Measurement device and method for volume of sealing part

A technology for volume measurement and seals, which is applied in the field of industrial manufacturing, can solve the problems that the accuracy of the inflation method is greatly affected by the ambient temperature, and there is no reliable method to detect the volume of seals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

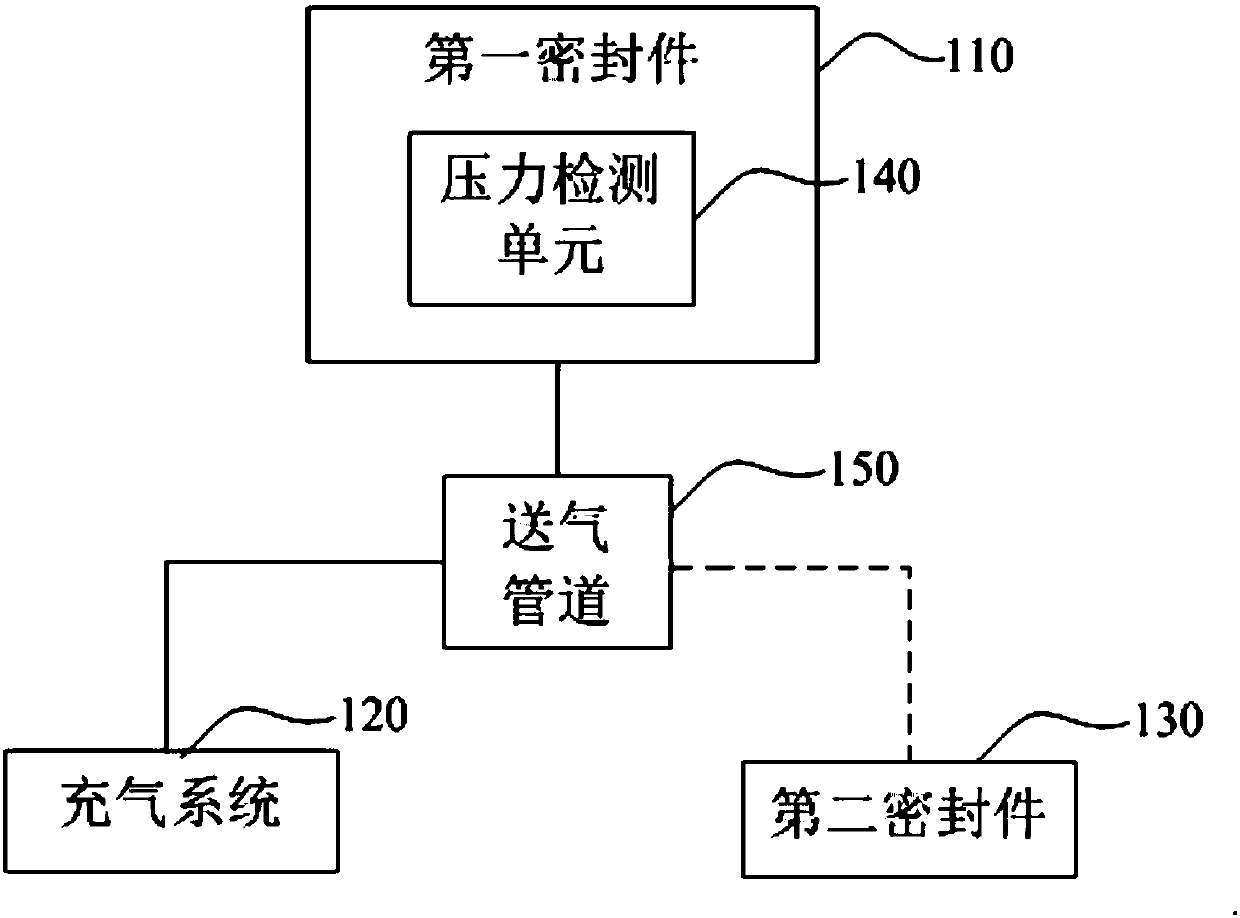

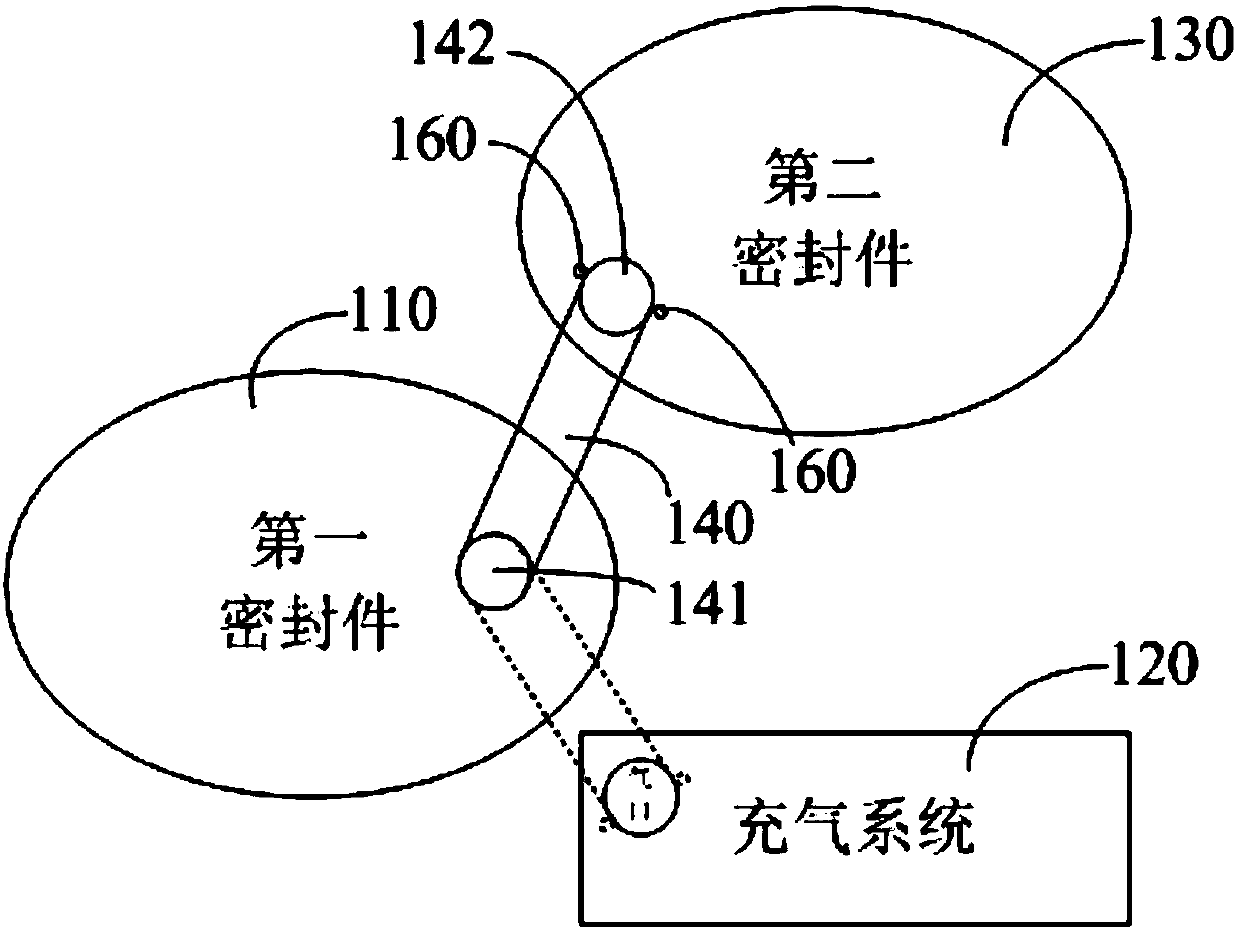

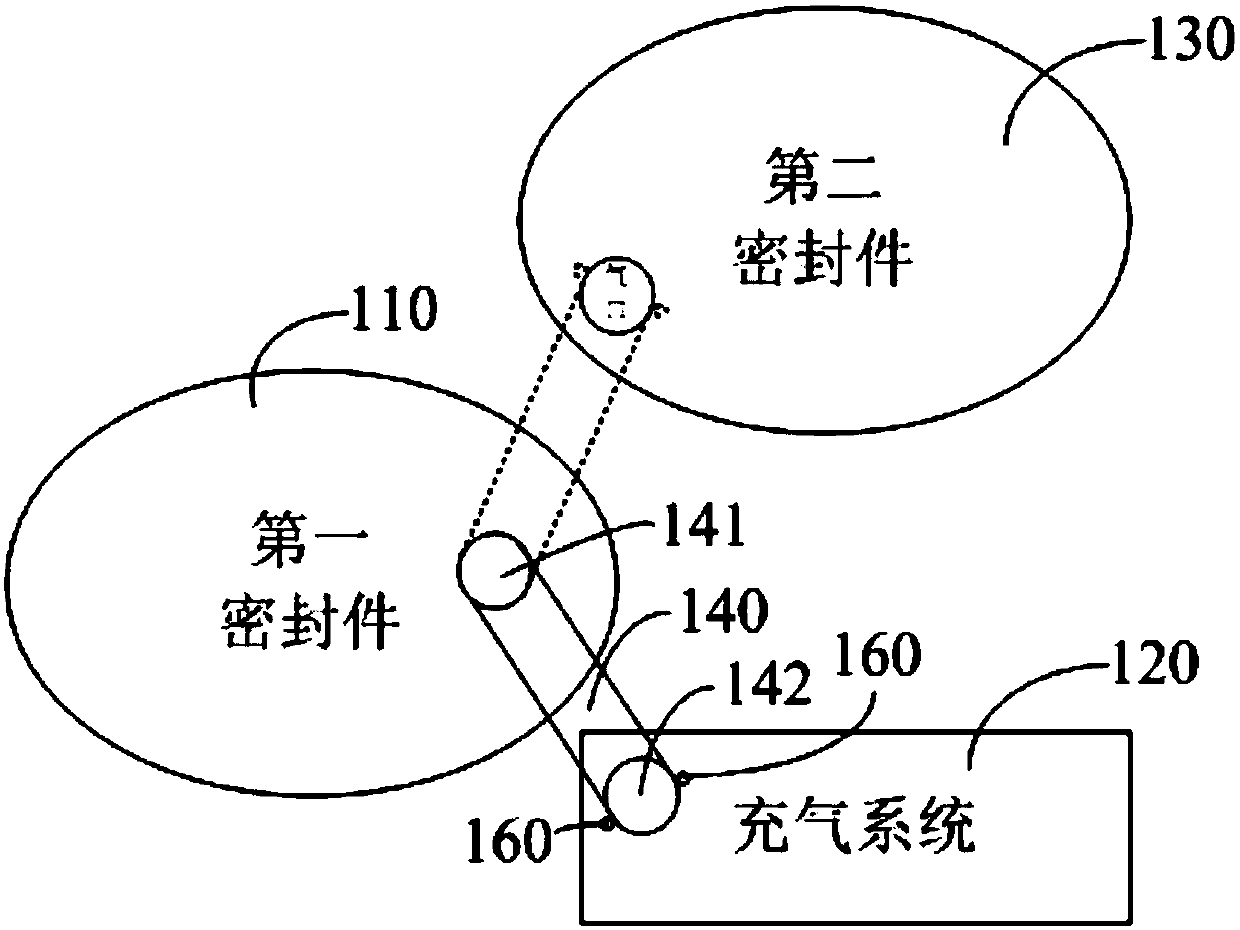

[0041] Please refer to figure 1 , figure 2 and image 3 As shown, the embodiment of the present invention provides a seal volume measuring device, including:

[0042] The first sealing member 110, in this embodiment, the first sealing member 110 is provided with a pressure detection unit 140;

[0043] An inflation system 120, connected to the first sealing member 110, for inflating the first sealing member 110;

[0044] An air delivery pipeline 150, connected between the first sealing member 110 and the second sealing member 120;

[0045] A control unit, configured to control the inflatable system 120 to close when a preset condition is reached, and control the air supply pipeline 150 to communicate with the first sealing member 110 and the second sealing member 130;

