Method for detecting bed boundary

A technology of formation interface and logging tools, which is applied in the directions of measurement, earthwork drilling and production, boreholes/well components, etc. It can solve the problems that directional resistivity measurement tools cannot meet the work needs, so as to improve practicability, ensure efficiency, and avoid vibrate or shake effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

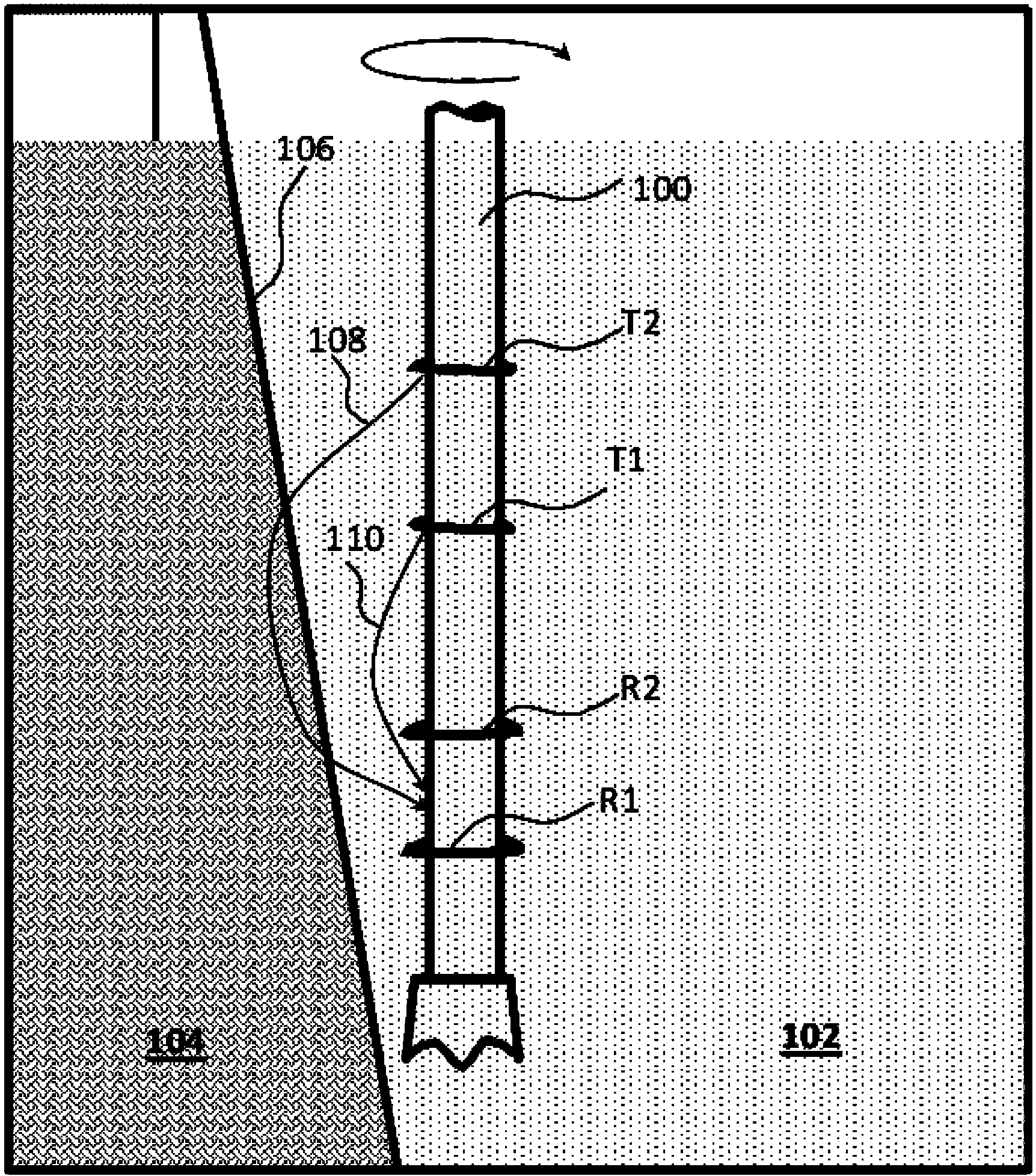

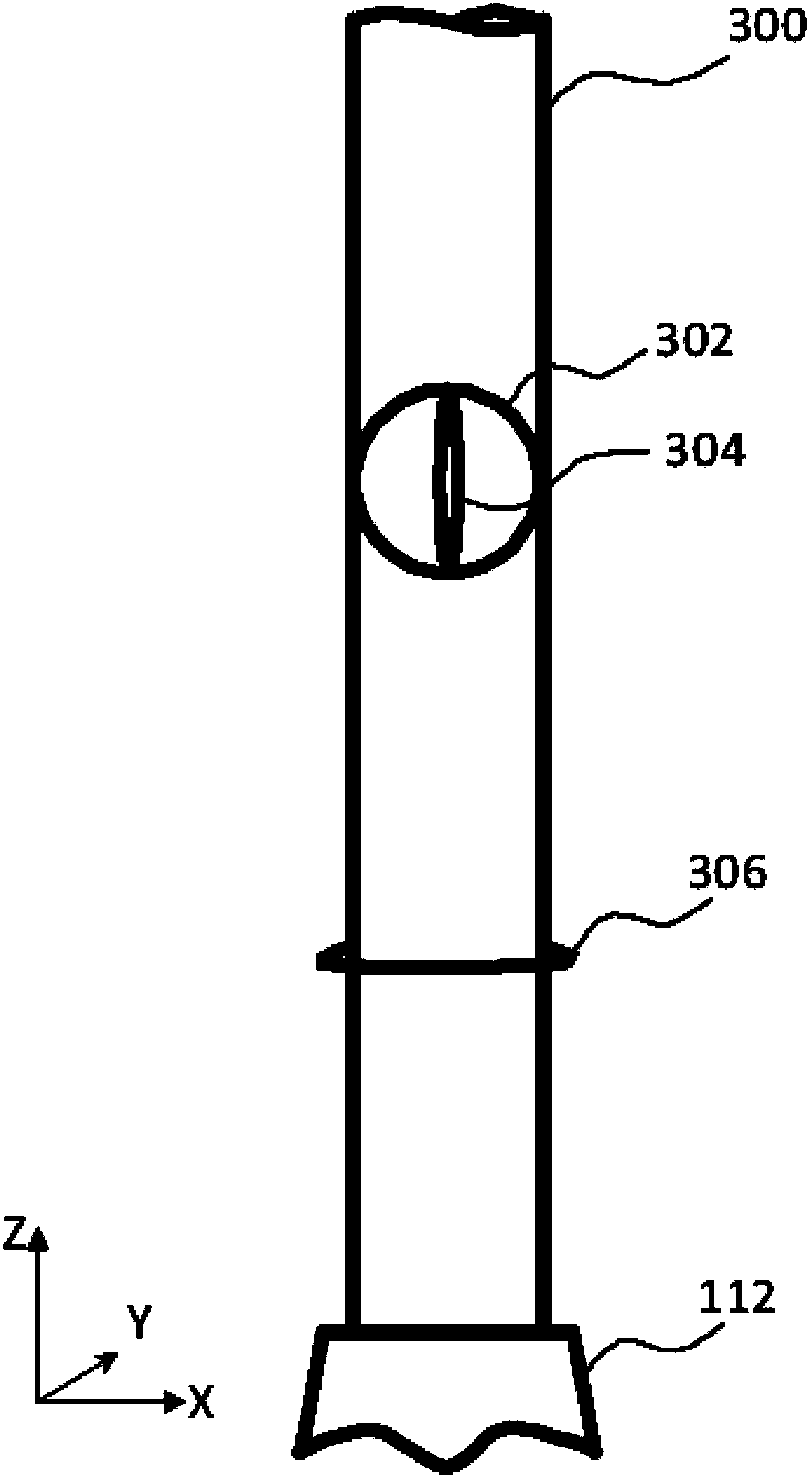

[0036] Figure 3A It is the front view of the directional resistivity measurement tool in the example of the present invention. A directional resistivity measurement tool may include a tool housing 300, two transmitters with x- and y-axes: an x-transmitter 304 and a y-transmitter 302, a receiver with a z-axis: a z-receiver machine 306, and the drill bit 112 at the distal end of the tool housing 300. A coordinate system (x, y, z) associated with the tool housing 300 . The direction of the longitudinal axis of the tool housing 300 is defined as the Z-axis of the current coordinate system (x, y, z). The x-transmitter 304, y-transmitter 302, and z-receiver 306 may include one or more antennas for tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com