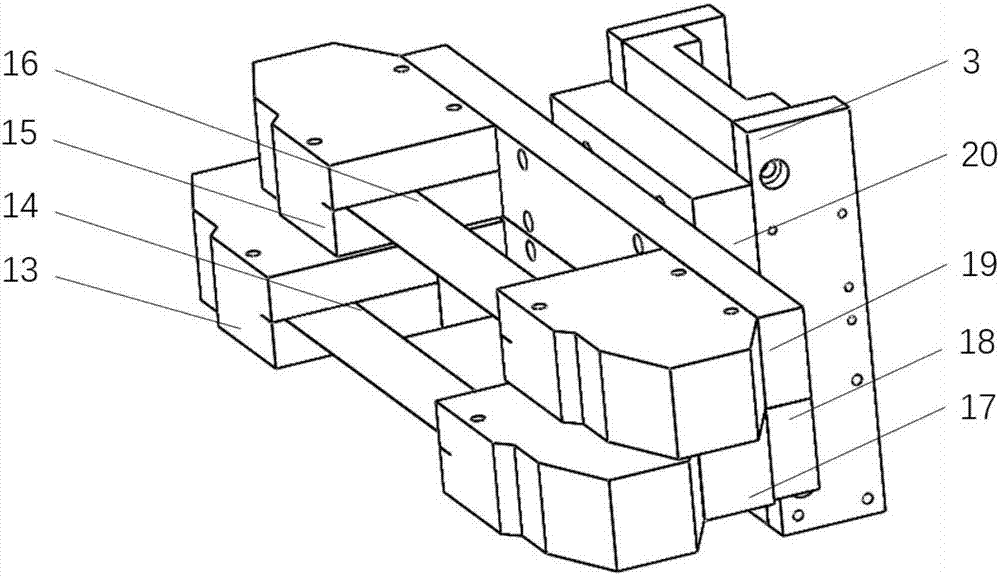

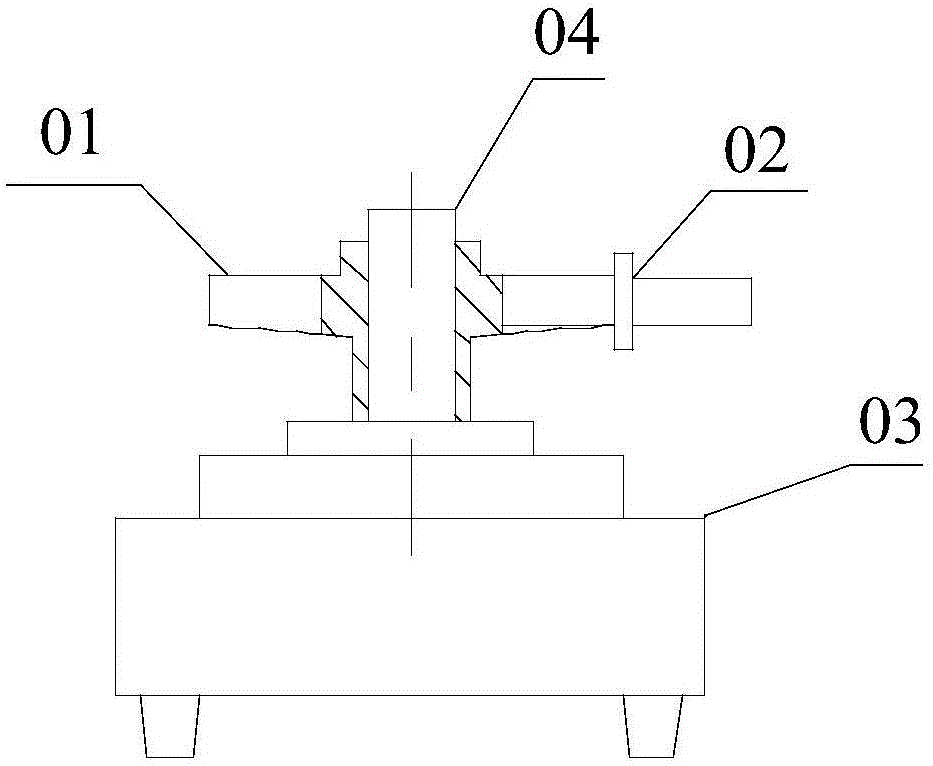

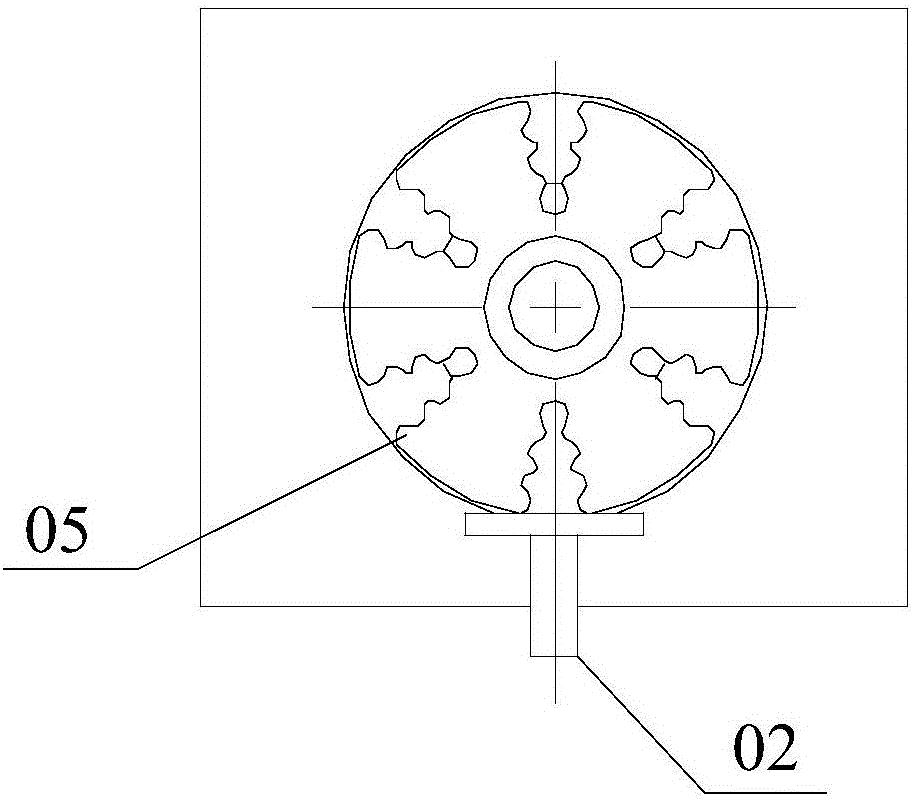

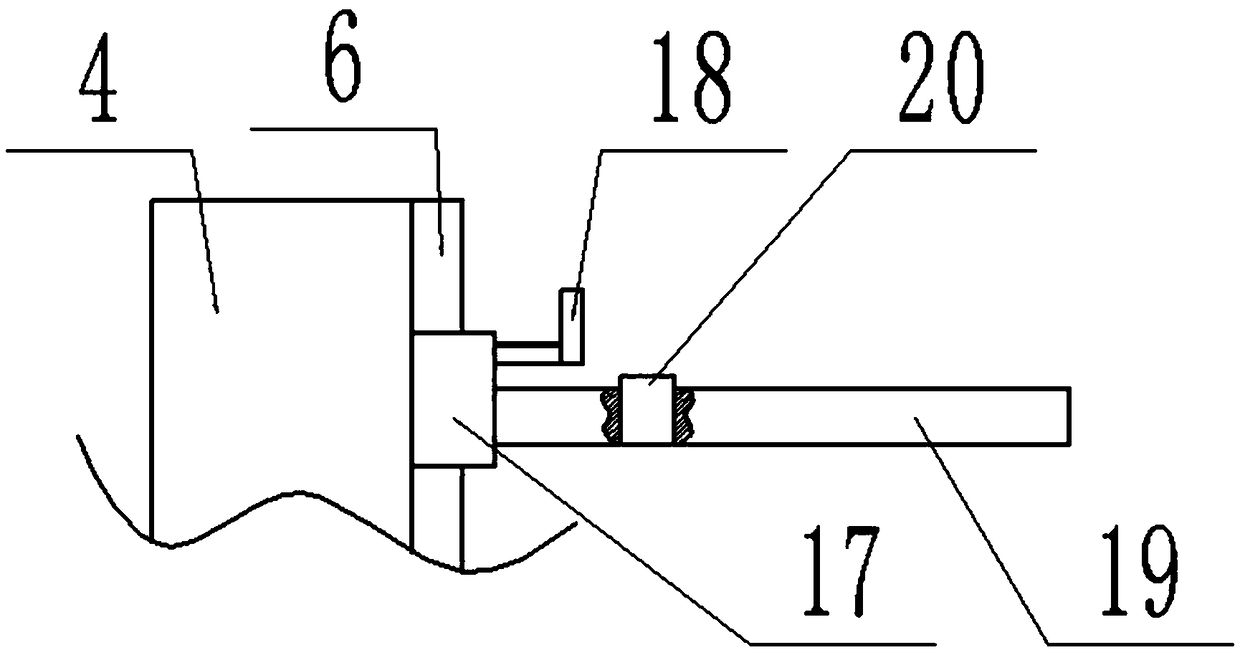

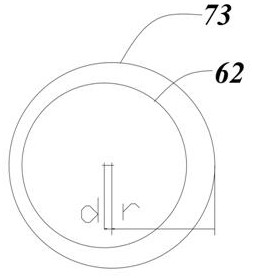

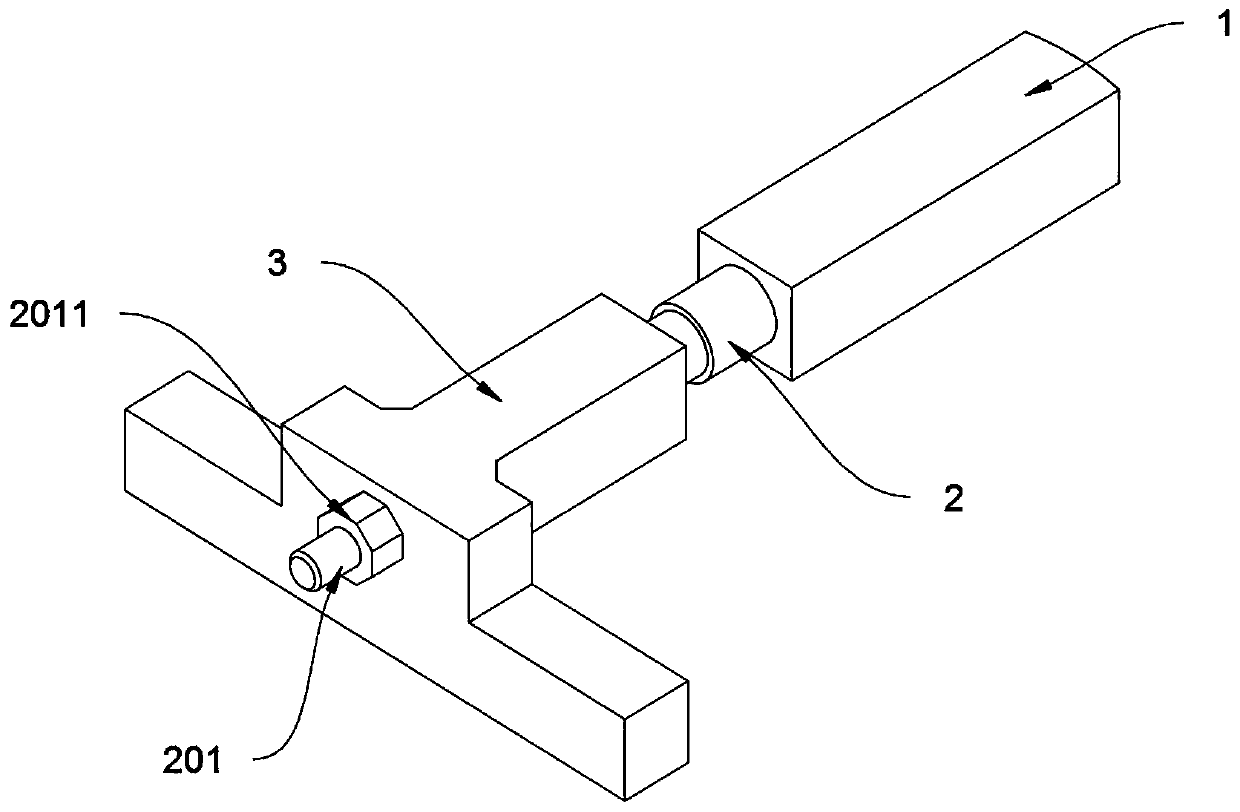

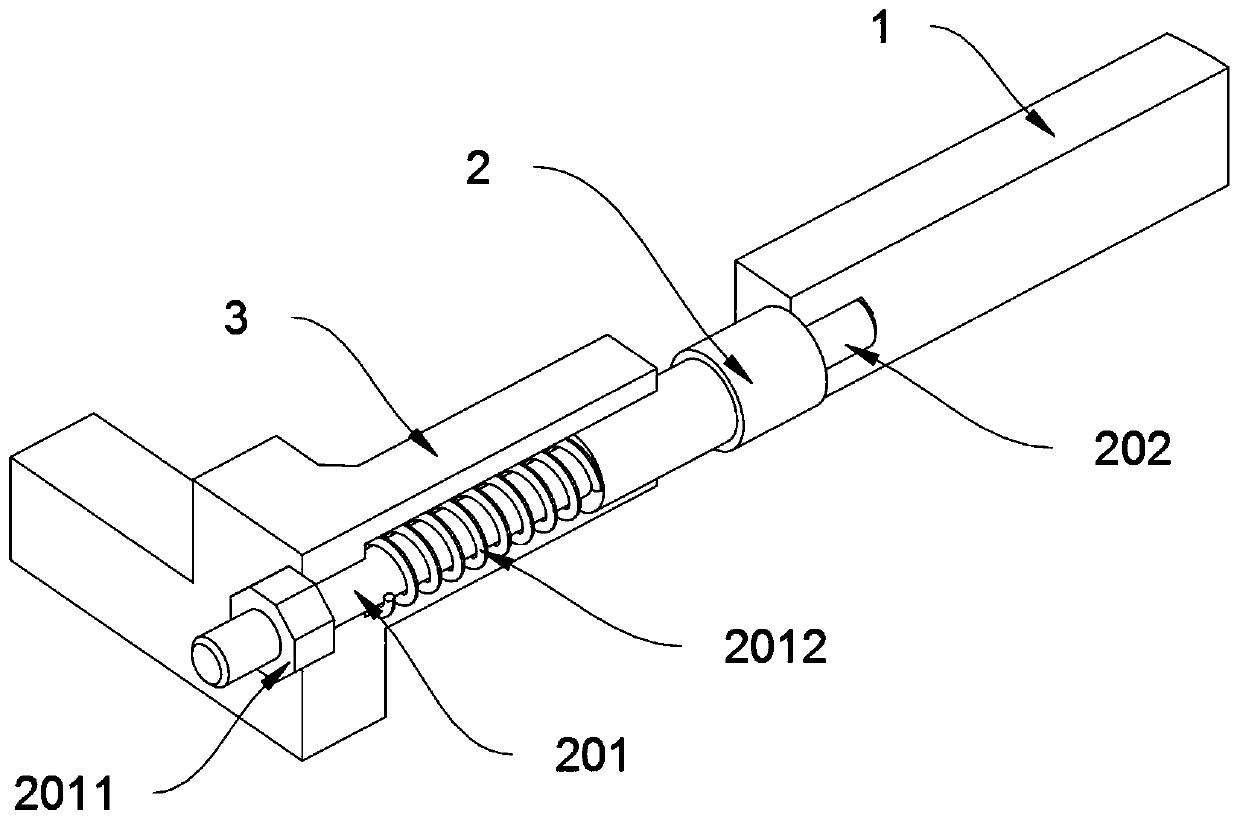

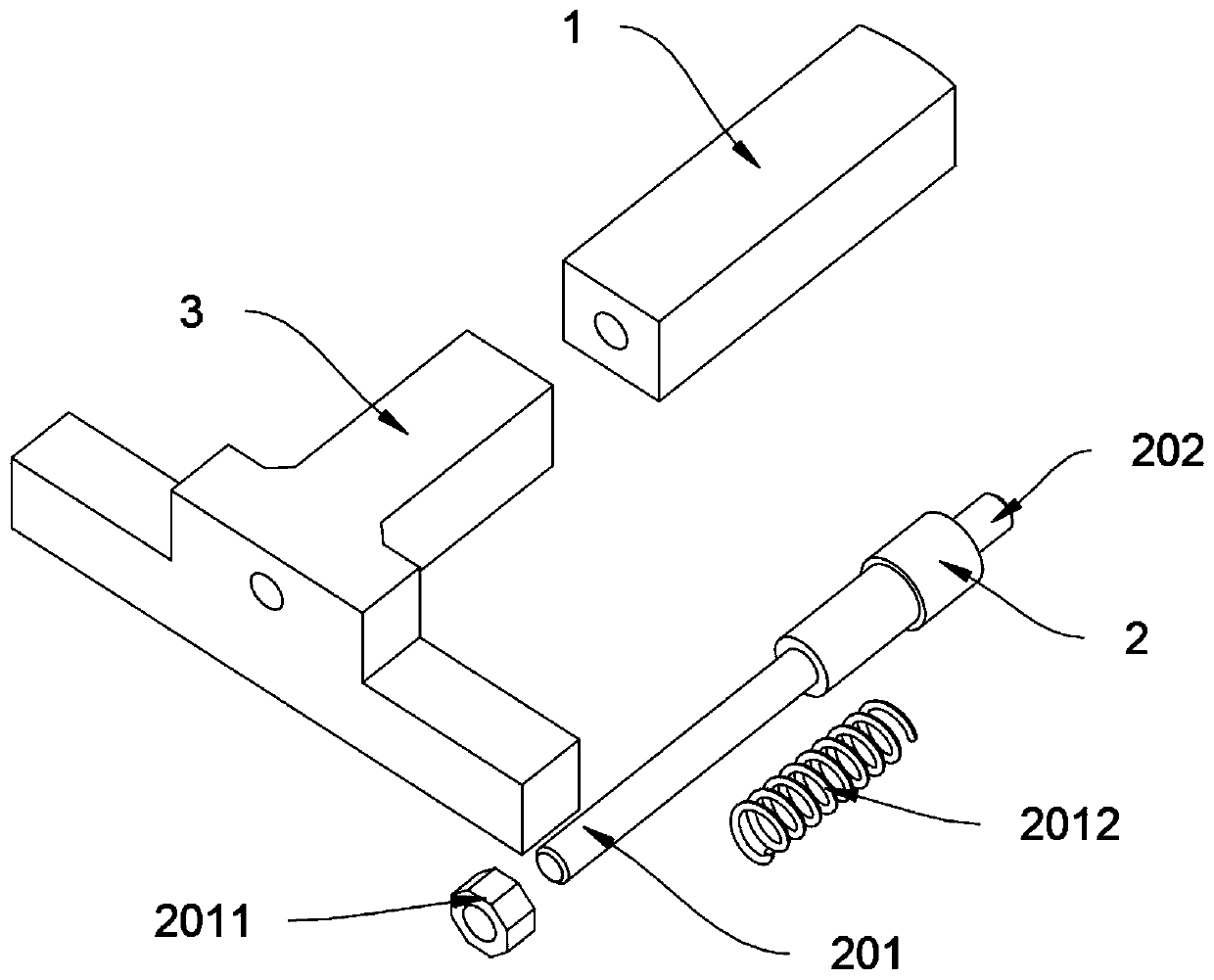

Horizontal gauge-aligning measuring device for measuring tenon groove center distance

ActiveCN106091884AEasy to operateImprove stabilityMechanical measuring arrangementsMeasurement deviceLong axis

The invention discloses a horizontal gauge-aligning measuring device for measuring a tenon groove center distance. The horizontal gauge-aligning measuring device includes a frame, a pair of finial devices (3) with superposed axes installed on the frame, a clamping device (7) controlling the finial devices (3) to loose or clamp a gauge-aligning piece and a part (4) to be measured, an adapter (6) capable of being installed in a standard tenon groove of the gauge-aligning piece, and a positioning device (2) capable of being installed on a long axis of the gauge-aligning piece. A radial face of the adapter (6) is in contact with that of the positioning device (2) and the two radial faces keep parallel. The horizontal gauge-aligning measuring device for measuring the tenon groove center distance effectively solves the inaccurate problem easily existing in a tenon groove measuring process.

Owner:HUNAN SOUTH GENERAL AVIATION ENGINE CO LTD

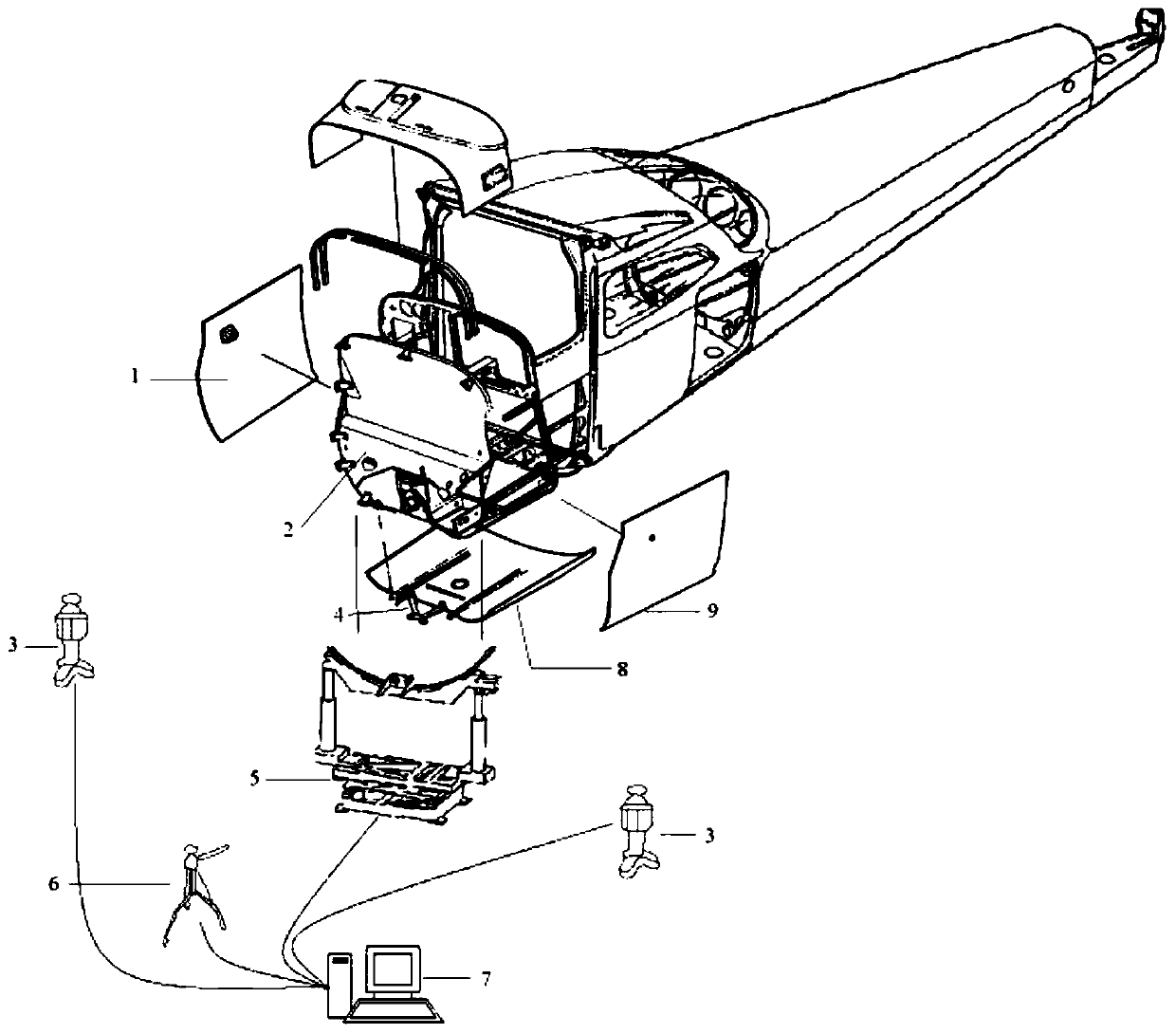