[0046] The pressure detection unit 140 is configured to obtain the initial air pressure of the first sealing member 110 when a preset condition is reached; The stable air pressure of the first seal 110;

...

no. 2 example

[0066] Please refer to Figure 4 Shown is another specific implementation of the sealing element volume measuring device of the present invention. In this embodiment, the first sealing element 110 is the sealing element to be tested, and the second sealing element 130 is the standard sealing element. Different from the first embodiment above, this embodiment integrates the control unit and the pressure detection unit into a control and pressure detection unit 170 . By integrating the control unit and the pressure detection unit, it is easy to improve the air pressure data collection and processing efficiency of the volume measurement device of the present invention.

[0067] At the same time, the first sealing member 110 and the second sealing member 130 are connected through a solenoid valve 180, and the solenoid valve 180 realizes switch control through the control and pressure detection unit 170. When a preset condition is reached, the control and pressure detection unit 17...

no. 3 example

[0071] Please refer to Figure 5 As shown, the embodiment of the present invention also provides a method for measuring the volume of the seal, which is applied between the inflatable system, the first seal and the second seal, including:

[0072] S101. Control the inflation system to inflate the first sealing member;

[0073] S102. Obtain the initial air pressure of the first sealing member when the preset condition is reached;

[0074] S103, controlling the inflation system to close, and communicating with the first sealing member and the second sealing member;

[0075] S104, acquiring the stable air pressure when the air pressure of the first sealing member and the second sealing member is stable;

[0076] S105. Determine the volume of the second sealing member at least according to the initial air pressure, the stable air pressure, and the volume of the first sealing member; or at least according to the initial air pressure, the stable air pressure, and the volume of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com