Device, apparatus and method for positioning measurement reference plane of measured object

A technology for measuring datums and positioning equipment, which is used in measuring devices, optical devices, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

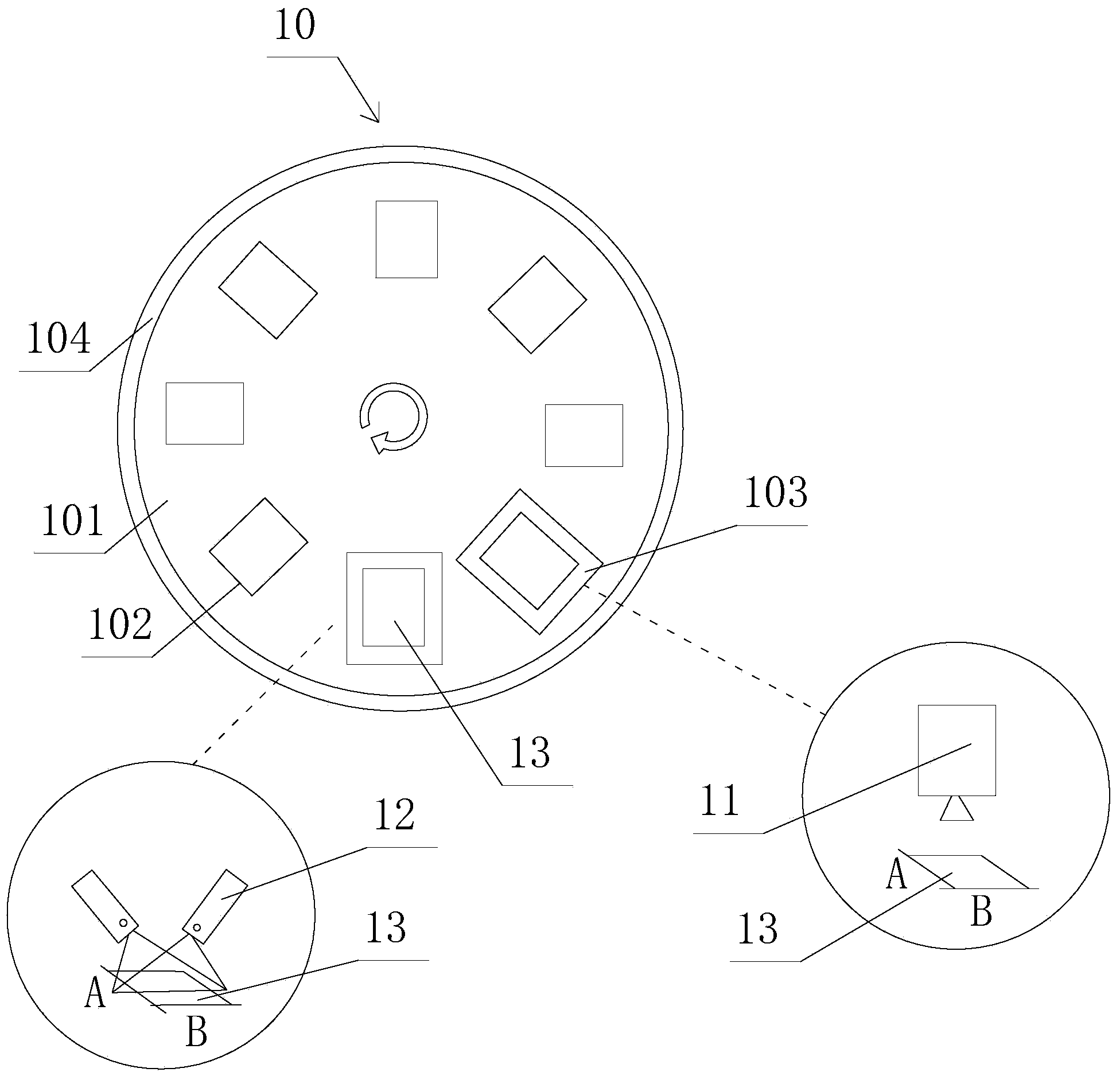

[0018] see figure 1 , the measuring datum plane positioning device of the measured object includes a measuring platform 10 , a processor (not shown in the figure), a video measuring instrument 11 , and two laser probes 12 .

[0019] The measuring platform 10 includes a stage 101 and a circular turntable 104. The stage 101 is provided with a number of stations 102 for carrying the measured object 13. In this embodiment, the stations 102 have 1-8 positions marked, Of course, the number of workstations 102 can be more or less, which can be determined according to practical applications. The layout of the workstations 102 is preferably evenly distributed on the loading platform 101 . In order to prevent the object under test 13 carried on the station 102 from moving, the object under test 13 can be firmly fixed on the station 102 using a fixing jig.

[0020] A work station 103 is fixed directly above each work station 102 , and the work station 103 can be fixed directly above th...

no. 2 approach

[0036] The measurement reference plane positioning device of the measured object in the second embodiment encapsulates the structural composition of the measurement reference plane positioning device of the measured object in the first embodiment. In addition, the measurement standard of the measured object in the second embodiment The measurement platform of the surface positioning device also includes a driver for driving the turntable 104 to rotate. In this way, the turntable 104 does not need to be rotated manually, and the rotation of the turntable 104 can be realized by turning on the driver, which saves manpower and improves efficiency.

no. 3 approach

[0038] The measurement reference plane positioning device of the measured object in the third embodiment encapsulates the structural composition of the measurement reference plane positioning device of the measured object in the second embodiment. In addition, the driver in the third embodiment does not need to be manually driven , but rely on the processor to drive.

[0039] The driver includes a driving mechanism and a triggering mechanism. The driving mechanism is used to drive the turntable 104 to rotate. The triggering mechanism is used to trigger the driving mechanism to run. The triggering mechanism is electrically connected to the processor to receive instructions from the processor. Although it is also necessary to manually give commands to the processor, the operation mode of the measuring datum plane positioning device for the measured object will be more friendly and simple. For example, when the computer is selected as the processor, it is only necessary to issue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com