Process for preparing citrate salt from mother liquor for citric acid production

A process method, citrate technology, is applied in the field of citrate preparation from mother liquor produced by citric acid, which can solve the problems of large manpower, consumption, and decline in the total yield of citric acid, so as to improve economic benefits, reduce duplication of labor, The effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

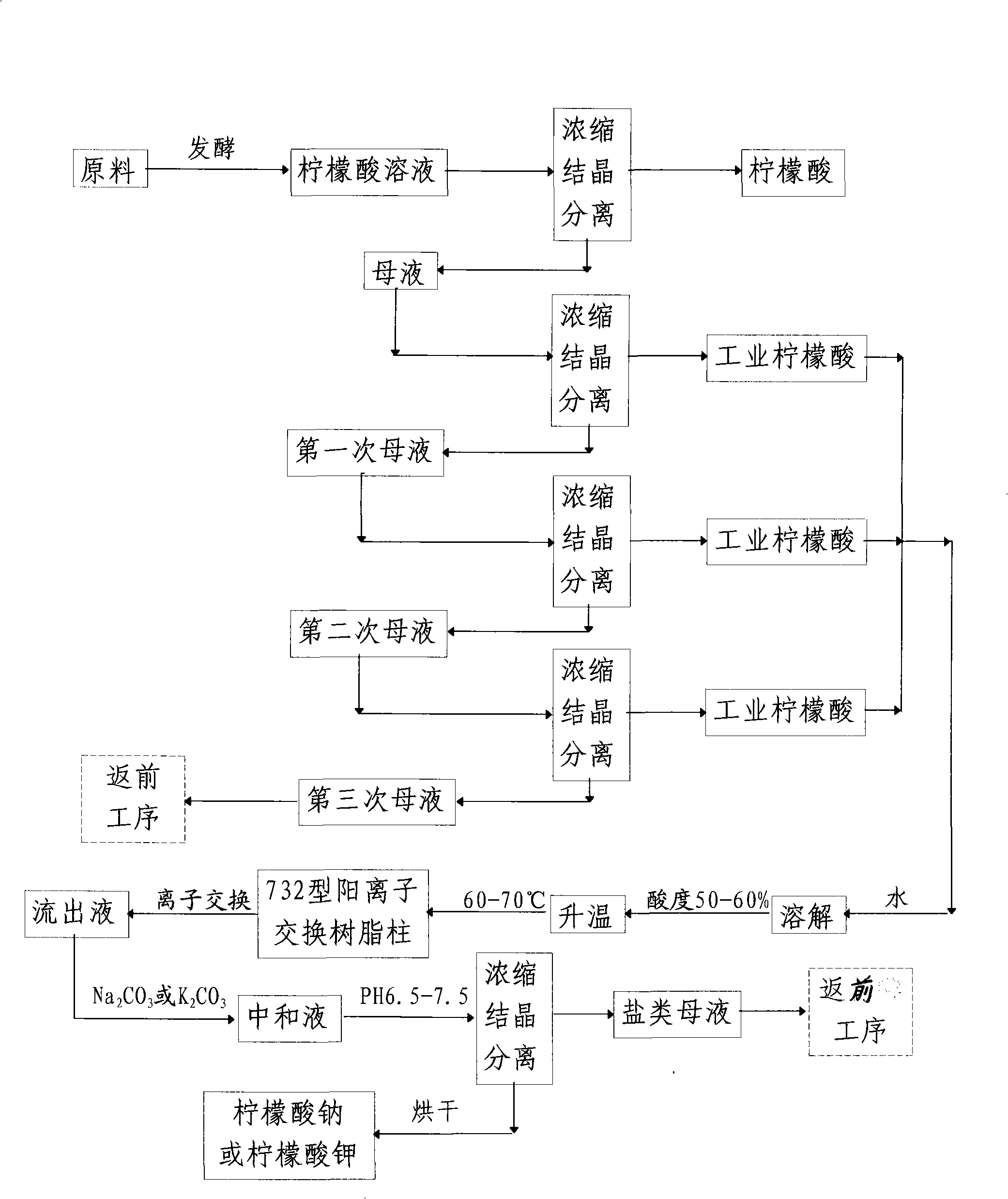

[0016] (1) Concentrate and crystallize the mother liquor after purifying citric acid from the citric acid solution obtained by fermentation to obtain industrial citric acid; then concentrate and crystallize the isolated first mother liquor to obtain industrial citric acid and the second separation Secondary mother liquor, then the second mother liquor is concentrated, crystallized, and separated to obtain industrial citric acid and the third mother liquor, and Fe in the third mother liquor at this time +3 Concentration > 200ppm, easy carbon compound κ value > 2.0, return it to the previous process in the citric acid production process for reprocessing. The return amount of this mother liquor is only about 2-3% of the total amount of citric acid solution obtained by fermentation.

[0017] (2) Merge the industrial citric acid obtained by the above three separations, add water to dissolve, control the acidity to 50-60%, heat up to 60-70°C, enter the treated 732 type cation resin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com