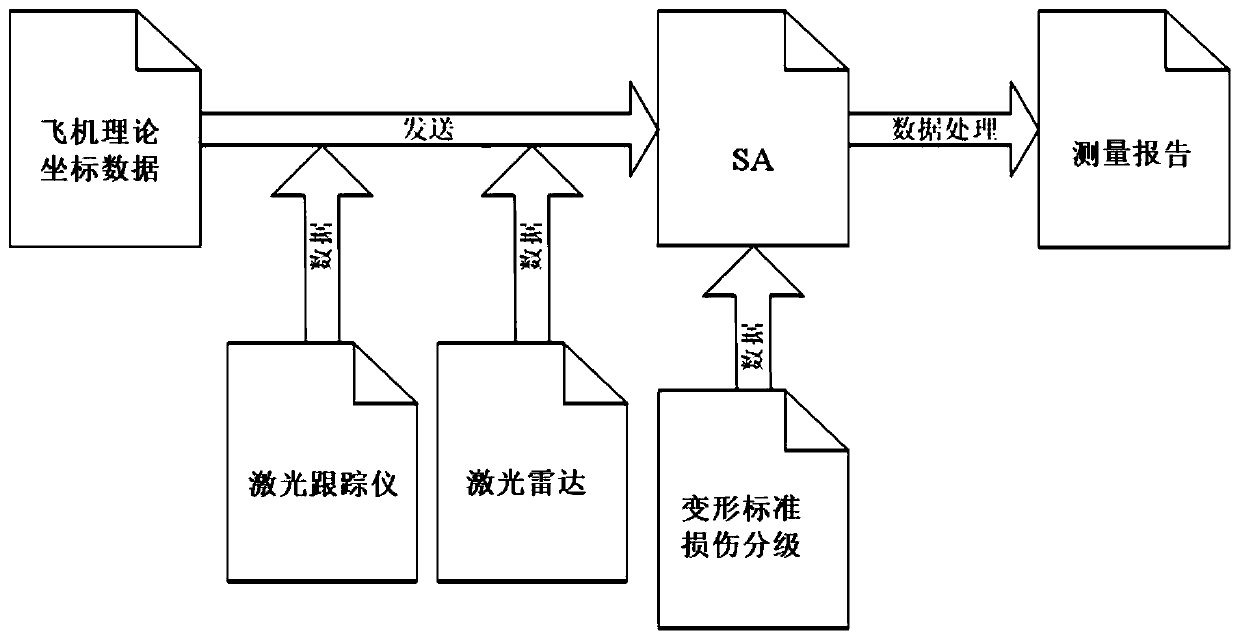

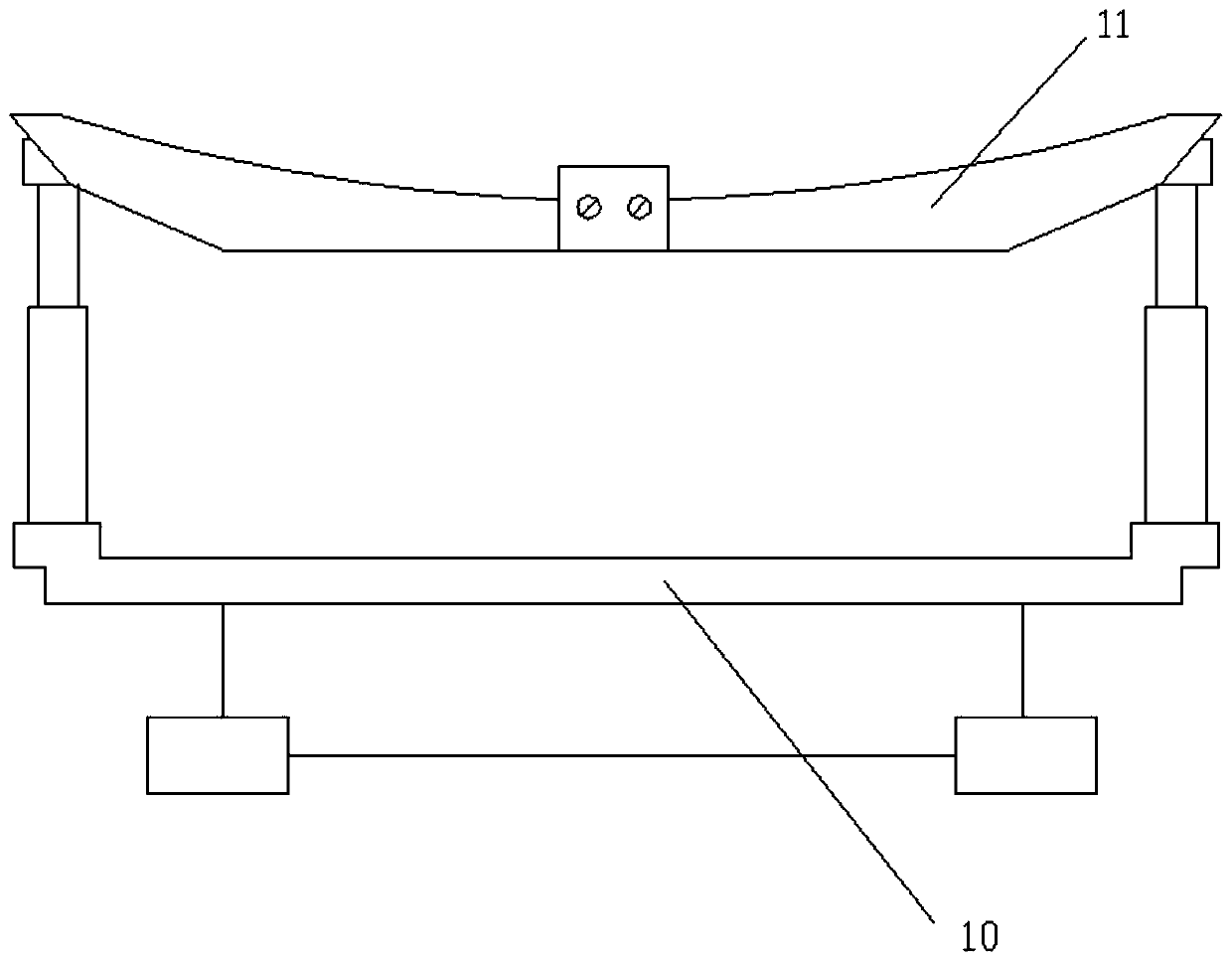

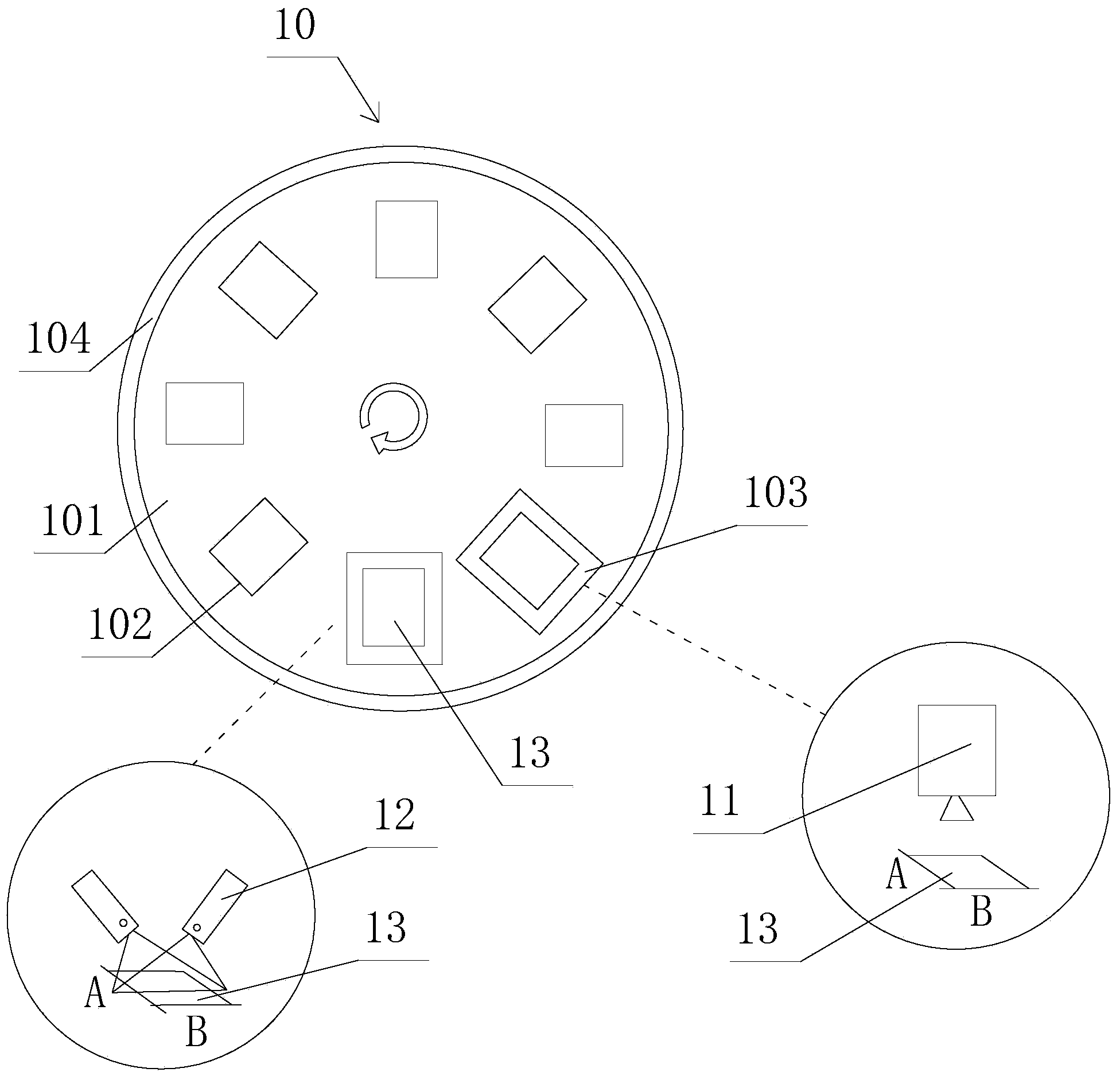

Digital measurement system and method for airplane structure deformation measurement and damage grading

InactiveCN111561874AWith automatic measurement functionFully automatedUsing optical meansStructural deformationRadar

The invention discloses a digital measurement system and method for airplane structure deformation measurement and damage grading. The digital measurement system comprises a laser tracker, a laser radar and a data acquisition and processing system, the data acquisition and processing system is in communication connection with the laser tracker and the laser radar, wherein the laser tracker is usedfor three-dimensional coordinates of key points on an airplane; the laser radar is used for detecting a free-form surface with an irregular shape; the data acquisition and processing system is responsible for storing aircraft structure data, fitting an equipment measurement coordinate system and an aircraft theoretical coordinate system, and constructing a unified measurement network, and acquiring and processing measurement data. Damage deformation of each part can be precisely measured, and deformation of large-size parts like wings and fuselage which cannot be found by naked eyes can be detected; the measurement process is simple, the measurement speed is high, the measurement period is short, the automation degree is high, and manual operation errors are avoided.

