Method for electroforming hard gold product

A technology of hard gold and products, applied in the field of gold production, can solve the problems of low yield, insufficient hardness, easy deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

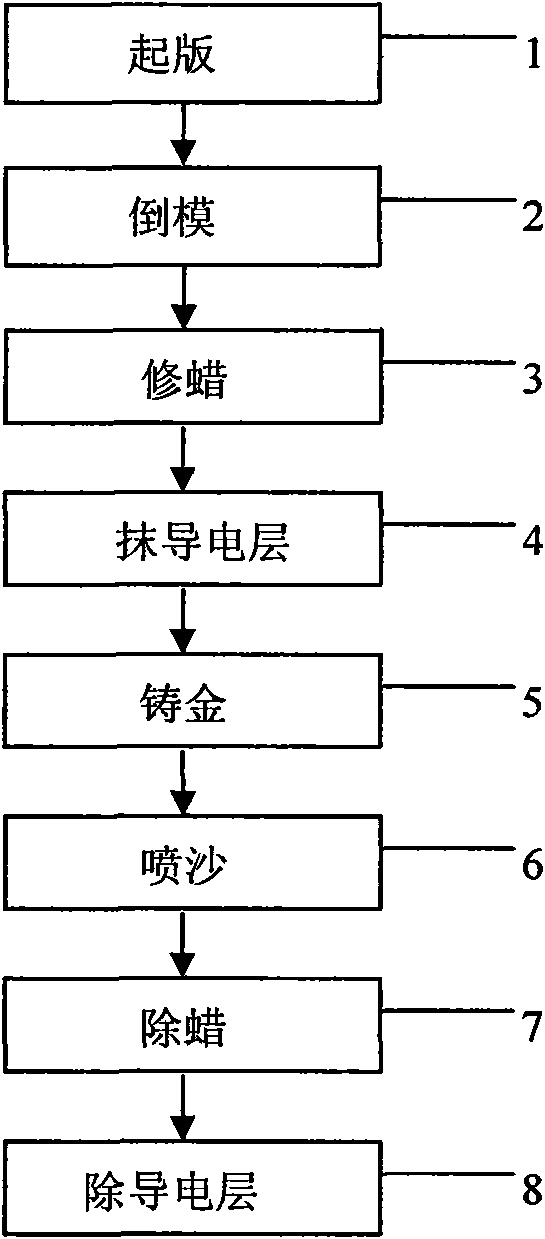

[0019] Such as figure 1 Shown is the flowchart of the method for electroforming hard gold products of the present invention. The method for electroforming hard gold products of the present invention specifically comprises the following steps:

[0020] Step 1. Starting plate: measure the size of the sample of the gold product to be processed, conduct pattern approval, and carve the sample with oil mud.

[0021] Step 2. Invert the mold: pour the engraved sample into the mold, inject wax into the rubber mold after the mold is turned over, and vacuumize the sample to make a wax mold; specifically, the mold includes pouring the glue and turning over the mold. The two-step process of receiving wax is the process of pouring glue and turning over the mold. The surface layer of the sample is covered with silica gel, and the silica gel is left to dry naturally, and then the sample is taken out to make a rubber mold; the wax is injected into the prepared rubber mold. Vacuum until the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com