Airplane component attitude adjusting and butting system based on four numeric control positioners, attitude adjusting platform and mobile bracket and corresponding method

A technology of numerical control positioner and mobile bracket, which is applied in the direction of aircraft parts, aircraft assembly, transportation and packaging, etc. It can solve the problems of not meeting the requirements of accurate docking and assembly of large parts, low quality, small volume, etc., and improve the accuracy of assembly Accuracy and assembly efficiency, application adaptability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

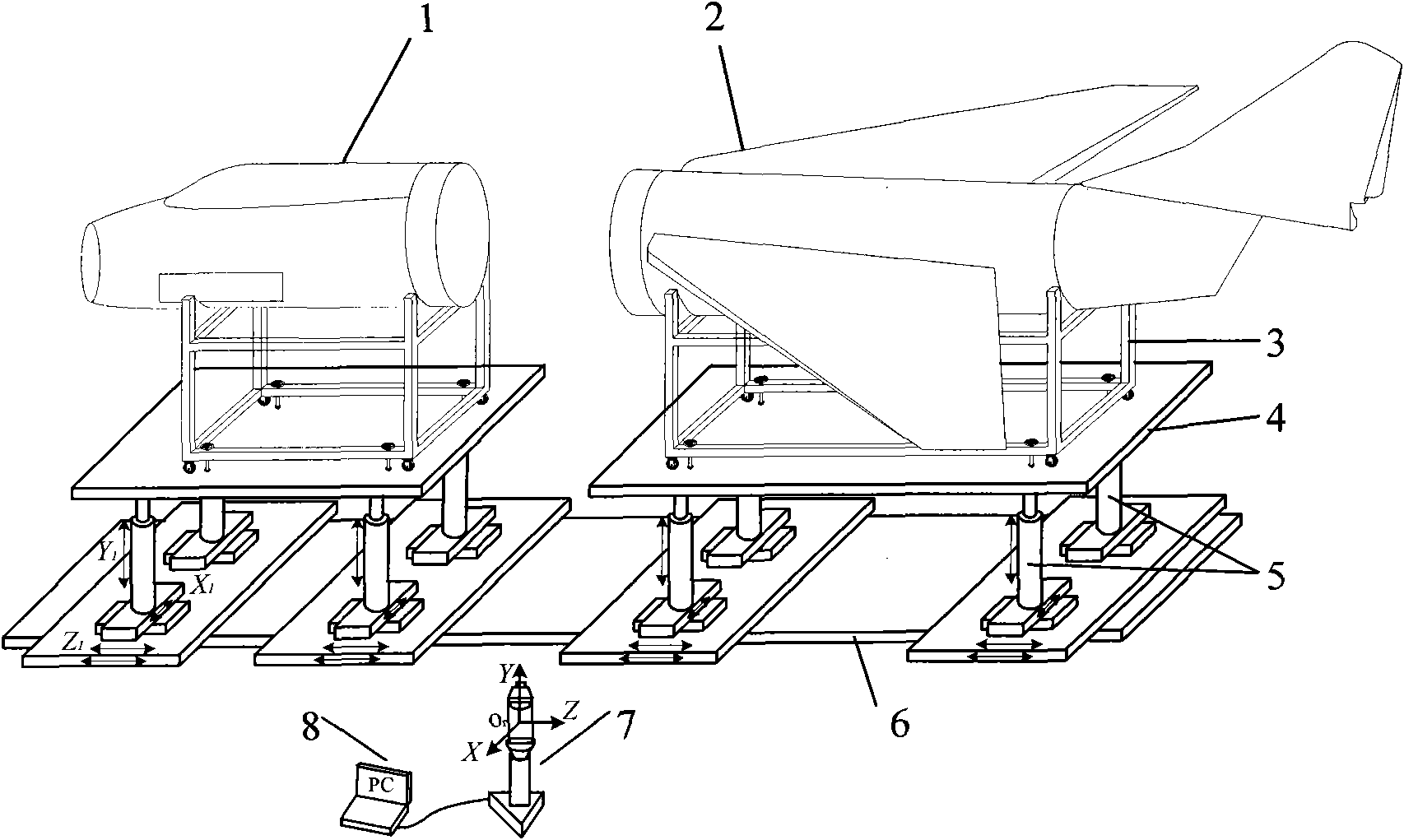

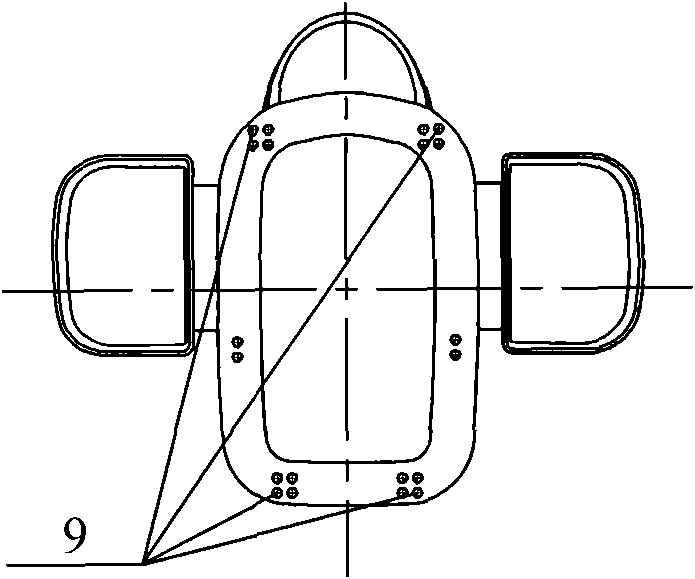

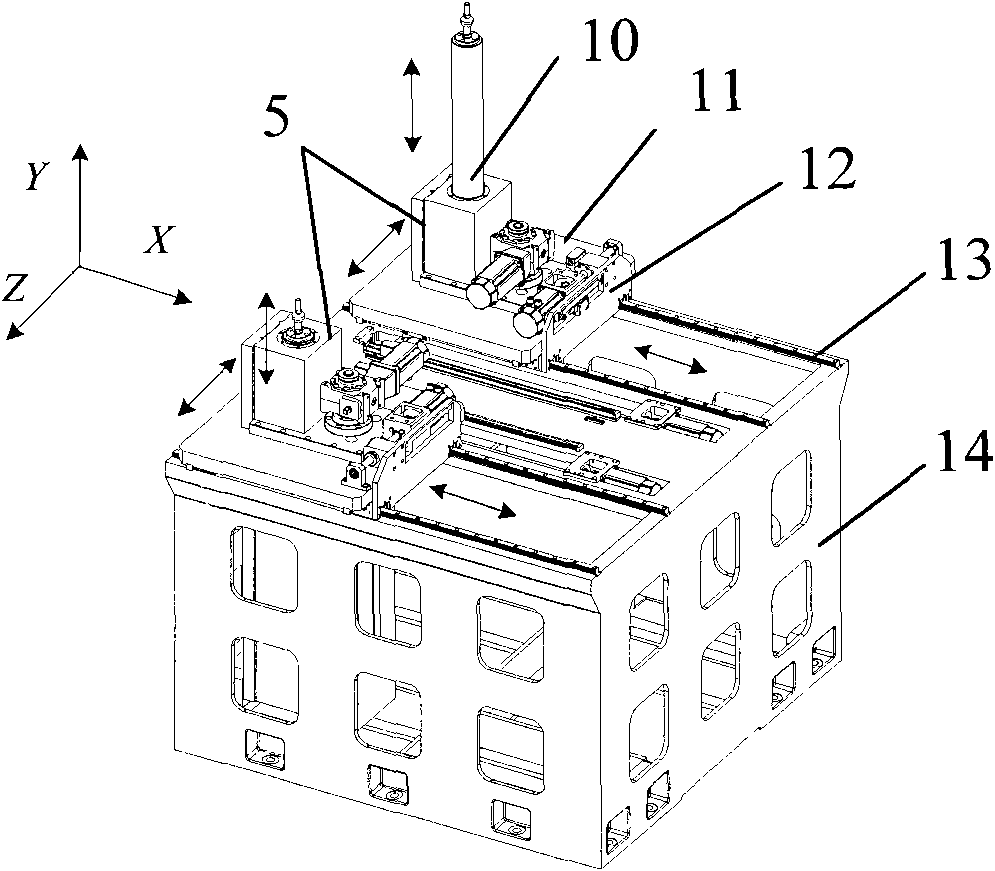

[0048] Such as Figure 1-5As shown, the aircraft component attitude adjustment and docking system based on four CNC positioners, attitude adjustment platforms and mobile brackets, including mobile brackets 3, attitude adjustment platforms 4, multiple CNC positioners 5, and CNC positioner group guide rails 6 , host computer 8, ball hinge connection and laser tracker 7; mobile bracket 3 includes U-shaped frame 15, jack bolt 16 and cone screw 17, cone screw 17 is hollow, and jack bolt 16 is set inside, and adjustment The bolt holes on the posture platform 4 are connected and fixed, and the U-shaped bracket 15 is provided with a wide strap and a belt take-up device for fixing the fuselage section; Sliding table 12, slider guide rail 13, CNC positioner base 14, absolute grating ruler and servo motor, two attitude-adjusting CNC positioners share one CNC positioner base 14 and electrical cabinet, and the electrical cabinet is placed in two CNC positioners. Between machine bases, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com