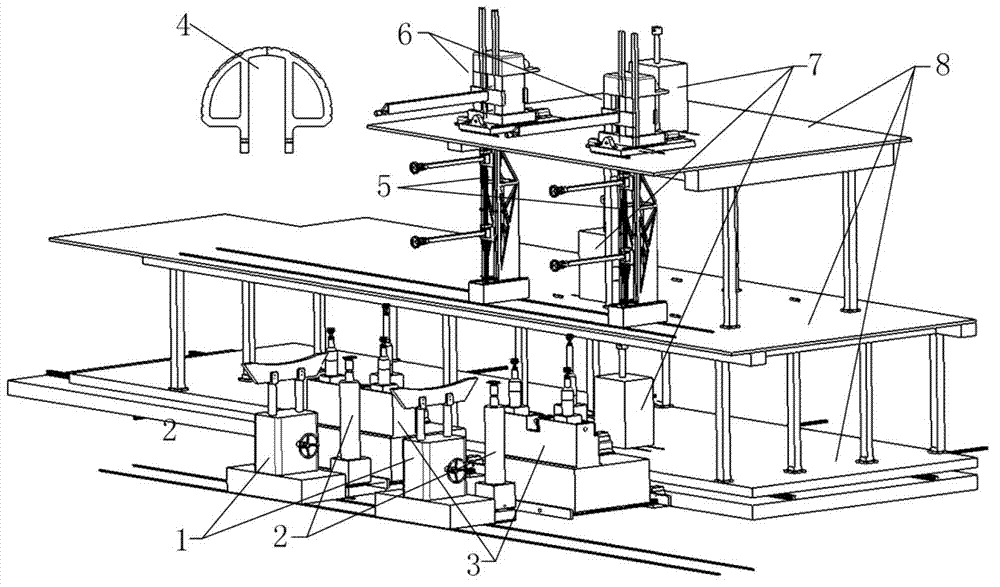

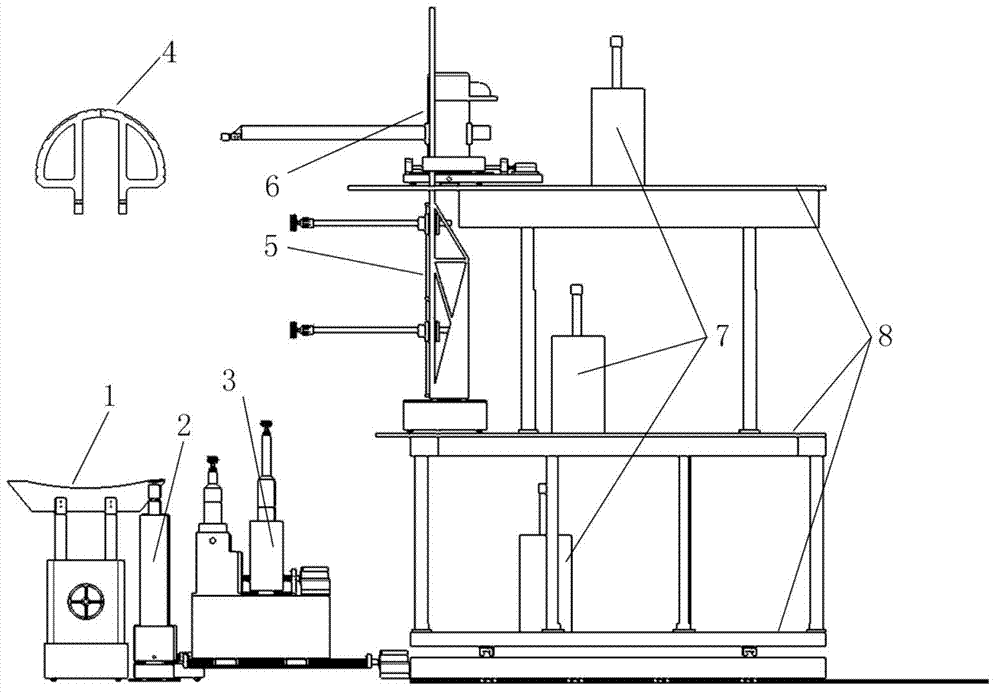

Method and device for folding and flexibly positioning body wallboard

A technology of fuselage panel and positioning method, which is applied in aircraft assembly, ground installations, aircraft parts, etc., can solve the problems of low degree of flexibility, large number of tooling, and high production cost, and achieves reduction of manual operations, simple loading and unloading, and satisfying effect on demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Method example:

