Highly precise detection machine

A detection machine and height measurement technology, applied in measurement devices, instruments, etc., can solve the problems of measurement accuracy gap, measurement interference factors cannot be excluded, measurement efficiency is low, etc., to reduce interference errors, improve measurement efficiency, and ensure measurement accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

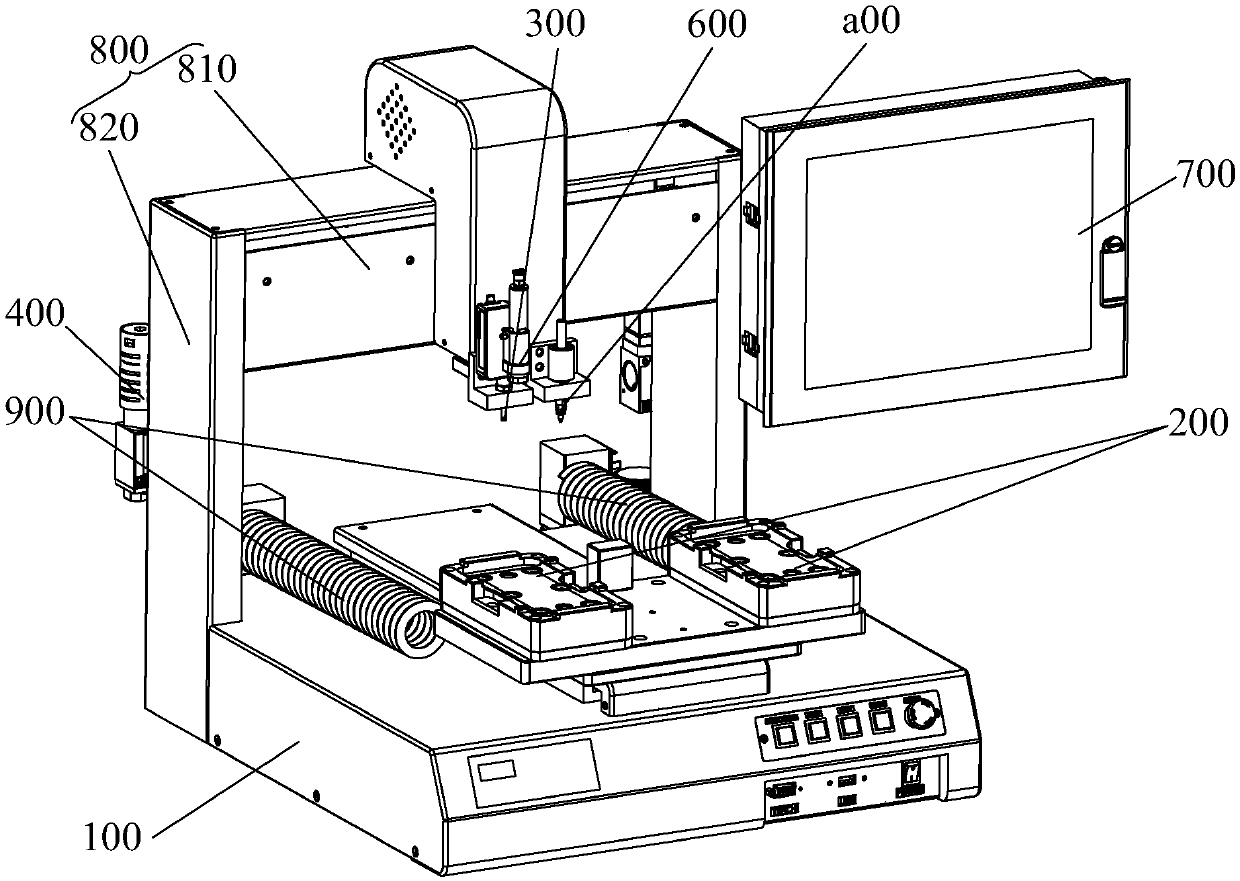

