ZIF-8 pyrolysis porous carbon-graphene composite material, manufacturing method and application thereof

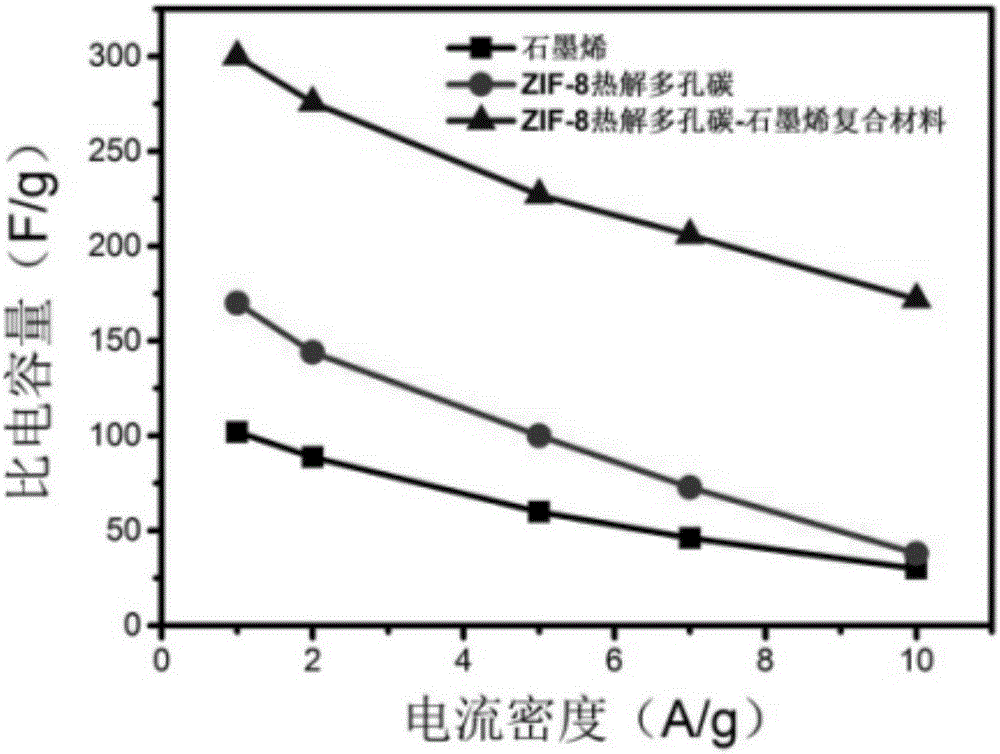

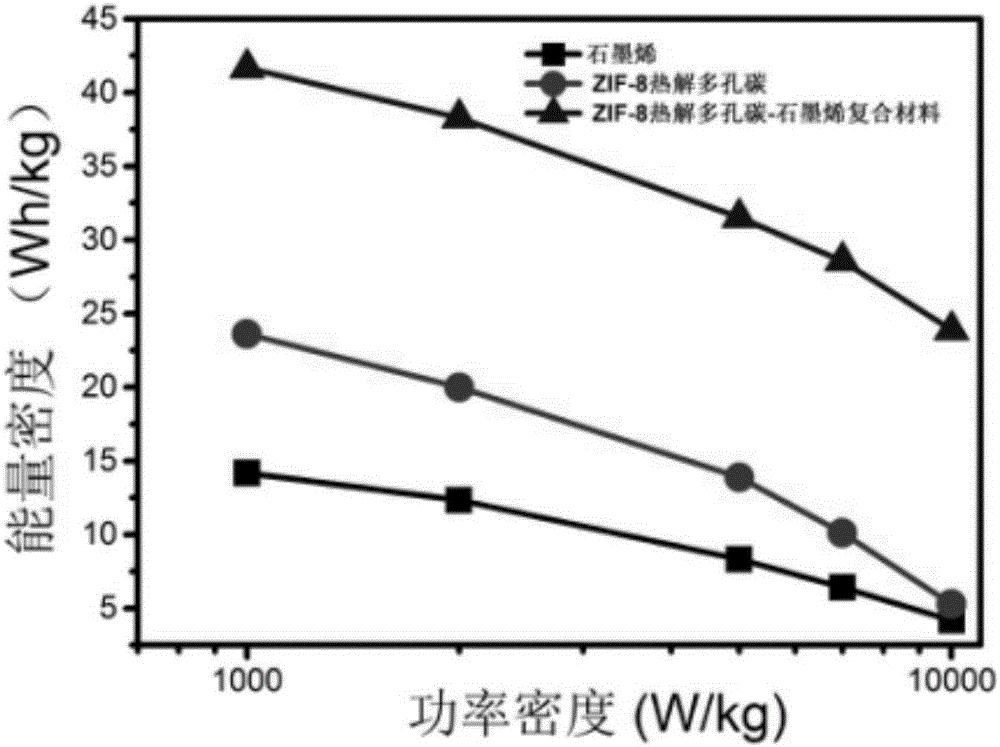

A composite material, ZIF-8 technology, applied in the field of nanomaterials, can solve the problems of low energy density, low capacity and poor rate, and achieve the effect of high energy density, high power density and good rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