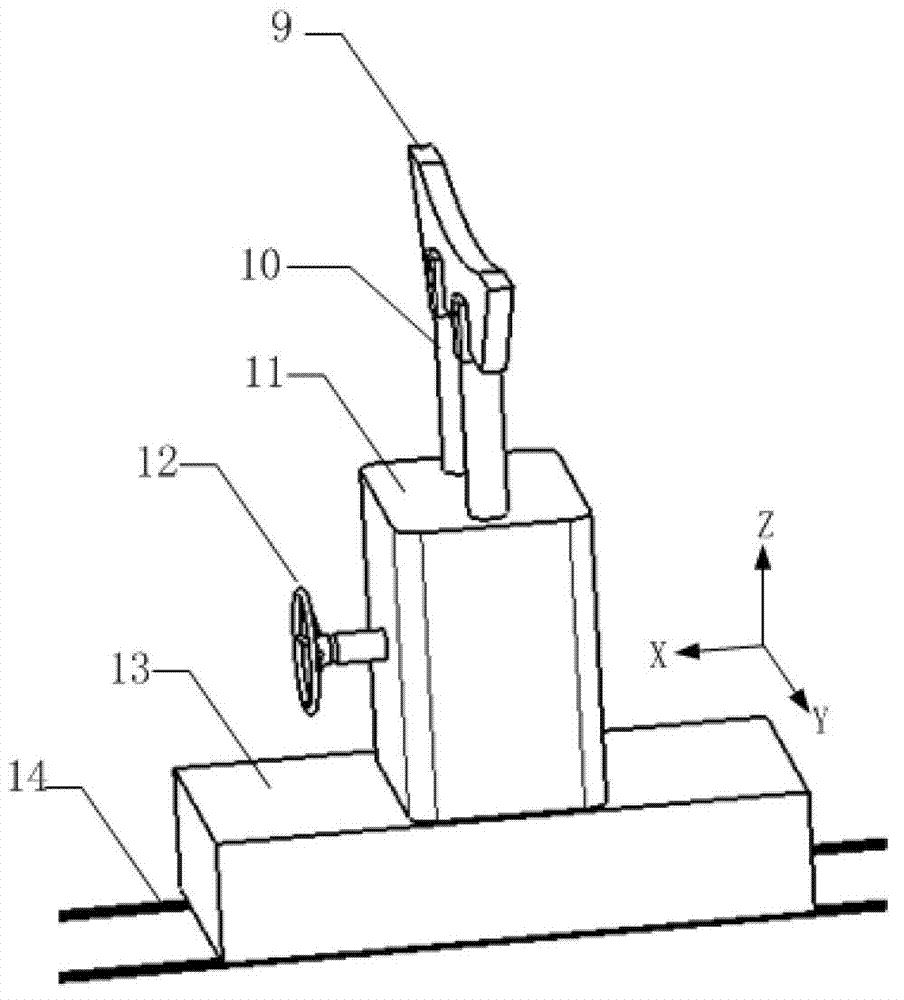

[0035] (1) Position and adjust the posture of the lower wall of the fuselage. After the lower wall plate is removed from the component assembly frame, use the lifting device to place the lower wall plate of the fuselage on the shape-preserving transport vehicle, so that the outer shape of the lower wall plate closely fits the inner surface of the shape-safe clamping plate, and along the X direction Transport the lower wall plate to the relevant station of the mobile workbench, and use the driving hand wheel to adjust the Z-direction height of the external clamping plate to prepare for the introduction of the lower wall plate positioner. After the lower wall panel enters the assembly workbench station, drive the upper base and the lower base of the four lower wall panel positioners to adjust the positioners in the Y and X directions respectively, and drive the telescopic columns of each positioner to adjust the height in the Z direction. Make the ball ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com