Owner:CIVIL AVIATION FLIGHT UNIV OF CHINA

Device, apparatus and method for positioning measurement reference plane of measured object

ActiveCN104296656AAccurate locationSolve the problem of measuring datum positioningUsing optical meansPoint cloudLaser scanning

The invention discloses a device, an apparatus and a method for positioning a measurement reference plane of a measured object. A turntable is firstly turned to carry the measured object to the position under a station provided with an image measurement instrument so as to obtain an image of the measured object, a processor extracts two intersecting edge line segments from the outmost edge of the measured object in the image, the two intersecting edge line segments serve as a first reference edge and a second reference edge, and a first reference edge coordinate and a second reference edge coordinate are correspondingly obtained; then the turntable is turned to carry the measured object to the position under a station provided with two laser measuring heads, the surface of the whole measured object, including the edge portion, is completely scanned along a predetermined scanning route, the relative relation of the image and laser on a space coordinate is utilized to obtain a point cloud formed by a plurality of laser points, the point cloud serves as laser scanning data, the processor performs fitting according to the laser scanning data to obtain a first reference plane parameter provided with the first reference edge and a second reference plane parameter provided with the second reference edge of the measured object, and the first reference edge coordinate and the second reference edge coordinate are correspondingly combined with the first reference plane parameter and the second reference plane parameter to obtain the accurate position of the measured object.

Owner:TZTEK TECH

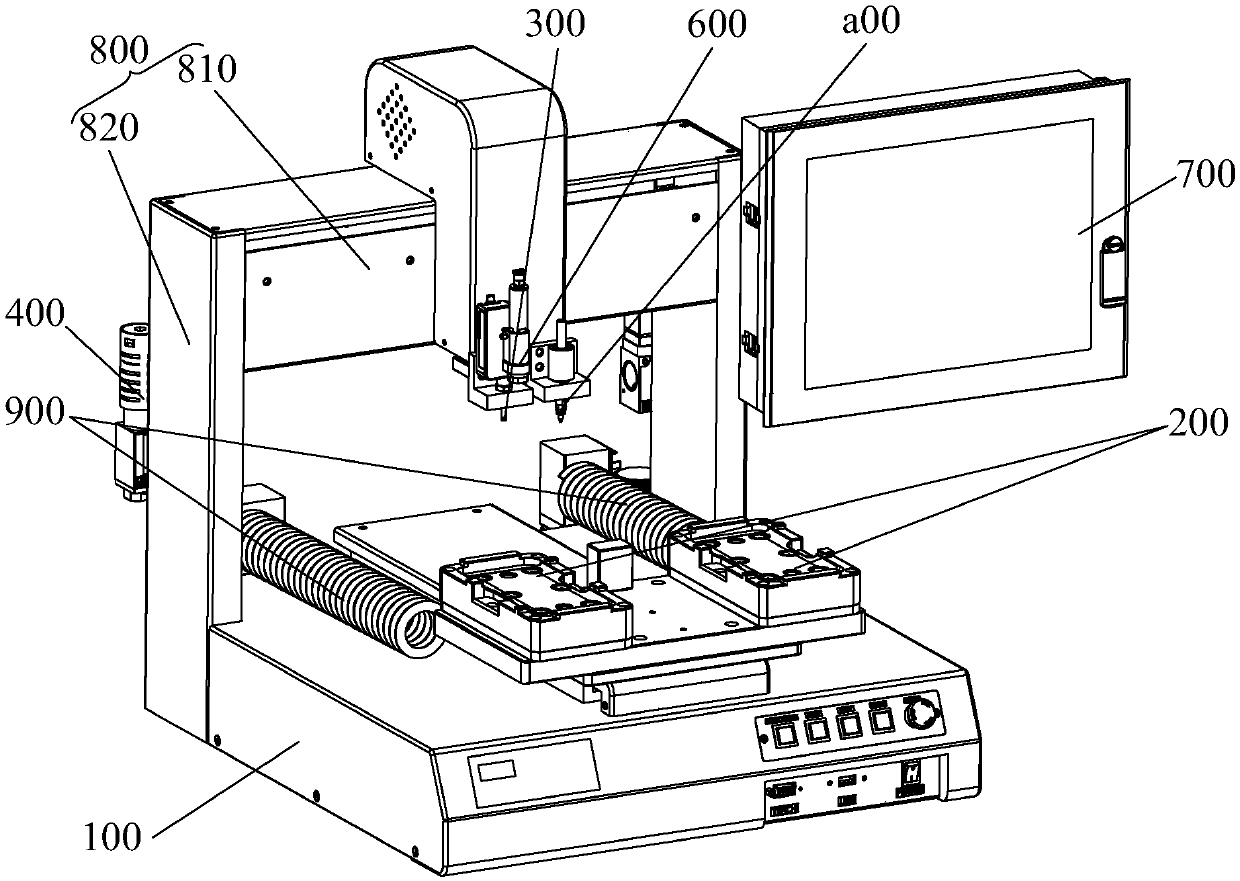

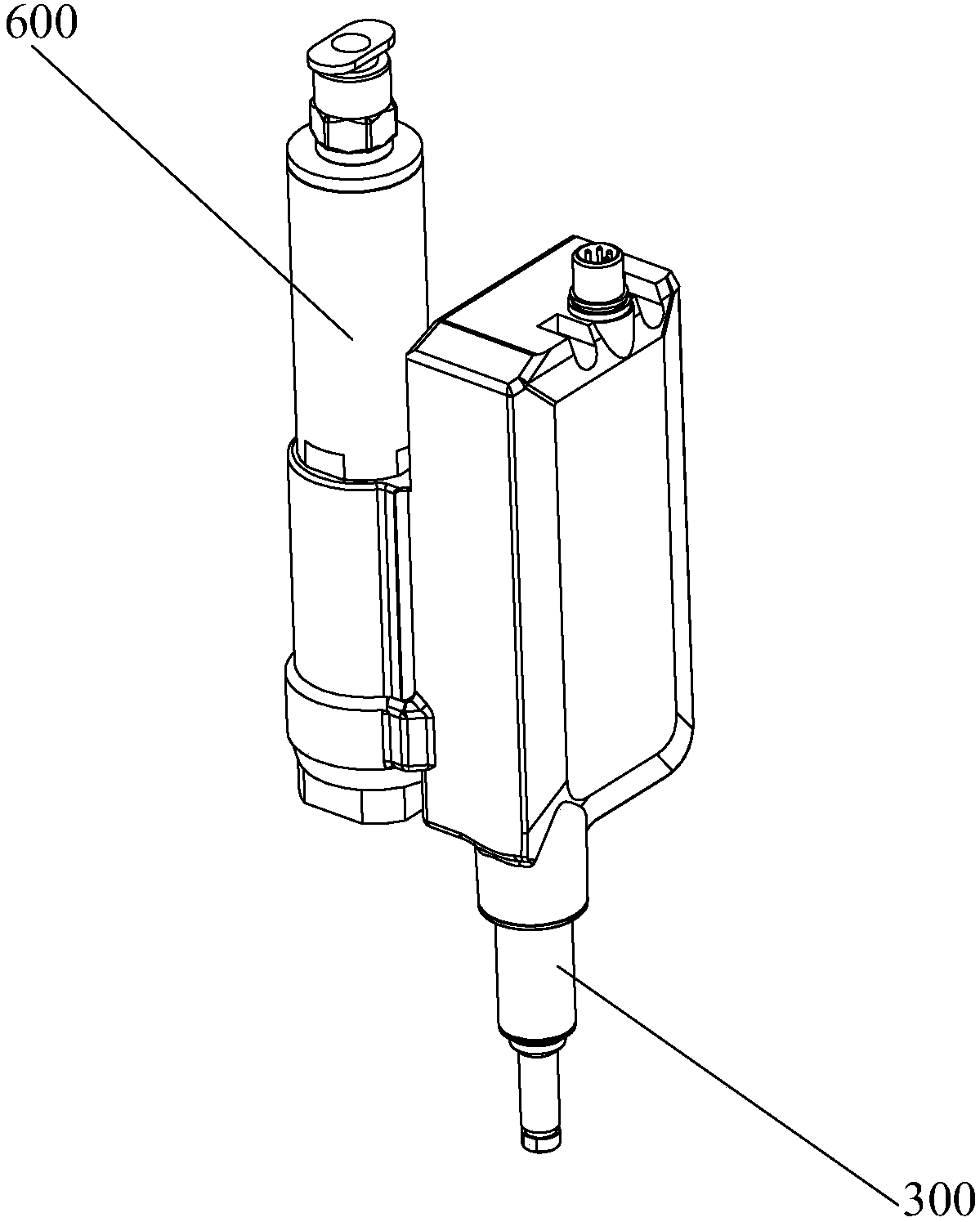

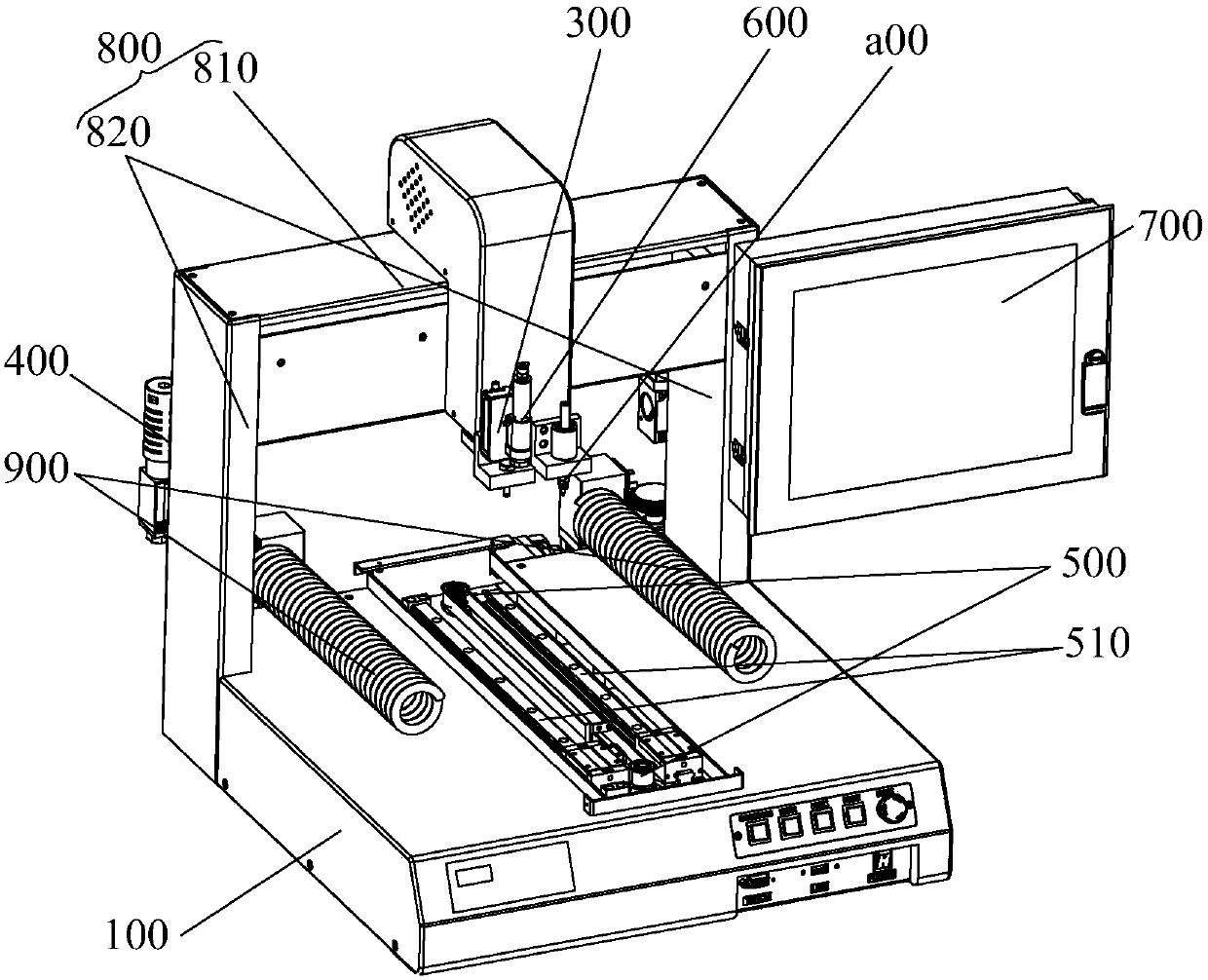

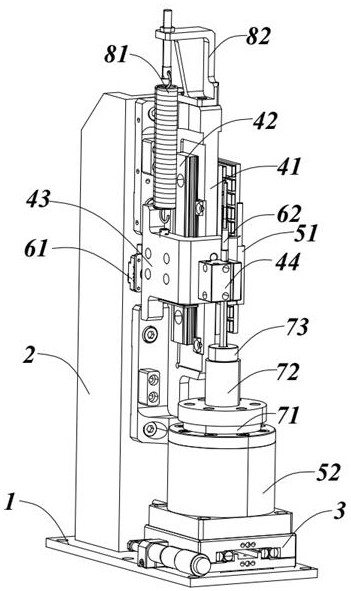

Highly precise detection machine

PendingCN108050974AGuaranteed measurement accuracyGuaranteed measurement efficiencyMeasurement devicesEngineeringHead moving

The invention discloses a highly precise detection machine. The highly precise detection machine comprises a base frame, a loading base arranged on the base frame and used for carrying a measuring workpiece, and a height measuring head suspended above the loading base. The loading base moves longitudinally relative to the base frame under the driving of a longitudinal drive device in order to movecloser to or away from the height measuring head, and the height measuring head moves transversely relative to the base frame under the driving of a transverse drive device and moves vertically relative to the base frame under the driving of a vertical drive device. The highly precise detection machine further includes a control device for controlling operation of the longitudinal drive device, the transverse drive device and the vertical drive device, and the control device is connected to the height measurement head to obtain measurement data of the highly precise detection machine and calculate a height value of the measuring workpiece. According to the highly precise detection machine, measurement accuracy is ensured while measurement efficiency is improved.