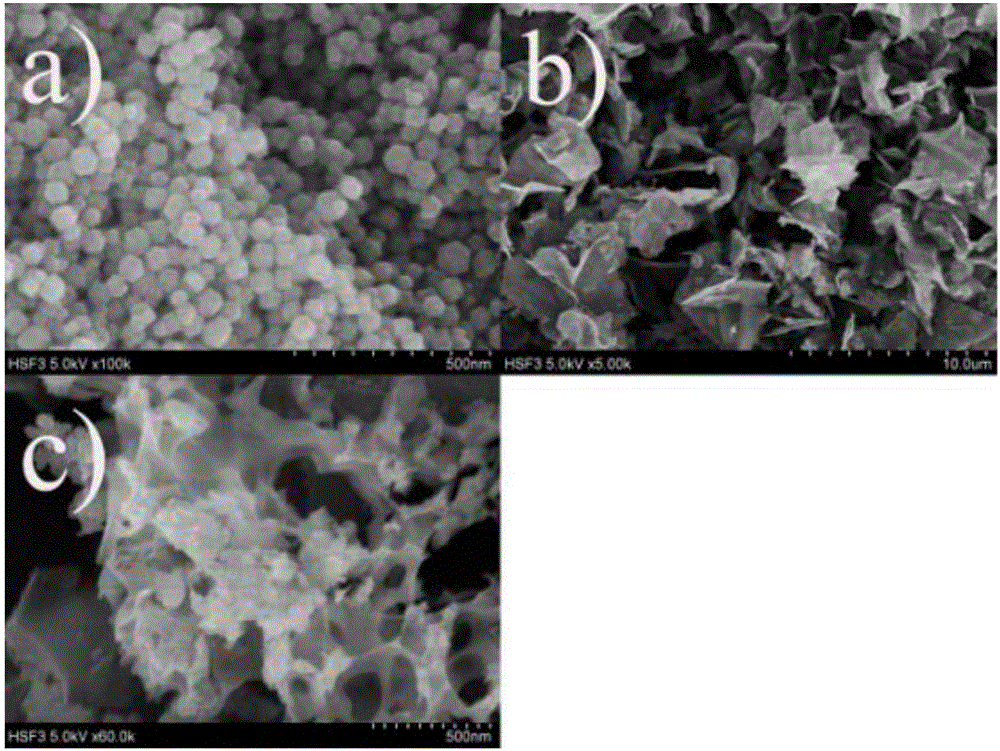

Image

Examples

Embodiment 1

[0033] (1) Mix zinc nitrate hexahydrate and 2-methylimidazole and dissolve them in methanol. The mass ratio of zinc nitrate hexahydrate, 2-methylimidazole and methanol is 1:8:700.

[0034] (2) The solution was left standing for 1 h to obtain a milky solution.

[0035] (3) The obtained solution was centrifuged at a speed of 10000 rpm for 10 min, and then washed three times with methanol to obtain ZIF-8 crystals.

[0036] (4) Dry the obtained ZIF-8 crystal; wherein, the drying temperature is 60° C., and the vacuum degree is -0.1 MPa.

[0037] (5) Mix the prepared ZIF-8 crystal with potassium citrate at a mass ratio of 1:20, and grind to obtain a uniform white powder.

[0038] (6) The obtained white powder was heated up to 800°C at 5°C / min under a nitrogen atmosphere, kept for 2h, and carbonized to prepare a ZIF-8 pyrolytic porous carbon-graphene composite.

[0039] (7) Wash the prepared ZIF-8 pyrolyzed porous carbon-graphene composite with 0.5 mol / L hydrochloric acid for 6 h, ...

Embodiment 2

[0043] (1) Mix zinc nitrate hexahydrate and 2-methylimidazole and dissolve them in methanol. The mass ratio of zinc nitrate hexahydrate, 2-methylimidazole and methanol is 1:8:700.

[0044] (2) The solution was left standing for 1 h to obtain a milky solution.

[0045] (3) The obtained solution was centrifuged at a speed of 10000 rpm for 10 min, and then washed three times with methanol to obtain ZIF-8 crystals.

[0046] (4) Dry the obtained ZIF-8 crystal; wherein, the drying temperature is 60° C., and the vacuum degree is -0.1 MPa.

[0047] (5) Mix the prepared ZIF-8 crystal with potassium citrate at a mass ratio of 1:5, and grind to obtain a uniform white powder.

[0048] (6) The obtained white powder was heated up to 800°C at 5°C / min under a nitrogen atmosphere, kept for 2h, and carbonized to prepare a ZIF-8 pyrolytic porous carbon-graphene composite material.

[0049] (7) The prepared ZIF-8 pyrolytic porous carbon-graphene composite material was washed with 0.5 mol / L hydr...

Embodiment 3

[0051] (1) Mix zinc nitrate hexahydrate and 2-methylimidazole and dissolve them in methanol. The mass ratio of zinc nitrate hexahydrate, 2-methylimidazole and methanol is 1:8:700.

[0052] (2) The solution was left standing for 1 h to obtain a milky solution.

[0053](3) The obtained solution was centrifuged at a speed of 10000 rpm for 10 min, and then washed three times with methanol to obtain ZIF-8 crystals.

[0054] (4) Dry the obtained ZIF-8 crystal; wherein, the drying temperature is 60° C., and the vacuum degree is -0.1 MPa.

[0055] (5) Mix the prepared ZIF-8 crystal with potassium citrate at a mass ratio of 1:40, and grind to obtain a uniform white powder.

[0056] (6) The obtained white powder was heated up to 800°C at 5°C / min under a nitrogen atmosphere, kept for 2h, and carbonized to prepare a ZIF-8 pyrolytic porous carbon-graphene composite material.

[0057] (7) The prepared ZIF-8 pyrolytic porous carbon-graphene composite material was washed with 0.5 mol / L hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com