Fabric artwork with mounting assembly for nesting in frame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

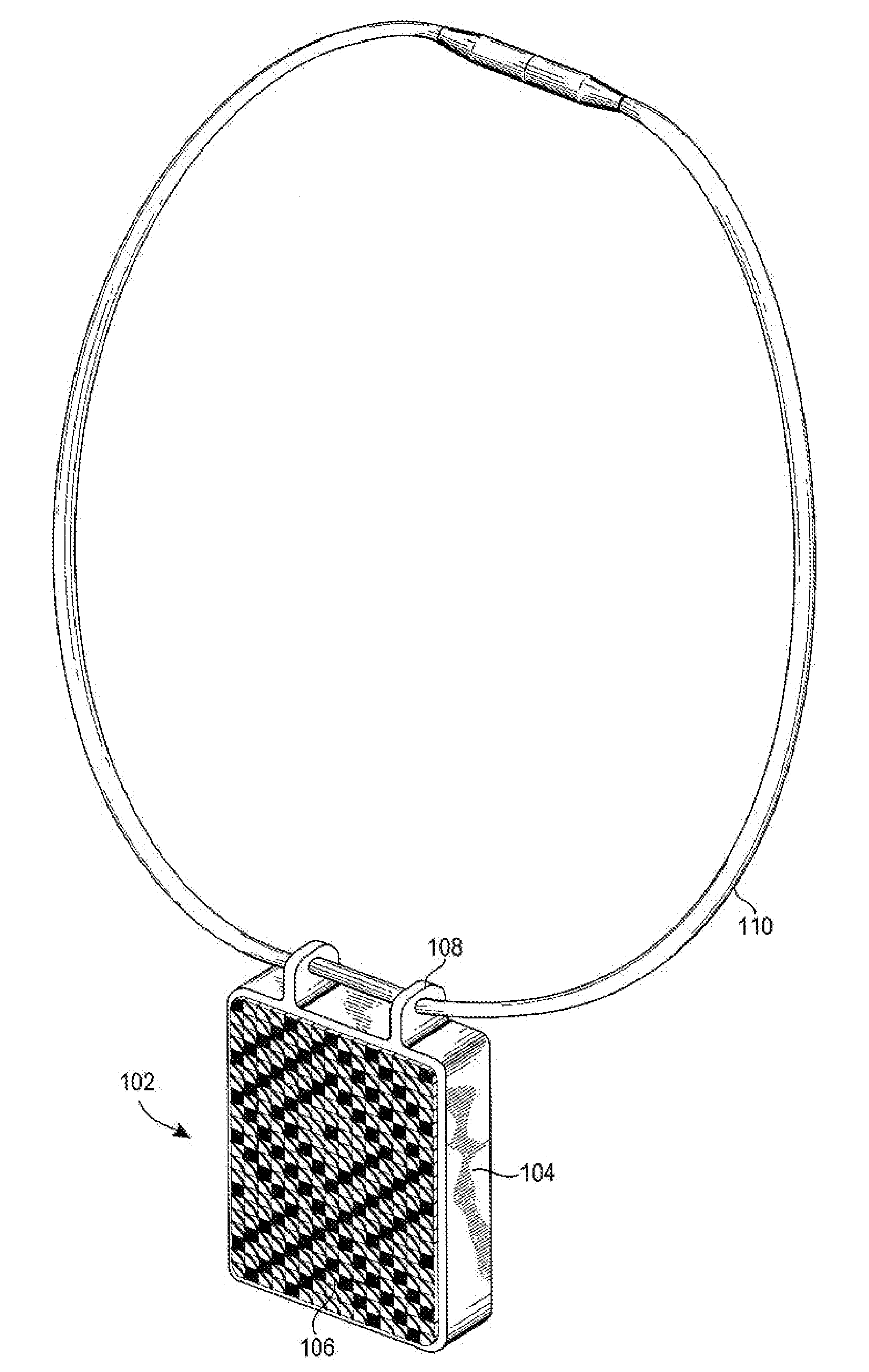

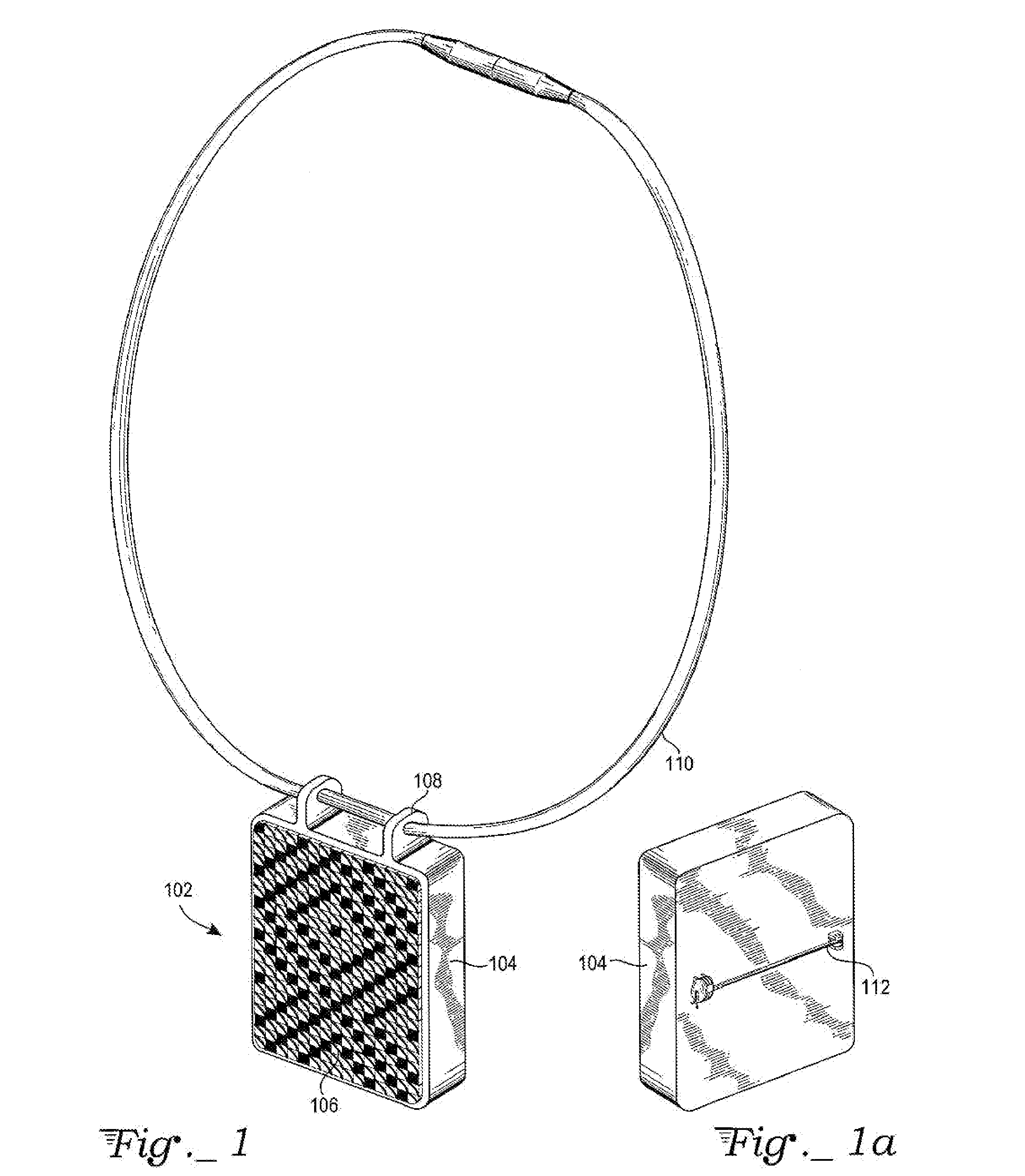

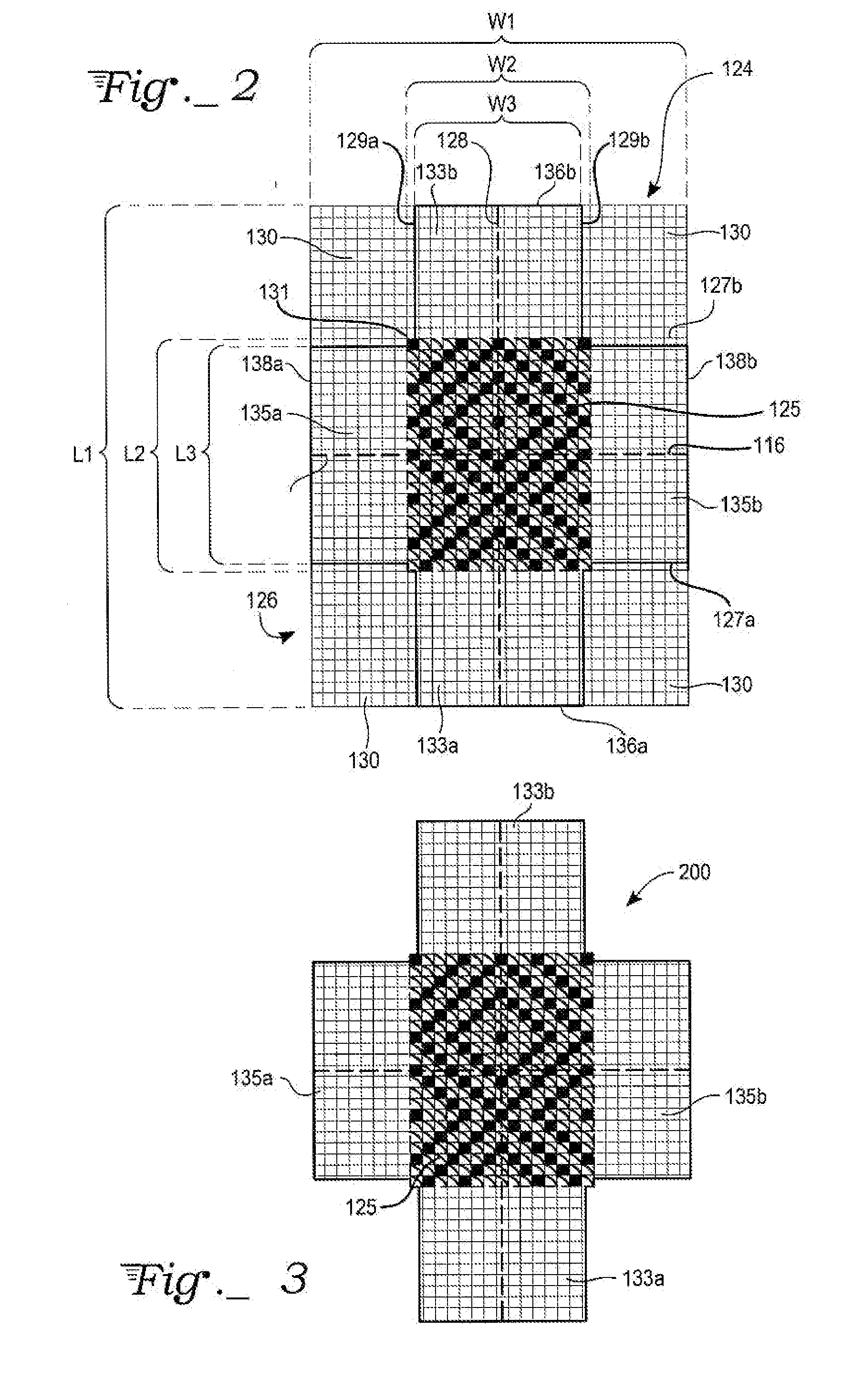

[0025]Referring to FIG. 1, a fabric artwork pendant 102 may be coupled to an attachment structure 110, such as a necklace, with a set of eyelets 108 formed on a special frame 104 of the present invention. In general, frame 104 may be manufactured from any suitably machinable, tooled, or molded material, such as metals e.g. aluminum, copper, steel, etc. or plastic, wood, ceramic, etc., preferably as a unitary article with a central well for the needlepoint artwork and optional integral eyelets 108. In this example, a pendant frame is shown with peripheral bosses, in this case eyelets, adaptable for jewelry uses. As an alternative to peripheral bosses, the backside of the frame could be provided with a pin to form a brooch. However other frames may be used, such as hanging frames, etc. The frame has a central well. typically one-eighth to three-eighths inches deep to accommodate a fabric artwork. The depth of the well is adjusted to the thickness of the artwork so that a slight amount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com