Owner:李益国

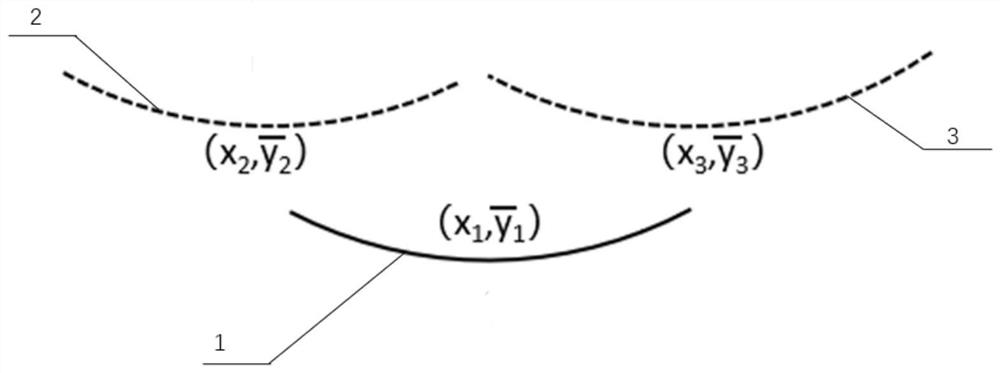

Method for measuring shape of general cable strand of suspension bridge based on machine vision

ActiveCN112815840AGuaranteed installation qualityHigh precisionUsing optical meansVisual monitoringMachine vision

The invention discloses a method for measuring the shape of a general cable strand of a suspension bridge based on machine vision. The method comprises the following steps: installing vision monitoring equipment; erecting a reference cable strand and a measurement layer cable strand of the main cable, installing light targets in the spans of the reference cable strand and the measurement layer cable strand respectively, and using visual monitoring equipment for collecting shake image data of the different light targets within preset time; analyzing and calculating the shaking image data to obtain the actual height difference between the reference cable strand and the measuring layer cable strand, namely the real-time linear data of the measuring layer cable strand; and moving the relative reference cable strand and the measurement layer cable strand upwards, and sequentially erecting the main cable strands from bottom to top through the same method. According to the method, a light target is installed in the span of a general cable strand and a reference cable strand, a visual monitoring device is used for collecting an orthographic light target image, shaking image data of the light target are analyzed, the actual space distance is converted according to the pixel distance, the height difference between the general cable strand and the reference cable strand is calculated, and then real-time line shape data of the general cable strand are obtained. And high-precision automatic measurement of the strand shape is realized.

Owner:CCCC SECOND HARBOR ENG +1

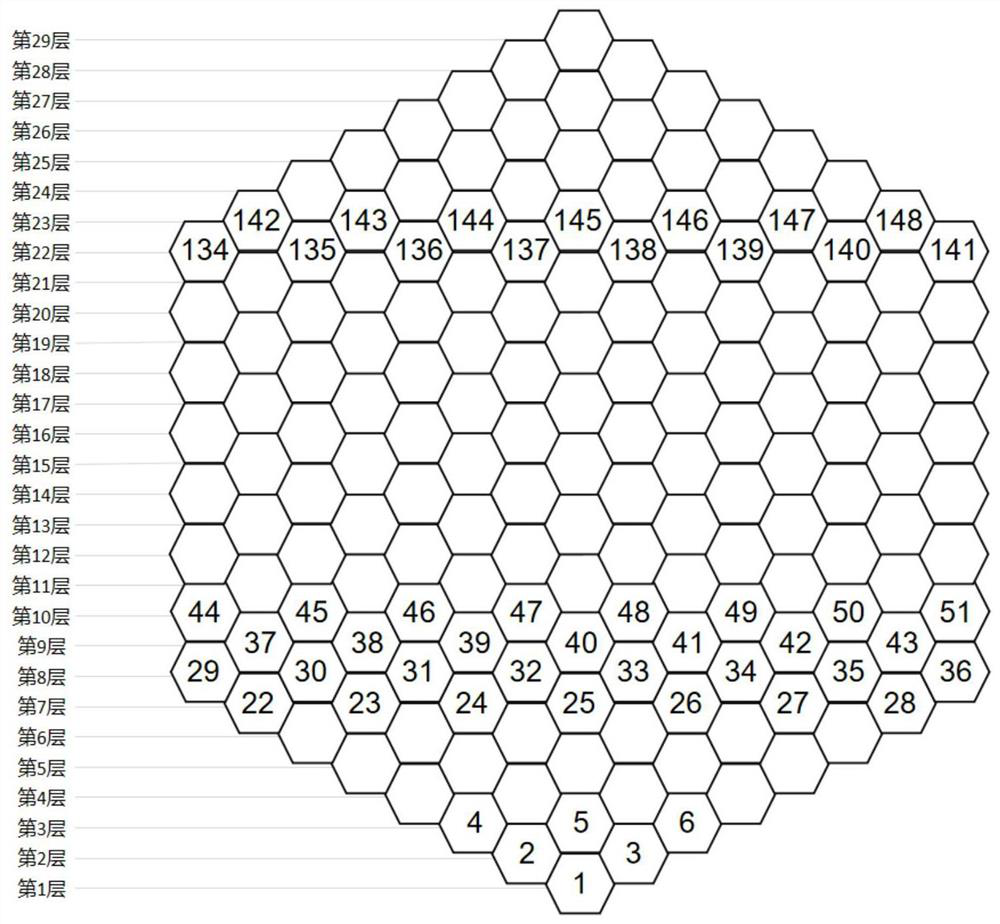

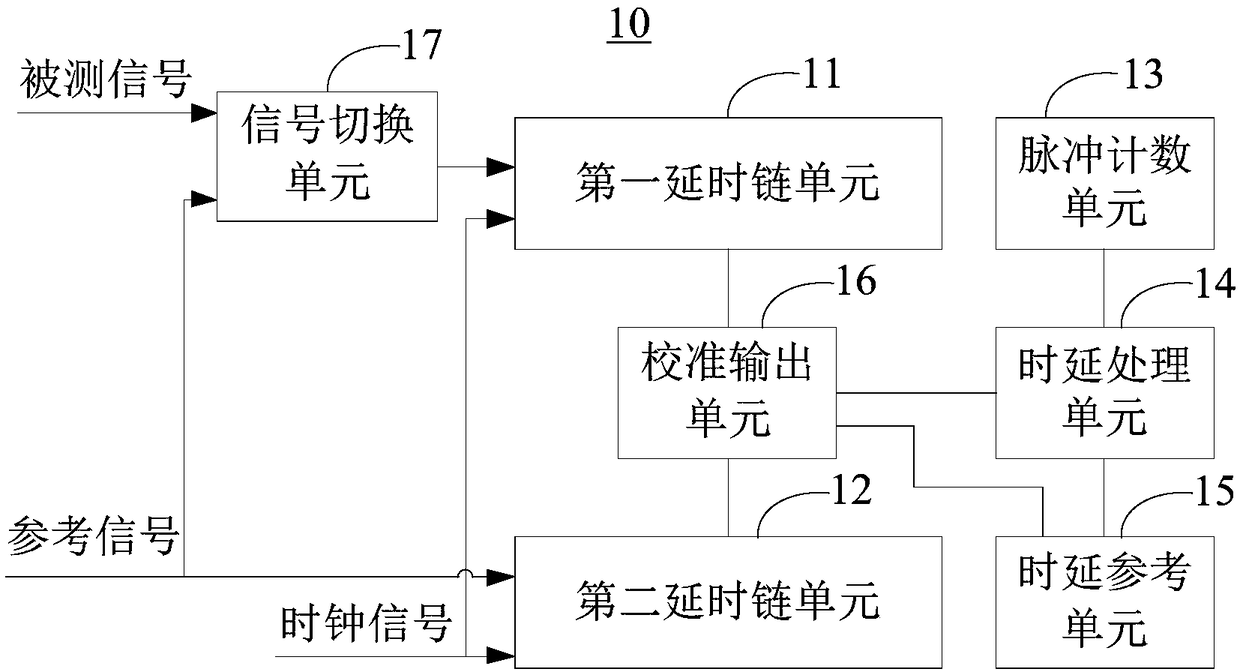

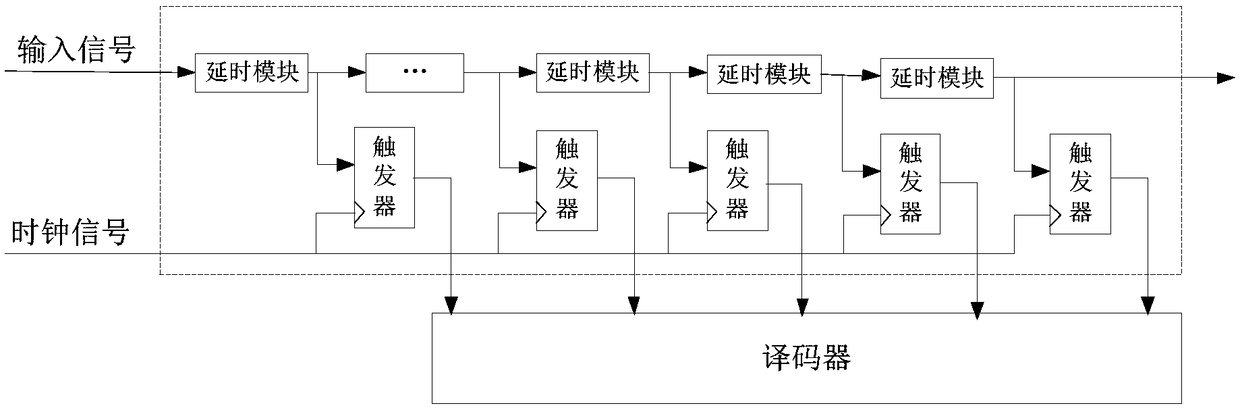

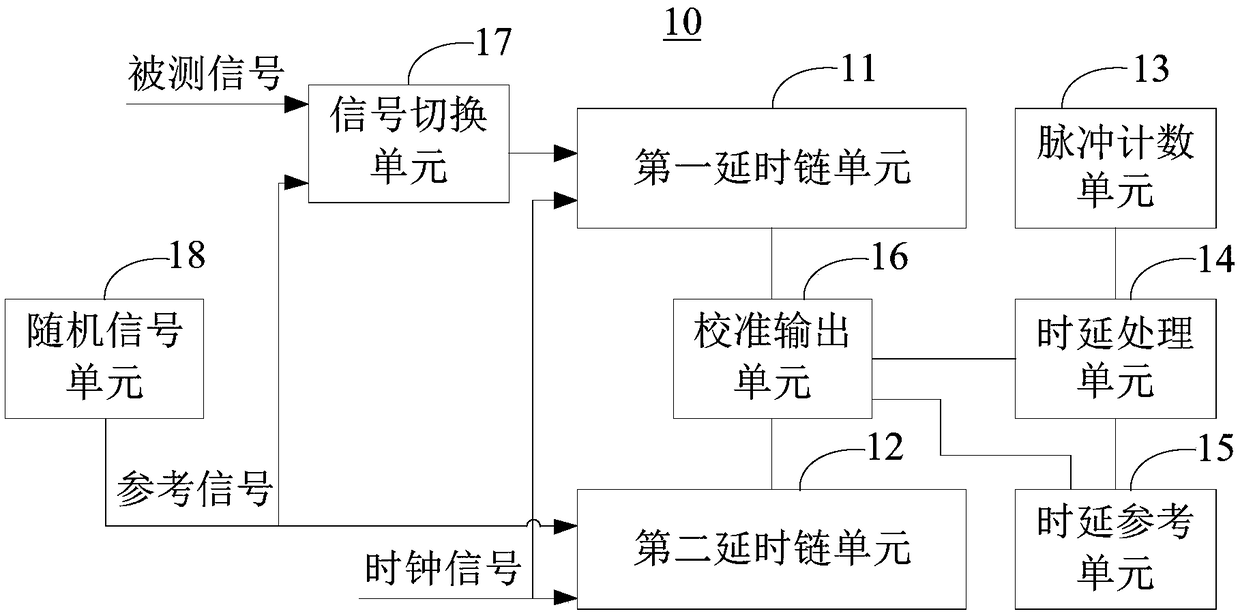

Delay calibration output device and method

ActiveCN109194458ALow costImprove measurement efficiencySynchronising arrangementOutput deviceBand counts

The present invention provides a delay calibration output device and method. The device comprises a first delay chain unit, a second delay chain unit, a pulse counting unit, a delay processing unit, adelay reference unit and a calibration output unit. The first delay chain unit is configured to transmit detected signals and generate first transmission data; the second delay chain unit is configured to transmit the reference signals and generate second transmission data; the pulse counting unit is configured to obtain counting data of the second delay chain unit; the delay processing unit is configured to obtain actual delay data according to the clock signals and the counting data of the second delay clock unit; the delay reference unit stores first reference delay data and second reference delay data; and the calibration output unit is configured to calibrate and output a delay value corresponding to the first delay chain unit at present according to the first reference delay data, the second reference delay data, the actual delay date, the second transmission data and the first transmission data. The device is low in delay calibration cost and high in delay calibration accuracy.

