Double decomposition precipitation transformation production method of potassium citrate

A potassium citrate, precipitation conversion technology, applied in the field of production of potassium citrate, can solve the problems of increased production cost, difficult to use, air pollution, etc., to achieve the effect of simplifying the production process, reducing the types of raw materials, and increasing the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

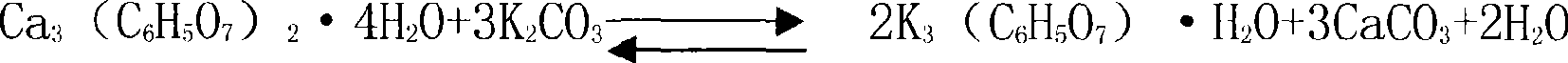

Method used

Image

Examples

Embodiment 1

[0034] A kind of double decomposition precipitation conversion production method of Potassium Citrate is characterized in that: it comprises the following steps:

[0035] (1) Preparation of citric acid filtrate: crush the corn through a hammer mill, spray the liquefier and liquefy the sugar in the liquefaction tank, add Aspergillus niger to ferment in the fermenter under the condition of forced ventilation, and then pass through the chamber press filter to obtain citric acid filtrate;

[0036](2), add citric acid filtrate and calcium carbonate in neutralization reaction tank and carry out neutralization reaction, produce solid calcium citrate: add 0.75 tons of calcium carbonate in every 1 ton of citric acid filtrate, keep pH value 5.0, temperature At 83°C, citric acid reacted with calcium carbonate and kept warm for 0.5 hours, then precipitated and filtered through a vacuum filter to make solid calcium citrate;

[0037] (3), washing to remove impurities: wash the solid calciu...

Embodiment 2

[0052] A kind of double decomposition precipitation conversion production method of Potassium Citrate is characterized in that: it comprises the following steps:

[0053] (1) Preparation of citric acid filtrate: pulverize corn through a hammer mill, spray liquefier and liquefy sugar in the liquefaction tank, add Aspergillus niger to ferment under forced ventilation in the fermenter, and press the filter to obtain citric acid filtrate;

[0054] (2), add citric acid filtrate and calcium carbonate to carry out neutralization reaction in neutralization reaction tank, produce solid calcium citrate: add 0.75 tons of calcium carbonate in every 1 ton of citric acid filtrate, keep pH value 4.5, temperature At 80°C, after the reaction between citric acid and calcium carbonate, keep warm for 0.5 hours, precipitate and filter through a vacuum filter to make solid calcium citrate;

[0055] (3), washing to remove impurities: wash the solid calcium citrate with 80°C hot water in vacuum filt...

Embodiment 3

[0070] A kind of double decomposition precipitation conversion production method of Potassium Citrate is characterized in that: it comprises the following steps:

[0071] (1) Preparation of citric acid filtrate: crush the corn through a hammer mill, spray the liquefier and liquefy the sugar in the liquefaction tank, add Aspergillus niger to ferment in the fermenter under the condition of forced ventilation, and then pass through the chamber press filter to obtain citric acid filtrate;

[0072] (2), add citric acid filtrate and calcium carbonate to carry out neutralization reaction in neutralization reaction tank, produce solid calcium citrate: add 0.75 tons of calcium carbonate in every 1 ton of citric acid filtrate, keep pH value 5.5, temperature at 85°C, after the reaction between citric acid and calcium carbonate, keep it warm for 0.5 hours, and make solid calcium citrate after precipitation and vacuum filtration;

[0073] (3), washing to remove impurities: wash the solid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com