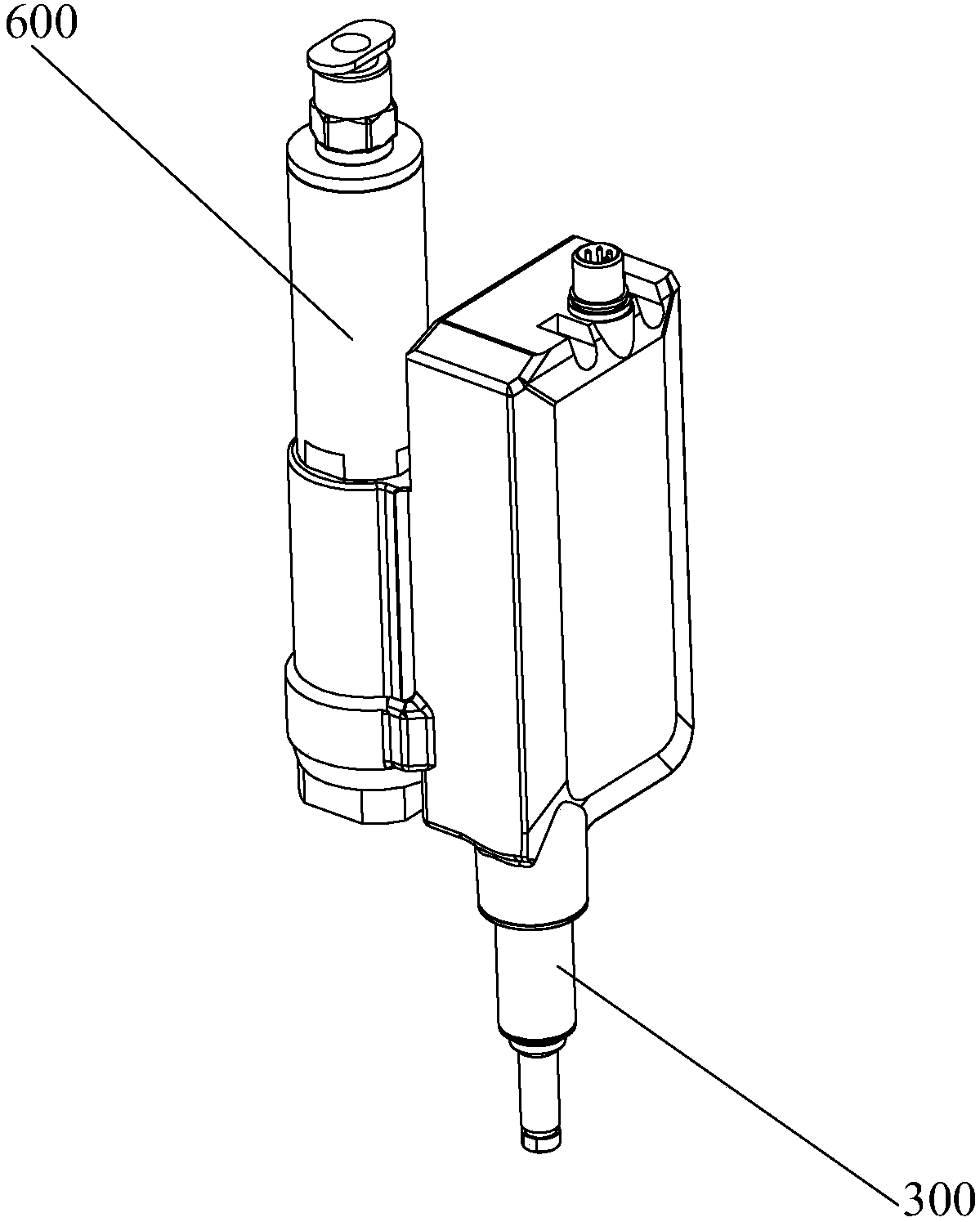

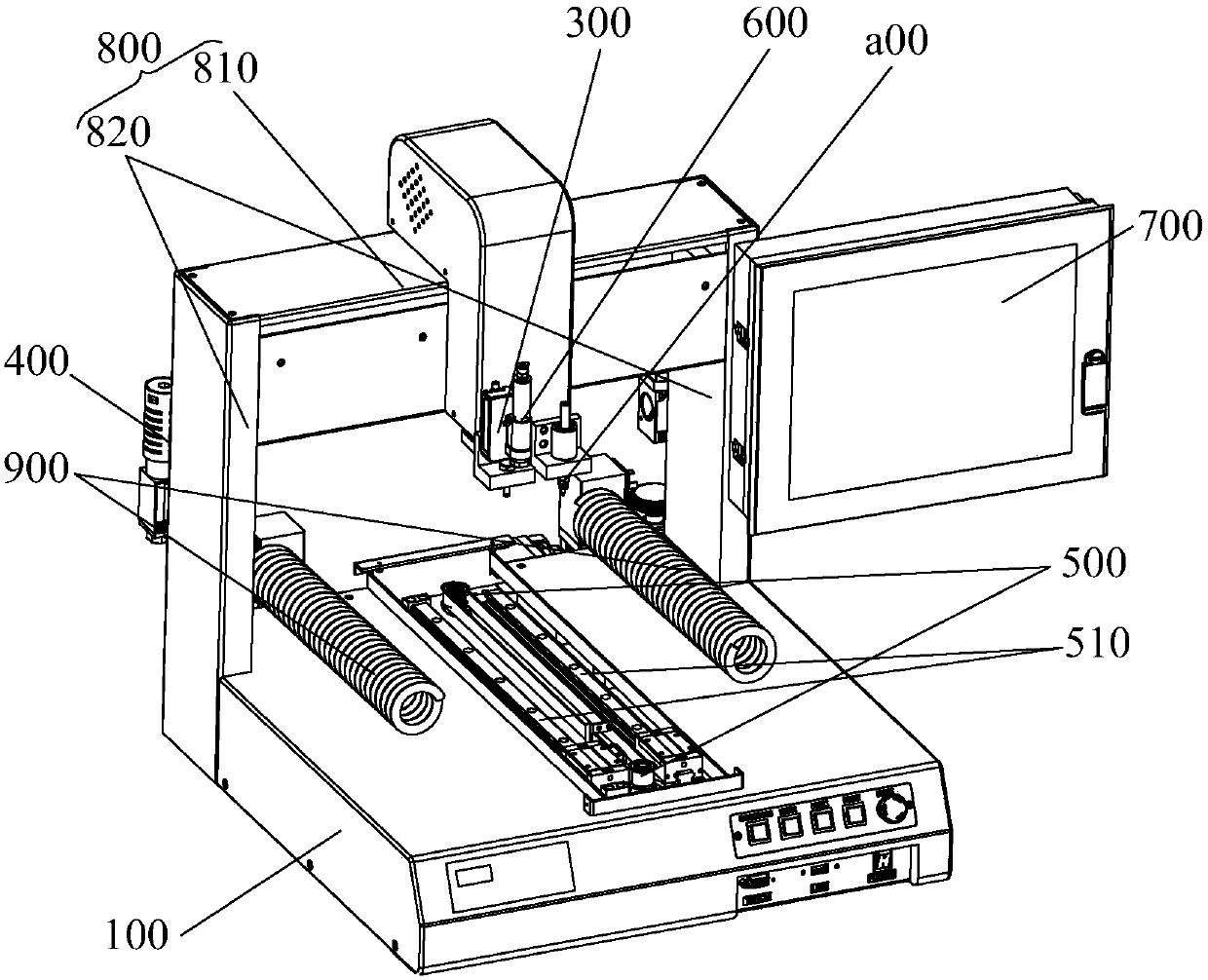

[0021] Such as figure 1 As shown, the high-precision detection machine provided by the present invention includes a base frame 100, a material carrier 200 arranged on the base frame 100 for carrying and measuring workpieces, and a height measuring head 300 suspended above the material carrier 200. The base 200 moves longitudinally relative to the bottom frame 100 under the drive of the longitudinal driving device 500 to approach or move away from the height measuring head 300, and the height measuring head 300 moves laterally relative to the bottom frame 100 under the driving of the horizontal driving device 400, and the vertical driving device 600 is driven to move vertically relative to the chassis 100; the highly precise detector also i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com