Owner:上海星秒光电科技有限公司 +1

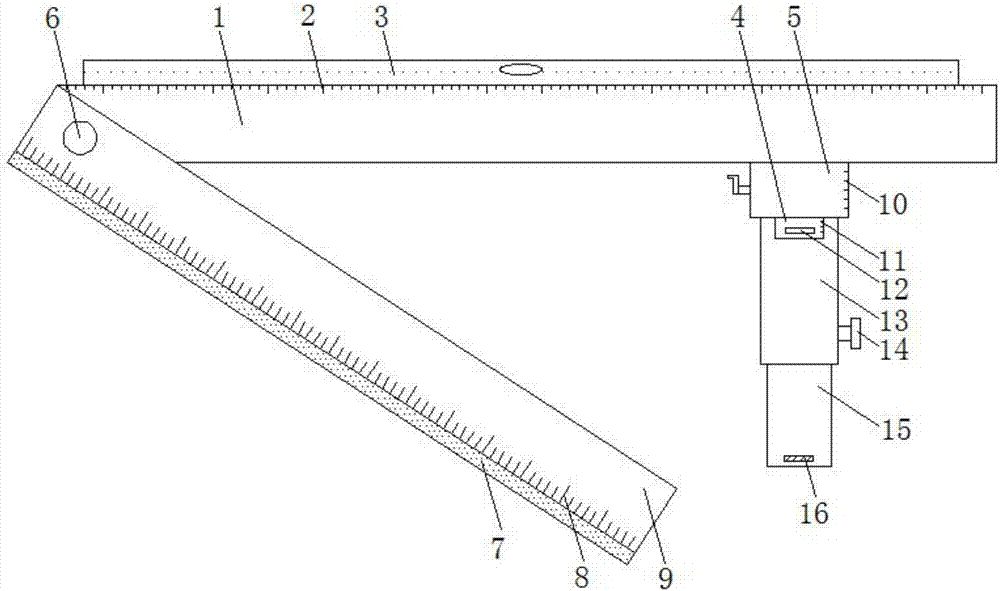

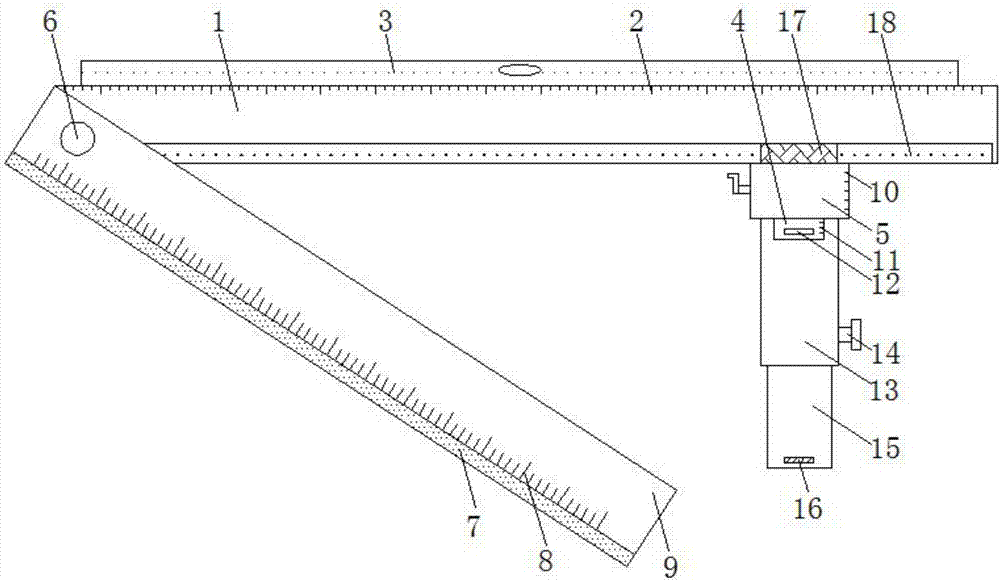

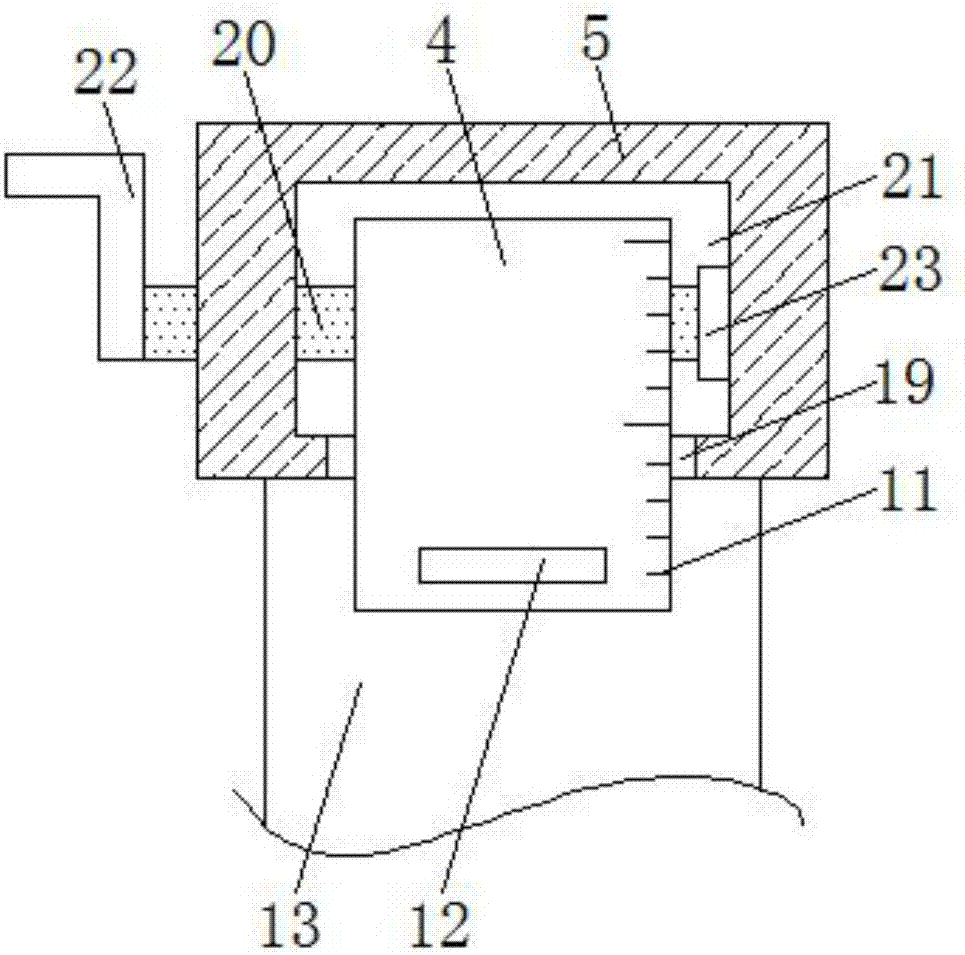

Combined convenient-to-carry side slope measurement ruler

The invention discloses a combined portable slope measuring ruler, which comprises a horizontal plate and an inclined plate, the inclined plate is located at the lower part of the horizontal plate, the left end of the horizontal plate is hinged with the left end of the inclined plate through pins, The bottom of the plate is provided with a clamping groove, the bottom of the horizontal plate is provided with a movable block, and the top of the movable block is fixedly connected with a clamping block suitable for the clamping groove, and the clamping block is clamped in the clamping groove. The bottom of the block is fixedly connected with a sleeve, the bottom of the sleeve is covered with a support rod, and the sleeve is fixed to the support rod through a screw. The combined and portable side slope measuring ruler can effectively adjust the protruding length of the support bar. The combined adjustment performance is good, and it can meet the measurement of different slope slopes. Reasonable adjustment of the angle between the support rods can be removed, which is more convenient to carry and effectively ensures the efficiency of slope measurement.

Owner:黎庆有

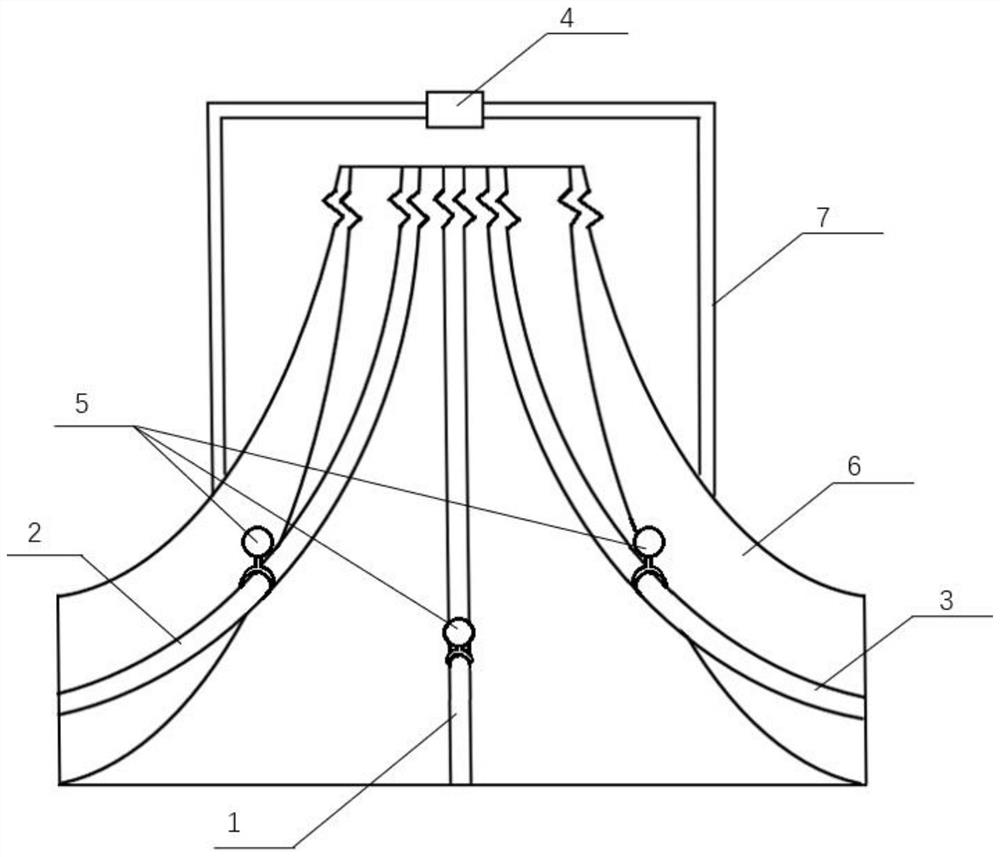

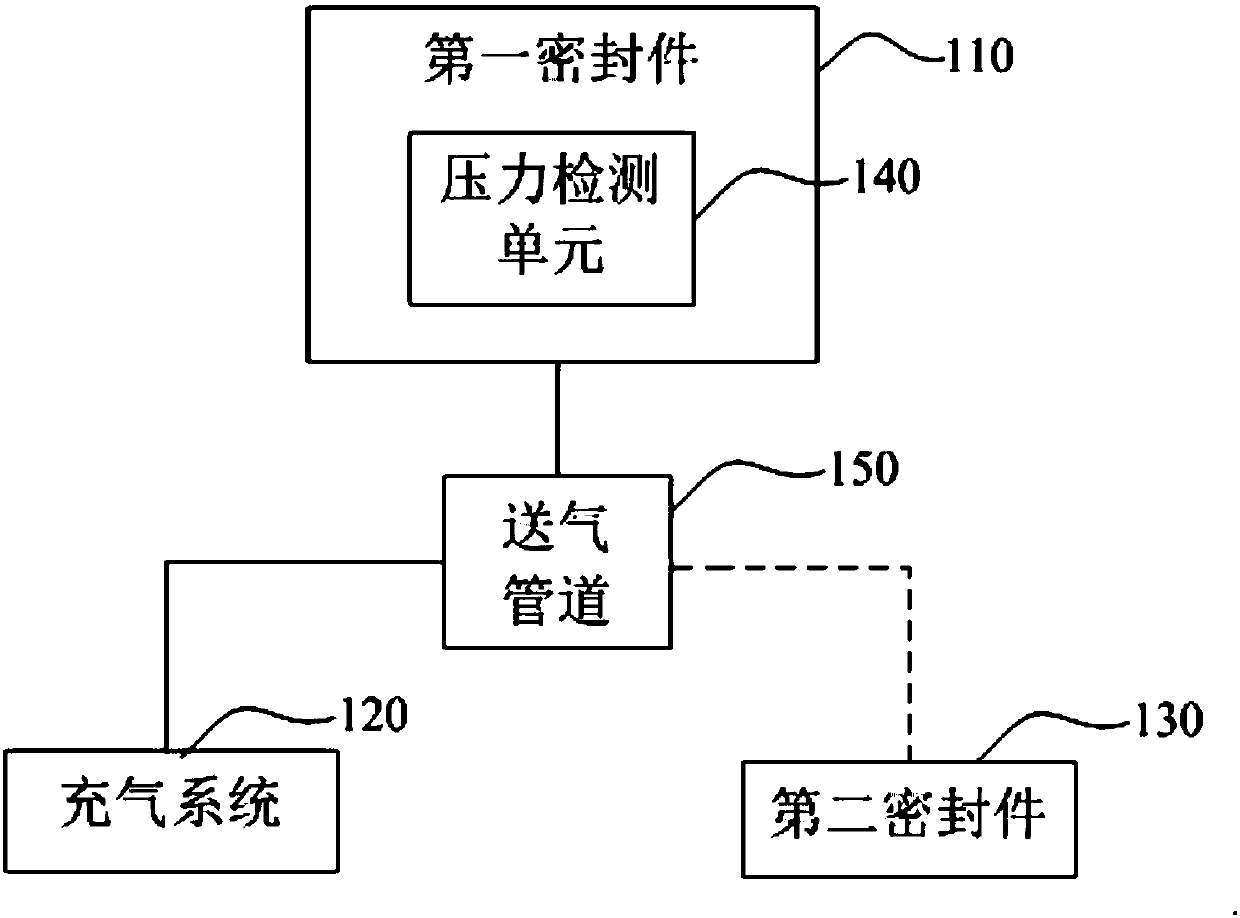

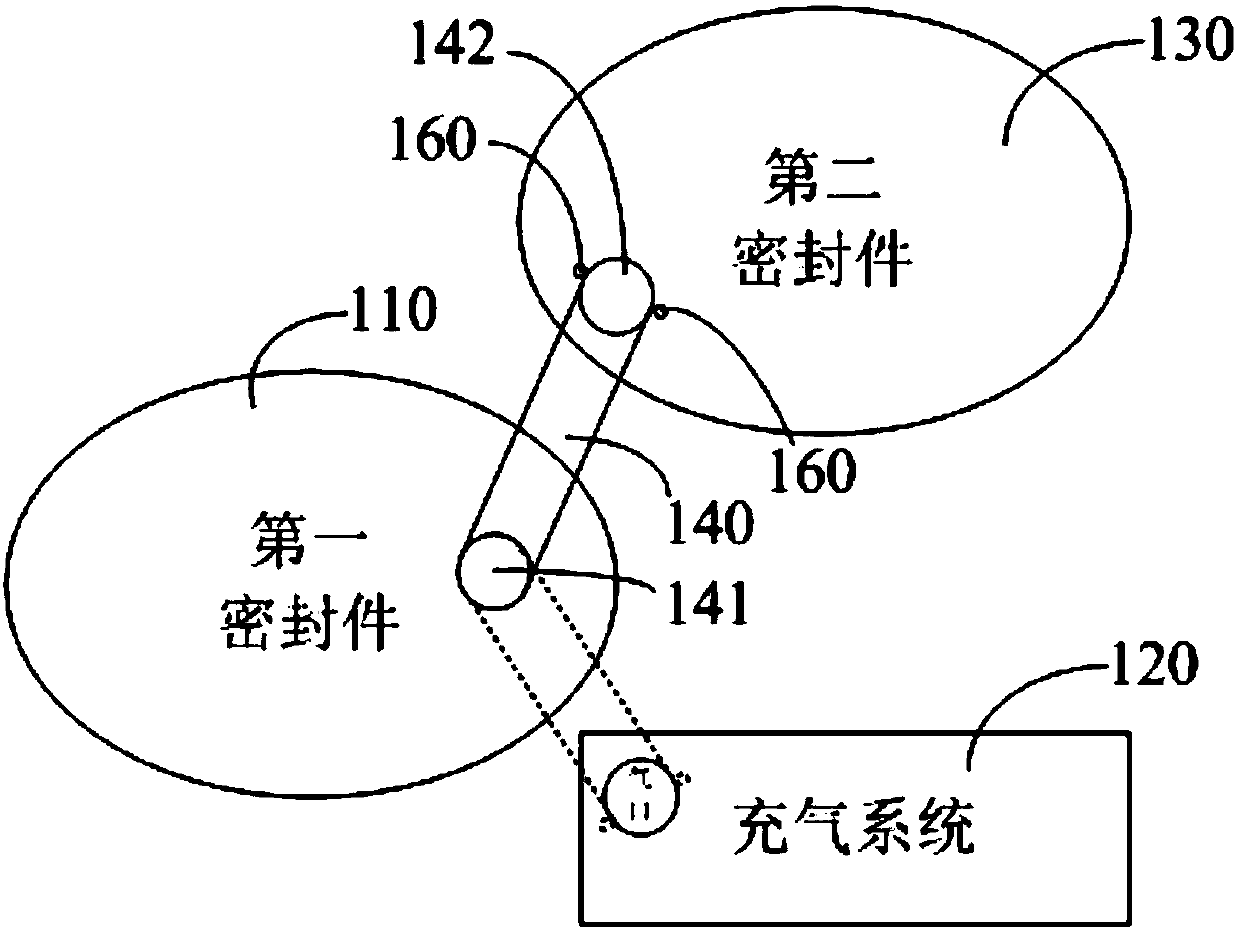

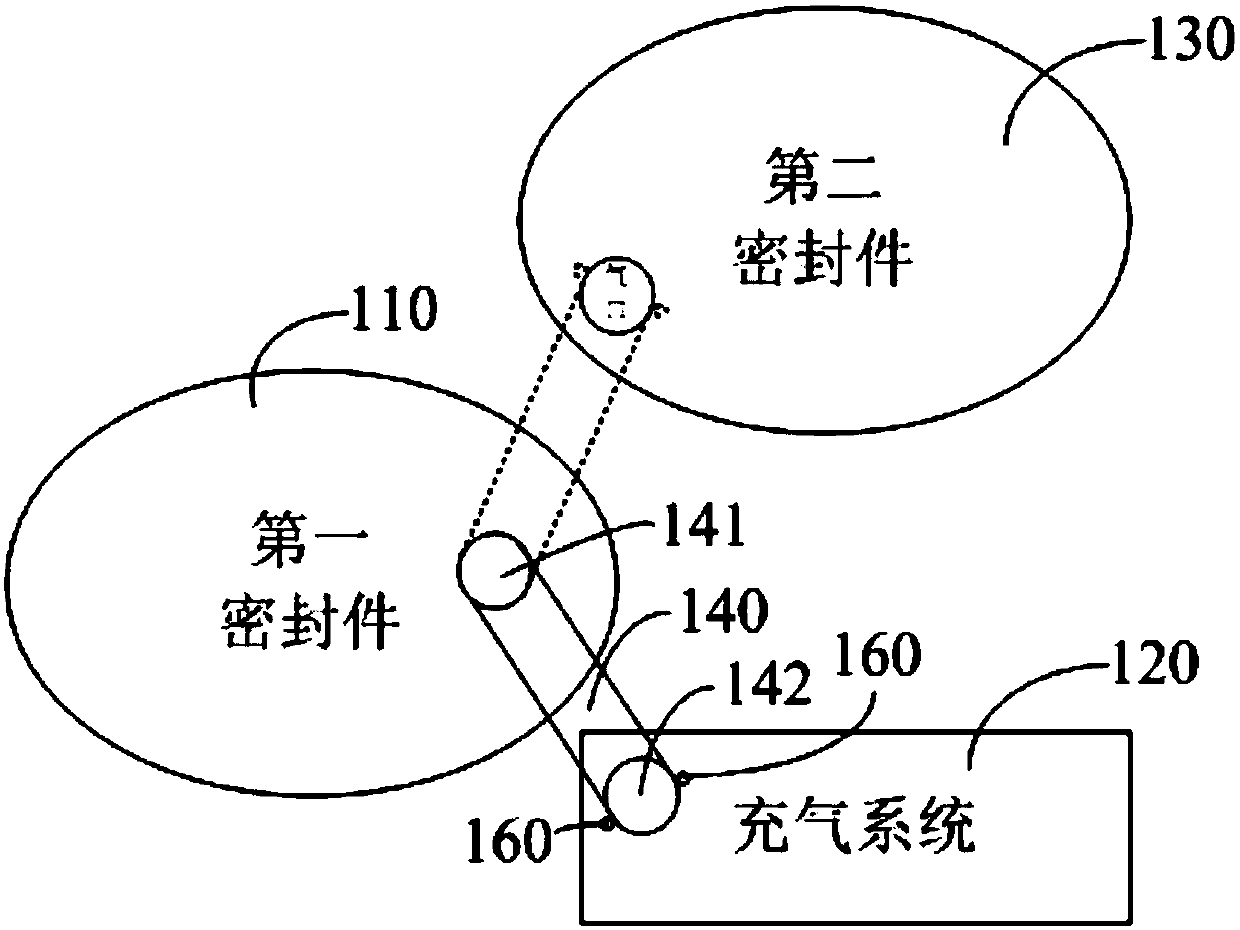

Measurement device and method for volume of sealing part

InactiveCN107843311AGuaranteed measurement efficiencyHigh measurement accuracyContainer/cavity capacity measurementMeasurement deviceEngineering

The invention relates to the technical field of machining and discloses a measurement device for the volume of a sealing part. The device comprises a first sealing part, an air inflation system, an air supply pipe, a control unit, a pressure detection unit and a processing unit. The air inflation system is used for inflating the first sealing part; the control unit is used for controlling the airinflation system to be closed and controlling the air supply pipe to be communicated with the first sealing part and a second sealing part when the preset condition is achieved; the pressure detectionunit is used for acquiring the initial air pressure of the first sealing part when the preset condition is achieved; when the pressure of the first sealing part and the second sealing part is stable,the stable air pressure of the first sealing part is acquired; the processing unit is used for determining the volume of the second sealing part at least according to the initial air pressure, the stable air pressure and the volume of the first sealing part, or the processing unit is used for determining the volume of the first sealing part according to the initial air pressure, the stable air pressure and the volume of the second sealing part. The invention further provides a measurement method for the volume of the sealing part. The method is applied to the system. The measurement device for the volume of the sealing part has the advantages of high measurement speed and accurate measurement results.

