Power tool control system

a control system and power tool technology, applied in the field of power tools, can solve the problems of difficulty in the use of such technology by the equipment operator, limited precision and accuracy of the work performed on these power tools, and difficulty in the experience of the operator, and achieve the effect of easy readable format and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0153] Reference will now be made in detail to the presently preferred embodiments of the invention, examples of which are illustrated in the accompanying drawings.

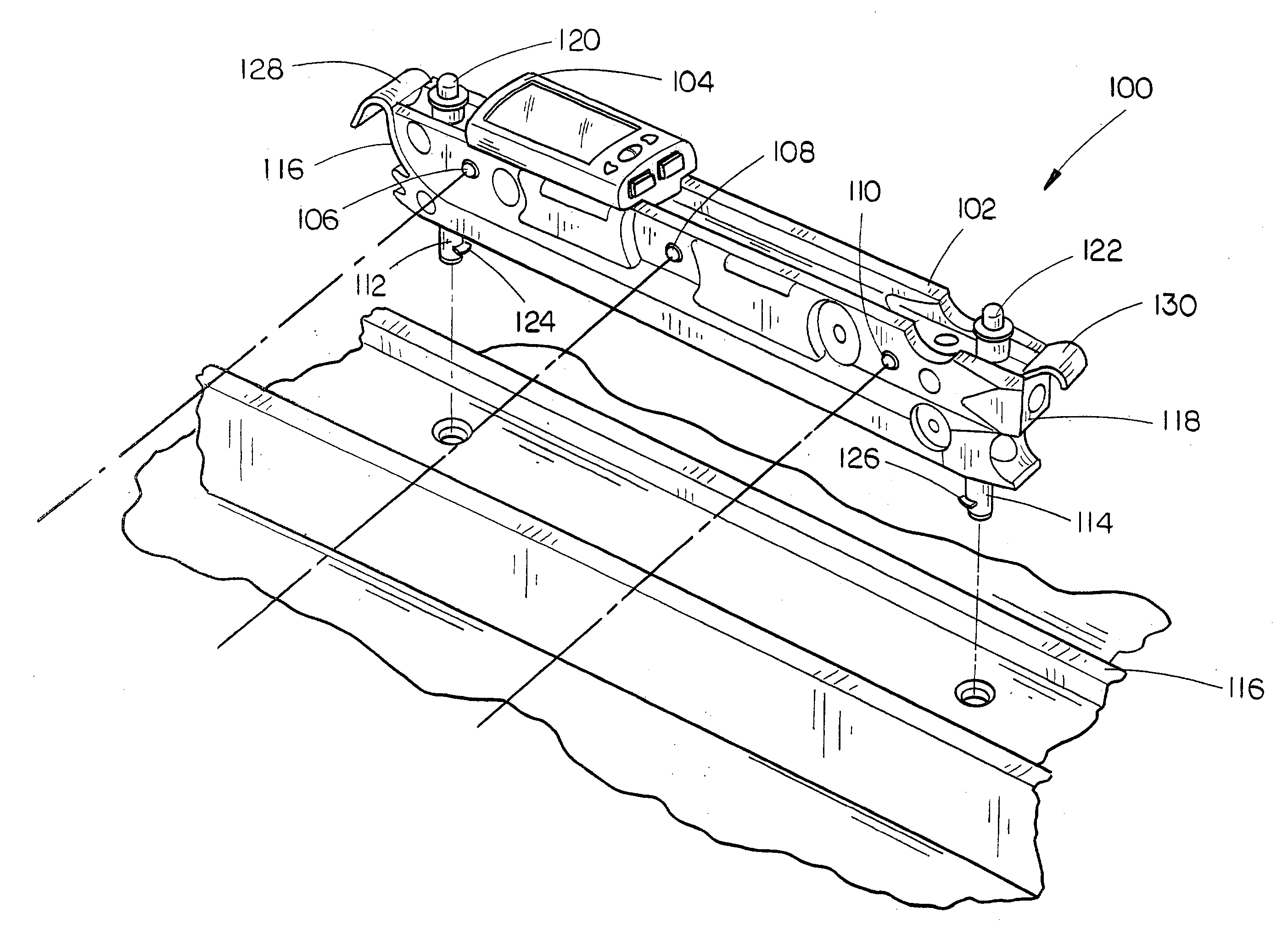

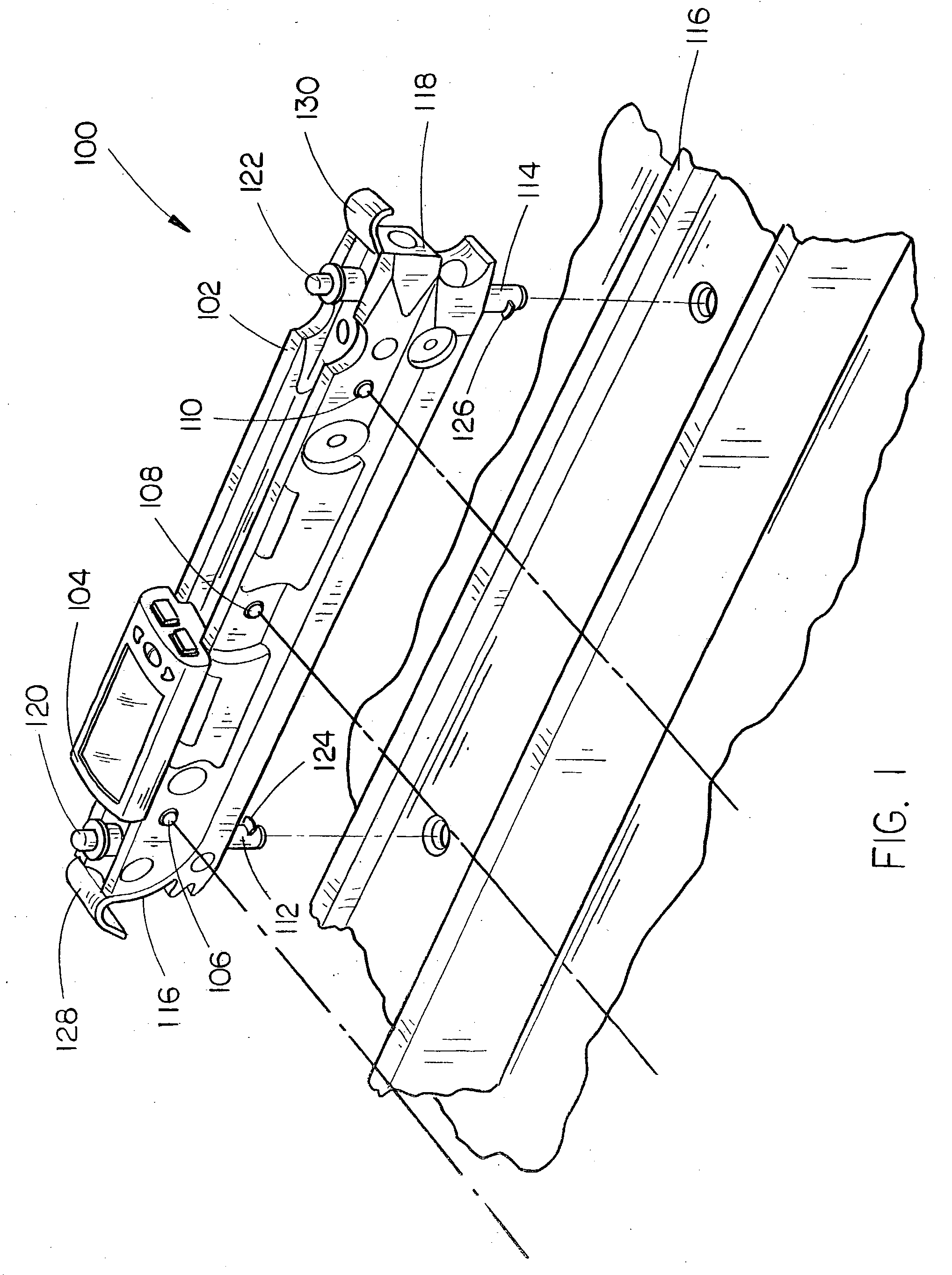

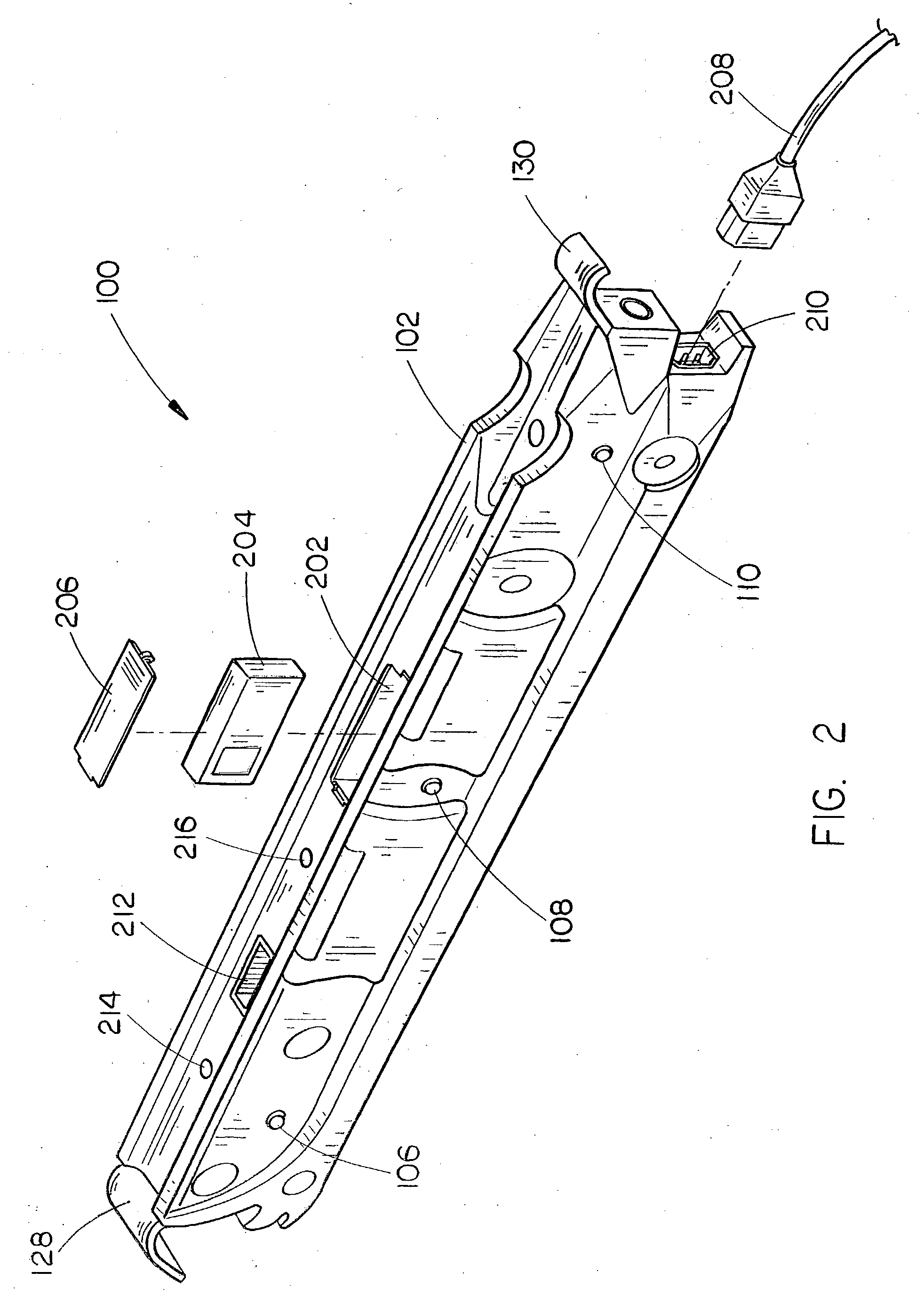

[0154] Referring generally now to FIG. 1, a laser apparatus 100 of the present invention is shown. In the present embodiment, the laser apparatus 100 comprises a housing 102 coupled with a computing system 104. Further, the housing 102 is disposed with a first laser source 106, a second laser source 108, and a third laser source 110. Alternatively, the housing 102 may include a greater or fewer number of laser beam sources in order to meet the needs of a manufacturer or consumer. Each of the three laser sources 106 through 110 is in communication with the computing system 104. In the current embodiment the communicative link is a wireless system, however, alternate systems, such as serial cable, infrared, or the like may be employed.

[0155] In the present embodiment, the laser sources 106 through 110 are enabled to emit ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com