Owner:李秀水

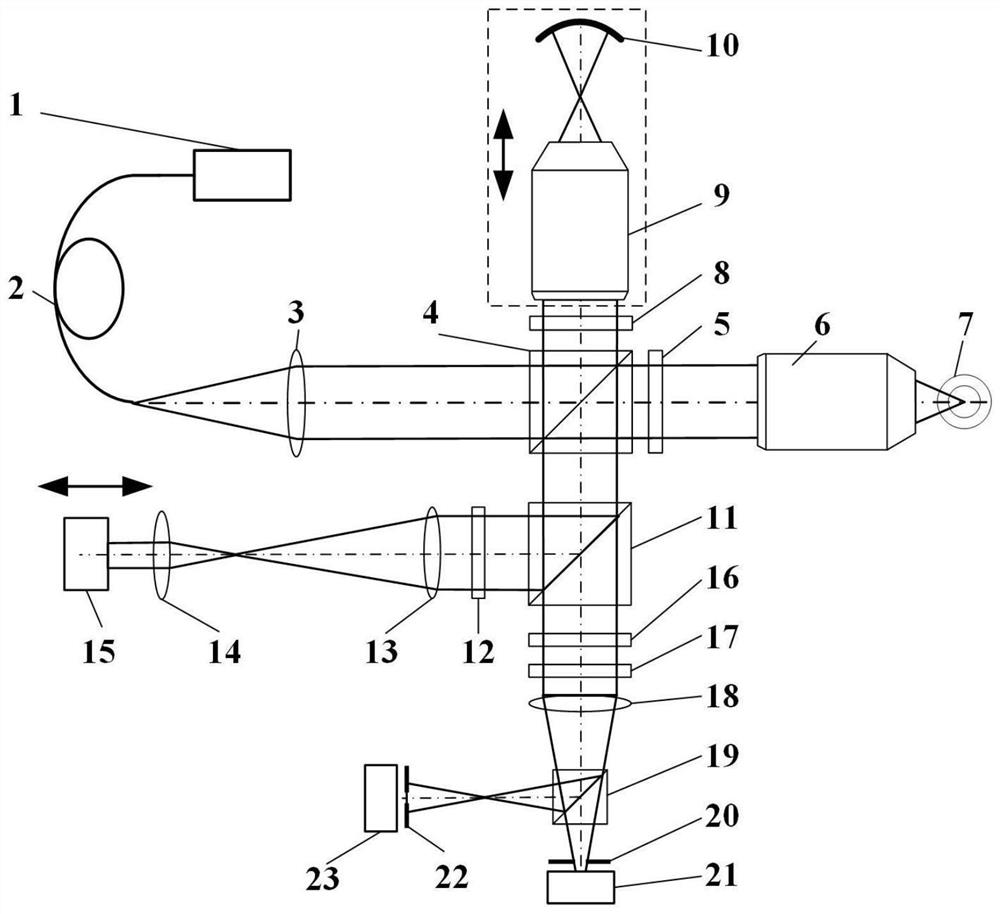

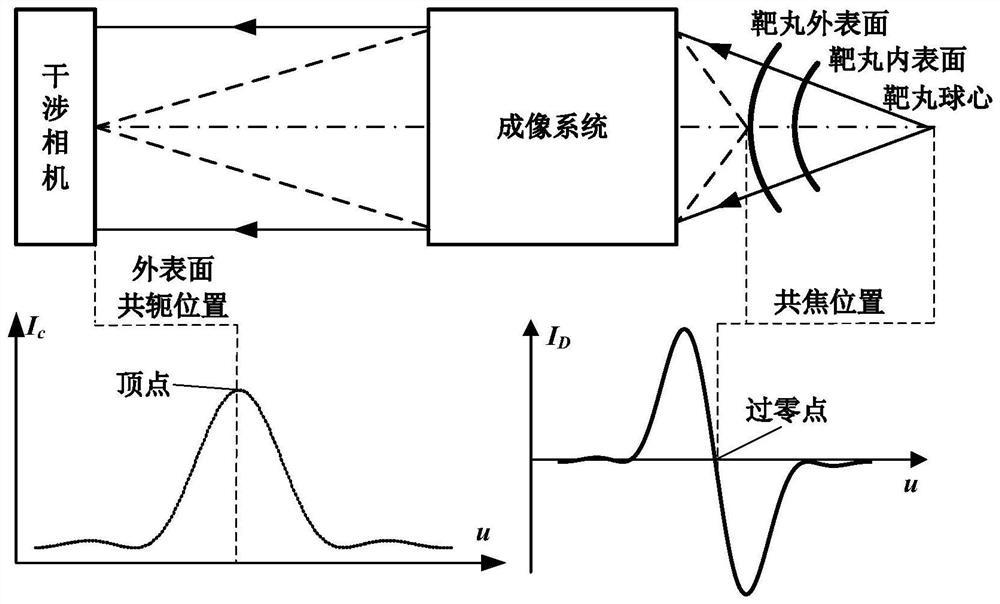

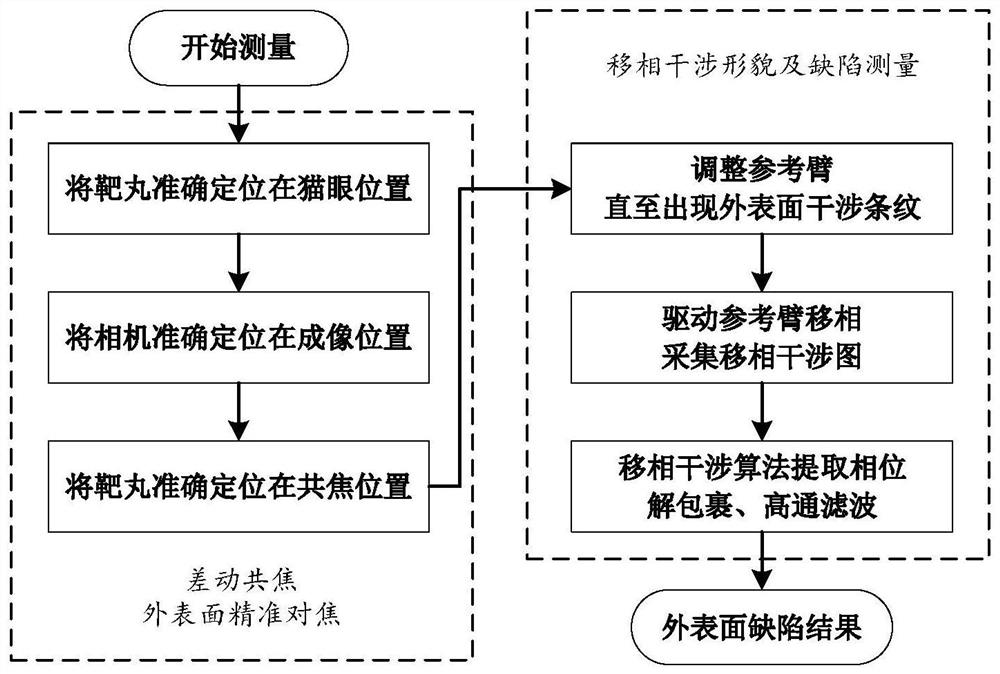

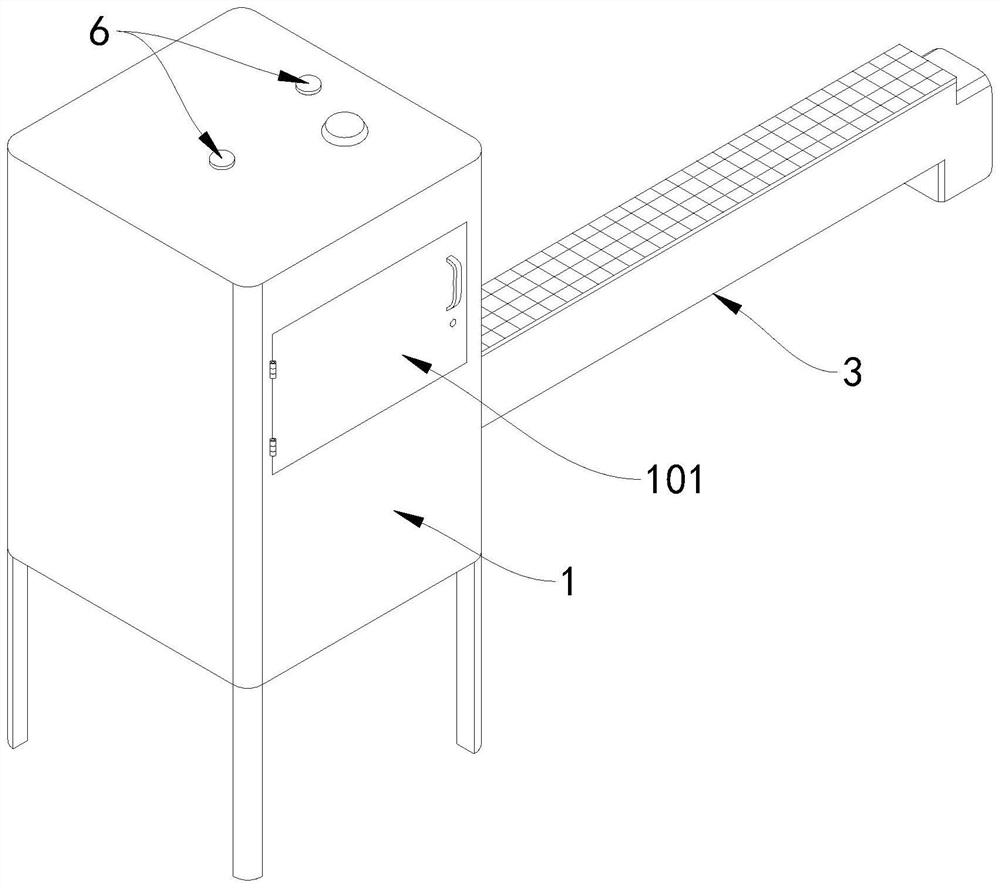

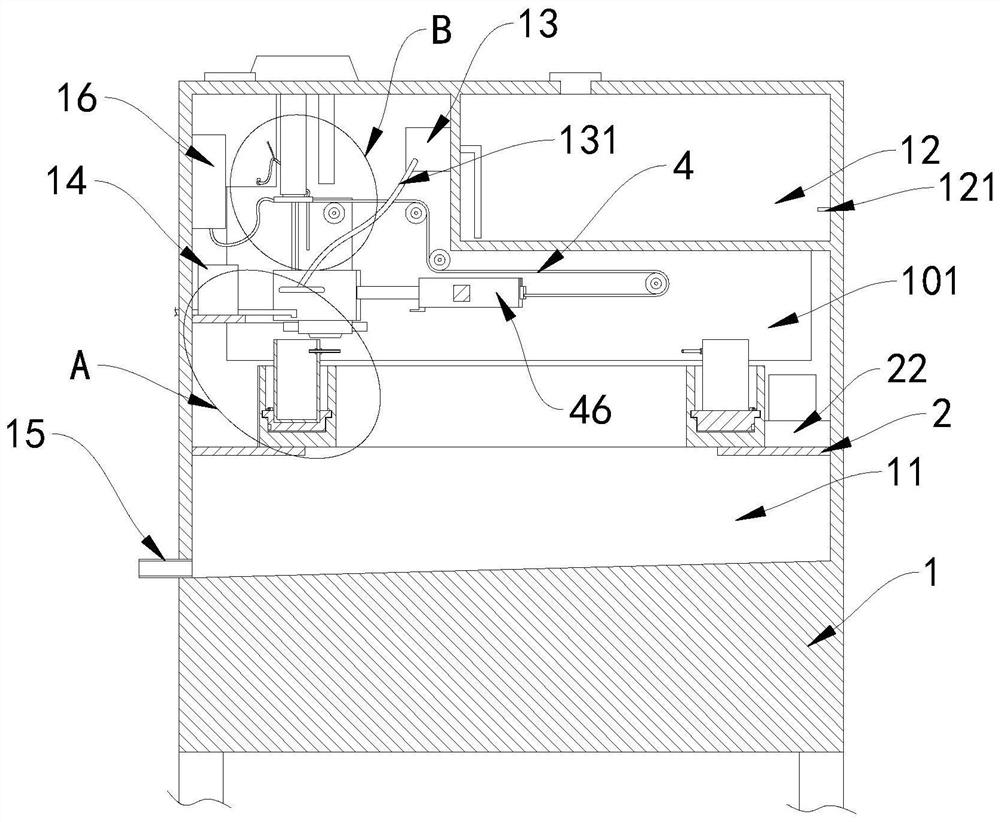

Differential confocal fixed-surface interference target outer surface defect detection method and device

ActiveCN112666172APrecise positioningGuaranteed measurement accuracyMaterial analysis by optical meansInterference microscopyAutofocus

The invention relates to a differential confocal fixed-plane interference target outer surface defect detection method and device, and belongs to the technical field of optical imaging and detection. According to the method, the zero crossing point of a differential confocal light intensity response curve is used for accurately positioning the axial positions of a target (a detected surface) and a camera (a detection surface), so that accurate and automatic focusing imaging of the outer surface is realized. A short coherent light source and a spherical reference mirror are adopted in an interference microscopic light path to generate an outer surface zero interference pattern; and then measuring outer surface defect distribution from the outer surface zero interferogram by using a phase-shifting interferometry. According to the invention, a more accurate adjustment judgment basis is provided for axial position adjustment of the target and the camera by using the accurate positioning characteristic of the differential confocal technology, so that the precision and efficiency of focusing and detection of the outer surface of the traditional interference microscopy method are effectively improved, and a necessary technical guarantee is provided for automatic detection. The invention provides a new technical approach for high-precision, high-efficiency and automatic detection of the outer surface defects of a large batch of targets.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Water quality sampling and detecting equipment for water pollution based on environmental protection

InactiveCN114324807AReduce labor intensityAvoid affecting the sampling test resultsWithdrawing sample devicesTesting waterWater storageWater quality

The invention discloses water quality sampling detection equipment for water pollution based on environmental protection, and relates to the technical field of environmental protection detection equipment. Comprising a machine body, a drainage cavity is formed in the machine body, a water storage cavity is formed in the drainage cavity, a first pump box internally provided with a first water pump is arranged on one side of the water storage cavity, a second pump box internally provided with a second water pump is arranged on one side of the inner wall of the drainage cavity, and a water quality detector is arranged on one side of the inner wall of the drainage cavity; a probe and a collecting plate are mounted on the water quality detector through a cable, and a collecting disc and a driving box are arranged at the top of the collecting plate. By arranging the machine body, the collection plate, the water taking mechanism, the detection mechanism and the gland structure, compared with a conventional collection device, the device automatically collects a water sample and completes detection and sample storage operation, workers do not need to frequently go to the site for collection, the labor intensity is reduced, and the device has a wide application prospect.

Owner:深圳市云传物联技术有限公司

Optical free-form surface full-aperture detection method based on multi-error real-time compensation

ActiveCN113175893AHigh measurement accuracyGuaranteed measurement efficiencyUsing optical meansGeometric properties/aberration measurementDual axisMeasurement precision

The invention provides a large-aperture optical free-form surface full-aperture detection device and method based on multi-error real-time compensation, and the detection device is used for detecting a free-form surface optical element, and comprises an X-axis motion execution system, a Y-axis motion execution system and a Z-axis motion execution system; a Y-axis position measurement system is used for measuring the position of the X-axis motion execution system on the Y axis; an X-axis position measurement system is used for measuring the position of the Z-axis motion execution system on the X axis; a double-axis tilt angle sensor is used for detecting space attitude variation of a non-contact displacement measuring head in an XZ plane and a YZ plane when the non-contact displacement measuring head moves along the X axis and the Y axis, and a Z-axis position measurement system is used for measuring the position of the non-contact displacement measuring head on the Z axis; and the non-contact displacement measuring head performs scanning motion along the surface of the free-form surface optical element. Damage to the surface of the element in the measurement process is avoided, the measurement motion error is compensated in real time, and the surface shape error measurement precision of the large-aperture free-form surface optical element is improved.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

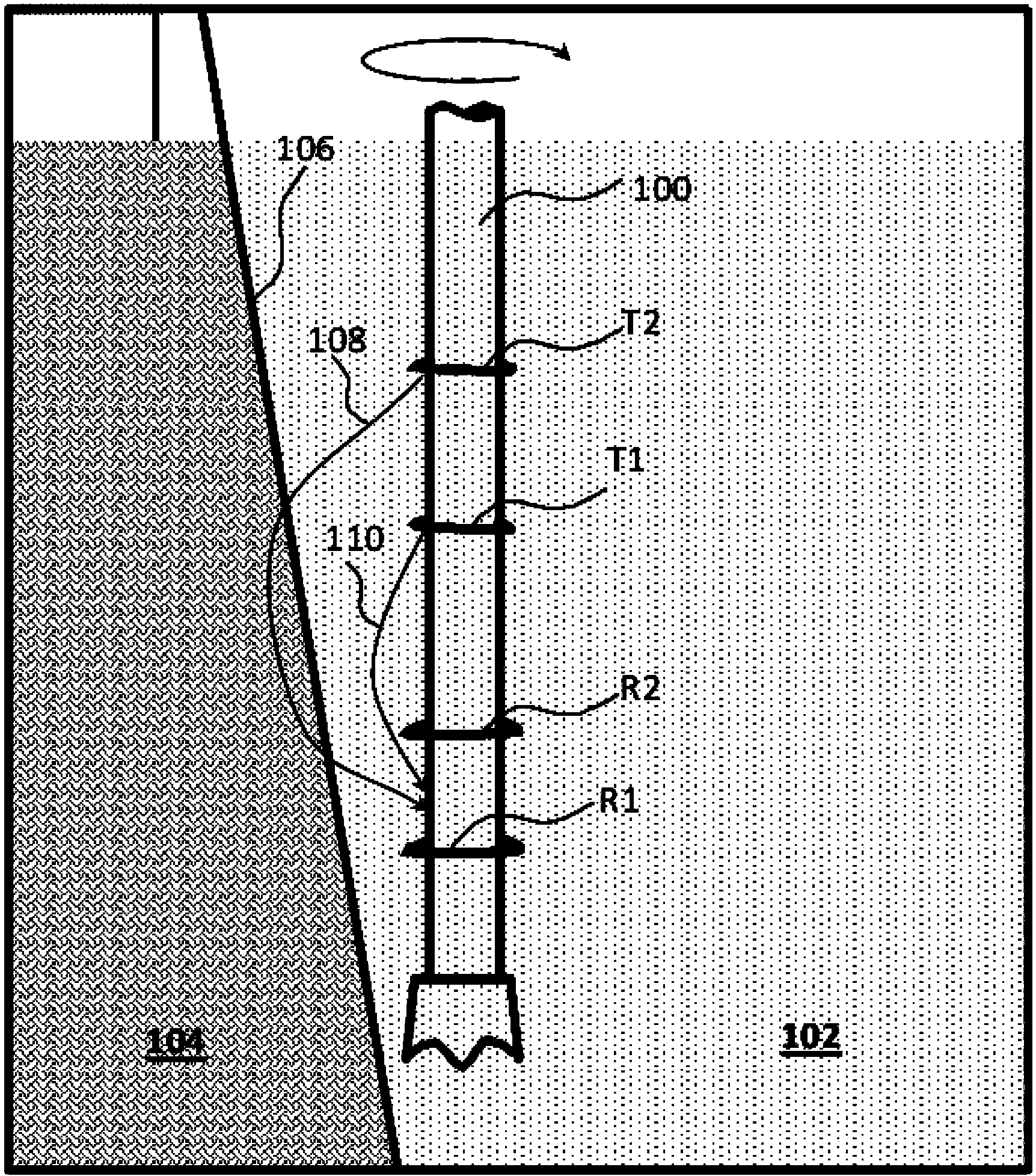

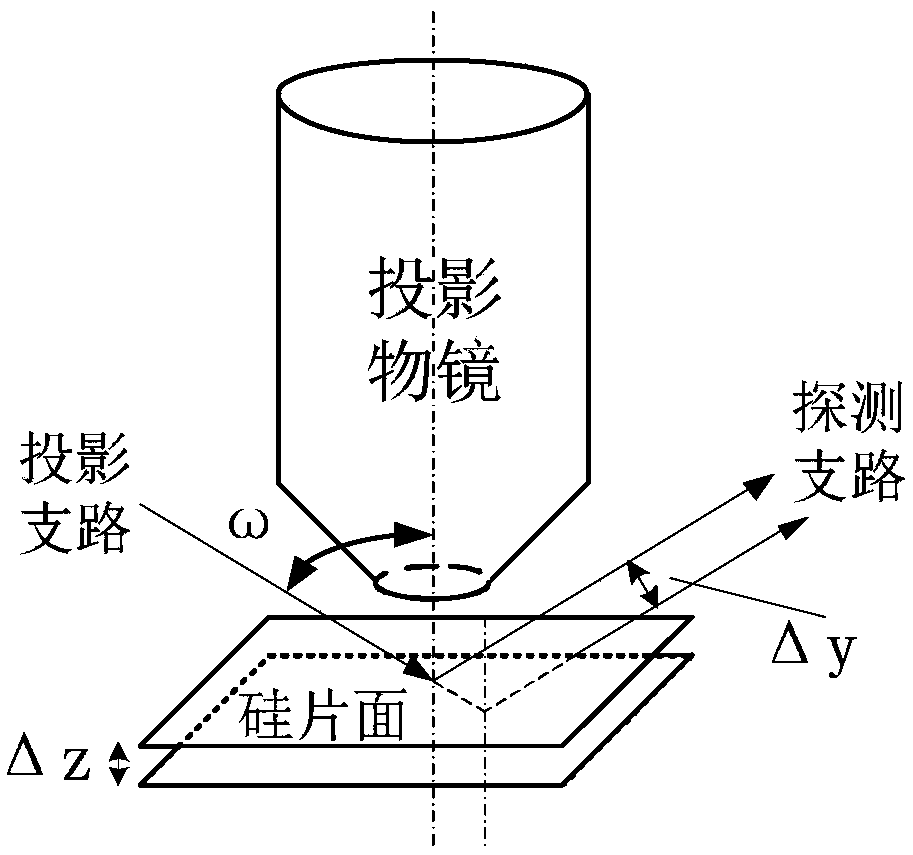

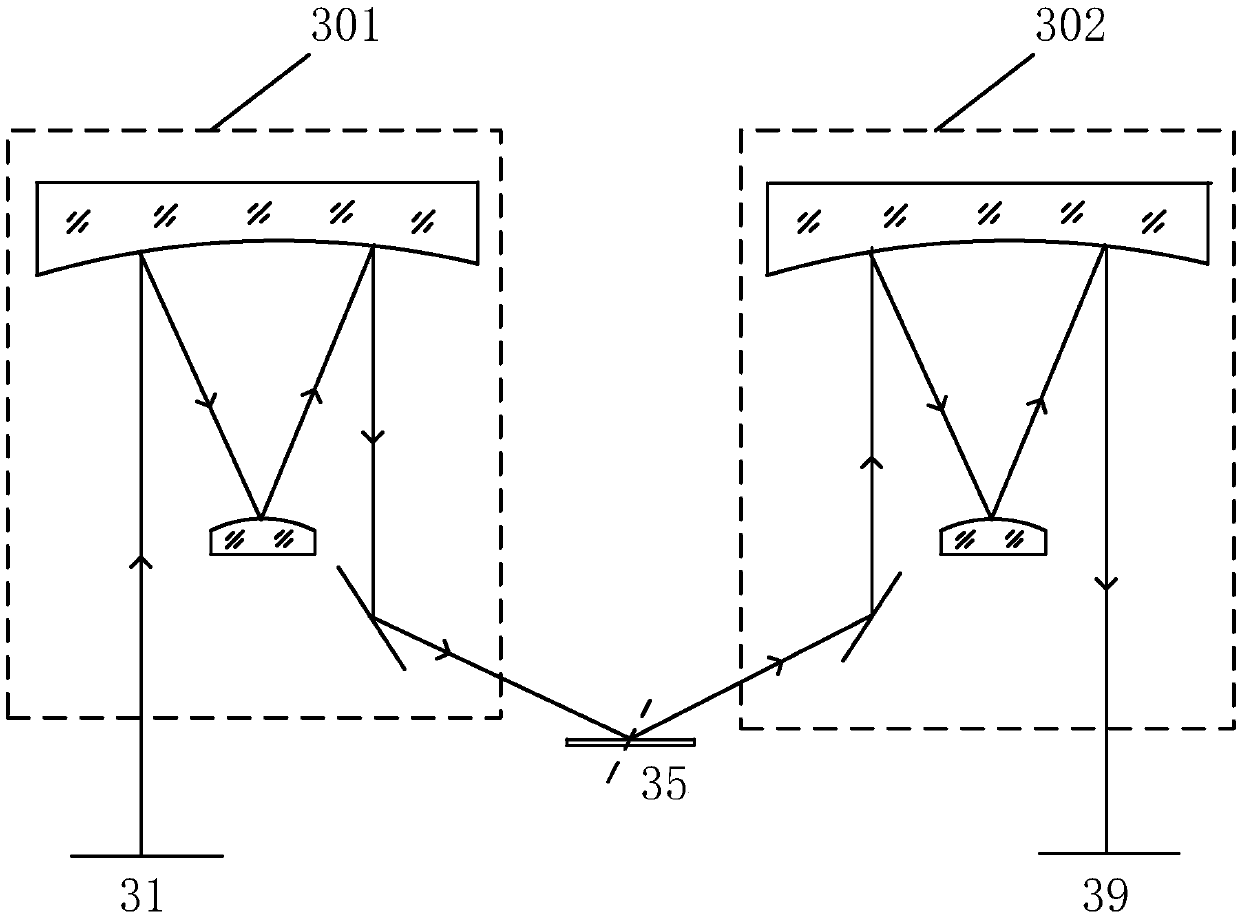

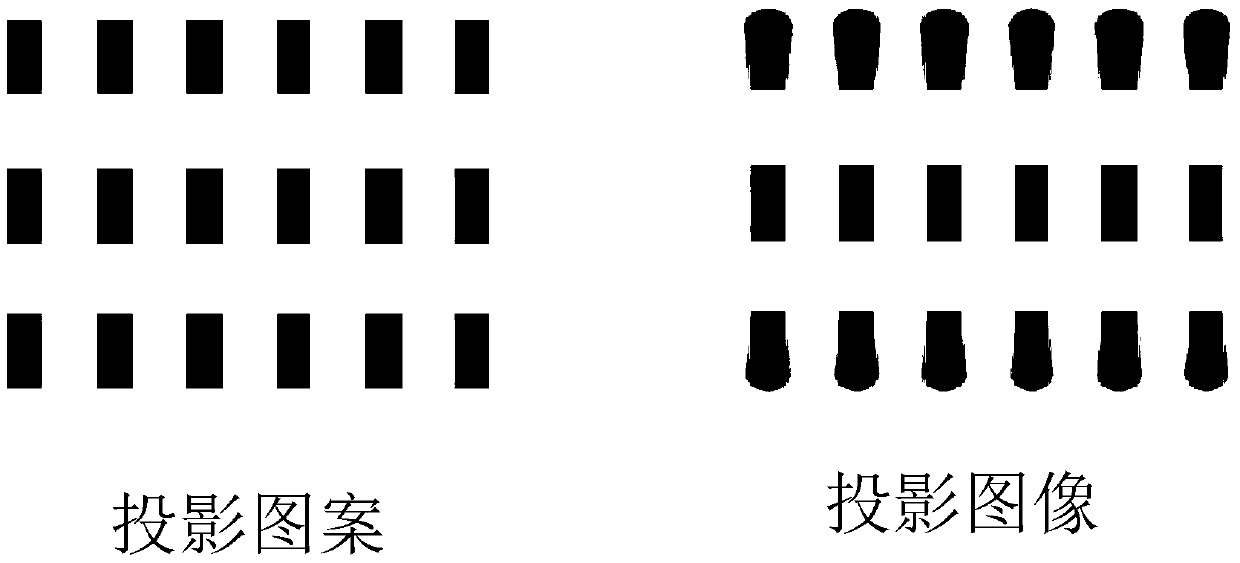

Optical measurement system

ActiveCN111090223AGuaranteed measurement efficiency and signal-to-noise ratioLess types of componentsPhotomechanical treatmentUsing optical meansOptical measurementsEngineering

The embodiment of the invention discloses an optical measurement system. The system comprises a light source unit, an illumination unit, a projection pattern unit, a projection branch circuit, a detection branch circuit and a detector, wherein the projection branch comprises at least one projection concave reflecting mirror and a projection convex reflecting mirror, the projection concave reflecting mirror and the projection convex reflecting mirror are of offset structures, the detection branch comprises at least one detection concave reflector and one detection convex reflector, the detection concave reflector and the detection convex reflector are of offset structures, a pattern surface and a receiving plane of the projection pattern unit meet the Schempflug condition, and a receiving plane and a detection surface of the detector meet the Schempflug condition. The system is advantaged in that the projection branch circuit and the detection branch circuit are arranged to be of offsetstructures, the pattern surface and the receiving plane of the projection pattern unit meet the Schempflug condition, the receiving plane and a detection surface of the detector meet the Schempflug condition, the Schempflug condition is combined with an Offner structure, measurement efficiency and a signal-to-noise ratio of the optical measurement system are ensured, and the optical measurement system is few in element variety and simple in structure.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

Garment measuring device and using method thereof

InactiveCN109247648AReduce labor intensitySimple structureClothes making applicancesElectric machineryEngineering

Owner:濮阳黑蚂蚁服饰有限公司

A horizontal table measuring device for measuring the center distance of tenons and grooves

ActiveCN106091884BEasy to operateImprove stabilityMechanical measuring arrangementsMeasurement deviceLong axis

Owner:HUNAN SOUTH GENERAL AVIATION ENGINE CO LTD

Mass spectrum equipment of accelerator, and method for measuring mass spectrum 14C of accelerator

InactiveCN100561221CEliminates cycle dryingImprove protectionStability-of-path spectrometersMaterial analysis by electric/magnetic meansHigh energyEnergy dispersion

The invention provides an accelerator mass spectrometry device based on a low energy dispersion RFQ accelerator and a corresponding accelerator mass spectrometry 14C measurement method, belonging to the technical field of accelerator mass spectrometry. The accelerator mass spectrometry device includes: an ion source, a buncher, an RFQ accelerator, an electron stripper, a high-energy analysis system, and a detector, the above components are connected in sequence, and the RFQ accelerator accelerates 14C, 12C, and 13C ions to a certain energy to carry out electron analysis. Stripping to remove molecular ion interference. The invention uses a low-energy-dispersion RFQ acceleration structure as the ion acceleration device in the 14C measurement accelerator mass spectrometry (AMS) system, and realizes the alternate acceleration of 14C, 12C, and 13C ions by alternately changing the RF power fed into the RFQ accelerator. There is no need for steel cylinders, insulating gas, alternate injection systems, etc. in traditional AMS, and the overall structure is simplified.

Owner:PEKING UNIV

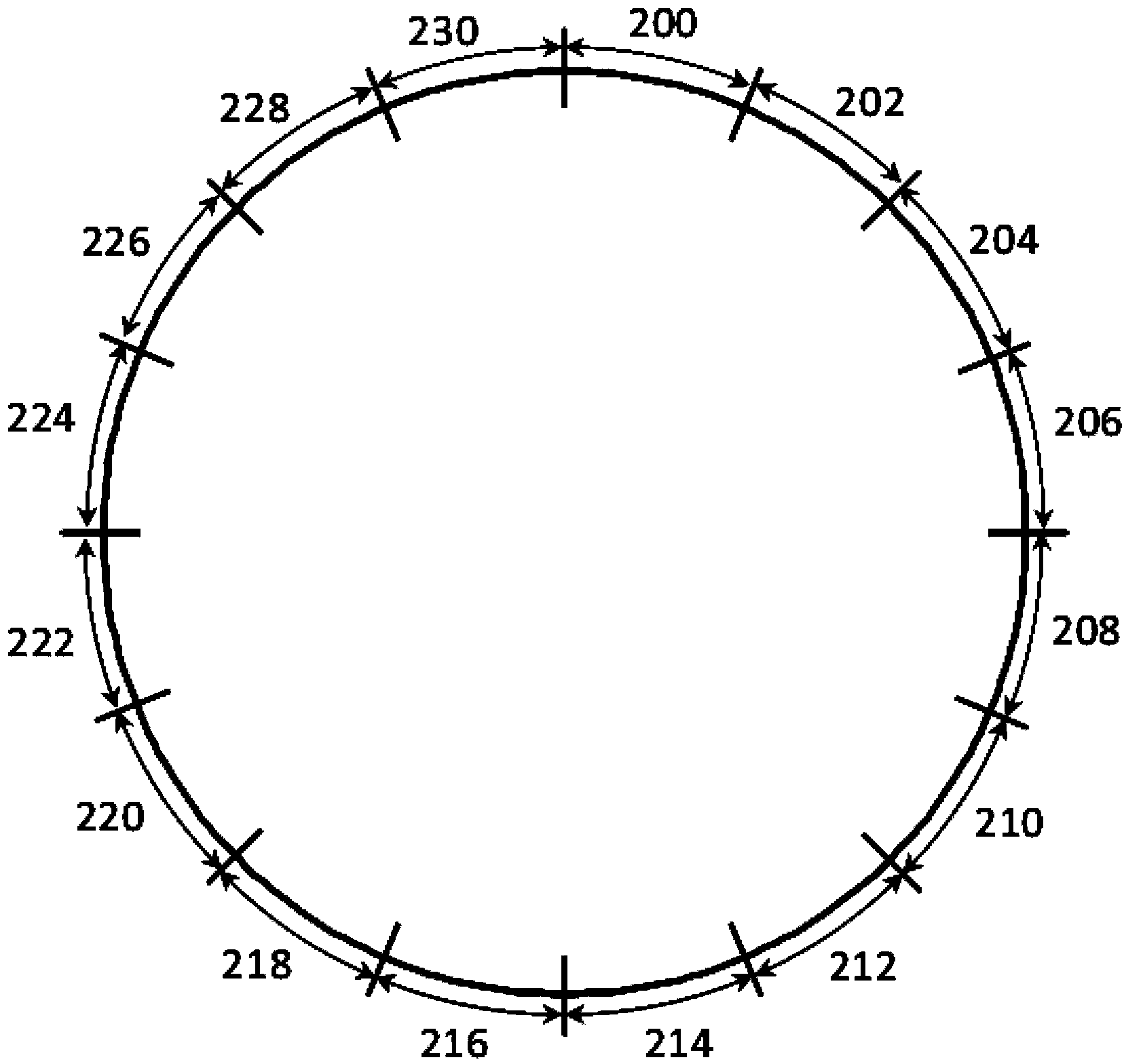

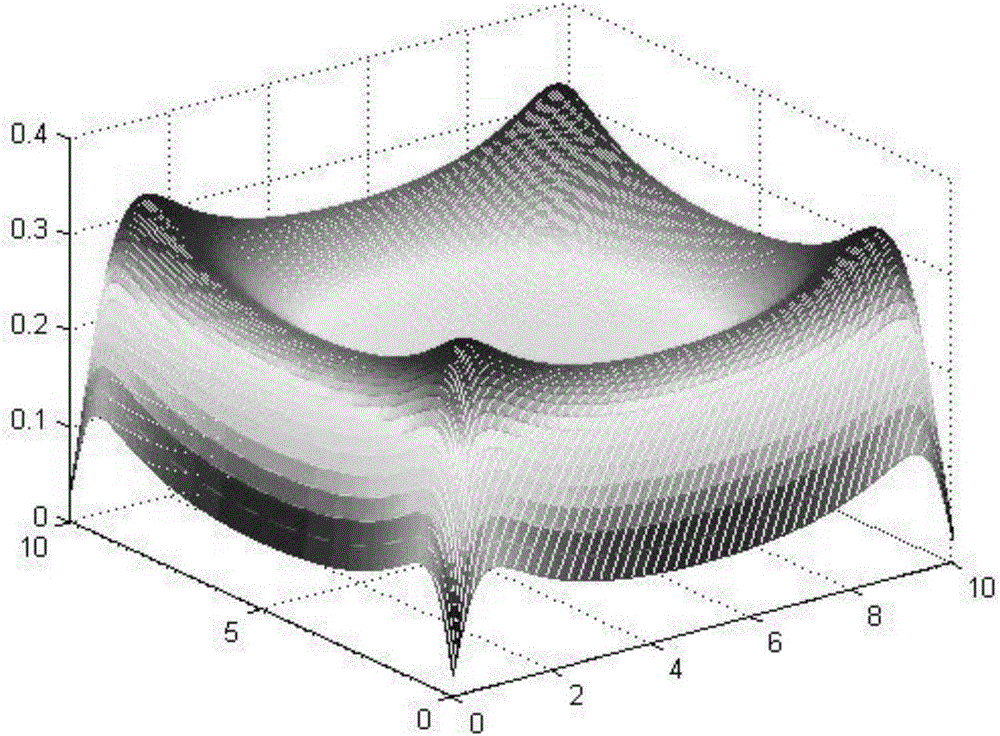

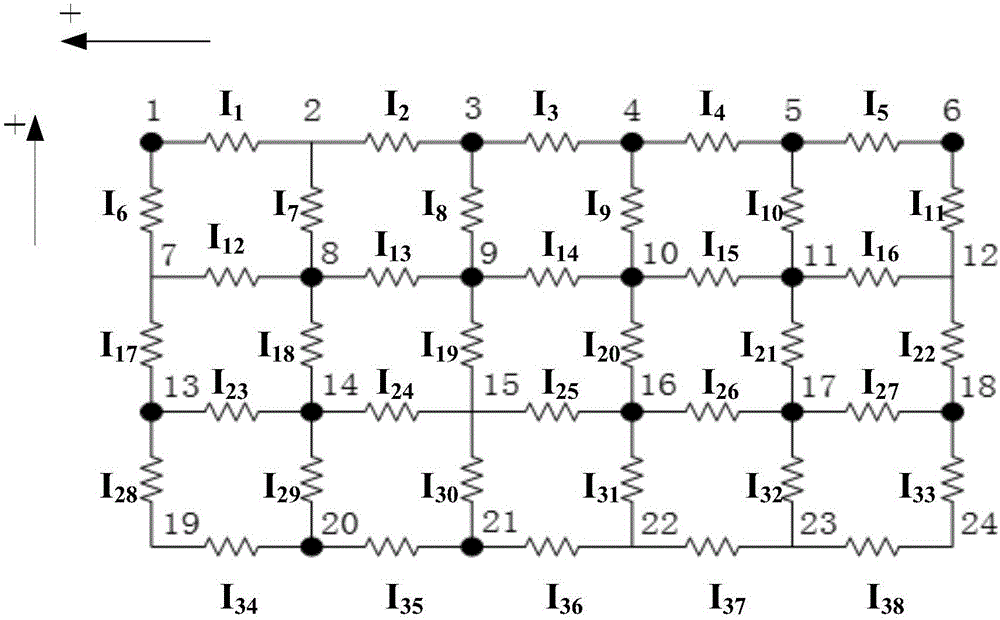

Infinitesimal segmentation and detection method for substation grounding grid corrosion detection

ActiveCN105823933AReduce sensitivityRealize block fault diagnosisEarth resistance measurementsElectrical resistance and conductanceGrounding grid

The invention discloses an infinitesimal segmentation and detection method for substation grounding grid corrosion detection. The method comprises steps: a different frequency excitation source is injected to two adjacent lower guiding bodies; surface magnetic induction intensity is measured, and surface grid magnetic induction intensity distribution data are acquired; the surface grid magnetic induction intensity distribution data are stored to a data table; according to a display result of the data table, whether the detected lower guiding body nodes belong to detectable nodes or undetectable nodes is judged; the surface magnetic induction intensity between the two detectable nodes is measured, and the surface magnetic induction intensity value between the two detectable nodes are acquired; a grounding grid resistance value between the two detectable nodes is calculated according to the surface magnetic induction intensity value, and the calculated grounding grid resistance value is used for judging corrosion happens to the grounding grid line between the two detectable nodes. The infinitesimal segmentation and detection method does not depend on a grounding grid drawing for calculation of a theoretical value or a simulation value, and the detection efficiency and the detection reliability are effectively improved.

Owner:西安上普电力工程有限公司

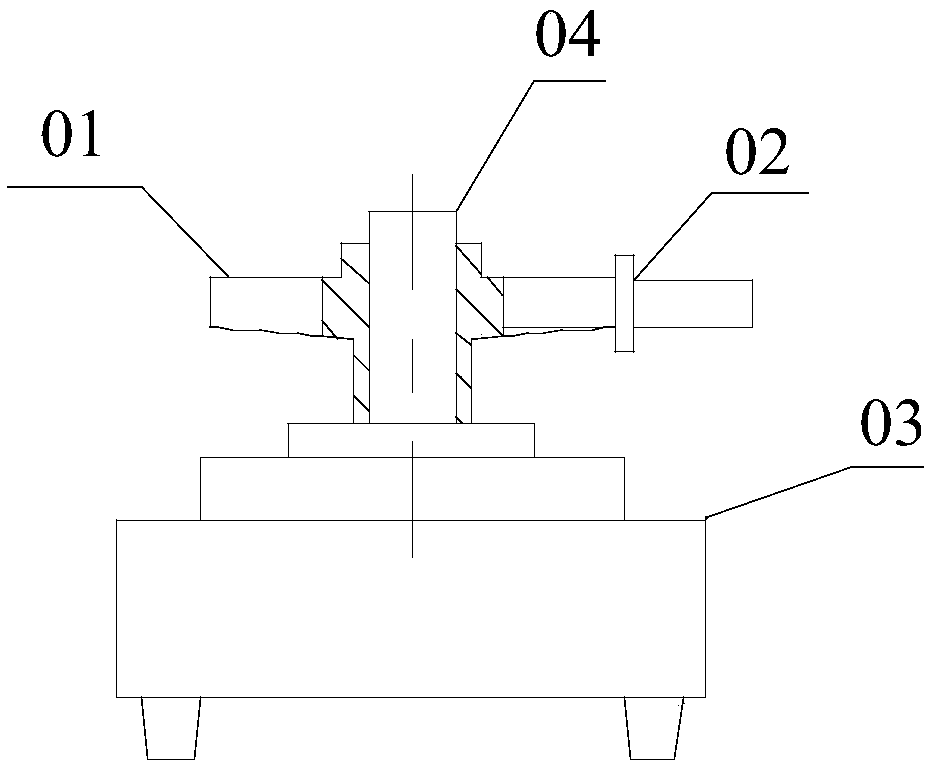

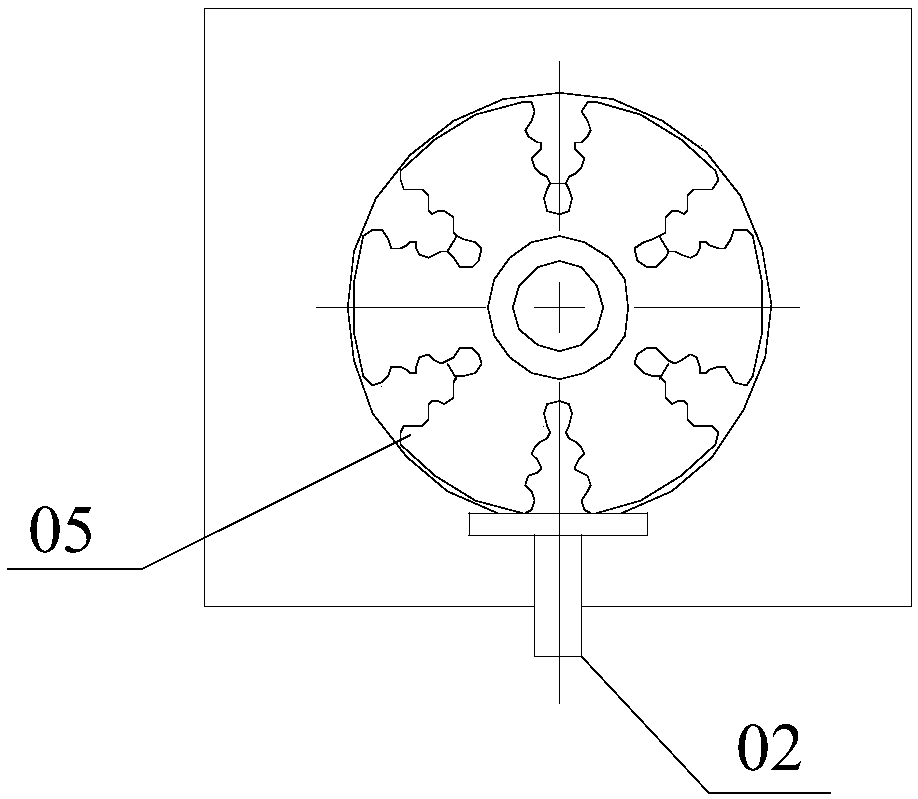

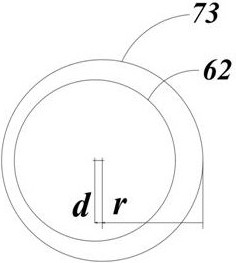

A measuring method of a cylindrical part inner and outer diameter measuring device

ActiveCN112179280BHigh measurement accuracyGuaranteed measurement efficiencyUsing optical meansMeasurement deviceElectric machine

The invention relates to a method for measuring a device for measuring inner and outer diameters of cylindrical parts. The device for measuring inner and outer diameters of cylindrical parts includes a base plate, a column vertically arranged on the base plate, a vertical movement assembly arranged on the column, and a The rotating assembly on the bottom plate, the workpiece fixture arranged on the rotating assembly, the measuring assembly arranged on the vertical motion assembly, the direct-drive linear motor, and the high-precision displacement sensor. The direct-drive linear motor drives the vertical motion assembly. The invention effectively reduces the influence of the eccentricity error of the columnar part on the measurement result of the inner and outer diameter in the clamping process; reduces the influence of the cylindricity of the part positioning surface and the coaxiality error of the part positioning surface and the measured surface on the measurement result of the inner and outer diameter of the cylindrical part; While ensuring the measurement efficiency, the non-contact measurement does not cause any interference or damage to the measured surface; and improves the measurement accuracy of the inner and outer diameters of cylindrical parts to the sub-micron level.

Owner:JIANGSU JITRI JINGKAI HIGH VALUE MFG CO LTD

Measuring method of columnar part inner and outer diameter measuring device

ActiveCN112179280AHigh measurement accuracyGuaranteed measurement efficiencyUsing optical meansMeasurement deviceElectric machine

The invention relates to a measuring method of a columnar part inner and outer diameter measuring device. The columnar part inner and outer diameter measuring device comprises a bottom plate, a standcolumn vertically arranged on the bottom plate, a vertical movement assembly arranged on the stand column, a rotating assembly arranged on the bottom plate, a workpiece clamp arranged on the rotatingassembly, a measuring assembly arranged on the vertical movement assembly, a direct-drive linear motor, and a high-precision displacement sensor, wherein the direct-drive linear motor drives the vertical movement assembly. According to the invention, the influence of the eccentric error of the columnar part in the clamping process on the inner and outer diameter measurement result is effectively reduced; the influence of the cylindricity of the part positioning surface and the coaxiality error of the part positioning surface and the measured surface on the inner and outer diameter measurementresult of the columnar part is reduced; the non-contact measurement ensures the measurement efficiency and does not interfere with or damage the measured surface. The measurement precision of the inner diameter and the outer diameter of the columnar part is improved to a sub-micron level.

Owner:JIANGSU JITRI JINGKAI HIGH VALUE MFG CO LTD

Adjustable special gauge for measuring space sizes of saddle baffles

InactiveCN111457824AGuaranteed accuracyReduce labor intensityMechanical clearance measurementsClassical mechanicsControl theory

The invention discloses an adjustable special gauge for measuring the spacing space sizes of saddle baffles, relates to the technical field of special gauges for saddles, and solves the problems of low detection efficiency and low measurement precision due to the fact that the size of an existing saddle needs to be measured manually. The adjustable special gauge comprises a pressure head, and thepressure head is movably connected to the front end of the adjusting shaft. The adjustable special gauge is based on structural characteristics of parts; a special measuring gauge is manufactured to ensure the measurement accuracy and efficiency, during measurement, after the positioning nut and the pressure head are adjusted to be completely attached to the diameter of the central bottom plate according to the actual size, the adjustable special gauge is taken out and then measured through a measuring tool, the accuracy of measured data is guaranteed, the measurement precision is improved, the labor intensity of staff can be relieved when the adjustable special gauge is used for measuring and detecting the saddle, and staff operation is facilitated.

Owner:DONGFENG SPECIAL PURPOSE VEHICLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com